Fluid Catalytic Cracking Feed Hydrotreatment and its Impact on Distribution of Sulfur and Nitrogen Compounds in FCC Diesel

2015-06-21BaiRuiChaiYongmingZhangChengtaoLiuChenguang

Bai Rui; Chai Yongming; Zhang Chengtao; Liu Chenguang

(1. State Key Laboratory of Heavy Oil Processing, College of Chemical Engineering, China University of Petroleum (East China), Qingdao 266580; 2. Hainan Petrochemical Company, Ltd., SINOPEC)

Fluid Catalytic Cracking Feed Hydrotreatment and its Impact on Distribution of Sulfur and Nitrogen Compounds in FCC Diesel

Bai Rui1,2; Chai Yongming1; Zhang Chengtao1; Liu Chenguang1

(1. State Key Laboratory of Heavy Oil Processing, College of Chemical Engineering, China University of Petroleum (East China), Qingdao 266580; 2. Hainan Petrochemical Company, Ltd., SINOPEC)

The sulfides and nitrogen compounds in FCC diesel were analyzed by gas chromatography equipped with a pulsed flame photometric detector (GC-PFPD) and gas chromatography coupled with nitrogen chemiluminescence detection (GC-NCD). And the variation of sulfides and nitrogen compounds in FCC diesel produced from gas oil feed hydrotreated at different temperatures was investigated. The test results showed that two main types of sulfur compounds, i.e. benzothiophenes (BTs) and dibenzothiophenes (DBTs) were found in diesel. Nitrogen compounds are mainly composed of non-basic nitrogen compounds, and indoles and carbazoles account for about 98% of the total nitrogen contents. The sulfides in FCC diesel obtained from hydrotreated feed are mainly BTs with a small amount of 4-MDBT and 4,6-DMDBT. With the increase in FCC feed hydrotreating temperature, indoles content in FCC diesel increases, while carbazoles content decreases.

GC-PFPD; GC-NCD; pre-hydrotreating; sulfides; nitrogen compounds; diesel

1 Introduction

Fluid catalytic cracking (FCC) process is one of important means for secondary processing of heavy petroleum fractions to form light distillates and accounts for one third of primary crude processing capacity. Over the recent years the FCC feed is becoming increasingly inferior since the ratio of vacuum resid blended into the FCC feed may reach 20%—50%[1]to significantly affect the quality of FCC diesel that cannot comply with the environmental requirements[2-4]. The hydrotreatment of FCC feed is one of the important technologies for improving the quality of FCC products which can influence the content and distribution of sulfur and nitrogen compounds in FCC diesel[9]. Hence the study of rules for conversion of sulfur and nitrogen compounds in diesel through hydrotreating of FCC feed is of great significance.

It is a common practice to adopt gas chromatography in combination with selective detectors for determining the content and distribution of various sulfur and nitrogen compounds in petroleum products[10-16]. In this paper the gas chromatography equipped with a pulsed flame photometric detector (GC-PFPD) and the gas chromatography coupled with the nitrogen chemiluminescence detection (GC-NCD) were used to analyze the types of sulfur and nitrogen compounds in the FCC diesel along with investigation of the impact of FCC feed hydrotreating temperature on sulfur and nitrogen compounds in FCC diesel.

2 Experimental

2.1 Instruments

A Varian CP-3800 gas chromatograph was used to analyze the sulfur compounds in FCC diesel. The said gas chromatograph was equipped with a Varian CP-8410 autoinjector, a Varian pulsed flame photometric detector (Varian PFPD) and a Varian Star chromatography workstaion.

An Agilent GC-7890A gas chromatograph was applied to determine the content of nitrogen compounds in FCC diesel, with HP-5 (30 m×0.32 mm×0.5 μm) serving as the chromatographic column, which was preheated at a rate of 5 ℃/min from 80 ℃ to 270 ℃, which was then main-tained for 5 minutes. The GC-NCD device was operated at 700 ℃ for measurements.

2.2 Experimental conditions and samples

The feedstock, which was a mixture of vacuum gasoil and delayed coker gasoil collected from a certain refinery, was subjected to hydrotreating in a 100-mL continuous fixed-bed high-pressure reactor at a hydrogen partial pressure of 10 MPa, a space velocity of 1.0 h-1, and a hydrogen/oil volume ratio of 700:1 to yield various FCC feed oil samples obtained at reaction temperatures of 350 ℃, 360 ℃ and 370 ℃, respectively.

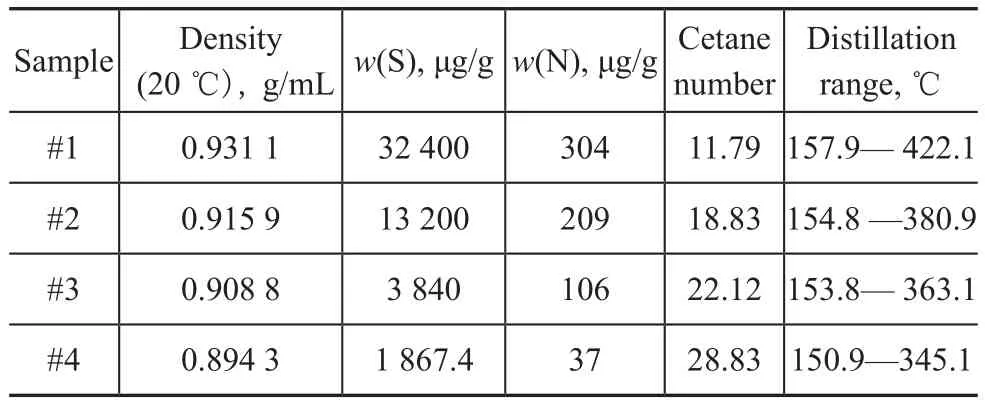

The mixed gasoil feedstock and hydrotreated gasoil feed samples obtained at different reaction temperatures were subjected to catalytic cracking reaction at a ZDT-1 riser FCC test unit, which operated in the presence of the LBO-16 catalyst to evaluate the reaction performance at a catalyst/oil ratio of 6, a residence time of 1.5 s, and a reaction temperature of 490 ℃. The properties of obtained diesel samples are presented in Table 1, in which the #1 FCC diesel sample was obtained from an unhydrotreated mixed gasoil, while #2—#4 FCC diesel samples were obtained from FCC feed that was previously hydrotreated at 350 ℃, 360 ℃ and 370 ℃, respectively.

Table 1 The properties of FCC diesel samples

3 Results and Discussion

3.1 Qualitative analysis of sulfur and nitrogen compounds in FCC diesel obtained from unhydrotreated mixed gasoil feed

The diesel fraction, which has a broad distillation range with relatively high boiling temperatures, contains sulfur compounds with very complicated structures[10]. Based on the standard sulfur compound samples and the rules on changes in boiling points of sulfur compounds with reference to relevant researches on qualitative analysis of sulfur compounds[18-19], the GC-PFPD technology was used to qualitatively analyze the sulfur compounds contained in the FCC diesel derived from the #1 unhydrotreated FCC feedstock. It can be seen from Figure 1 that there are more than 200 sulfur compounds in the FCC diesel derived from the unhydrotreated FCC feedstock, which mainly cover non-heterocyclic and heterocyclic sulfur compounds. The non-heterocyclic sulfur compounds include mercaptans, thioethers and disulfides that mainly exist in low-boiling fractions, while the heterocyclic sulfur compounds include thiophenic compounds, benzothiphenes (BTs) and dibenzothiophenes (DBTs).

Figure 1 GC-PFPD chromatogram of sulfur compounds in FCC diesel

It can be seen from Table 2 that the sulfur compounds in FCC diesel mainly cover BTs and DBTs with a relatively simple structure, which are comprised of thiophenes with short alkyl side chains in the light fraction which is formed in the course of catalytic cracking of heavy oil fraction. The amount of sulfur in BTs and DBTs accounts for 7.07% and 86.92% of total sulfur content in the FCC diesel, respectively. The content of C2—C4alkyl and C6alkyl substituted benzothiophenes (C2-BT, C3-BT, C4-BT, and C6-BT) is relatively high in BTs. The content of C1—C3alkyl substituted dibenzothiophenes (C1-DBT, C2-DBT, C3-DBT) in DBTs is quite high, among which C2-DBT has a highest ratio, while the higher alkyl substituted sulfur compounds account for a low percentage.

Table 2 Type and amount of sulfides in FCC diesel derived from unhydrotreated feed

The nitrogen content in petroleum fractions is far less than the sulfur content. However, the hydrodenitrogenation (HDN) reaction is much tougher than hydrodesulfurization reaction along with high hydrogen consumption in the course of HDN reaction. The nitrogen compounds in diesel are generally divided according to their basicity into basic nitrogen compounds and non-basic nitrogen compounds, among which the basic nitrogen compounds mainly include anilines, quinolines and pyridines that mainly exist in the low-boiling fraction, while the non-basic nitrogen compounds mainly cover indoles, carbazoles and their derivatives that mainly exist in heavy oil fractions[15].

Figure 2 presents the distribution of various types of nitrogen compounds in FCC diesel derived from catalytic cracking of un-hydrotreated FCC feedstock. It can be seen from Figure 2 that after 20 minutes of residence time the intensity of nitrogen compounds’ peaks was apparently increased and reached a maximum value after around 25 min. By means of the existing standard samples of some nitrogen compounds and the study on qualitative analysis of relevant nitrogen compounds[20-21], the chromatographic peaks of nitrogen compounds in FCC diesel shown in Figure 2 were categorized and identified qualitatively, with the data depicted in Table 3.

It can be seen from Table 3 that the nitrogen compounds in FCC diesel mainly include the homologs of anilines, indoles, quinolines and carbazoles. The nitrogen amount of aniline homologues, which consist of aniline and C1— C4alkyl anilines, accounts for only 1.0% of total nitrogen content, while the quinoline-type nitrogen concentration is rather low and accounts for 0.3% of total nitrogen content. The indole content was not identified because of its very low concentration among its homologues, but the nitrogen concentration of C1—C4alkyl indoles is quite high and accounts for about 22.7% of total nitrogen content. The nitrogen amount of carbazole homologues including mainly carbazole and C1—C4alkyl carbazoles accounts for 76.0% of total nitrogen content. It is quite clear that the FCC diesel fraction mostly contains basic nitrogen compounds, while the nitrogen concentration of indole and carbazole homologues accounts for around 98% of total nitrogen content.

Figure 2 GC-NCD chromatogram of FCC diesel

Table 3 Type and amount of nitrogen compounds in FCC diesel derived from unhydrotreated FCC feed

3.2 Rules on conversion of sulfur compounds in FCC diesel derived from hydrotreated FCC feed

By virtue of experiments for evaluating the properties of hydrotreated FCC feed it is possible to investigate the influence of the reaction temperature for hydrotreatment of FCC feed on the distribution of sulfur compounds in the FCC diesel fraction.

It can be seen from Figure 3 showing the rules relating to changes in sulfur compounds of FCC diesel fractions derived from hydrotreated and un-hydrotreated FCC feedstocks that the No.2 FCC diesel derived from FCC feed, hydrotreated at 350 ℃, contains apparently less BTs, while the No.4 FCC diesel derived from FCC feed, hydrotreated at 370 ℃, basically does not contain BTs along with avery low concentration of dibenzothiophenes (DBTs). It can be seen from Table 4 on various sulfur compounds in FCC diesel fractions that the DBTs in FCC diesel fractions derived from hydrotreated FCC feed oil apparently decrease along with a relatively high concentration of BTs. In the No.2 FCC diesel the sulfur amount in DBTs accounts for only 45.6% of total sulfur content. The No.4 FCC diesel contains a minimum ratio of DBTs, the sulfur amount of which is equal to only 4.6% of total sulfur content, and its sulfur amount of BTs accounts for 84% of total sulfur content. Therefore BTs assume a dominating ratio of sulfur compounds in the No. 4 FCC diesel.

Figure 3 GC/PFPD chromatograms of FCC diesel derived hydrotreated and unhydrotreated feed

Table 4 The amount of sulfur compounds in FCC diesel derived from hydrotreated feedμg/g

The type and position of substituting groups have different influence on the reactivity of alkyl substituted dibenzothiophenes. The substituting groups at positions 1, 2 and 7 have insignificant impact on adsorption of sulfur atoms on active sites of the catalyst. However, such sulfur compounds as 4-MDBT and 4,6-DMDBT because of their spatial hindrance of substituting groups can affect the adsorption of sulfur atoms on active sites of the catalyst, resulting in lower HDS rate[22]. The mass fraction of two kinds of methyl dibenzothiophene sulfides in FCC diesel derived from the hydrotreated FCC feed is presented in Table 5. It can be seen from Table 5 that the sulfur compounds in FCC diesel fraction derived from the hydrotreated FCC feedstock consist of mainly BTs, which can be removed in the course of diesel hydrotreating, and the low concentration of 4-MDBT and 4,6-DMDBT can carve out a promising shortcut route for manufacture of ultralow-sulfur (ULS) diesel.

Table 5 The concentration of two kinds of methyl dibenzothiophene sulfides in FCC diesel derived from hydrotreated feedμg/g

3.3 Influence of feedstock hydrotreatment on nitrogen compounds in FCC diesel

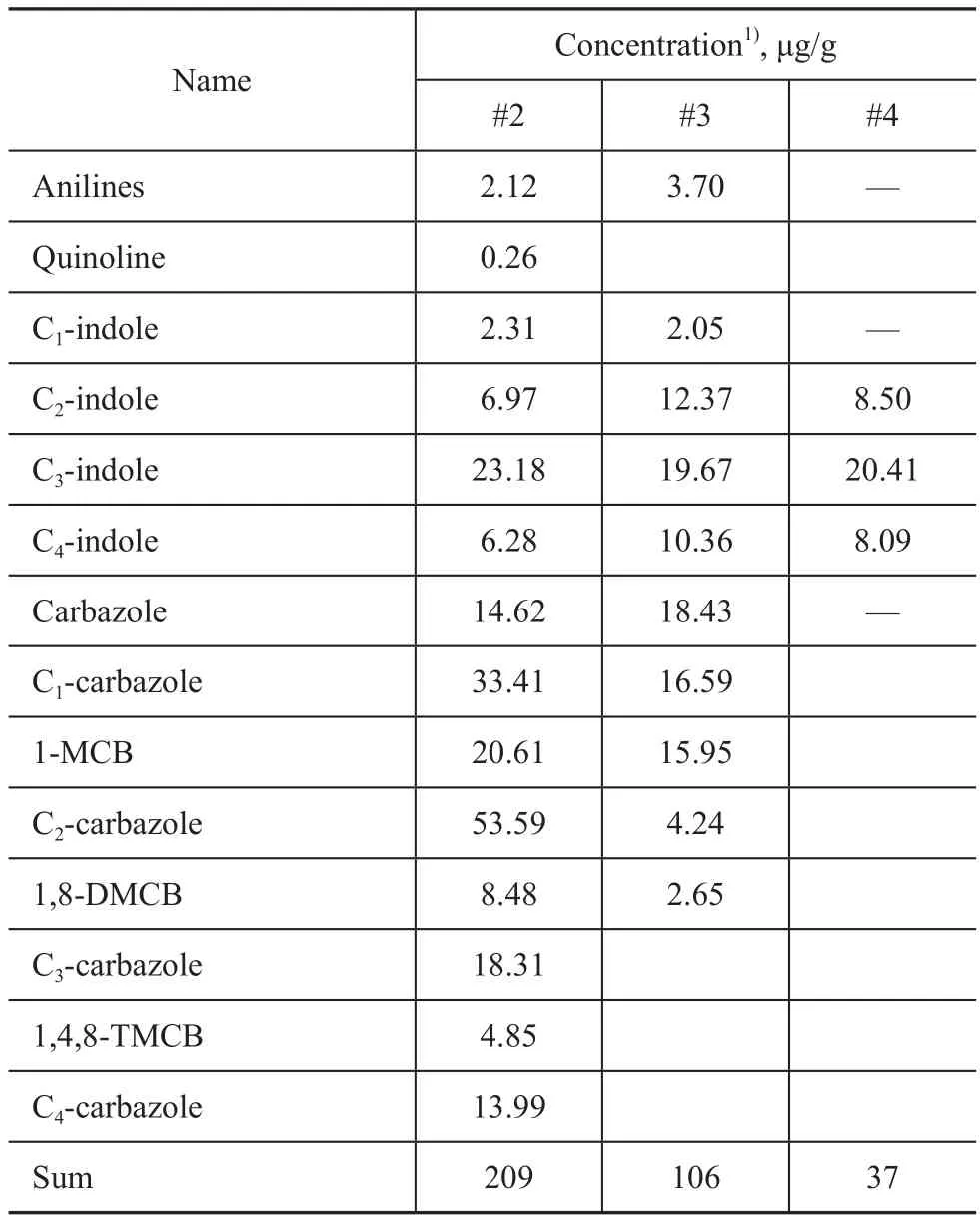

The external standard method was adopted to quantitatively analyze the nitrogen compounds contained in FCC diesel fractions derived from hydrotreated FCC feed oil, with the results presented in Table 6. It can be seen from Table 6 that in the No.2 FCC diesel sample the nitrogen compounds with a nitrogen concentration exceeding5% decrease in the following order: ethyl carbazole>C1-carbazole>propyl indole>1-methyl carbazole>propyl carbazole. In the No.3 FCC diesel sample the nitrogen compounds with a nitrogen concentration exceeding 10% decrease in the following order: propyl indole>carbazol> C1-carbazole>1-methyl carbazole>ethyl indole, while in the No.4 FCC diesel sample the nitrogen compounds mostly consist of indoles, among which the nitrogen concentration of propyl indole accounted for 55.2% of total nitrogen content, with the nitrogen concentration of ethyl indole and butyl indole accounting for around 20% of total nitrogen content each.

Table 6 The amount of nitrogen compounds in FCC diesel derived from hydrotreated feed

The carbazoles with substituting groups at the positions 1 and 8 have very low activity to be hydrotreated[20]. It can be seen from Table 6 that the No.2 FCC diesel contains more homologues of carbazole with alkyl substituting groups located at the position 1, such as 1-methylcarbazole, 1,8-DMCB and 1,4,8-TMCB. In the No.2 FCC diesel the nitrogen concentration of 1-MCB was 20.61 mg/g, and that of 1,8-DMCB and 1,4,8-TMCB was equal to 8.48 mg/g and 4.85 mg/g, respectively. It is evident that the No.2 FCC diesel had a high content of 1-MCB, 1,8-DMCB and 1,4,8-TMCB, and in the No.3 FCC diesel the nitrogen concentration of these three compounds was less, while these three compounds were not identified in the No.4 FCC diesel sample.

The nitrogen compounds in the No.2—No.4 FCC diesel samples derived from hydrotreated FCC feed oil were mainly composed of indoles and carbazoles, with their nitrogen concentration accounting for more than 95% of total nitrogen content. The nitrogen concentration of indoles accounts for 18.53% and 41.93% of total nitrogen amount in the No.2 FCC diesel and No.3 FCC diesel, respectively, while the nitrogen concentration of carbazoles accounts for 80.33% and 54.58% of total nitrogen amount in the above-mentioned two FCC diesel samples, respectively. In the No.4 FCC diesel sample the nitrogen concentration of indoles accounts for 98% of total nitrogen content while carbazoles are not identified in this FCC diesel sample. It can be learned that with an increasing temperature for hydrotreatment of FCC feedstock, the concentration of carbazoles in the FCC diesel fraction gradually decreased and the nitrogen compounds in FCC diesel consisted of mainly indoles. Since carbazoles are the most refractory type of nitrogen compounds to be removed through processing, the rules on their distribution in the course of HDN reaction are of great significance. The hydrotreatment of heavy petroleum fraction can reduce the concentration of carbazoles in FCC diesel fraction, which is conducive to the post-hydrotreating of FCC diesel.

The aniline content in FCC diesel fraction is quite low. The aniline-type nitrogen concentration in the No.3 FCC diesel sample accounts for 4% of total nitrogen content, while the aniline-type nitrogen concentration in the No.1 and No.2 FCC diesel samples is all less than 2% of total nitrogen content. The quinolone content in FCC diesel samples is very low. For example, the quinolone-type nitrogen concentration in the No.2 FCC diesel sample accounts for around 0.3% of total nitrogen content, while no quinoline is identified in No.3 and No.4 FCC diesel samples.

4 Conclusions

1) The sulfur compounds in FCC diesel mainly consist of BTs and DBTs, and the dibenzothiophenic nitrogen concentration accounts for 86.92 % of total sulfur mass fraction, while the nitrogen compounds in FCC diesel are mostly composed of non-basic nitrogen compounds, in which the indole-type and carbazole-type nitrogen concentration accounts for 98% of total nitrogen content.

2) After hydrotreatment of FCC feedstock, the sulfur compounds in FCC diesel fraction obtained thereby are mainly composed of BTs that can be easily removed during hydrotreating of diesel fraction. The 4-MDBT and 4,6- DMDB content in FCC diesel is quite low, which can carve out a promising route for producing of ultralowsulfur diesel.

3) With the increase in temperature for hydrotreatment of FCC feedstock, the concentration of carbazoles among the nitrogen compounds gradually decreases, and the indole-type nitrogen compounds occupy a dominant ratio. Therefore hydrotreatment of FCC feedstock can reduce the concentration of carbazoles in the FCC diesel fraction, which would be conducive to the post-hydrotreating of FCC diesel.

[1] Qian Bozhang, Zhu Jianfang. The world crude oil quality trends and challenges China is facing [J]. Natural Gas and Oil, 2006, 24(4): 61-65 (in Chinese)

[2] Badawi M, Vivier L, Duprez D. Kinetic study of olefin hydrogenation on hydrotreating catalysts[J]. Journal of Molecular Catalysis A: Chemical, 2010, 320(1/2): 34-39

[3] Mochizuki T, Itou H, Toba M, et al. Effects of acidic properties on the catalytic performance of CoMo sulfide catalysts in selective hydrodesulfurization of gasoline fractions[J]. Energy & Fuels, 2008, 22(3): 1456-1462

[4] Deng Zhanghuo, Wang Tiefeng, Wang Zhanwen. Hydrodesulfurization of diesel in a slurry reactor[J]. Chemical Engineering Science, 2010 65(1): 480-486

[5] Sano Y, Choi Kh, Korai Y, et al. Adsorptive removal of sulfur and nitrogen species from a straight run gas oil over activated carbons for its deep hydrodesulfurization[J]. Applied Catalysis B: Environmental, 2004, 49(4): 219-225

[6] Sano Y, Choi Kh, Korai Y, et al. Effects of nitrogen and refractory sulfur species removal on the deep HDS of gas oil[J].Applied Catalysis B: Environmental, 2004, 53(3): 169-174

[7] Rana M S, Sámano V, Ancheyta J, et al. A review of recent advances on process technologies for upgrading of heavy oils and residua[J]. Fuel, 2007, 86(9): 1216-1231

[8] Stratiev D S, Shishkova I K, Dobrev D S. Fluid catalytic cracking feed hydrotreatment and its severity impact on product yields and quality [J]. Fuel Processing Technology, 2012, 94(1): 16-25

[9] Vistisen P Æ, Zeuthen P. Reactions of organic sulfur and nitrogen compounds in the FCC pretreater and the FCC unit[J]. Industrial & Engineering Chemistry Research, 2008, 47(21): 8471-8477

[10] Yin Changlong, Zhao Huiji, Xu Yongqiang, et al. Study on transformation of sulfides in the process of deep hydrodesulfurization of diesel[J]. Journal of the China University of Petroleum (Edition of Natural Science), 2007, 31(4): 134-138 (in Chinese)

[11] Gao Liping, Liu Peng, Gu Tao, et al. Characterization of sulfur compounds in diesel fractions[J]. Journal of Fuel Chemistry and Technology, 2009, 37(2): 183-188 (in Chinese)

[12] Ling Fengxiang, Yao Yintang, Ma Bo, et al. Study of sulfur compounds in diesel fuel by GC-atomic emission detection[J]. Journal of Fuel Chemistry and Technology, 2002, 30(6): 535-539 (in Chinese)

[13] Depauw G A, Froment G F. Molecular analysis of the sulphur components in a light cycle oil of a catalytic cracking unit by gas chromatography with mass spectrometric and atomic emission detection[J]. Journal of Chromatography, 1997, 761(1/2): 231-247

[14] Yang Yongtan, Wang Zheng, Yang Haiying, et al. Determination of sulfur compounds in diesel fuel by gas chromatography flame ionization detector-sulfur chemiluminescence detector and data comparison of sulfur compounds by sulfur chemiluminescence detector and atomic emission detector[J]. Chinese Journal of Analytical Chemistry, 2005, 33(11): 1517-1521 (in Chinese)

[15] Yang Yongtan. Distribution determination of nitrogen compounds in FCC diesel fuel using gas chromatography[J]. Chinese Journal of Chromatography, 2008, 26(4): 478-483 (in Chinese)

[16] Han Xiaoyu, Ma Bo, Ling Fengxiang, et al. Study on nitrides distribution in fluid catalytic cracking diesel[J]. 2006, 13(2): 7-9 (in Chinese)

[17] Lü Zhifeng, Zhan Fengtao, Li Lin, et al. Separation and identification of nitrogen compounds in diesels[J]. Petrochemical Technology, 2001, 30(5): 399-401 (in Chinese)

[18] Ma X, Sakanishi K, Isoda T, et al. Determination of sulfur compounds in non-polar fraction of vacuum gas oil[J]. Fuel, 1997, 76(4): 329-339

[19] Mossner S G, Wise S A. Determination of polycyclic aromatic sulfur heterocycles in fossil fuel-related samples[J]. Analytical Chemistry, 1999, 71(1): 58-69.

[20] Wiwel P, Knudsen K, Zeuthen P. et al. Assessing compositional changes of nitrogen compounds during hydrotreating of typical diesel range gas oils using a novel preconcentration technique coupled with gas chromatography and atomic emission detection[J]. Industrial & Engineering Chemistry Research, 2000, 39(2): 533-540

[21] Yang Yongtan, Wang Zheng, Yang Haiying, et al. Study on distribution of nitrogen compounds in FCC diesel by gas chromatography-atomic emission detector[J]. Chinese Journal of Chromatography, 2004, 22(5): 500-503 (in Chinese)

[22] ShafiR, Hutchings G J. Hydrodesulfurization of hindered dibenzothiophenes: An overview[J]. Catalysis Today, 2000, 59(3/4): 423-442

date: 2014-10-15; Accepted date: 2014-12-08.

Professor Liu Chenguang, E-mail: cgliu@upc. edu. cn.

杂志排行

中国炼油与石油化工的其它文章

- Study on Surface Adsorption and Inhibition Behavior of Corrosion Inhibitors Contained in Copper Foil Rolling Oil

- Synthesis of Petroleum Sulfonate Surfactant with Ultra-Low Interfacial Tension in Rotating Packed Bed Reactor

- Simultaneous Removal of H2S and Organosulfur Compounds from Lique fied Petroleum Gas Using Formulated Solvents: Solubility Parameter Investigation and Industrial Test

- Effect of Dodecylbenzene Sulfonic Acid Used as Additive on Residue Hydrotreating

- Sulfur Distribution during Hydrothermal Liquefaction of Lignite, Wheat Straw and Plastic Waste in Sub-Critical Water

- Simulation Optimization and Experimental Study of Cross-Wall Adiabatic Dividing Wall Column Used to Separate Hexane-Heptane-Octane System