Effect of moisture content on the ultrasonic acoustic properties of wood

2015-06-05HuiminYangLeiYuLihaiWang

Huimin Yang•Lei Yu•Lihai Wang

Effect of moisture content on the ultrasonic acoustic properties of wood

Huimin Yang1•Lei Yu1•Lihai Wang1

We determined the ultrasonic velocity and energy attenuation value of three tree species(basswood,elm, and fir)1 pertree in differentmoisture contentlevels,using RSM-SY5 ultrasonic testing instrument,and analyzed the regularity of ultrasonic velocity and energy attenuation values with moisture content,respectively.The ultrasonic velocity of the three species decreased as moisture content increased,with the turning point at 32%of moisture content.When the moisture content was more than 32%, the growth curve of ultrasonic wave velocity was flattened. The moisture contents of all three species increased under the any point moisture content of 1–60%.The differentiation degrees of energy attenuation value of three species were higher than the corresponding ultrasonic wave velocity,when the moisture contentwas less than 15%.The differentiation degrees of the energy attenuation value of three species was higher than the corresponding ultrasonic velocity,when the moisture content was more than 15%.

Ultrasonic·Moisture content·Velocity· Energy attenuation·Wood

Introduction

The spread of ultrasonic waves in wood is affected by many factors.Dry shrinkage and wet expansion is the inherent physical properties of wood.Warpage and deformation often occur in Wood products.So the moisture contentis one of the important factors of wood.

Beall et al.(1994),Kawamoto(1994),Lemaster and Quarles et al.(1990),Bucur and Feeney(1992)studied the effect of anisotropy and heterogeneity on wood characteristics.Ultrasonic wave velocity decreased when moisture was higherin the radialdirection than thatin the tangential direction.Their findings also showed that the changes in the growth ring,naturaldefects,moisture,and temperature will cause attenuation of the acoustic ultrasonic parameters.For out-of-axis propagation the longitudinal direction of wood displays the most dispersion with respect to frequency,while the tangential propagation direction displays the least dispersion.Attenuation is generally greater for out-of-axis propagation.Wang and Chuang (2000)studied the relationship between the dynamic modulus of elasticity,static modulus of elasticity,and moisture content of Crytomeria japonica D.Don.The results showed thatthe effectof MC on propagation velocity and ultrasonic velocity is similar.The velocity reduces with the increment of moisture content,but it is different when MC>FSP(fiber saturation point)and MC<FSP.

Quarles(1990)studied the effect of MC on the attenuation of ultrasonic energy,which was similar in longitudinal direction and radial direction.Attenuation was constant when the MC was below 18%but it increased when MC was above 18%.Ilic(2001)studied the Eucalyptus regnans F.Muell that the dynamic elastic modulus and wave velocity changed along with the change of MC along the fiber direction.The speed had been increased inthe form ofcurve from raw materialto the dry state.Halabe et al.(1997)studied the regression relationship of propagation velocity,the dynamic modulus of elasticity and modulus of elasticity,bending strength in two kinds of raw material,and dry wood.Sandoz(1993)studied the effect of MC on ultrasonic velocity and corrected using a bilinear model with a change of the slope at MC=32% (for spruce and fir).

MC is a greatsignificance to the classification of wood. Brashaw et al.(2004)detected the propagation velocity with the change of MC in southern pine and Douglas fir in the United States.Chan et al.(2011)discussed the effects of sound on pine wood in terms of temperature and water content.Chen et al.(2012)studied the effect of moisture, species,and duration of service on stress-wave speed in wood members located in historical buildings.The speed decreases when MC is higher in the radial direction than that in the tangential direction.Liao et al.(2012)had a preliminary analysis of the effect of MC on wood-resistance detection and the propagation velocity with larch as test object.The effects of moisture content on resistance were obvious,and the influence of moisture content on stress-wave velocity was not affected.Si et al.(2007) indicated that MC had a significant effect on measuring results butthere was little effecton the coefficient of correlation between tested parameters and the dynamic moduli of elasticity,and there were significant coefficients of correlation between three dynamic moduli of elasticity.

Clearly,many researchers focused on the variation of ultrasonic propagation velocity and MC as opposed to the variation of energy attenuation of ultrasonic wave and MC. In our study,we analyzed regularity and correlation of ultrasonic velocity and energy attenuation value with moisture content.

Materials and methods

Experimentalequipment

Nonmetal ultrasonic detector,the RSM-SY5 model,was developed by the Intelligent Instrument Research of Chinese Academy of Sciences,Wuhan Institute of Rock and Soil Mechanics.Ultrasonic acoustic parameters of the specimen were measured by ultrasonic pulse transmission method in this phase.

High-frequency wood moisture meter made in Harbin YUDA Electronic Technology Co.,Ltd.,the FD-100B model,was used to determine the originalmoisture content of the specimens.

Electric thermostatic drying oven made in Shanghai Lei Yun Test Instrument Manufacturing Co.,Ltd.,the 101-IA model,was used to drying specimen when measuring the moisture content.

Electronic balance was used to determine quality of specimen when measuring the moisture content.Electronic balance was developed by Sartorius Stedim Biotech.

Materials

We used three kinds of tree species,including basswood, elm and fir,combining with the characteristics of forest farm in northeast China in winter logging with the diameter levelin more than 35 and 60 cm in length from Fangzheng Forestry Bureau in Heilongjiang Province.The logs of three tree species were carried back to laboratory immediately after being sealed in a plastic bag for determining the sample’s moisture content.Each sample was processed into 80 small specimens of 400×30×30 mm,and the specimen surface was polished.

Experimental program

The ultrasonic detector has a sensor at each end:the transmission sensor sends an ultrasonic pulse wave to the other side,and the reception sensor receives it.Each specimen was measured for 10 times with good accuracy,and the ultrasonic wave propagation velocity and the energy attenuation values were also recorded.

The samples were then putinto an electric thermostatic drying oven for drying,which was setto 105°C.After 1 h, the samples were weighed by an electronic balance,m, ultrasonic acoustic parameters were detected immediately, and then the samples were dried.The experiment was repeated 10 times until the parameters of the weight no longerchanged,and the weightwas recorded.Based on the weight of the wet parameters m and oven-dry parameters m0,the specimen water contentcan be calculated with the Eq.1.

Results and discussion

Correlation between ultrasonic transmission speed and MC

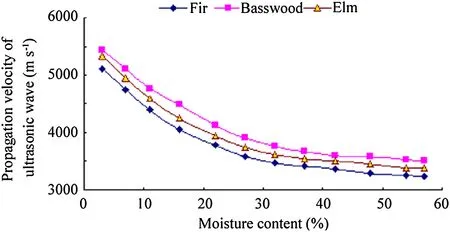

The change curve in Fig.1 is aboutthe effectof MC on the propagation velocity of an ultrasonic wave in basswood, elm and fir specimens,as shown in Table 1.

Fig.1 Effect of MC on propagation velocity of ultrasonic waves at differentspecies

In Fig.1,the speed of ultrasonic waves in the three woods(basswood,elm and fir)are similar atdifferent MC. It increases successively in same MC,and the speed decreases gradually with the MC increasing.Based on the propagation characteristics of ultrasonic waves,wave velocity is closely related to the impedance of the medium. Impedance changes with different MC levels,so the speed of ultrasonic wave in wood is inversely related to MC. When the MC is higher,the ultrasonic wave velocity is lower.Ultrasonic wave velocity decreases quickly when the MC is less than 32%,and the fallrange is larger and the obverse is also true.The wood fiber saturation pointis an important cut-off point in terms of the physical and mechanical properties of wood.Above the fiber saturation point,the bound-water is saturation,and the fiber is fullof water,and the redundantwater in the cellchamber is in the form of free water,which will not cause wood swelling.

Therefore,the regularity of ultrasonic transmission speed in differentwoods is as follows:the ultrasonic wave velocity decreases quickly while the MC increases,when the MC is less than 32%;and the ultrasonic wave velocity decreases gradually with the MC increasing,when the MC is more than 32%.With the MC increasing in different woods,all the ultrasonic transmission speeds have a decreasing trend.The tree species is the inevitable determinant of the ultrasonic wave velocity,and the speed of ultrasonic wave in the woods(basswood,elm and fir)increases successively with the same MC.

The regularity of the energy attenuation with the MC changing

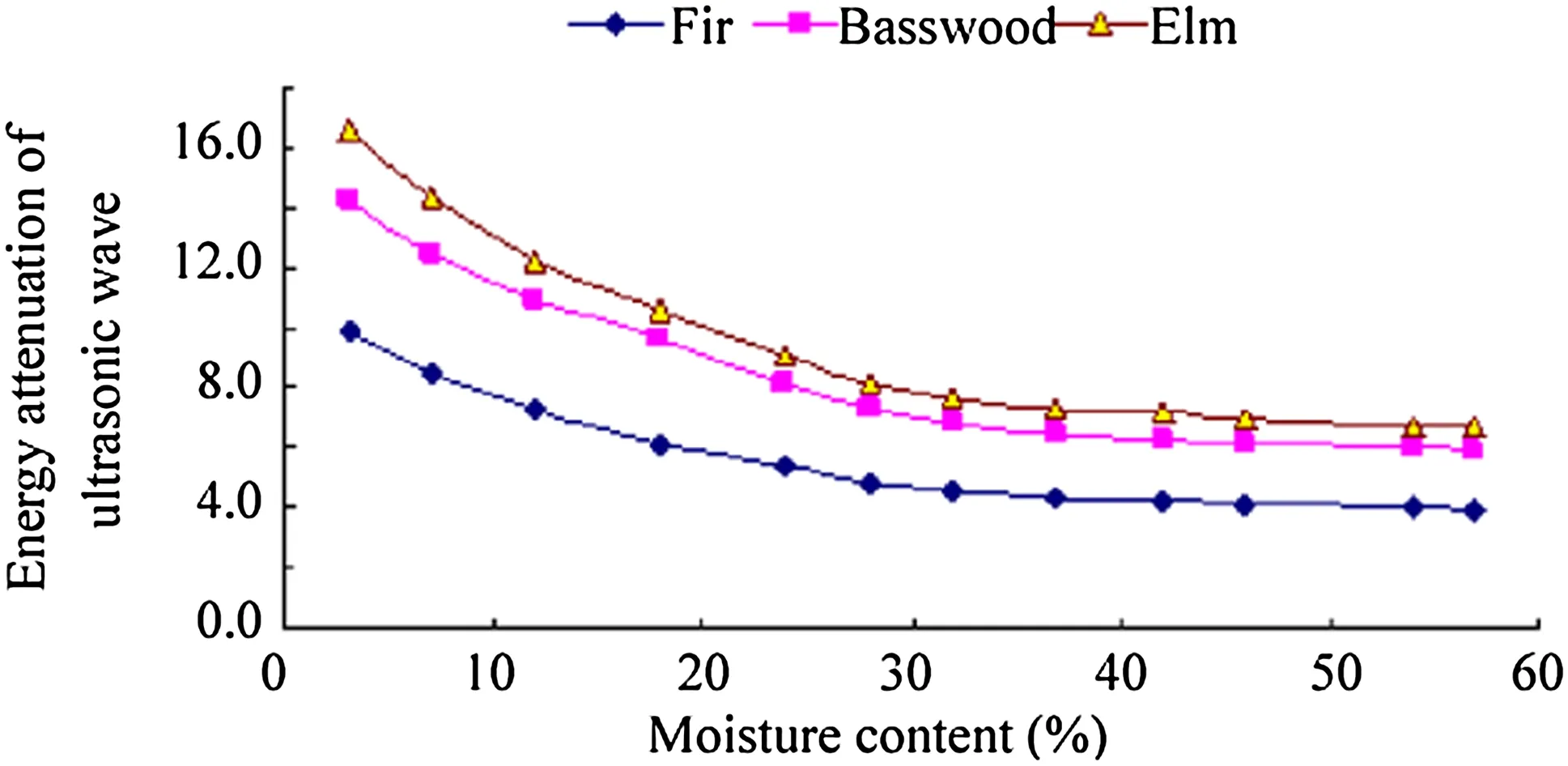

Figure 2 shows the effect of MC on energy attenuation of ultrasonic wave at different species.

In Figs.1 and 2,the ultrasonic transmission speed and energy attenuation of ultrasonic waves with the changing MC is similar.The discrimination of energy attenuation is higher than the ultrasonic transmission speed in the tree woods,when the MC is between 0 and 15%.As the MC increases,the discrimination of the ultrasonic transmission speed became obvious.

Correlation between ultrasonic transmission parameters and MC.

We used SPSS statistical software for ultrasonic wave propagation data at different levels of moisture content to analyze linear regression for the more specific relationship between moisture content and ultrasonic propagation velocity,and to establish the regression model(Table 2).

Regression model:y=ax+b,where,y is the propagation speed,and x is the moisture content(MC).

The correlation of the ultrasonic propagation velocity in tree woods is all more than 0.9,which indicates that the regression model has a high degree of goodness of fit,so we can estimate the ultrasonic propagation velocity in woods at different MC and use the ultrasonic velocity.

We can obtain the correlation of the acoustic velocity and MC by the regression analysis,in the whole MC rang,although the ultrasonic wave propagation velocity increases as the MC increases or decreases.The rate of the ultrasonic velocity changes were not the same in the moisture content of the fiber saturation point,and the influence of MC>32%on ultrasonic propagation velocity is less than thatof MC<32%.The lineareffectof MC on propagation velocity of ultrasonic waves,when the MC is larger than fiber saturation point,is less than thatwhen the MC is less than fiber saturation point.

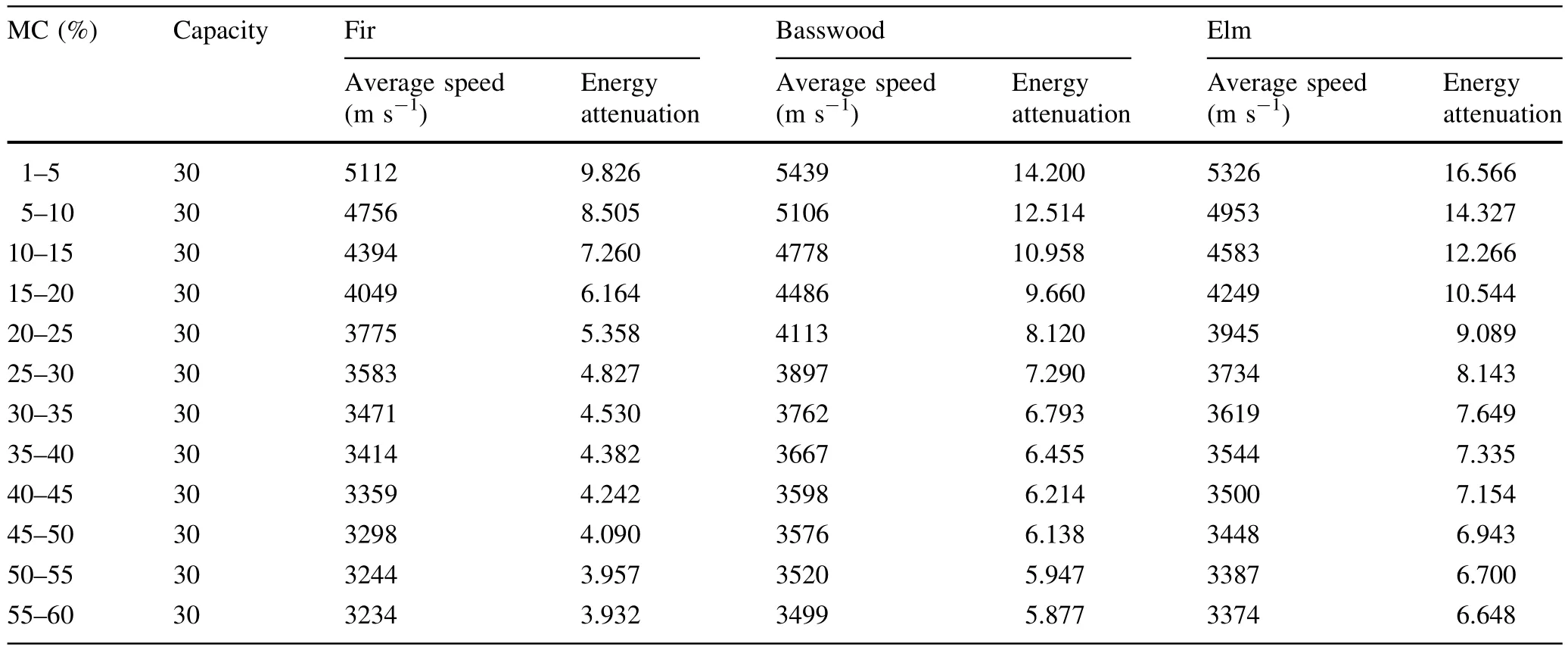

Table 1 The energy attenuation and mean values propagation speeds of ultrasonic wave at different MC

Fig.2 Effect of MC on energy attenuation of ultrasonic wave at different species

Table 2 Regression of MC and velocity of ultrasonic wave

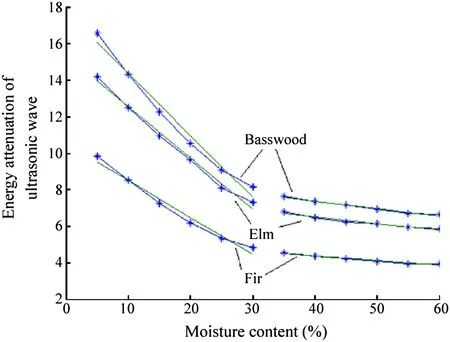

Using regression analysis of the ultrasonic energy attenuation at different MC levels,the regression curves of MC and the ultrasonic energy attenuation are shown in Fig.3.

Under the regression model,the energy attenuation decreases as the MC increases when the MC is less than 32%.When the MC is more than 32%,the energy attenuation almost does not change with the MC.Two main factors affect the relationship between the moistures in wood and signalattenuation.First,the waves scatter atthe cellwalloraround the cellwall,and the attenuation caused by the scattering mainly depends on the water content(in the curve partwhen the MC is less than 18%).The second signal attenuation mechanism appears when the cell containing free water and particle vibration caused by ultrasonic energy(which causes relative movementbetween the cell wall and a small amount of free water)causes wave energy loss.RMS voltage and attenuation have significant change and the velocity variation is notsignificantwith the change of water content.Therefore,RMS voltage and attenuation can reflectthe sample watercontent,butacoustic velocity does not.

Fig.3 The correlation of moisture content and energy attenuation

Conclusion

Using quantitative analysis,the ultrasonic wave velocity obviously decreases with the increase in moisture content when the moisture content is below the fiber saturation point(32%).When the moisture content is more than 32%,the growth of ultrasonic wave velocity flattens out with the increasing of moisture content.

The attenuation trends of ultrasonic energy and ultrasonic velocity with the change of moisture content are similar among in three species.The differentiation degrees of energy attenuation on basswood,elm and fir are higher than those of the ultrasonic wave velocity when the moisture content is less than 15%.The differentiation degrees of energy attenuation value on basswood,elm and fir are higher than those of the ultrasonic wave velocity on three woods when the moisture content was in 15–60%, and the differentiation degrees of basswood and elm are more than that of fir.

AcknowledgmentsThis work was financially supported by‘‘The Fundamental Research Funds for the Central Universities’’, DL12BB12 and 2572014CB35.

Beall FC,Biernacki JM,Lemaster RL(1994)The use of acoustoultrasonics to detect bio deterioration in utility poles.Journalof Acoustic Emission 12(1/2):55–64

Brashaw BK,Wang XP,Ross RJ,Pellerin RF(2004)Relationship between stress wave velocities of green and dry veneer.Forest Products Journal.55(6):85–89

Bucur V,Feeney F(1992)Attenuation of ultrasound in solid wood. Ultrasonics 30(2):76–81

Chan JM,Walker JC,Raymond CA(2011)Effects of moisture contentand temperature on acoustic velocity and dynamic MOE of radiate pine sapwood boards.Wood Sci Technol 45(4): 609–626

Chen YP,Li H,Li DQ,Zhang T(2012)Effects on stress wave speed inside wood members in historicalbuildings.China Wood Indus 26(2):37–40

Halabe UB,Bidigalu GM,GangaRao HVS,Rose RJ(1997) Nondestructive evaluation of green wood using stress wave and transverse vibration techniques.Mater Eval 55(9): 1013–1018

Ilic J(2001)Variation of the dynamic elastic modulus and wave velocity in the fiber direction with other properties during the drying of Eucalyptus Regnans F.Muell.Wood Sci Technol 35(1):157–166

Kawamoto S(1994)Attenuation of ultrasonic waves in wood. Mokuzai Gakkaishi 40(7):772–776

Liao CH,Zhang HJ,Li DQ(2012)Effect of water content on rapid detection index properties of wood.Jiangsu Agric Sci 40(6):280–282(in Chinese)

Quarles SL(1990)The effect of moisture content and ring angle on the propagation of acoustic signals in wood.J Acoust Emiss 9(3):189–195

Rl Lemaster,Sl Quarles(1990)The effectof same-side and throughthickness transmission modern signal propagation in wood. J Acoust Emiss 9(1):17–24

Sandoz J(1993)Moisture content and temperature effect on ultrasound timber grading.Wood Sci Technol27(5):373–380

Si H,Lu ZY,Wang LC(2007)Influence of moisture content on the dynamic MOE of Larchwood.Wood Proces Mach 1:16–19(in Chinese)

Wang SY,Chuang ST(2000)Experimental data correction of the dynamic elastic module velocity and density of solid wood as a function of MC above the fiber saturation point.Holzforschung 54(3):309–314

22 June 2014/Accepted:2 September 2014/Published online:9 May 2015

©Northeast Forestry University and Springer-Verlag Berlin Heidelberg 2015

The online version is available at http://www.springerlink.com.

Corresponding editor:Yu Lei.

Huimin Yang and Lei Yu have contributed equally to this research.

✉Lihai Wang yanghuimin0608@163.com

1Northeast Forestry University,Harbin 150040,China

杂志排行

Journal of Forestry Research的其它文章

- Management of pests and diseases of tropical sericultural plants by using plant-derived products:a review

- Gamma generalized linear model to investigate the effects of climate variables on the area burned by forest fire in northeast China

- Diversity,abundance,and structure of tree communities in the Uluguru forests in the Morogoro region,Tanzania

- Brazilian savanna re-establishment in a monoculture forest: diversity and environmental relations of native regenerating understory in Pinus caribaea Morelet.stands

- Carbon storage and sequestration rate assessment and allometric model development in young teak plantations of tropical moist deciduous forest,India

- Use of infrared thermal imaging to diagnose health of Ammopiptanthus mongolicus in northwestern China