Numerical Study on Mechanical Properties of Steel Fiber Reinforced Concrete by Statistical Second-order Two-scale Method

2014-04-14ZhangNieandWu

Y.Zhang,Y.F.Nie and Y.T.Wu

1 Introduction

With the rapid development of material science and technology,steel fiber reinforced concrete(SFRC)is widely used in constructions of high-rise buildings or critical protective structures due to its outstanding mechanical performance over conventional plain concrete.Since the steel fibers were first proposed as dispersed reinforcement for concrete,a certain number of experimental researches have been carried out to investigate the mechanical properties of fiber reinforced concrete.Song et al.[Song and Hwang(2004)]investigated the strength improving potentials of high-strength steel fiber reinforced concrete with steel fibers of volume fractions varying from 0.5%to 2.0%and concluded that the compressive strength increased with the fiber content.Nataraja et al.[Nataraja,Dhang and Gupta(1999)]carried out an experimental work to study the stress-strain behavior of steel fiber reinforced concrete with compressive strength ranging from 30 to 50 MPa.The toughness property of SFRC was also investigated in another experimental study carried out by Banthia et al.[Banthia and Sappakittipakorn(2007)].The advantage of laboratory test is that it lies on the direct access to material information at the relevant scale for analysis of the structure.On the other hand,it has the complex experimental programs and costs a lot of time.The numerical simulation provides a powerful tool to handing this kind of problem.

Generally SFRC is considered as a typical example of randomly heterogeneous composite material in the view of material structure.So far,some numerical methods to evaluate the mechanical properties of randomly heterogeneous composite materials have been developed,such as the Hashin-Shtrikman bounds[Hashin and Shtrikman(1963)],the self-consistent method[Hill(1965);Budiansky(1965)],the Eshelby’s equivalent inclusion method[Eshebly(1959)],and the Mori-Tanaka homogenization method[Mori and Tanaka(1973);Pasa-Dutra,Maghous,Campos-Filho and Pacheco(2010)].Rencently,Dong et al.have developed a novel numerical tool"Computational Grains",which enables a direct numerical simulation of a large number of heterogeneities of materials and structures,without using brutal force FEM,see[Dong,Gamal and Atluri(2013);Dong and Atluri(2012a);Dong and Atluri(2012b)].Although these methods can be applied to predict the effective elastic properties of SFRC,the determination of strength properties of fiber reinforced concrete remains an important task.This is because that few of these methods can be employed to calculate the local strain and stress fields.So the strength properties can’t be evaluated by these methods.Moreover,under constant mechanical load,the concrete material has a creep phenomenon which is usually described in the viscoelastic model.So evaluation of the viscoelastic properties of concrete material is a meaningful work.In addition,few of the above mentioned methods can take into account all the microstructure characteristics of SFRC,especially for the random distribution characteristic of steel fibers.

In this paper,a statistical second-order two-scale(SSOTS)analysis method is introduced to predict the elastic,strength and viscoelastic properties of SFRC.The SSOTS method[Li and Cui(2005);Han,Cui and Yu(2008);Yang,Cui,Nie and Ma(2012);Yang,Cui,Nie,Wu,Yang and Wu(2013)]is on the basis of asymptotic expansion homogenization and Monte Carlo method and it can take into account all the microstructure information of SFRC.Above all,compared with the traditional homogenization method,the SSOTS method can effectively catch the local stain and stress information in the structures through the two-order displacement solution.Naturally,the strength limit parameters can be evaluated by introducing the appropriate strength criterion.According to the correspondence principle,the viscoelastic properties can also be evaluated by this method.

This paper is organized as follows.In section 2,the microstructure of SFRC is represented by setting up a statistic screen point wise and the formulation of SSOTS method is derived.Section 3 deals with the evaluation of the mechanical properties of SFRC.Finally,some numerical results are shown to verify the feasibility and effectiveness of this numerical method for SFRC.The influence of distribution of steel fiber to mechanical properties for SFRC is also displayed by calculating the mechanical parameters in three typical cases.

2 Statistical second-order two-scale method

2.1Microstructure Representation of SFRC

Steel fiber reinforced concrete is a typical randomly heterogeneous material.Suppose that it is made from the concrete matrix and steel fiber reinforcement with random distribution.Each steel fiber can be regarded as an ellipsoid specially.An ellipsoid in 3D space can be denoted by 9 random parameters,including the coordinates of the center(x1,x2,x3),the sizes of the long,middle and short axis(a,b,c)and three Euler angles(θ1,θ2,θ3)of the rotations.Then the microstructure of the steel fiber reinforced concrete can be represented as follow:

1)At an arbitrary pointxin the macroscopic structure Ω,there exists a cell with sizeε,satisfyinga≪ε≪L,whereLis the size of macroscopic structure Ω.And all the ellipsoids in the cell subject to a specific probability distribution modelP.2)Let the random vectoru=(x1,x2,x3,a,b,c,θ1,θ2,θ3).Suppose that the cellεYcontainsIellipsoids,whereYdenotes the normalized cell.Then we defineω=(u1,u2,···,uI−1,uI).Obviously,it is a sample of the probability distribution modelP.

Then for a sampleω,the mechanical parameters of SFRC can be defined as follow:

Figure 1:Structure representation of the steel fiber reinforced concrete

2.2SSOTS formulation

According to the microstructure representation in Section 2.1,for the structure Ω,the boundary value problem ofits mechanicalbehaviorcan be expressed asfollows:

where u0(x)reflects the macroscopic behaviors of the structure,and is called as the homogenization solution;Nα1(y,ωs)andNα1α2(y,ωs)involve the microstructural information,and are matrix-valued functions.And u0(x),Nα1(y,ωs)andNα1α2(y,ωs)are determined in the following ways:

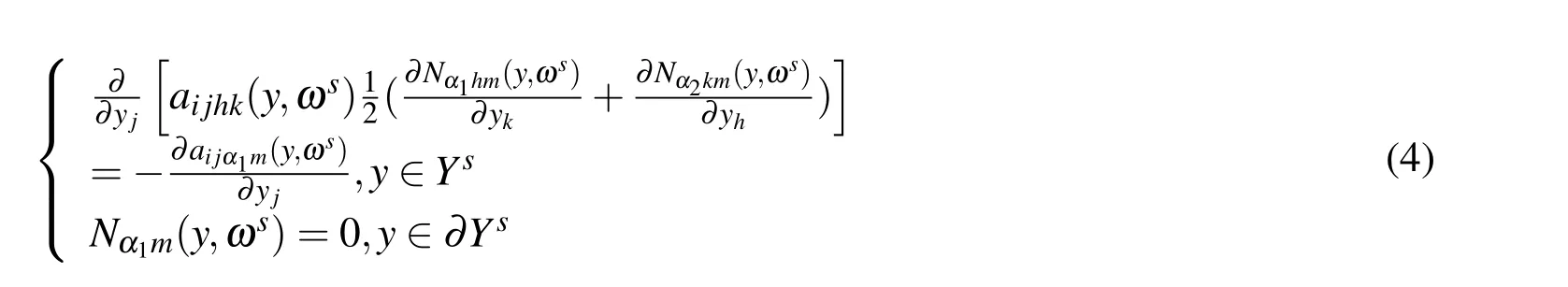

1)Forl=1 and the sampleωs,Nα1m(y,ωs)(α1,m=1,2,3)are solutions of the following problem:

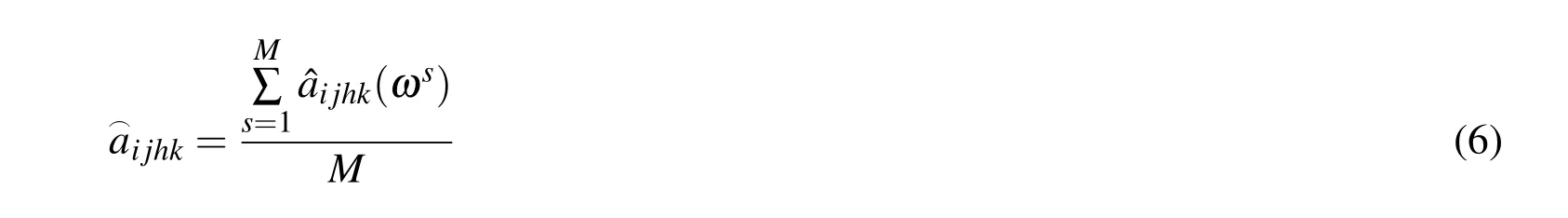

2)The homogenized parametersˆaijhk(ωs)are calculated by the following formula

According to the Kolmogorov’s strong law of large numbers,we defined the expected homogenized parameters^aijhkas follow

whereMis the number of samples.

3)u0(x)isthe homogenized displacementvectorforthe structure and isthe solution of the following problem

4)Forl=2,Nα1α2m(y,ωs)(α1,α2,m=1,2,3)are solutions of the following problem

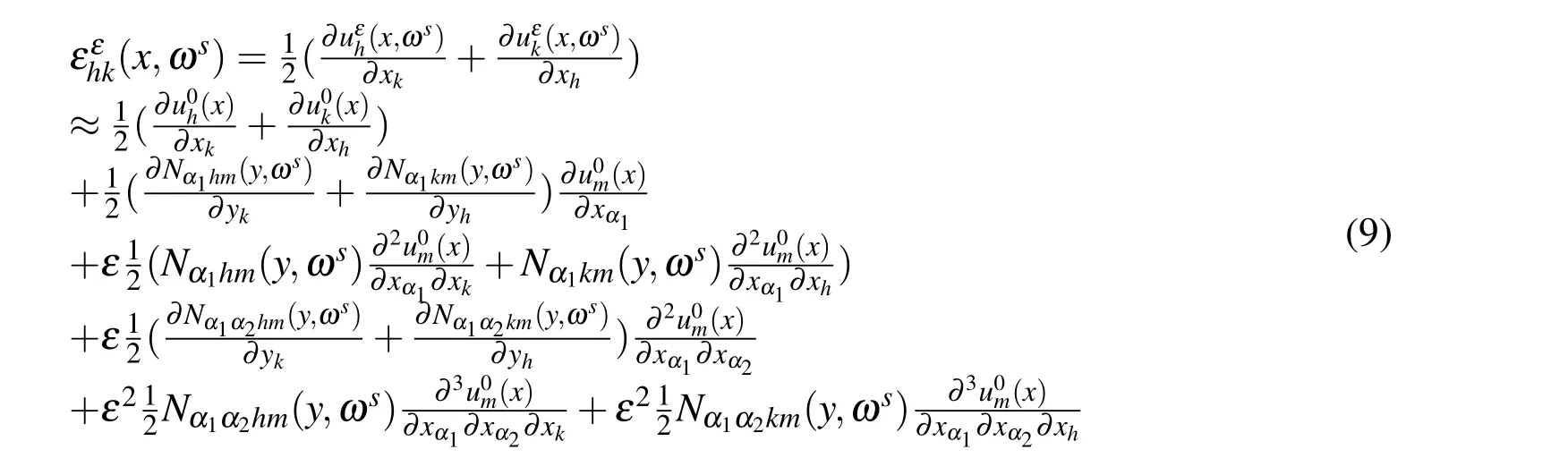

As the undetermined functions in(3)have been defined,the strain field in the whole structure can be approximately expressed as

And by the generalized Hooke’s law,the expression of the stress field can be obtained

Then the stresses at any pointxare naturally used to evaluate the strength properties of SFRC.

3 Macroscopic mechanical properties of steel fiber reinforced concrete

This section devotes to deal with the evaluation of the elastic,strength and viscoelastic properties of SFRC.As emphasized by Eq.(5)and(6),the homogenized elastic coefficients can be computed in the same way as the traditional homogenization method.And the evaluation of strength and viscoelastic properties is modeled as follow.

3.1Strength limit of SFRC

To evaluate the strength limit properties,selecting a suitable strength criterion is very important.In this paper,the strength capacities of concrete matrix are assumed to be described by a Drucker-Prager[Pasa-Dutra,Maghous and Campos-Filho(2013)].The Drucker-Prager criterion can be expressed in the following form:

whereσrepresents the stress field which can be obtained by the Eq.(10),and‖s‖=(s:s)1/2 is the norm of the deviatoric stress tensor;σmdenotes the strength limit of the material;αmis a scalar ranging between 0 and 1.When the scalarσmequals 0,the Drucker-Prager criterion will degenerate to the Von Misses criterion in particular.The later criterion is applied to the steel fibers,when evaluating the strength parameters of the SFRC.In this paper,we generate a set of samplesωsto obtain their strength limit.Naturally,by using Kolmogorov’s strong law of large numbers,the expected strength limit of the SFRC can be expressed as follow

whereMis the number of samples.

3.2Viscoelastic behavior of SFRC

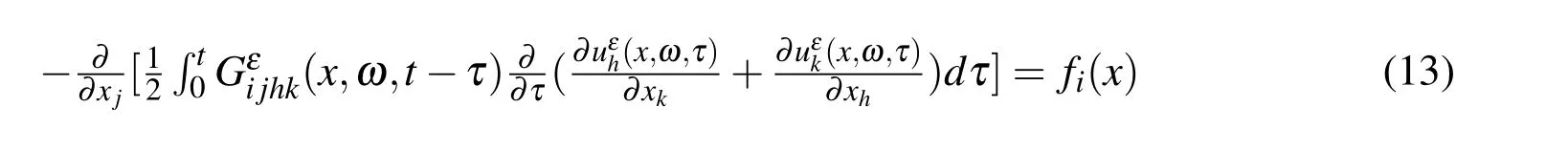

Under constant mechanical loading,the concrete specimen exhibits the creep phenomenon,which can be described as a non-ageing viscoelastic model.In nonageing liner viscoelasticity,the stress tensor is related to the strain history,and has the following representation:

whereGεijhk(x,ω,t)refers to fourth-order relaxation modulus tensor.Recalling that the Laplace transformation is defined as

so that the viscoelastic relationship writes in terms of Laplace transformation

which expresses an elastic type relationship formally in the Laplace domain space.The simple and commonly used model for linear viscoelastic solid consists in the association in series of a spring(stiffnessE1)and a Kelvin element with spring stiffnessE2and dashpot viscosityη.The relaxation modulusG(t)can be expressed as

4 Numerical examples

In this section,some numerical examples are given to show that the present algorithm is feasible and effective in predicting the mechanical properties of SFRC.

Ashour et al.and Thomas et al.have tested the elastic and strength properties of the steelfiberreinforced concrete by mechanicsexperimentrespectively[Ashour,Wafa and Kamal(2000);Thomas and Ramaswamy(2007)].The steel fibers used in their experiments have the same mechanical properties:Young’s modulus 210000Mpa,Poisson’s ratio 0.30.The values of mechanical properties of the concrete as provided in their experiments are list in Tab.1.The numerical results obtained by the SSOTS method are shown in follows,and the results are based on the statistics of 50 samples.At first,the results of homogenized Young’s modulus estimated by SSOTS are obtained.Fig.2 and Fig.3 respectively display the estimates of Y-oung’s modulus of SFRC,together with the experimental data.As it appears from the follow figures,the numerical results of SSOTS method agree with the experimental data and the Young’s modulus increases as the volume fraction of steel fiber increasing.Next,the numerical results of the strength properties of SFRC predicted by the SSOTS method are shown.In engineering,the compressive strength and tensile strength ofconcrete are commonly concerned.Unlike othermaterials,the compressive strength of concrete is far larger than its tensile strength.The two strength limit parameters of SFRC are evaluated by the above SSOTS method and the comparison of numerical results and experimental results is shown in Tab.2.The numerical results have the same tendency with the experimental data and the discrepancy of them remains lower than 10%.

Table 1:Mechanical properties of concrete in experiments[Thomas and Ramaswamy(2007);Ashour,Wafa and Kamal(2000)]

Figure 2:Young’s modulus predicted by SSOTS method and experiment data[Thomas and Ramaswamy(2007)]]

Figure 3:Young’s modulus predicted by SSOTS method and experiment data[Ashour,Wafa and Kamal(2000)]

Table 2:Numerical and experimental results for strength properties of SFRC[Ashour,Wafa and Kamal(2000);Thomas and Ramaswamy(2007)]

Figure 4:Creep strain predicted by SSOTS method and experimentally measured at a stress/strength ratio 0.3[Mangat and Azari(1985)]

Figure 5:Creep function predicted by SSOTS method and experimentally measured at a stress/strength ratio 0.25[Chern and Young(1989)]

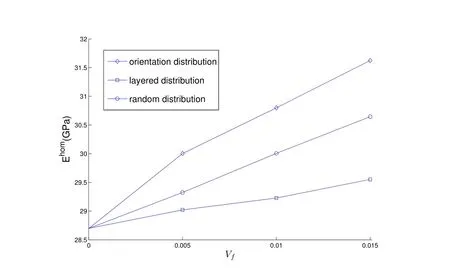

4.1Discussion on the distribution of steel fiber

In order to investigate the influence of distribution of steel fibers on the mechanical properties of SFRC,three typical distribution models of fibers are considered,as shown in Fig.6.We calculate the mechanical properties of steel fiber reinforced concrete with these three different distribution models respectively.Fig.7,Fig.8 and Fig.9 show the numerical results predicted by SSOTS method.The results show thatthe distribution offibers hasa certain impacton the mechanicalproperties of steel fiber reinforced concrete,especially when the steel fibers hold in a high volume fraction relatively.Due to the heterogeneous distribution of steel fiber,the anisotropy of SFRC is emerged and the enhancement effect is more obvious in the specific direction when the steel fiber has an orientation distribution.These results may provide a reference for manufacturing the steel fiber reinforced concrete.

Figure 6:Microstructure representation of fiber distribution:(a)random distribution,(b)orientation distribution,(c)layered distribution

Figure 7:Influence of fiber distribution on the homogenized Young’s modulus

5 Conclusions

In this paper,a SSOTS method is introduced to predict the macroscopic mechanical properties of steel fiber reinforced concrete.The microstructure of SFRC is first described by the statistical random model.Then the SSOTS formulation is derived to estimate the elastic properties analytically.This model successfully predicts the values of the Young’s modulus of SFRC,as emphasized by comparison of the numericalresults in the presentwork and the experimentdata.Through the twoorder displacement solution,the expression of the stress field is obtained.Then the strength limit parameters are evaluated by introducing the Drucker-Prager strength criterion.In addition,the viscoelastic behavior of SFRC is also investigated by the presented method and the correspondence principle.The numerical results of strength and viscoelastic properties are also compared with the available experiment data.Moreover,the influence of distribution of steel fibers on the mechanical properties is investigated.The results show that the SSOTS method is feasible and effective for predicting the mechanical properties of SFRC.

Figure 8:Influence of fiber distribution on the compressive strength

Figure 9:Influence of fiber distribution on the creep strain of SFRC

Acknowledgement:The authors would like to acknowledge the National Natural Science Foundation of China(No.11071196 and 90916027)for financial support to carry out this study.

Ashour,S.A.;Wafa,F.F.;Kamal,M.I.(2000): Effect of the concrete compressive strength and tensile reinforcement ratio on the flexural behavior of fibrous concrete beams.Engineering Structures,vol.22,no.9,pp.1145–1158.

Banthia,N.;Sappakittipakorn,M.(2007): Toughness enhancement in steel fiber reinforced through fiber hybridization.Cement and Concrete Composites,vol.37,no.9,pp.1366–1372.

Budiansky,B.(1965): On the elastic moduli of some heterogeneous materials.Journal of the Mechanics and Physics of Solids,vol.13,pp.223–227.

Chern,J.C.;Young,C.H.(1989): Compressive creep and shrinkage of steel fibre reinforced concrete.International Journal of Cement Composites and Lightweight Concrete,vol.11,no.4,pp.205–214.

Dong,L.T.;Atluri,S.N.(2012):Development of 3D Trefftz Voronoi Cells with Ellipsoidal Voids&/or Elastic/Rigid Inclusions for Micromechanical Modeling of Heterogeneous Materials.CMC–Computers,Materials&Continua,vol.30,no.1,pp.39–81.

Dong,L.T.;Atluri,S.N.(2012): T-Trefftz Voronoi cell finite elements with elastic/rigid inclusions or voids for micromechanical analysis of composite and porous materials.CMES–Computer Modeling in Engineering&Sciences,vol.83,no.2,pp.183–219.

Dong,L.T.;Gamal,S.H.;Atluri,S.N.(2013): Stochastic Macro Material Properties,Through Direct Stochastic Modeling of Heterogeneous Microstructures with Randomness of Constituent Properties and Topologies,by Using Trefftz Computational Grains(TCG).CMC–Computers,Materials&Continua,vol.37,no.1,pp.1–21.

Eshebly,J.D.(1959):The elastic field outside an ellipsoidal inclusion.Proceedings of the Royal Society of London.Series A,Mathematical and Physical Sciences,vol.252,no.1271,pp.561–569.

Han,F.;Cui,J.Z.;Yu,Y.(2008):The statistical two-order and two-scale method for predicting the mechanics parameters of core-shell particle-filled polymer composites.Interaction and Multi-scale Mechanics:An International Journal,vol.1,no.2,pp.231–250.

Hashin,Z.;Shtrikman,S.(1963): A variational approach to the theory of the elastic behavior of multiphase materials.Journal of the Mechanics and Physics of Solids,vol.11,no.2,pp.127–140.

Hill,R.(1965):A self-consistent mechanics of composite materials.Journal of the Mechanics and Physics of Solids,vol.13,pp.213–222.

Li,Y.Y.;Cui,J.Z.(2005):The multi-scale computational method for mechanics parameters of the materials with random distribution of multi-scale grains.Composites Science and Technology,vol.65,no.9,pp.1447–1458.

Mangat,P.S.;Azari,M.M.(1985): A theory for the creep of steel fibre reinforced cement matrices under compression.Journal of Materials Science,vol.20,no.3,pp.1119–1133.

Mori,T.;Tanaka,K.(1973):Average stress in matrix and average elastic energy of materials with misfitting inclusion.Acta Metallurgica,vol.21,no.5,pp.571–574.

Nataraja,M.C.;Dhang,N.;Gupta,A.P.(1999):Stress-strain curves for steelfiber reinforced concrete under compression.Cement and Concrete Composites,vol.21,no.5,pp.383–390.

Pasa-Dutra,V.F.;Maghous,S.;Campos-Filho,A.(2013): A homogenization approach to macroscopic strength criterion of steel fiber reinforced concrete.Cement and Concrete Research,vol.44,pp.34–45.

Pasa-Dutra,V.F.;Maghous,S.;Campos-Filho,A.;Pacheco,A.R.(2010):A micromechanical approach to elastic and viscoelastic properties of fiber reinforced concrete.Cement and Concrete Research,vol.40,no.3,pp.460–472.

Song,P.S.;Hwang,S.(2004): Mechanical properties of high-strength steel fiber-reinforced concrete.Construction and Building Materials,vol.18,no.9,pp.669–673.

Thomas,J.;Ramaswamy,A.(2007): Mechanical properties of steel fiberreinforced concrete.Journal of Materials in Civil Engineering,vol.19,no.5,pp.385–392.

Yang,Z.H.;Cui,J.Z.;Nie,Y.F.;Wu,Y.T.;Yang,B.;Wu,B.(2013):Microstructural Modeling and Second-Order Two-Scale Computation for Mechanical Properties of 3D 4-Directional Braided Composites.CMC–Computers,Materials&Continua,vol.38,no.3,pp.175–194.

Yang,Z.Q.;Cui,J.Z.;Nie,Y.F.;Ma,Q.(2012):The Second-Order Two-Scale Method for Heat Transfer Performances of Periodic Porous Materials with Interior Surface Radiation.CMES–Computer Modeling in Engineering&Sciences,vol.88,no.5,pp.419–442.

Yu,Y.;Cui,J.Z.;Han,F.(2008):An effective computer generation method for the composites with random distribution of large numbers of heterogeneous grains.Composites Science and Technology,vol.68,no.12,pp.2543–2550.

杂志排行

Computers Materials&Continua的其它文章

- Optimization of Johnson-Cook Constitutive Model for Lead-free Solder Using Genetic Algorithm and Finite Element Simulations

- Effect of Gravitational Field and Temperature Dependent Properties on Two-Temperature Thermoelastic Medium with Voids under G-N Theory

- Anti-plane Circular Nano-inclusion Problem with Electric Field Gradient and Strain Gradient Effects