Estimating harvest costs and projecting quantities of logging residues for small-scale forestry in Nasushiobara, Tochigi Prefecture, Japan

2014-09-06ChikaraNakahataRyoUemuraMasashiSaitoKanaeKanetsukiKazuhiroAruga

Chikara Nakahata · Ryo Uemura · Masashi Saito Kanae Kanetsuki · Kazuhiro Aruga

ORIGINAL PAPER

Estimating harvest costs and projecting quantities of logging residues for small-scale forestry in Nasushiobara, Tochigi Prefecture, Japan

Chikara Nakahata · Ryo Uemura · Masashi Saito Kanae Kanetsuki · Kazuhiro Aruga

Received: 2013-10-29; Accepted: 2013-12-24

© Northeast Forestry University and Springer-Verlag Berlin Heidelberg 2014

We used GIS on a regional scale to estimate and compare supply potentials and costs of small-scale logging systems, a mini-forwarder and a 4-ton truck operated by private logging contractors, and manual logging and a light truck operated by individual forest owners, with the mechanized operational system of the Forest Owners’ Association. Total potential yields of timber and logging residues were estimated as 418,895 m3and 254,962 m3, respectively. The economic balances were estimated and available amounts were projected as supply potentials from profitable sub-compartments. As a result, available amounts of timber and logging residues were estimated at 376,466 m3(89.9%) and 203,850 m3(80.0%), respectively. Because their transport expenses were lower than for other systems the most profitable sub-compartments were operated by private logging contractors who sold logging residues at a plant. The profitable sub-compartments operated by individual forest owners were few because the extracting distances were usually greater than 20 m. Raising logging residue prices from 3,000 yen·m-3to 4,080 yen·m-3or 6,800 yen·m-3, and establishing forest roads, which reduced some extracting distances to less than 20 m, increased the number and area of profitable sub-compartments, and increased available amounts of logging residues.

GIS, supply potentials, private logging contractor, individualforest owner, Forest Owners’ Association

Introduction

The oil crises of the 1970s spurred research into bioenergy. Although promising results were obtained from the studies (Agriculture, Forestry and Fisheries Research Council Secretariat 1991), a commercial bioenergy project was not implemented because the crude oil price stabilized at a lower level and the expected demand declined in Japan. Now, however, biomass as a renewable and carbon-neutral energy resource is becoming of interest again as a measure against climate change and to improve energy security. Among various biomass resources in Japan, woody biomass in particular attracts attention. This is not just because it is abundant, but also because its energy use is expected to contribute to revitalizing forests and forestry product industries that have been depressed for the last 30 years. Maintaining the ecological, economic, and social functions of man-made forests that have been degraded through neglect, is also important.

An agrarian organization in the Nasunogahara area in Tochigi Prefecture is willing to conduct thinning operations and extract thinned wood for biomass power generation in cooperation with the Forest Owners’ Association in Nasushiobara. This nurtures river resources as well as maintains forests for soil and water conservation. Forest ownership in Japan is characterized by a large number of small, fragmented, and scattered forest owners (Forestry Agency 2009). The optimal method for extracting logging residues from these small, fragmented, and scattered forests should be determined separately from assessments of mechanized operational systems used on the much larger aggregated forestry operation sites.

In a previous study (Nakahata et al. 2013), small-scale logging systems operated by a private logging contractor and an individual forest owner were investigated. Then, the equations to estimate productivities and costs were established with the cycle times, volumes, and hourly operational expenses consisting oflabor and machinery expenses. Finally, the costs of the small-scale systems, a mini-forwarder and a 4-ton truck operated by a private logging contractor, and manual logging and a light truck operated by an individual forest owner, were estimated and compared with the mechanized operational system of the Forest Owners’ Association. As a result, the mechanized operational system was determined to have the highest cost and was not competitive for small forestry operations and small stem volumes. The small-scale systems could be effective for harvesting small areas.

The investigation and examination of operational and stand conditions were limited in the previous study (Nakahata et al. 2013), and further investigations were needed to examine operational and stand conditions. Furthermore, operational and stand conditions could be examined using Geographical Information System (GIS) using the method of our previous study (Aruga et al. 2013b). Numerous studies examined the availability of woody biomass resources using GIS. Iuchi (2004) and Kamimura et al. (2009) developed techniques for estimating the yield of woody biomass, including logging residues, sawmill residues, and construction waste woods, in terms of regional energy in units of cities and towns.

In addition to supply potentials, Yoshioka et al. (2005b) and Kinoshita et al. (2009) devised techniques for estimating the regional harvest volumes and costs of logging residues in units of sub-compartments corresponding to conventional forest management units in Japan. Yagi et al. (2007) and Yamamoto et al. (2010) developed techniques that expressed them in units of kilometer-scale grids of cities and towns. Nord-Larsen et al. (2004), Rørstad et al. (2010), and Aruga et al. (2006a) discussed the long-term feasibility of timber and forest biomass resource harvest by predicting future forest resources using growth models while optimizing the allocation of fuel wood using linear programming or random search. Aruga et al. (2006b) and Panichelli et al. (2008) discussed the scales and locations of bio-energy facilities based on the relationship between the predicted supply and the procurement costs of forest biomass resources. Ranta (2005), Möller et al. (2007), and Viana et al. (2010) devised a technique for expressing this on a national scale. Zambelli et al. (2012) developed a tool for forest biomass evaluation based on the Free and Open Source Software for Geo-spatial (FOSS4G) which was selected as a Decision Support System to guarantee the maximum sharing of information and to enable shared development.

In addition to these methods for the estimation of yields and costs, Yamaguchi et al. (2010) and Aruga et al. (2013b) developed a technique for estimating yields of logging residues by considering the economic balances estimated from regional revenues and costs of both timber and logging residues in units of sub-compartments. Kinoshita et al. (2010) established a technique to express these in units of cities and towns. However, these studies focused on the mechanized operational systems instead of small-scale systems. In many regions of the world, small-scale harvesting machines have been used in forestry where terrain condition and size of forest operations are not limiting (Akay 2005).

The goal of our study was to estimate and compare harvesting costs and yields of logging residues in the context of small-scale systems, a mini-forwarder and a 4-ton truck operated by private logging contractors, and manual logging and a light truck operated by individual forest owners, with those by the mechanized operational system of the Forest Owners’ Association on a regional scale using the method of our previous study (Aruga et al. 2013b).

Materials and methods

Study site and data

Our study site was at Nasushiobara in Tochigi Prefecture, Japan (Fig. 1). We analyzed major plantation species, such as Japanese cedar and Japanese cypress that were owned by private individuals and local governments. Private individuals and local governments owned 7,340 sub-compartments of Japanese cedar comprising 2,850 ha, and 2,521 sub-compartments of Japanese cypress comprising 1,103 ha.

Fig. 1: Stand species

Forest-registration data (stand ages, tree species and site indices) and GIS data (information on roads and sub-compartment layers) from the Tochigi Prefectural Government were used in the study, as were 10-m-grid digital elevation models (DEMs) from the Geographical Survey Institute. Private individuals and local governments owned 6,342 sub-compartments of Japanese cedar comprising 2,464 ha, and 1,862 sub-compartments of Japanese cypress comprising 839 ha based on 10-m grids. The number and area of sub-compartments in the 10-m grids were 16% less than those of the actual sub-compartments because there were small sub-compartments of less 0.01 ha that could not be recognized in the 10-m grids.

Projected logging amounts

Available logging amounts were projected in the following order: (1) sub-compartments for thinning and final felling operations were selected based on stand ages; (2) potential yields were estimated based on cutting and extraction rates; (3) forwarding and transport distances were estimated; (4) total expenses for thinning and final felling operations with each operation system were estimated; (5) incomes were estimated; (6) profitability was estimated; (7) available amounts were projected as supply potentials from profitable sub-compartments. A simple version of“Methods” will be described below. Full technical details will be found in an earlier paper (Aruga et al. 2013b).

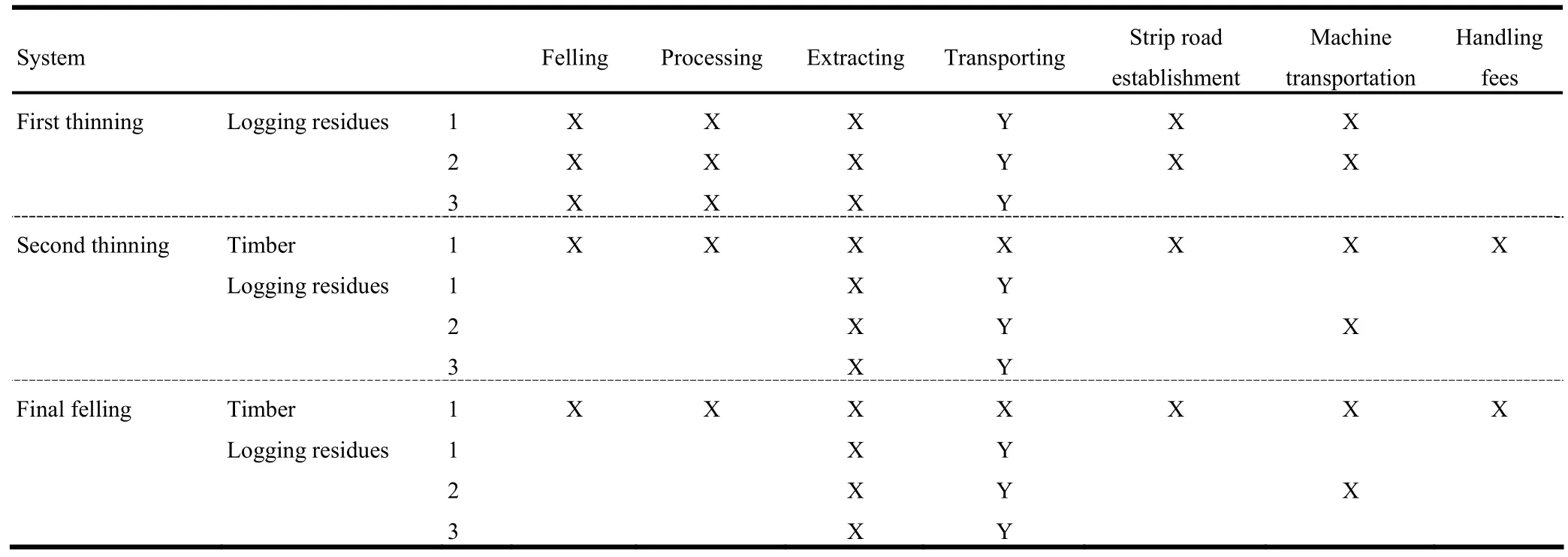

Estimating total expenses

Costs for first thinning operations were estimated for the following operational systems (Table 1): (1) all operations conducted by the Forest Owners’ Association, (2) all operations conducted by private logging contractors, and (3) all operations conducted by individual forest owners (Table 2). Costs for the second thinning and final felling operations were estimated for the following operational systems: logging residues harvested by the Forest Owners’ Association, private logging contractors, or individual forest owners after timber harvesting by the Forest Owners’ Association. Because logging residues harvested by individual forest owners were assumed to be manual operations, extraction distances were limited to within 20 m. Our study assumed that private logging contractors and workers from the Forest Owners’ Association were professionals, whereas individual forest owners were amateurs and had recently commenced logging residue extractions.

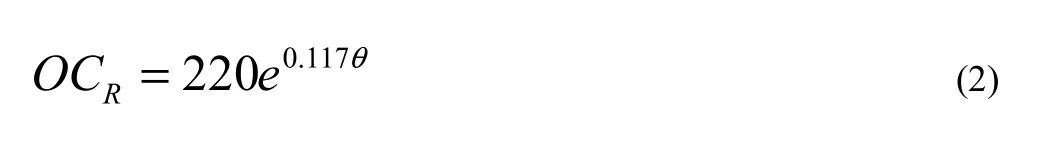

Strip road establishment expenses, machine transportation expenses, and the handling fees associated with the log market were estimated as indirect operational expenses. The strip roads were 2.0 m wide for private logging contractors and 3.5 m wide for the Forest Owners’ Association (Sawaguchi 1996). Strip road establishment expenses were estimated with slope angles θ (°).

for 2.0 m wide private logging contractor roads

for 3.5 m wide Forest Owners’ Association roads

Machine transport expenses were estimated by unit costs of 5,000 yen per machine. The transportation of four machines, a back hoe, a grapple-loader, a processor, and a forwarder, were included for the Forest Owners’ Association. The transport of only one machine, a mini forwarder, was included for the private logging contractors, and no machine transport was included for individual forest owners because they did not use machines, only chainsaws. Handling fees associated with the log market were estimated using piling costs of 700 yen·m-3and 10% of timber prices (yen·m-3).

Table 1: Cost estimation

Estimating available amounts of timber and logging residues from profitable sub-compartments

Revenues were estimated using potential yields and log prices: 10,000 yen·m-3for Japanese cedar and 20,000 yen·m-3for Japanese cypress, and logging residues: 3,000 yen·m-3for the power generation plant and 1,000 yen·m-3for landing sales. For thinning operations, subsidies are paid in Japan. Subsidies were estimated using standard unit costs, areas, assessment coefficients, and the subsidy rate of the Tochigi Prefectural Government (2010a). Standard unit costs were determined by ages, thinningrates, and whether extractions occurred (Aruga et al. 2013b). The assessment coefficient and the subsidy rate were assumed to be 1.7 and 4/10, respectively. For the first thinning operations, we applied standard unit costs at a thinning rate of 25% and extraction. For the second thinning operations, we applied standard unit costs at a thinning rate of 35% and extraction.

For strip-road establishment on sub-compartments with subsidized thinning operations, the subsidy (Table 3) was also estimated using the standard unit costs, length, assessment coefficient, and subsidy rate (Tochigi Prefectural Government 2010a). The standard unit cost for strip-road establishment was determined by the average slope angle (°) and road width. After the incomes were estimated, the profitability was estimated and available amounts were projected as supply potentials from profitable sub-compartments.

Table 2: Direct operating expenses

Table 3: Subsidies for strip-road establishment (yen·m-1)

Results

The number and area of sub-compartments analyzed in this study, which included Japanese cedar and Japanese cypress more than 25 years old and owned by private individuals and local governments, were 7,268 and 2,999 ha, respectively (Table 4). These represented 89% of the total number of sub-compartments and 91% of the total area. The number of sub-compartments was 1,585 (21.8%), 4,301 (59.2%), and 1,382 (19.0%) for the first thinning, the second thinning, and the final felling operations, respectively. The area of the sub-compartments was 718.03 ha (23.9%), 1,746.93 ha (58.3%), and 533.60 ha (17.8%) for the first thinning, the second thinning, and the final felling operations, respectively. The largest number of sub-compartments was selected for second thinning operations because forests in this region were mainly between 45 and 55 years old.

Total supply potentials for timber and logging residues were 418,895 m3and 254,962 m3, respectively (Fig. 2, 3 and 4). The supply potentials for timber were 0 m3(0.0%), 139,398 m3(33.3%), and 279,497 m3(66.7%) for the first thinning, the second thinning, and final felling, respectively. The supply potentials for logging residues were 44,314 m3(17.4%), 145,088 m3(56.9%), and 65,561 m3(25.7%) for the first thinning, the second thinning, and final felling, respectively. The largest potential yields for logging residues were from the second thinning, but those for timber were from the final felling because of a higher timber rate.

The minimum harvest cost when selling logging residues at a plant was 820 yen·m-3and the average was 2,763 yen·m-3(Fig. 2). The minimum harvest cost when selling logging residues at landings was 128 yen·m-3and the average was 1,980 yen·m-3(Fig. 3). Because equations to estimate costs included forwarding and transport distances, slope angles, stem and log volumes, the costs of some sub-compartments that had longer forwarding and transportation distances, steeper terrain, and/or smaller volumes were higher.

First thinning operations had the highest costs because they included all of the estimated costs for harvesting logging residues and no timber extraction revenues. The minimum costs of the first thinning, 1,936 yen·m-3, were higher than the 867 yen·m-3of the second thinning, and the 820 yen·m-3of the final felling when logging residues were to be sold at the plant. This was also true for the average costs of 10,598 yen·m-3, 1,322 yen·m-3, and 1,435 yen·m-3for the first thinning, the second thinning, and the final felling, respectively. Similar results were found when logging residues were to be sold at landings. The minimum and average costs of the first thinning, 1,313 yen·m-3and 9,749 yen·m-3, respectively, were higher than those of the second thinning, 128 yen·m-3and 550 yen·m-3, respectively, and the final felling, 256 yen·m-3and 570 yen·m-3, respectively. These were similar to the results of Aruga et al. (2006b) andYamaguchi et al. (2010).

Table 4. The number and area of profitable sub-compartments

Fig. 2: The relationships between potential yields of logging residues and estimated average harvest costs when selling logging residues to the power generation plant

Fig. 3: The relationships between potential yields of logging residues and estimated average harvest costs when selling logging residues at landings

The minimum and average costs of timber were 4,200 yen·m-3and 10,756 yen·m-3, respectively (Fig. 4). The minimum and average costs of timber from the second thinning, 5,604 yen·m-3and 18,537 yen·m-3, respectively, were higher than those from the final felling, 4,200 yen·m-3and 7,389 yen·m-3, respectively. The average cost of timber from the second thinning, 18,537 yen·m-3, was close to the 17,988 yen·m-3result of Yamaguchi et al. (2010). The average cost of timber for the final felling, 7,389 yen·m-3, was between the 6,979 yen·m-3previously estimated by Aruga et al. (2006b) and the 10,776 yen·m-3estimated by Yamaguchi et al. (2010). Because the ratios of areas for Japanese cedar and cypress were 79% and 21%, respectively, their supply potentials were 384,806 m3and 33,089 m3, respectively (Fig. 4). The minimum cost of Japanese cypress, 6,703 yen·m-3, was higher than that of Japanese cedar, 4,200 yen·m-3, as was the average cost of 20,441 yen·m-3versus 9,957 yen·m-3, because stands of Japanese cypress were younger in this region and had lower potential yields than did stands of Japanese cedar.

On 2,833 ha, 94.5% of the area studied, private logging contractors had the lowest costs when selling logging residues at the plant. On only 165 ha, 5.5% of the area studied, did the Forest Owners’ Association have the lowest costs. When selling logging residues at landings, the area with the lowest costs occupied by the Forest Owners’ Association was 1,514 ha (50.5%), followed by private logging contractors at 1,474 ha (49.1%). The private logging contractors had lower costs in more areas than the Forest Owners’ Association when selling to the plant versus at landings because the transport expenses of the private logging contractors were lower than those of the Forest Owners’ Association when distances were under 60 km (Table 2). Individual forest owners only had the lowest costs in 0.88 ha (0.03%) and 11.17 ha(0.37%) of the area studied when selling logging residues at the plant and at landings, respectively, because the number of sub-compartments with extracting distances of less than 20 m was small, and the transportation expenses of individual forest owners were higher than those of private logging contractors and the Forest Owners’ Association when the transportation distance was more than 5 km.

Fig. 4: The relationships between potential yields of timber and estimated average harvest costs

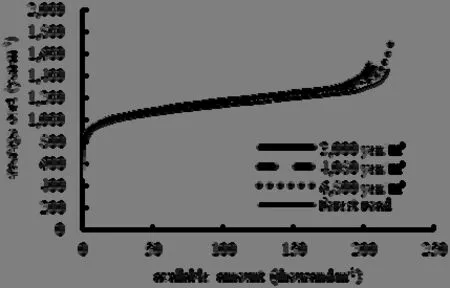

The number and area of profitable sub-compartments were 5,900 (81.2%) and 2,319 ha (77.3%), respectively (Fig. 4). The available amounts of timber and logging residues were 376,466 m3(89.9%) and 203,850 m3(80.0%), respectively. There were almost profitable sub-compartments when selling logging residues at the plant because the differences in logging residue prices between the plant and landings were higher than transportation expenses from these sub-compartments. The minimum and average costs of logging residues were 820 yen·m-3and 1,512 yen·m-3, respectively (Fig. 6).

The number and area of profitable sub-compartments were 1,308 (82.5%), 3,326 (77.3%) and 1,280 (92.6%) for the first thinning, the second thinning, and the final felling operations, respectively, and their areas were 470.99 ha (65.6%), 1,339.97 ha (76.7%), and 507.87 ha (95.2%), respectively. The ratios of the number and area of profitable sub-compartments to the number and area of analyzed sub-compartments for final felling were higher than those of first and second thinning because of larger timber volumes with higher prices (Table 4). The available amounts of timber and logging residues were 0 m3(0.0%) and 28,078 m3(63.4%), respectively, for the first thinning, 108,484 m3(77.8%) and 112,912 m3(77.8%), respectively, for the second thinning, and 267,982 m3(95.9%) and 62,860 m3(95.9%), respectively, for final felling.

Almost profitable sub-compartments were operated by private logging contractors when selling logging residues at the plant because the transportation expenses of private logging contractors were lower than those of the other systems. Conversely, only 0.01 ha (0.00%) of profitable sub-compartments were occupied by individual forest owners when selling logging residues at the plant and were only 1.84 ha (0.06%) when selling logging residues at landings because few sub-compartments had extracting distances of less than 20 m. When selling logging residues at landings, only sub-compartments occupied by individual forest owners were profitable because the transportation expenses of the individual forest owners were higher than the differences in logging residue prices between the plant and landings.

Fig. 5: Profitable sub-compartments

Fig. 6: The relationships between available amounts of logging residues and estimated average harvesting costs on profitable sub-compartments

Discussion

In addition to a logging residue price of 3,000 yen·m-3, a logging residue price of 4,080 yen·m-3, estimated based on 0.68 t·m-3and 6,000 yen·t-1, was examined in case additional subsidies (Japanese Forestry Investigation Committee 2011a) are introduced in Japan. Additionally, a price of 6,800 yen·m-3, estimated based on 0.68 t·m-3and 10,000 yen·t-1, was also examined in case a Feed-in Tariff (FIT) is also introduced (Japanese Forestry Inves-tigation Committee 2011b).

The number and area of profitable sub-compartments at the 4,080 yen·m-3logging residue price were 6,044 (83.2%) and 2,388 ha (79.6%), respectively (Table 5). The available amount of logging residues was 209,100 m3(82.0%). Almost profitable sub-compartments were for selling logging residues at the plant because the differences in logging residues prices between the plant and landings were higher than transportation expenses from almost all sub-compartments. The minimum and average costs of logging residues were 820 and 1,559 yen·m-3, respectively (Fig. 6). The number and area of profitable sub-compartments were 1,345 (84.9%), 3,404 (79.1%) and 1,295 (93.7%) for the first thinning, the second thinning, and final felling, respectively, and their areas were 499.40 ha (69.6%), 1,376.99 ha (78.8%) and 511.31 ha (95.8%), respectively.

The number and area of profitable sub-compartments at the 6,800 yen·m-3logging residue price were 6,292 (86.6%) and 2,518 ha (84.0%), respectively (Table 7). The available amount of logging residue was 219,230 m3(86.0%). All profitable sub-compartments were for selling logging residues at the plant. The minimum and average costs of logging residues were 820 and 1,701 yen·m-3, respectively (Fig. 6). The number and area of profitable sub-compartments were 1,406 (88.7%), 3,571 (83.0%) and 1,315 (95.2%) for the first thinning, the second thinning, and the final felling, respectively, and their areas were 557.27 ha (77.6%), 1,436.83 ha (82.3%), and 523.68 ha (98.1%), respectively. Higher logging residue prices increased the number and area of profitable sub-compartments as well as the available amount of logging residue.

If landings were not on existing roads in this study, the nearest grids from the landings on the existing roads were set as the new landings. Then, forwarding distances from the original landings to the new landings were taken into account using the detour ratio. However, operational expenses would be reduced when forest roads were established between the original landings and the new landings rather than strip roads because transportation expenses were lower than extracting expenses. The sub-compartments having individual forest owners as the optimum system would increase because the extracting distances of some sub-compartments would be reduced to under 20 m. Forest road establishment expenses, which should be paid for by public budgets, were not considered in our study.

Table 5: The number and area of profitable sub-compartments with different conditions

After forest road establishment, the number and area of profitable sub-compartments increased to 6,557 (90.2%) and 2,475 ha (82.6%), respectively (Table 5). Available amounts of logging residues also increased to 216,837 m3(85.1%). Almost profitable sub-compartments were for selling logging residues at the plant. The minimum and average costs of logging residues were 257 yen·m-3and 1,458 yen·m-3, respectively (Fig. 6). The number and area of profitable sub-compartments were 1,431 (90.3%), 3,761 (87.4%) and 1,365 (98.8%) for the first thinning, the second thinning, and the final felling, respectively, and their areas were 497.23 ha (69.3%), 1,447.57 ha (82.9%), and 530.63 ha (99.4%), respectively. The ratio of the number and area of profitable sub-compartments to the number and area of analyzed sub-compartments for final felling was almost 100%. Therefore,establishing forest road networks was still necessary to reduce harvest costs and to increase available amounts of logging residues in this region where the forest road network density is relatively high (27 m·ha-1).

After forest road establishment, sub-compartments with individual forest owners as the optimum system increased from 0.01 ha (0.00%) to 0.25 ha (0.01%) when selling logging residues at the plant and from 1.84 ha (0.06%) to 4.88 ha (0.16%) when selling logging residues at landings (Table 4 and Table 5). However, the increases were small. Suzuki et al. (2009) estimated the case of the zero labor costs for an individual forest owner who is a self-employed operator. The self-employed operators were assumed to obtain income from selling logging residues rather than extracting timber. Estimations in this study were based on labor costs to an individual forest owner of 1,300 yen·h-1, equal to the labor costs of a private logging contractor and the Forest Owners’ Association. After forest road establishment without the labor costs of an individual forest owner, the number and area of profitable sub-compartments increased slightly to 6,564 (90.3%) and 2,476 ha (82.6%), respectively (Table 5). Available amounts of logging residues also increased slightly to 216,884 m3(85.1%). However, sub-compartments with individual forest owners as the optimum system increased significantly from 0.25 ha (0.01%) to 121.87 ha (4.1%) when selling logging residues at the plant and from 4.88 ha (0.16%) to 14.14 ha (0.5%) when selling logging residues at landings (Table 5). Therefore, manual logging with a self-employed operator was economically viable for an individual forest owner.

Conclusion

Almost profitable sub-compartments were operated by private logging contractors when selling logging residues at the plant because the transportation expenses of private logging contractors were lower than those of the other systems. Conversely, profitable sub-compartments occupied by individual forest owners were rare because few sub-compartments had extracting distances of less than 20 m. However, sub-compartments with individual forest owners as the optimum system increased after forest road establishment, especially without the labor costs of an individual forest owner because of a reduction in the extracting distances for some sub-compartments. Furthermore, the number and area of profitable sub-compartments as well as available amounts of logging residues also increased after forest road establishment. Therefore, establishing forest road networks was one option to reduce harvesting costs and to increase available amounts of logging residues.

Another option would be to change extraction systems. The individual forest owner without machinery could play an important role in logging residue extraction on small, fragmented and scattered forests all over Japan as well as in other regions of the world. However, extraction distances of manual logging would be short and labor loads would be strong. Therefore, individual forest owners should introduce and use mini-forwarders (Nakahata et al. 2013) or farm tractors which were commonly used for various forest harvesting tasks in some European counties (Spinelli et al. 2012) to reduce labor loads and provide stable supply of logging residues to a woody biomass power generation plant.

Logging residue prices of 4,080 yen·m-3and 6,800 yen·m-3were examined in addition to the logging residue price of 3,000 yen·m-3. As a result, there were increases in the number and area of profitable sub-compartments as well as in available amounts of logging residues. Therefore, subsidies and a Feed-in Tariff were effective in increasing the availability of logging residues. The subsidy system in Japan changed in 2011, and the new system provides subsidies for thinning on sites larger than 5 ha with production volumes greater than 10 m3·ha-1. However, forest ownership in Japan is characterized by a large number of small, fragmented, and scattered forest owners, and many forest owners own less than 1 ha of forest area. To apply a new subsidy system, neighboring small sub-compartments were aggregated to more than 5-ha forestry operation sites. Aruga et al. (2013a) examined effects of aggregating forests, establishing forest road networks, and mechanization on operational efficiency and costs. Six ha was found to be an appropriate site area with minimum operation expenses in this region. Therefore, supply potentials and costs of the mechanized system should be estimated based on aggregated stands more than 5 ha instead of small sub-compartments less than 1 ha and compared with those of the small-scale systems.

Many studies estimated technically feasible and economically viable forest biomass resources as available amounts (Nord-Larsen et al. 2004, Aruga et al. 2006a, 2006b, 2011 and 2013b; Viana et al. 2010). However, socially acceptable forest management plans should be established to aggregate neighboring small sub-compartment of private forests. This would be important for extracting logging residues from such small, fragmented and scattered forests all over Japan as well as in some other regions of the world. Niyodo, a local community in the Kochi area of southwestern Japan, recently started a government-subsidized woody biomass utilization project. Although the expected largest source of logging residues was the large-scale system, the small-scale systems procurement was, in fact, the greatest (Suzuki et al. 2009). This project used community currency to encourage individual forest owners to extract logging residues and to revitalize local economies that have been depressed for the last 30 years according to the forest and forest products industries. Such a socially acceptable system for each community would also be an important establishment.

Environmental aspects like nutrient loss and species richness may be affected by extracting logging residues. Rørstad et al. (2010) incorporated environmental considerations at stand level and protection of key habitats in the model through a reduction of the net harvesting volume by 5% and have run a separate environmental scenario to exclude logging residue extractions from stands with a low site index. Many other studies have discussed energy balances and CO2emissions (Faaij et al. 1997; Forsberg 2000; Yoshioka et al 2005a; Aruga et al. 2011). Small-scale forestry operations with manual logging and small sized machines would be environmentally sound forestry systems with low logging impacts and high energy efficiencies as well as low CO2emissions.

Acknowledgment

We are grateful to the Tochigi Prefectural Government for providing the required data.

Agriculture, Forestry and Fisheries Research Council Secretariat. 1991. Biomass Conversion Project. Tokyo: Korin Publishing Co., Ltd.

Akay AE. 2005. Determining cost and productivity of using animals in forest harvesting operations. Applied Sciences Research, 1(2): 190−195.

Aruga K, Yoshioka T, Sakurai R. 2006a. Long-term feasibility of timber and forest biomass resources at an intermediate and mountainous area: balance of harvesting volumes using random search. Journal of Japan Forest Engineering Society, 21: 49–59 (in Japanese with English summary).

Aruga K, Tasaka T, Yoshioka T, Sakurai R, Kobayashi H. 2006b. Long-term feasibility of timber and forest biomass resources at an intermediate and mountainous area: (2). Examining the optimum scale of an energy plant. Journal of Japan Forest Engineering Society, 21: 185–192 (in Japanese with English summary).

Aruga K, Murakami A, Nakahata C, Yamaguchi R, Yoshioka T. 2011. Discussion on economic and energy balances of forest biomass utilization for small-scale power generation in Kanuma, Tochigi prefecture, Japan. Croatian Journal of Forest Engineering, 32: 571–586.

Aruga K, Hiyamizu G, Nakahata C, Saito M. 2013a. Effects of aggregating forests, establishing forest road networks, and mechanization on operational efficiency and costs in a mountainous region in Japan. Journal of Forestry Research, 24(4): 747–754.

Aruga K, Murakami A, Nakahata C, Yamaguchi R, Saito M, Kanetsuki K. 2013b. A model to estimate available timber and forest biomass and reforestation expenses in a mountainous region in Japan. Journal of Forestry Research, 24(2): 345–356.

Faaij A, van Ree R, Waldheim L, Olsson E, Oudhuis A, van Wijk A, Daey-Ouwens C, Turkenburg W. 1997. Gasification of biomass wastes and residues for electricity production. Biomass and Bioenergy, 12(6): 387−407.

Forestry Agency, The Ministry of Agriculture, Forestry and Fisheries of Japan. 2009. Annual report on trends I Forest and forestry. Fiscal Year 2008 (summary), Tokyo, p. 31.

Forsberg G. 2000. Biomass energy transport: Analysis of bioenergy transport chains using life cycle inventory method. Biomass and Bioenergy, 19(1): 17−30.

Iuchi M. 2004. Development of the support system for biomass energy business plans: the data base and evaluation models to simulate the collection cost. Socio-economic Research Center, Y03023, p. 26 (in Japanese with English summary).

Japanese Forestry Investigation Committee. 2011a. Tosa No Mori System in which thinned trees are traded with community currency for 6,000 yen/ton begins in Chizu Town, Tottori Prefecture and the system has been prevailing. Rinsei (Forest policy) News, 409: 14 (in Japanese).

Japanese Forestry Investigation Committee. 2011b. Wood chip for power generation paid attention to Feed-in Tariff (FIT), which would improve the unit price of logging residue to 20 yen/kWh: This would promote effective utilization of logging residues. Rinsei (Forest policy) News, 405: 7 (in Japanese).

Kamimura K, Kuboyama H, Yamamoto K. 2009. Estimation of spatial distribution on wood biomass supply potential for three prefectures in the northern Tohoku Region. Journal of the Japan Institute of Energy, 88(10): 877–883 (in Japanese with English Summary).

Kinoshita T, Inoue K, Iwao K, Kagemoto H, Yamagata Y. 2009. A spatial evaluation of forest biomass usage using GIS. Applied Energy, 86: 1–8.

Kinoshita T, Ohki T, Yamagata Y. 2010. Woody biomass supply potential for thermal power plants in Japan. Applied Energy, 87: 2923–2927.

Möller B, Nielsen PS. 2007. Analyzing transport costs of Danish forest wood chip resources by means of continuous cost surfaces. Biomass and Bioenergy, 31(5): 291–298.

Nakahata C, Aruga K, Takei Y, Yamaguchi R, Ito K, Murakami A, Saito M, Tasaka T, Kanetsuki K. 2011. Improvement on operational efficiencies and costs of extracting thinned woods using a processor and a forwarder in Nasunogahara area: (II) based on comparative analyses of current operations and mechanized operations. Bulletin of Utsunomiya University Forest, 47: 27–34 (in Japanese with English summary).

Nakahata C, Aruga K, Saito M, Kanetsuki K. 2013. Examining the optimum method to extract logging residues from samall-scale forestry in the Nasunogahara area, Tochigi Prefecture, Japan. Small-scale Forestry, DOI 10.1007/s11842-013-9252-4 (published online: 27 October 2013).

Nord-Larsen T, Talbot B. 2004. Assessment of forest-fuel resources in Denmark: Technical and economic availability. Biomass and Bioenergy, 27(2): 97−109.

Panichelli L, Gnansounou E. 2008. GIS-based approach for defining bioenergy facilities location: A case study in Northern Spain based on marginal delivery costs and resources competition between facilities. Biomass and Bioenergy, 32: 289−300.

Ranta T. 2005. Logging residues from regeneration fellings for biofuel production-a GIS-based availability analysis in Finland. Biomass and Bioenergy, 28: 171–182.

Rørstad P, Trømborg E, Bergseng E, Solberg B. 2010. Combining GIS and forest modelling in estimating regional supply of harvest residues in Norway. Silva Fennica, 44: 435−451.

Sawaguchi I. 1996. Studies on forest-road evaluation and forest-road standards in mountain forests: (I) characteristics of parameters for forest-road evaluation. Bulletin of the Forestry and Forest Products Research Institute, 372: 1–110 (in Japanese with English summary).

Spinelli R, Magagnotti N. 2012. Wood extraction with farm tractor and sulky: estimating productivity, cost and energy consumption. Small-scale Forestry, 11: 73−85.

Suzuki Y, Hatano Y, Murakami S, Okazawa T, Sagayama S, Gotou J, Ichihara T, Miyoshi K. 2009. Harvesting and transportation of logging residue logs accumulated along road side for woody biomass plant in a local community. In: 2009 Council on Forest Engineering (COFE) Conference Proceedings: “Environmentally Sound Forest Operations.” Lake Tahoe, June 15-18, 2009, pp. 1−8.

Tochigi Prefectural Government. 2010a. Forestation program standard unit cost table of Fiscal year 2010. Tochigi (in Japanese).

Viana H, Cohen WB, Lopes D, Aranha J. 2010. Assessment of forest biomass for use as energy. GIS-based analysis of geographical availability and locations of wood-fired power plants in Portugal. Applied Energy, 87: 2551−2560.

Yagi K, Nakata T. 2007. Economic analysis on small-scale forest biomass gasification considering regional resource distribution and technical char-acteristics. Journal of the Japan Institute of Energy, 86: 109–118 (in Japanese with English summary).

Yamamoto H, Nakata T, Yabe K. 2010. Design of biomass co-firing system considering resource distribution and transportation optimization. Journal of the Japan Institute of Energy, 89: 42–52 (in Japanese with English Summary).

Yamaguchi R, Aruga K, Murakami A, Saito M, Ito K. 2010. Development of the model to estimate the harvesting volumes and costs of logging residues considering economic balances of timber and logging residue harvesting in Sano city, Tochigi Prefecture. Journal of the Japan Institute of Energy, 89: 982–995 (in Japanese with English Summary).

Yoshioka T, Aruga K, Nitami T, Kobayashi H, Sakai H. 2005a. Energy and carbon dioxide (CO2) balance of logging residues as alternative energy resources: System analysis based on the method of a life cycle inventory (LCI) analysis. Journal of Forest Research, 10: 125−134.

Yoshioka T, Sakai H. 2005b. Amount and availability of forest biomass as an energy resource in a mountain region in Japan: a GIS-based analysis. Croatian Journal of Forest Engineering, 26: 59–70.

Zambelli P, Lora C, Spinelli R, Tattoni C, Vitti A, Zatelli P, Ciolli MA. 2012. GIS decision support system for regional forest management to assess biomass availability for renewable energy production. Environmental Modelling and Software, 38: 203−213.

DOI 10.1007/s11676-014-0482-x

The online version is available at http://www.springerlink.com

Chikara Nakahata, Ryo Uemura, Kazuhiro Aruga ()

Department of Forest Science, Faculty of Agriculture, Utsunomiya University, 350 Mine, Utsunomiya 321-8505, Japan.

Tel: +81-28-649-5537, Fax: +81-28-649-5545

E-mail: aruga@cc.utsunomiya-u.ac.jp

Masashi Saito

Frontier Agriscience and Technology Center, Faculty of Agriculture, Shinshu University, Nagano 399-4598, Japan

Kanae Kanetsuki

Nasunogahara Land Improvement Districts, Tochigi 329-2807, Japan

Corresponding editor: Yu Lei

杂志排行

Journal of Forestry Research的其它文章

- Growth and yield of two grain crops on sites former covered with eucalypt plantations in Koga Watershed, northwestern Ethiopia

- Carbon stock in Korean larch plantations along a chronosequence in the Lesser Khingan Mountains, China

- Biomass accumulation and nutrient uptake of 16 riparian woody plant species in Northeast China

- Cloning and sequence analysis of nine novel MYB genes in Taxodiaceae plants

- Genetic and morphological variation in natural teak (Tectona grandis) populations of the Western Ghats in Southern India

- Improved salt tolerance of Populus davidiana × P. bolleana overexpressed LEA from Tamarix androssowii