Study on Image-denoising of Liquid Column in Investment Casting Auto-pouring System

2015-02-20YANGHuiyingDUWenbin

YANG Huiying,DU Wenbin

(1.Shenyang Ligong University,Shenyang,110159,China; 2.Northeastern University,Shenyang,110004,China; 3.Shenyang Railway Signal Co.,Ltd,Shenyang,110025,China)

Study on Image-denoising of Liquid Column in Investment Casting Auto-pouring System

YANG Huiying1,2,DU Wenbin3

(1.Shenyang Ligong University,Shenyang,110159,China; 2.Northeastern University,Shenyang,110004,China; 3.Shenyang Railway Signal Co.,Ltd,Shenyang,110025,China)

The application of investment casting auto-pouring system can improve the efficiency of manual-pouring system to a certain extent.The judgment of start-stop time depends on the preprocessing of original image collected by the CCD camera.Several methods are presented to denoise the liquid column image.The method of morphological image processing is feasible in theory,and it is important whether to choose the structural element or not.The method of pouring image projection is less affected the image of spure cup.The complexity of image window algorithm is minimal.

auto-pouring system;image-denoising of liquid column;morphological method;image projection processing

With the development of technology auto-pouring system become more and more popular than before.This system can improve the efficiency of investment casting.The manner is using CCD camera instead of the human-eyes,acquiring the spure cup image,and then preprocessing the image in order to getting the parameters of spure cup level[1].

In most cases,there are lots of noises such as liquid splashes and liquid column in the original image.If we can’t make the image processing,we can not judge the level from the image.So choosing an algorithm which is appropriate and fast is very important thing.

This paper discuss how to use different methods to replace the noises of liquid column,mainly compares the morphological image processing with histogram projection image processing.

Figure 1 shows the structure of auto-pouring system based on CCD camera.First of all acquiring the pouring image of spure cup from the CCD camera,the stopper rod control the start and stop time of pouring,the IPC is responsible for the image processing and control signal sending and receiving[2-3].

Figure 1 Structure of Auto-pouring System

1 INTERFERENCE OF LIQUID COLUMN

Investment casting is a very complex procedure.The whole time of one piece casting cost just about ten seconds (different module cost different time).If the IPC sends the stop time signal in advance,it will cause the casting blank below grade.If the IPC sends the stop time signal too late,it will cause the molten waste(Fig.2a).So the stop time is very important in foundry goods product.From the figure 2b we can see the liquid column is the noise of judging the spure cup level.So we should replace the noises at first with image preprocessing in order to getting the accurate time for controlling the stopper rod.

Figure 2 Image of Spure Cup from the Investment

2 MORPHOLOGICAL IMAGE DENOISING

In order to get the feature of spure cup,we choose the morphological image processing operation called morphological opening denoise the liquid column.The morphological opening ofAbyB,is simply erosion ofAbyB,followed by dilation of the result byB.

Mathematically,dilation is defined in terms of set operations.The dilation ofAbyB,denotedA⊕B,is defined as equation (1):

(1)

That Ø is the empty set andBis the structuring element.In words,the dilation ofAbyBis the set consisting of all the structuring element origin locations where the reflected and translatedBoverlaps at least some portion ofA.The mathematical definition of erosion is similar to that of dilation.The erosion ofAbyB,denotedAΘB,is defined as equation (2):

AΘB={z|(B)z∩Ac≠Ø}

(2)

In other words,erosion ofAbyBis the set of all structuring element origin locations where the translatedBhas no overlap with the background ofA.

The morphological opening ofAbyB,denotedA∘B,is defined as equation (3):

A∘B=(AΘB)⊕B

(3)

The details of reduce the liquid column described as follows[4]:

1) Search the point of the image horizontal,find the point of intersection coordinate(x1,y1) and (x2,y2) with the liquid column,then calculate the width of liquid column which described in the following equation (4):

d=|x2-x1|

(4)

Wheredis the distance between point (x1,y1) and point (x2,y2) of liquid column.

2) Use the Eq.(4) continue searching the widthdof liquid column,defineddmaxequals to the biggest value ofd;

3) Because of the effect of gravity,the bottom of liquid column is less than the value ofdmax,while the value ofdstart decreasing,stop searching the point of column,defined as equation (5):

ser=dmax+nandsel=n+1,n∈[1,2]

(5)

4) Cross structuring element shows below:

Figure 3 Cross structuring element

5) Process the real time image using the morphological opening with the structuring element in Fig.3.

3 IMAGE PROCESSING OF IMAGE PROJECTION METHOD

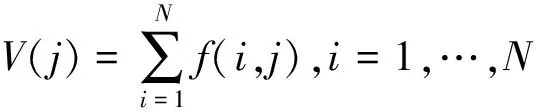

The image projection method algorithm describes as follows:

The column projection:

(6)

The row projection:

(7)

(8)

The details of image projection method is getting the coordinates which are the point of inflection on the project curve,then fill the areas which determined by the coordinates of four points black color.

4 EXPERIMENTAL RESULTS AND ANALYSIS

Figure 4 shows the procedure of image projection method,first of all we should transfer the RGB image which is shows in Figure 2b to gray-level image(Figure 4a),then threshold the gray-level image with fixed segmentation[5](the result shows in Figure 4b).

Figure 4 Image Projection Method Preprocessing

From the Figure 4 above can see that the Figure 4c is the vertical projection of the result of image segmentation(Figure 4b),and the Figure 4d is the horizontal projection of Figure 4b.After analysis the Figure 4c and Figure 4d,can get the coordinates of the four inflection point,fill the regions with black color at last,can get the result of image projection method showing in Figure 5d.

Figure 5 Result of Morphological Image Processing and

Figure 5a is the result of morphological image processing,it shows the opening operation which the structural elements are too large.Can see that this method can replace liquid column,but it also destroy shape of spure cup image.So can’t use this result to judge the spure cup level.The Figure 5b shows the structural elements which are too small,so can not clean up the whole liquid column in the image,so can not use this result judge the spure cup level.How to choose the appropriate structural elements are the key points of morphological image processing.

Compare the last result of morphological method with the image projection method which are show in Figure 5c and d,can see these two pictures just look like the same,but after calculate the pixels of white point,Figure 5c contains 339 white points,Figure 5d contains 416 white points.So there are errors between these two methods.

5 CONCLUSION

This research will improve the accuracy of spure level judgment.The morphological image processing is good for image,but it is complex to determine the structural elements toward the video frequency.The image projection method is fast and efficient.It is more suitable for practical application.

REFERENCES:

[1]Wang Yong-guo,Miao LI-gang.Automatic Pouring System for Metal Casting Based on Learning from Example[J].Foundry Technology,2010,31(11):1503-1506.

[2]Noda Y,Suzuki M,Terashima K.Optimal Sequence Control of Automatic Pouring System in Press Casting Process by using Greensand Mold[C].2006 SICE-ICASE International Joint Conference,2006:4083-4088.

[3]Terashima K,Hamaguchi M,Yamaura K.Modeling and input shaping control of liquid vibration for automatic pouring system[C].Proceedings of 35th IEEE Conference on Decision and Control,1996,4:4844-4850.

[4]YANG Hui-ying,Du Wen-bin,ZHANG Lu.The Appfication of Image Recognition Method Based on Hu-moment Invariants in Auto-pouring System[J].Transactions of Shenyang Ligong University,2009,28(5):34-37.

[5]Otsu N.A threshold selection method from gray-level histograms[J].IEEE Transactions on Systems,Man,and Cybernetics,1979,9(1):62-66.

(责任编辑:马金发)

1003-1251(2015)02-0091-04

TP2;TG2 Document code: A

Received date: 2013-12-11

Biography: YANG Huiying(1982—),female,lecturer,Search direction:Digital image processing.