Application of Improved Hybrid Interface Substructural Component Modal Synthesis Method in Vibration Characteristics of Mistuned Blisk

2014-02-07BAIBinBAIGuangchenandLIChao

BAI Bin*,BAI Guangchen,and LI Chao

School of Energy and Power Engineering,Beihang University,Beijing 100191,China

1 Introduction1

Substructural CMS is a very effective method for solving the mechanical structures,the DOF can be reduced obviously by this method which has already formed systemic theory.It includes the free ISCMSM,the fixed ISCMSM and the HISCMSM.The basic idea is a kind of“pieces”analytical method.The whole structure is divided into many relatively simple substructures.The vibration characteristics of each substructure are obtained by FEMM,analytic method and experimental method and so on.Then these substructures are assemblied by the coordinating conditions.For instance,SHANMUGAM,et al[1],developed a fixed-free ISCMSM for carrying out rotordynamic analysis with the gyroscopic effects being considered.This method was able to predict the whirl frequencies and the unbalance response accurately.The proposed technique had been validated for two systems:1)a cantilever rotor with a heavy disc at its free end,and 2)a typical twin-spool aeroengine rotor-bearing configuration.CUI,et al[2],built the parametric solid models based on the combined structure model which was established by using dynamic substructural methed.She introduced virtual materials and by modifying the properties of them to make the FEM’s modes results come consistent with the experimental ones and this method could settle the foundation of the further research on the engine's dynamic simulation.RIVAS-GUERRA,et al[3],studied the maximum amplification of the steady state forced response of bladed disks due to mistuning.He proposed an optimization strategy and considered the worst case disk.The mistuned properties were sought to maximize the response of a specific blade.Also he recovered the upper bound of Whitehead for all engine orders and number of blades and a simple yet reliable approximation of the resonant mode shapes and natural frequencies of the worst disk.MARTEL,et al[4],did the most similar work to RIVAS-GUERRA.BAI,et al[5],proposed the mechanical dynamic assembly reliability(MDAR)theory and a distributed collaborative response surface method(DCRSM)to improve the accuracy and efficiency of dynamic assembly relationship reliability analysis considering the randomness from a probabilistic perspective.BECK,et al[6],did the most similar work to BAI.JUNG,et al[7],developed a novel methodology to predict the nonlinear forced response of mistuned turbine engine rotors with a cracked blade and the approach provided significant computational cost savings while ensuring good accuracy relative to full-order finite element analyses.Furthermore,the effects of the cracked blade on the mistuned system were investigated.BLAHD,et al[8],established reduced-order modeling(ROM)to predict dynamic response for a mistuned industrial turbomachinery rotor.SUN,et al[9],provided the modal truncation augmentation(MTA)method to simulate the blade loss of an aircraft gas turbine rotor mounted on rolling element bearings with squeeze film dampers.This method could predict the maximum contact load and the corresponding stress on an elliptical contact area between the races and balls during the blade loss simulations.

Compared with the overall structure FEMM,the computational efficiency of this method is increased significantly under the condition of meeting the computational accuracy.So many people had done a lot of investigations,such as,FEINER,et al[10–11],investigated the vibratory response of the system based on a mistuned ROM called the fundamental mistuning model(FMM)and it was applicable to isolated families of modes.But this method was particularly suited to integrally bladed rotors and the blades cannot be removed for individual measurements.BHARTIYA,et al[12],developed modified modal domain analysis(MMDA)in the ROM of a bladed rotor with geometric mistuning which showed deviations in mass and stiffness matrices by Taylor series expansions and the orthogonal decomposition variables represented geometric variations of blades,but it could not calculate the large and complex model.MCGEE III,et al[13],established a three-dimensional(3D)elasticity spectral-based energy model of high functional way engine fan.The vibration response and flutter control of cold-stream,high-bypass ratio were studied and the aeroengine fans were regarded as wide-chord laminated composite blades,but the mistuning of blades were not considered.LIU,et al[14],proposed an improved technique the CMS for nonclassically damped systems with the second-order approximation,but the technique based on free-interface vibration modes.Although the influence of the high order-frequency modals truncated were considered,the method was rather tedious.LAXALDE,et al[15],researched multistage cyclic structures and each stage was modeled by its elementary sector and the interstage coupling was achieved through a cyclic recombination of the interface DOF.Also he presented the forced response application in which synchronous engine order type excitations were considered,but each stage’s sector was handled directly by FEM and it spent a lot of time and the efficiency was very low.The substructural CMS method was utilized by YANG,et al[16]and MAO,et al[17]in the response analysis,only the FRF was applied,the matrix dimension was reduced,the computational efficiency was increased,but the computational error was large.D’SOUZA,et al[18],utilized ROM to analyze the nonlinear vibration of multistage bladed-disk systems with small blade-to-blade mistuning and a cracked blade based on the cyclic symmetric analysis and CMS.SUN,et al[19],proposed a FEM of the flexible dual rotors,considering the nonlinear of the rolling bearing and the squeeze film damper,and simulated the transient responses of mistuned blades.MARINESCU,et al[20],presented a combined ROM method,the crack of the blades was considered and the displacements and deformations of the crack were modeled in the relative coordinates and the effects of the mistuning were captured by component mode mistuning,but the application range of it was small.Based on the CMS,BLADH,et al[21],used the ROM to analyze the probability of forced response,then a secondary modal analysis reduction technique(SMART)was proposed and the computational efficiency was further improved,but computational accuracy was seriously declined.LIM,et al[22],predicted the blade stress levels from ROM of mistuned blisk.In his work,three indicators calculated directly from ROM were proposed as a way to estimate blade stress levels in a straightforward,systematic,and inexpensive manner.But the accuracy and the efficiency of the above research are both not high.

With the continuous development of the engineering and the technology,more and more large and complex mechanical structures are appearing,such as,high-rise buildings,aerospace system engineerings,marine oil platforms and so on which contain nonlinear constitutive relationship,random excitation,complex boundary conditions and other factors.The classical SCMSM can not solve the problem.Even if it can be used,a lot of time will be spent and the efficiency will be extremely low.

Based on the deficiencies of above analysis,an improved HISCMSM is proposed.The ROMs of the substructures are assembled via the double coordinating conditions of the displacement and the force,the dynamic characteristics of the whole structure can be acquired.The DOF is far less than the overall structure FEMM,meanwhile,substructures can be parallel calculated and the computational efficiency is higher than the classical HISCMSM.Its precision is not inferior to the overall structure FEM.It is an effective method to analyze the large and complex system which is convenient to improve and calibrate the model.Only the changed substructure needs to be analyzed once again while the other substructures keep the same and they can be directly called from the original super unit matrix documents.It is better than only using the free ISCMSM or the fixed ISCMSM.The improved HISCMSM adopts different interfaces according to the features of each substructure.It can calculate super big model and change the sub-systematic project expediently without designing the whole structure.The computational efficiency is greatly

increased on the premise of the computational precision.

2 Basic Theory Analysis of the Substructure

The blisk is complicated mechanical structure,which needs to be dispersed tens of thousands of DOF if the overall FEMM is used and it requires a lot of time,the requirement of the computer’s configuration is very high.In no influence its precision conditions,it is divided into the bladed and the disk substructures in order to improve the computational efficiency.However,the HISCMSM is mainly used in the relatively independent large and complex structure system especially for the blade-disk coupling system.The disk can be isolated as the main body part and blades can be isolated as the branch of parts.

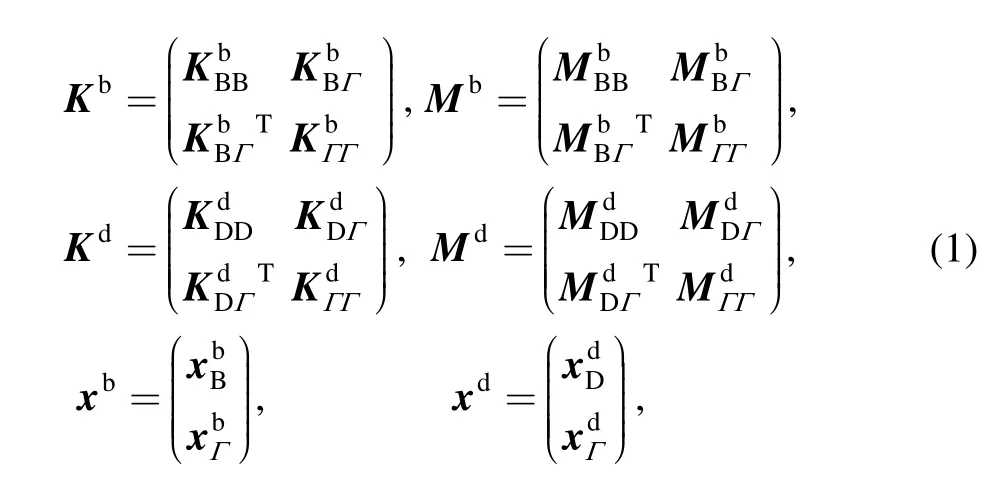

The stiffness matrix,the mass matrix,the displacement of the bladed and the disk substructures are respectively given as Kb,Mb,Kd,Md,xb,xd:

where B—Internal DOF of the blade,

Γ—Interface DOF of the blades and disk,

D—Internal DOF of the disk.

2.1 Fixed interface substructural bladed ROM

According to the characteristics of the blisk,blades were investigated by the fixed ISCMSM as the branch parts when the HISCMSM was adopted.The equation of motion is given by

which can be rewritten as

The characteristic equation of the blade is given by

The main modal matrix is expressed as

The constraint modal matrix is given by

The modal matrix of the blade is described as

The displacement of the blade can be expressed by

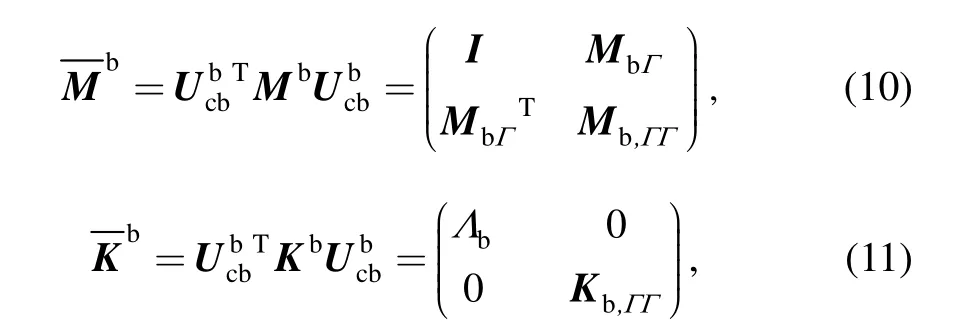

The stiffness matrix and the mass matrix of the bladed ROM are respectively given by

where

When the coupling between blades hardly existed,they can be extended to corresponding N matrixes,which are respectively written as

2.2 Free interface substructural ROM of the disk

According to the circumferential symmetrical theory,the disk which belonged to a complex circular structure was investigated by the free ISCMSM as the main body.The kinematic equation is given by

The characteristic equation of the disk is described as

The main modal matrix is expressed by

The constraint modal matrix is given by

The displacement of the disk can be expressed as

The modal matrix of the disk is described as

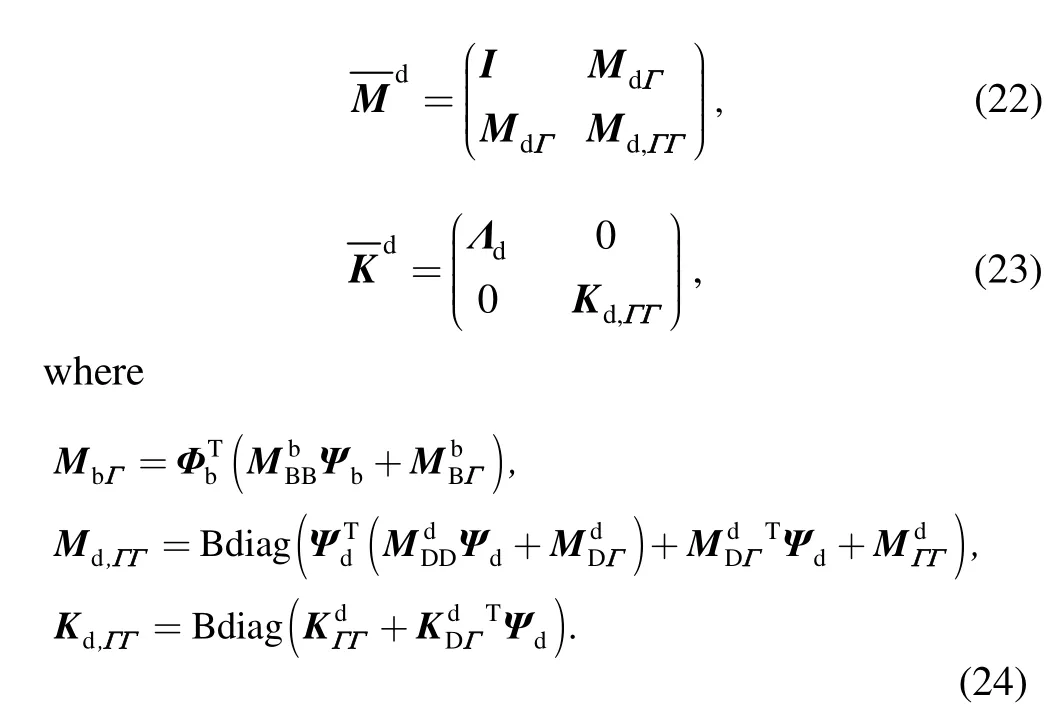

The stiffness matrix and the mass matrix of the disk ROM are respectively described as

2.3 Comprehensive hybrid interface blisk ROM

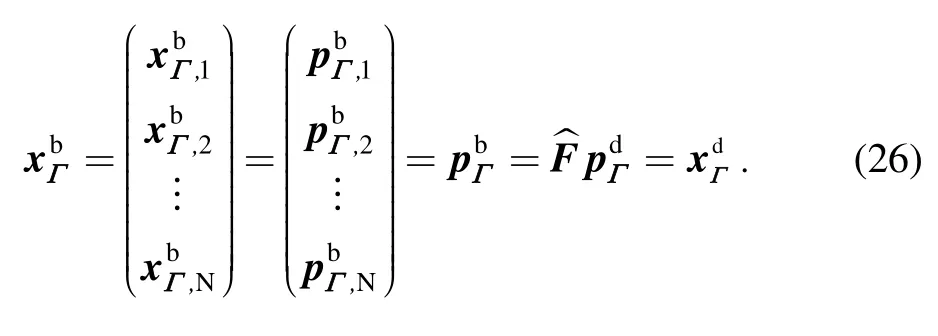

The coordinating condition between the substructures was a key factor which affected their accuracy.The actual connection ways between substructures were varied,such as,bolt connection,welding,riveting,etc.Generally,the connection could be handled for rigid connection,flexible connection or a simple displacement continuous condition.The double coordinating conditions of the displacement and the force were accepted in the process of synthesis,that is

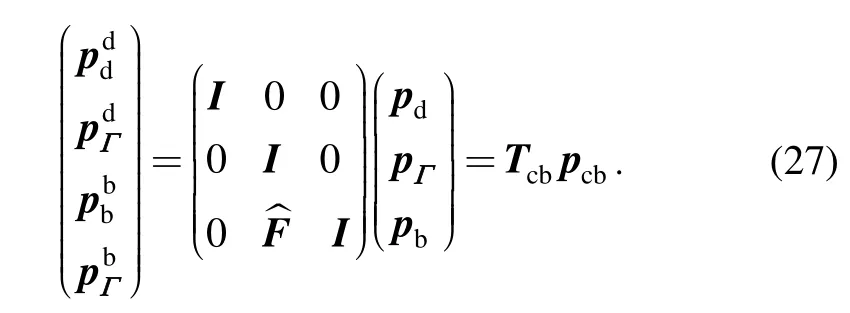

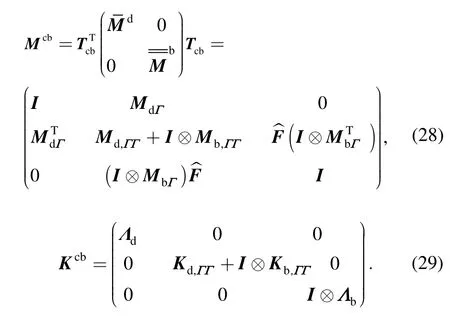

Substituting Eq.(9)and Eq.(20)into Eq.(25),it can be rewritten as

The coupling constraint of the substructures is given by

The comprehensive mass matrix and stiffness matrix of the blisk are respectively described as

3 Engine Order Excitation Force

Considering the coordinate transformation relationship of Eq.(9),Eq.(20)and constrained relationship of Eq.(27),the modal force vector is written as

4 Mistuned Simulation

The disk and the blade were respectively regarded as tuned and mistuned substructures.The blade was simulated as blade stiffness deviation or elastic modulus deviation to its nominal value,in fact,it was natural frequency deviation.Mistuned stiffness for the k-th order modal of the n-th blade is given by

mb—Modal number of the blade whose high order modes are truncated.

The mistuned stiffness matrix is expressed as follows

5 Dynamical Model of ROM

5.1 Classical ROM

The dynamical model of the mistuned blisk in the modal coordinates is deduced by Eq.(27),Eq.(28),Eq.(30)and Eq.(34),which is written as

where Ccb—Sticky modal damping

The blisk dimension is the sum of the main modal mbof the blade,the main modal mdof the disk and the constraint modes mΓ.The main modals are much less than the DOF of every substructure in the physical coordinates,so model size is greatly reduced.

5.2 Improved ROM

Eq.(35)may be written as Eq.(37)if the damping is not considered

众所周知,传统铣刨加铺工艺耗时长并需整幅或半幅封闭道路,而且铣刨时还会产生噪音、扬尘和废料污染,更重要的是,铣刨时产生的振动会容易引起桥梁的共振,给桥梁的质量安全带来极大威胁。与此同时,传统工艺(含微表处)治标不治本,原桥面的病害没有得到解决、材料没有得到改善,而且还会增加桥梁恒载。

Order:b+d+Γ=α.

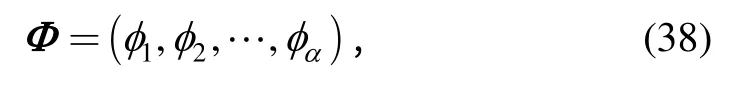

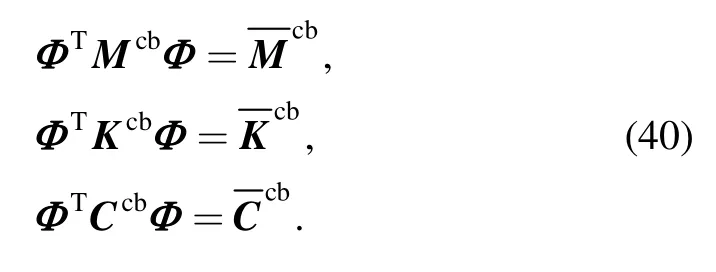

The modal matrix is written as

Eq.(35)is orthogonal transformed and it can be rewritten as

where

Assumption that the dynamic load responsepcbof the blisk is expressed with a linearly independent vector and it is written as

But there is still large amount of calculation via the classical method,so Eq.(41)can be further expressed as

Substituting Eq.(42)into Eq.(39),

The integral kinematic equation is obtained,but each substructure equation is not connected.Due to mutual constraints of the substructures,X is expressed as independent coordinates Xiand no independent coordinates Xf.The X is written as

where H—Coefficient matrix of the constrained equation.

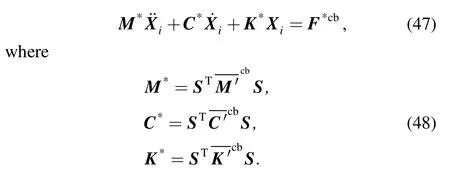

Substituting Eq.(45)into Eq.(43)which is multiplied STin the left,

Actually,Eq.(47)is m independent differential equations.The natural frequencies and the responses of the integral structure can be obtained.The order is respectively reduced twice with different methods,the interface displacement condensation method is applied at the first time and the comprehensive modal condensation method is adopted at the second time.It is better than only using the free ISCMSM or the fixed ISCMSM.The computational efficiency is increased greatly under the condition of meeting the computational accuracy.

6 Modal Analysis

6.1 Analysis procedure of CMS

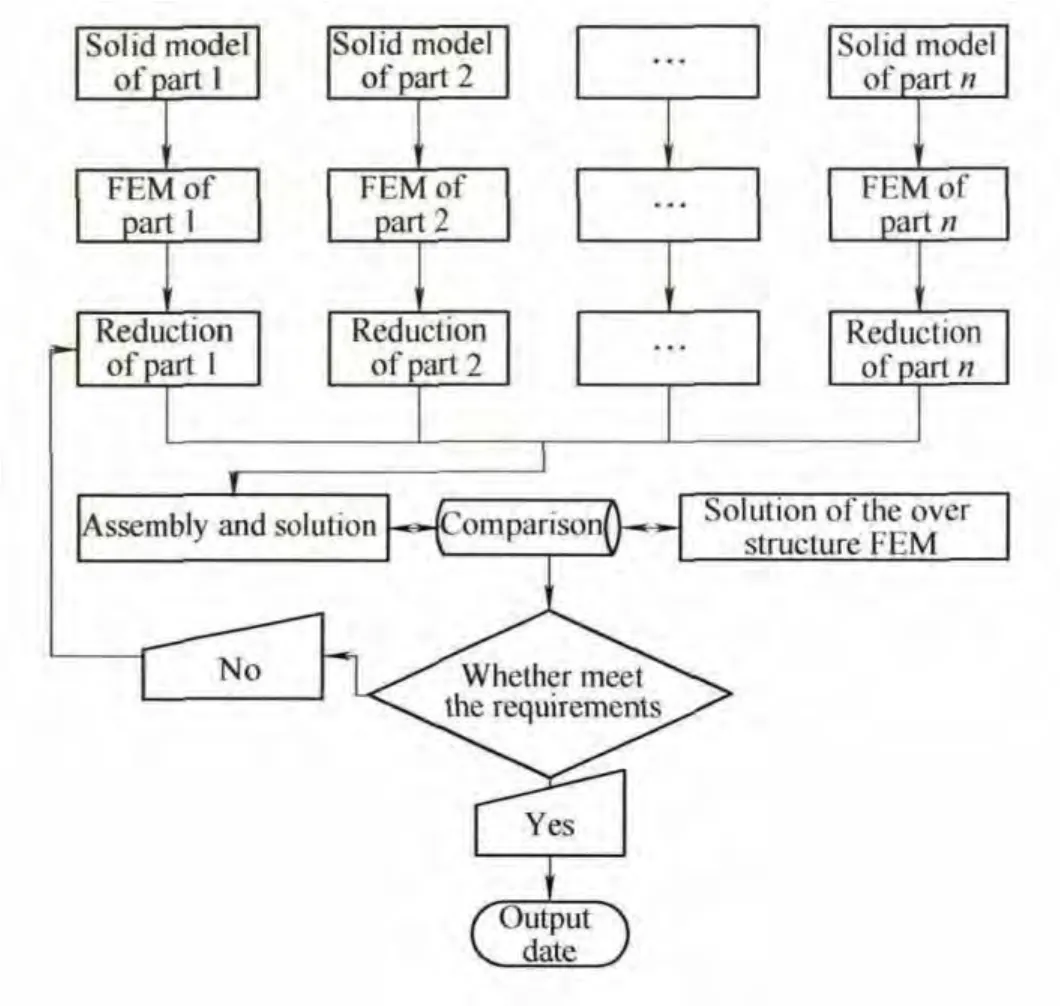

The CMS was a very effective method to solve the large and complex structure,which was investigated by dividing the whole structure into several substructures.The characteristic matrixs of the substructures were condensed and assembled to solve the natural frequency and modal shape.Their analytical process was shown in Fig.1.

Fig.1.Analytical procedure of the CMS

6.2 Substructural FEM

The FEM was built by the improved HISCMSM and it was effectively and dynamically connected by the double coordinating conditions of the displacement and the force.The comprehensive process was shown in Fig.2.

6.3 Modal analysis of three methods

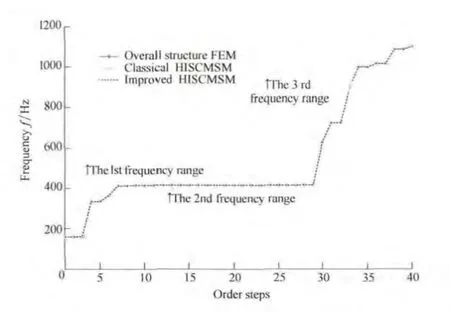

For the large and complex mechanical structure,such as,the blisk,the vector iteration method and the Rayleign-Ritz(R-R)method could be used,but they did not guarantee a better precision.The subspace iteration method could guarantee the accuracy and the economical,but its computational process was slower 5 to 10 times than the Lanczos method for the same problem.So the Lanczos method was adopted,the first 40 natural frequencies were comparatively analyzed by the improved HISCMSM,the classical HISCMSM and the overall FEMM method when w=800 rad/s,t=650 ℃,which were shown in Fig.3 and Table 1.

Fig.2.Comprehensive process of the substructures

Fig.3.Modal frequencies and deviation analysis of three methods

Fig.3 and Table 1 show that the errors of the blisk’s natural frequencies are respective 0.002%–0.157% and 0.005%–0.186% by the improved HISCMSM and the classical HISCMSM.The natural frequencies obtained by the improved HISCMSM are much more close to the overall structure FEMM than the classical HISCMSM.So the computational accuracy of the improved HISCMSM is higher than the classical HISCMSM.It also shows that the frequencies appear dense area and transition area.Curve slopes of them are smooth and small in the modal dense area,the main reason may be that they are dominated by the vibration of the blades.The frequencies’distribution has a higher density,which is the result of the weak coupling between the blades.Curve slopes of them are steep in the modal transition area,the main reason may be that they are leaded by the vibration of the disk or the coupled of the blades-disk.

Table 1.First forty natural frequencies and error rate of three methods

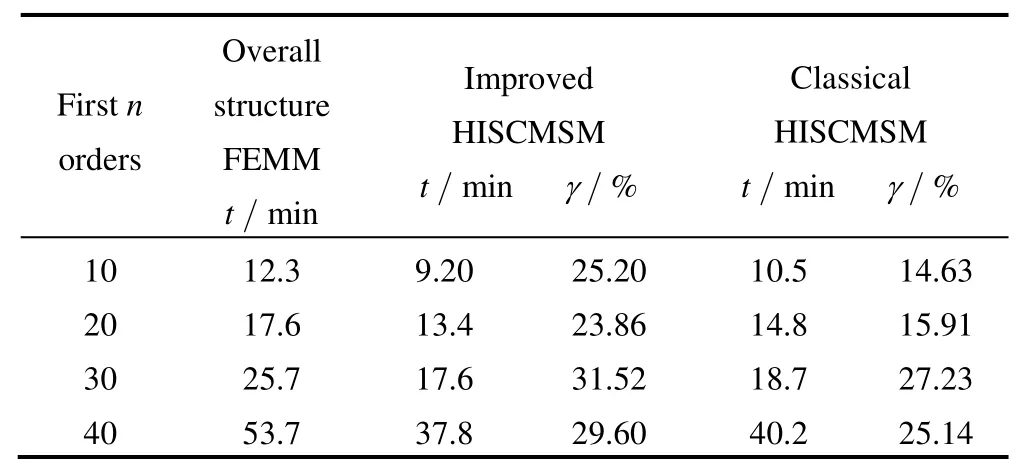

In order to research the different modal orders’impact to the computational efficiency,the first 10,20,30,40 natural frequencies were respectively calculated by the overall structure FEMM,the classical HISCMSM and the improved HISCMSM.Their computational time and saving rate were shown in Table 2.

Table 2.Computational time and saving rate of three methods

Compared with the overall structure FEMM,the computational time is respectively shortened by 14.63%–27.23% and 23.86%–31.52% by the classical HISCMSM and the improved HISCMSM in Table 2.The computational efficiency of the improved HISCMSM is much more increased than the classical HISCMSM.So the improved HISCMSM is better than the classical HISCMSM and the overall structure FEMM in the computational efficiency and the computational accuracy.

6.4 Analysis of the factors influencing the frequency

The resonance of the mistuned blisk would occur when excitation frequency was equal to or close to its natural frequency.It would be very dangerous once resonance occurring,reasonable controlling the factors influencing the natural frequency was very significant to reduce the destructiveness of the mistuned blisk,so the investigation of the factors influencing the natural frequency was very necessary.

6.4.1 Influence of the centrifugal force

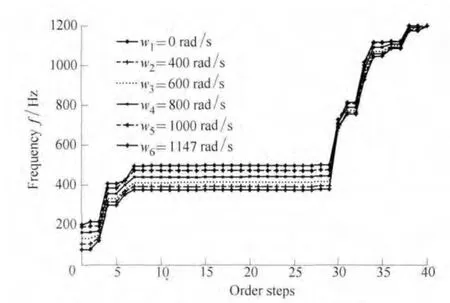

The aeroengine was working in the high rotational speed,the vibration in the state of rotation was what under the centrifugal force.The higher the rotational speed,the greater the centrifugal force,so in order to research the influence of the centrifugal force on the natural frequencies of the mistuned blisk,in fact,investigating the influence of the rotational speed on them.The natural frequencies in the typical orders were respectively calculated in the different rotational speeds by the improved HISCMSM,which were shown in Table 3.

The fluctuation of the frequencies is larger in the low-order than in the high-order with the rotational speed increasing in Table 3,for instance,the first order and the fortieth order respectively increase 28.051 Hz,26.29 Hz,30.81 Hz,27.58 Hz,16.82 Hz,and 3.4 Hz,4.1 Hz,5.5 Hz,6.9 Hz,5.9 Hz when rotational speed is enhanced from 0 rad/s to 1150 rad/s.The model dense area of the frequencies is narrow in the low-orders and the high-orders,but it is wide in the middle-orders,such as,it is very dense from the seventh to the twenty-ninth order frequency.The incremental trend of the frequency is reduced by improving the rotational speed from the low-order to the high-order.The frequency increasingly enhances with the rotational speed increasing of the whole process.It can be seen that the change of frequency is larger in the static or the low rotational speed than the high rotational speed,for instance,it is respectively increased 1117.85 Hz,1093.2 Hz,1071.01 Hz,1045.70 Hz,1025.02 Hz,1014.10 Hz from the first order to the fortieth order in the 0 rad/s,400 rad/s,600 rad/s,800 rad/s,1000 rad/s,1147 rad/s.So only research the static frequency is not scientific,reasonable speed must be considered,which provides a reference value for the dynamic designing of the mistuned blisk.

Table 3.Natural frequencies in the different rotational speeds

When the effect of temperature was not considered,the natural frequencies of the mistuned blisk in different rotational speeds were shown in Fig.4.

Fig.4.Natural frequencies changes of different rotational speeds

The inquiry shows that the natural frequency is increased with the rotational speed enhancing in Fig.4.The main reason is that the mistuned blisk will produce qualitative centrifugal force when rotational speed is improved and this centrifugal force usually acts on the mistuned blisk as drawing force.There is a tendency to return to its original equilibrium position by this tension force which has the stiffness of the mistuned blisk strengthened,so the natural frequencies are increased.It is also observed that the rotational speed has greater influence on the low-order modal than the high-order modal.

6.4.2 Influence of the temperature

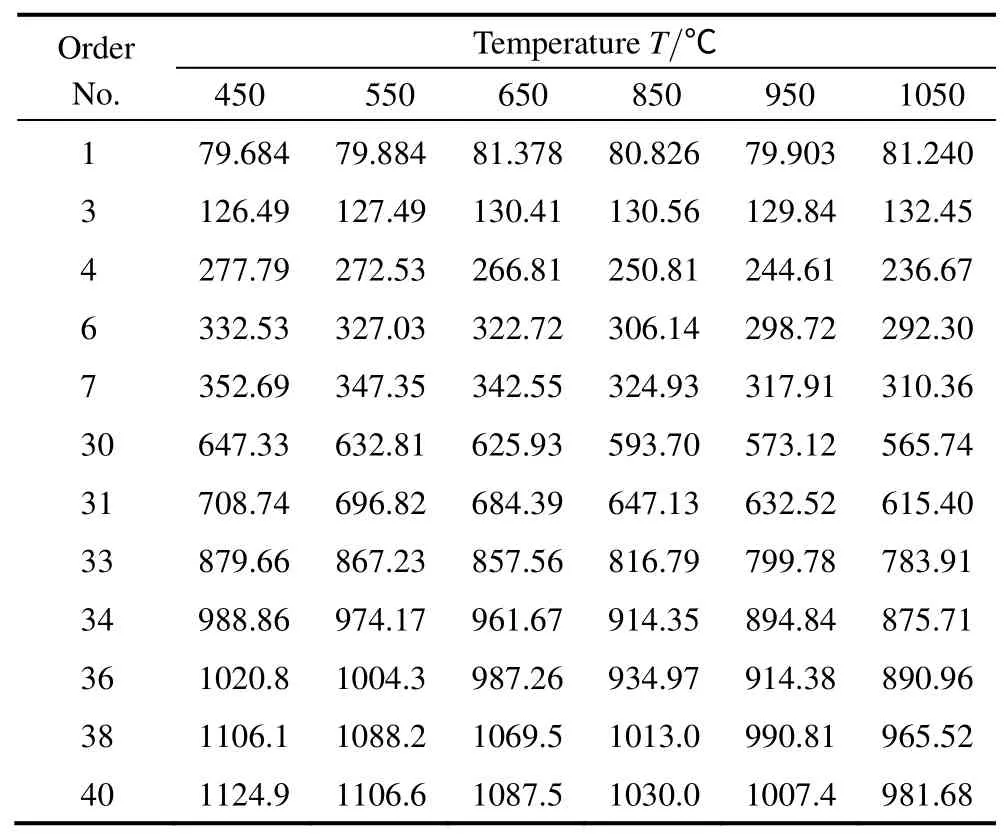

The aeroengine was working in the environment of high gas temperature,the performance of the material would be changed in the high temperature,that was,the elastic coefficient of material would be changed,the stiffness of the mistuned blisk would be changed,so the natural frequency would be changed.The typical orders were respectively calculated in the different temperatures by the improved HISCMSM,which were shown in Table 4.

Table 4.Natural frequencies in the different temperatures

The change of the frequencies are very little in the same order in the low-orders in Table 4,such as,the first order changes respectively 0.211 Hz,1.494 Hz,0.552 Hz,0.923 Hz,1.337 Hz between two temperatures when they are enhanced from 450 ℃ to 1050 ℃ and the first three orders are almost improved.But they start to decline with the temperature increasing in the same order from the fourth order.The decreasing extent of the frequency is enlarged from the low-order to the high-order between two temperatures,but enlarged range of the frequency from the first order to the fortieth order is gradually reduced with the temperature increasing,for instance,it is increased respectively 1045.216 Hz,1026.716 Hz,1006.122 Hz,949.174 Hz,927.497 Hz,900.441 Hz.So the temperature must be considered when the frequencies of the mistuned blisk are researched.

When the effect of rotational speed was not considered,the natural frequencies of the mistuned blisk in different temperatures were shown in Fig.5.

It is shown that the fluctuation of the frequency in high-order are bigger than in the low-order,however,the natural frequency is increasing or reducing which is not steady.The main reason is that the higher the temperature,the elastic coefficient of material smaller,which makes the natural frequency decreased.Its impact on the model dense area is similar with the influence of rotational speed.

Fig.5 Natural frequencies in the different temperatures

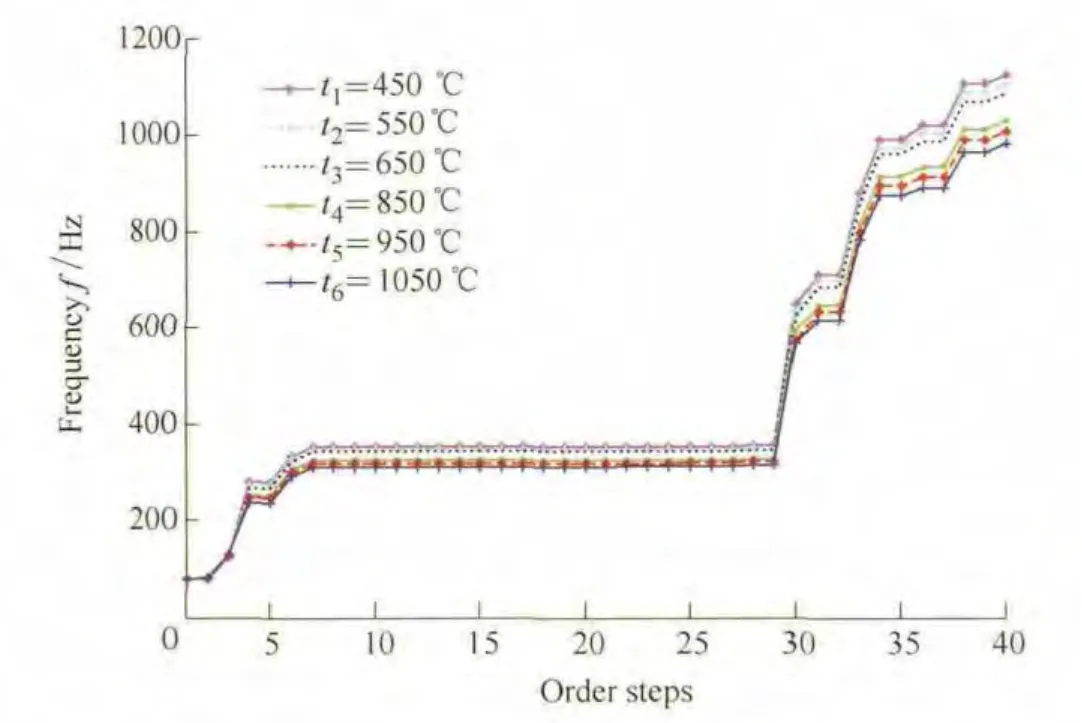

6.4.3 Influence of the temperature and rotational speed

Actually,the aeroengine was working in the environment of high rotational speed and high gas temperature,which made it produce centrifugal force and the elastic coefficient of material changed.The investigation of the rotational speed and the temperature’s influence to the mistuned blisk was very necessary.It was conform to the actual requirements.The natural frequencies in the typical orders were respectively calculated in the different rotational speeds and the temperature by the improved HISCMSM,which were shown in Table 5.

Table 5.Natural frequencies in the different rotational speeds and temperatures

It shows that the frequency is larger when the temperature and the rotational speed are both considered than only the temperature is considered in Table 5,but it is smaller than only the rotational speed is considered,such as,the frequency is 158.23 Hz when w=800 rad/s,t=650 ℃,162.00 Hz when w=800 rad/s and 81.378 Hz when t=650 ℃ in first order.When the temperature and the rotational speed are both considered,the decreasing extent of the frequency is increasingly enlarged compared with only the rotational speed is considered,but the ampliative extent of the frequency is increasingly contractible compared with only the temperature is considered from the low-order to the high-order.For instance,compared with w=800 rad/s,the frequency respectively declines 3.77 Hz,26.99 Hz,104 Hz and 106.1 Hz when w=800 rad/s and t=650 ℃,and compared with t=650 ℃,it respectively improves 76.855 Hz,69.9 Hz,16.5 Hz,14.1 Hz in the first order,the seventh order,thirty-eighth order and the fortieth order.The change extent of the frequency is larger in the high temperature and the high rotational speed than in the low temperature and the low rotational speed in the same order,for example,compared with only w=800 rad/s is considered or only t=650 ℃ is considered,the frequency respectively declines 3.77 Hz or increases 76.855 Hz when w=800 rad/s and t=650℃ are both considered,but respectively it declines 10.32 Hz and increases 117.05 Hz when w=1150 rad/s and t=950 ℃ are both considered in the first order.

When the effect of rotational speed and temperature were both considered,the natural frequency’s changes of the mistuned blisk were shown in Fig.6.

It is shown that the changes of the natural frequency are not large when the rotational speed and temperature are both considered in Fig.6,such as,when t=650 ℃,w=800 rad/s and t=950 ℃,w=1147 rad/s,the curve of the modals are close to each other.The main reason is that the rotational speed makes the frequencies increased and the temperature makes them decreased.The difference of the rise-fall rate with each other is small,which makes the variation of the mistuned blisk’dynamic frequency tiny.It is also seen that when the rotational speed and the temperature are both considered,the curve of the frequencies is much more close to the curve only the rotational speed is considered,the influence of the rotational speed is bigger than the temperature to the frequencies.So reasonable control the rotational speed and the temperature is good for controlling the natural frequency of the mistuned blisk.

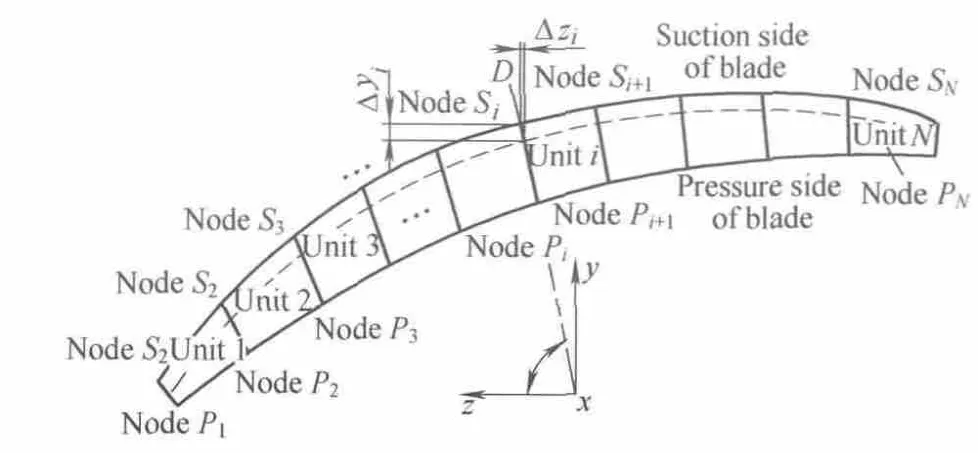

6.4.4 Influence of the geometric dimensioning mistuned

The geometric dimensioning of blisk would change due to processing and manufacturing,installation and nonuniform wear and so on,that was,it occured geometric mistuned.It would lead to the mass and the stiffness changing which urged the natural frequency to be varied.And once it was closed to the excitation frequency,the blisk would occur larger vibration or even resonance,which might give rise to damaging,so it was very necessary to research the influence of geometric dimensioning changing on the frequency.

Assume that the disk and the blade are respectively regarded as tuned and mistuned substructures.Bladed sectional method was used to change the geometric dimensioning of the blade,a benchmark bladed section was selected according to the feature of the bladed surface,which was shown in Fig.7.The i-th(i=1,2,3,...,N)pair node coordinates were respectively Si(Xs,i,Ys,i,Zs,i),Pi(Xp,i,Yp,i,Zp,i),unit i is surrounded by two pairs adjacent nodesSi,Pi,and Si+1,Pi+1.The thinner,the thicker blade or the damaged blade tip were respectively simulated based on the benchmark bladed section through thickness reduction,thickness increase or removing units.

Fig.7.Schematic diagram of bladed sectional method

The FEMs of the geometric dimensioning mistuned blades were established according to the schematic diagram Fig.7,which are shown in Fig.8.The blade units and nodes could be operated directly by this method and different size of blade could be simulated,and the practicability of this method was very strong.

The natural frequencies in the typical orders were respectively calculated in the different geometric dimensioning mistuned by the improved HISCMSM,which were shown in Table 6.

Table 6.Natural frequencies in the different geometric dimensioning mistuned

Table 6 shows that the fluctuation of the frequency is tiny in the whole process,for instance,considering w=800 rad/s,t=650 ℃,the natural frequency respectively change 0.74 Hz,1.2 Hz when the blade tip is damaged,0.68 Hz,0.1 Hz when the blade is thick,0.87 Hz,0 Hz when the blade is thinned in the first order and in the fortieth order.so the influence of the geometric dimensioning’change to the modal is small.

When the effect of geometric dimensioning mistuned is considered,the changes of the mistuned blisk’s natural frequencies were shown in Fig.9.

Fig.9 shows that four curves almost overlap which are w=800 rad/s t=650 ℃,w=800 rad/s t=650 ℃ and the blade tip is damaged,w=800 rad/s t=650℃ and the blade is thinned,w=800 rad/s t=650 ℃ and the blade is thick.So the geometric dimensioning mistuned has puny influence on the modal.It is also seen that the natural frequencies are very closed to only the rotational speed is considered in the low-order,but they decline and are closed to only the temperature is considered in the high-order,so the rotational speed has a greater influence on the low-order modal and the temperature has a greater influence on the high-order modal.

7 Modal Shape Analysis

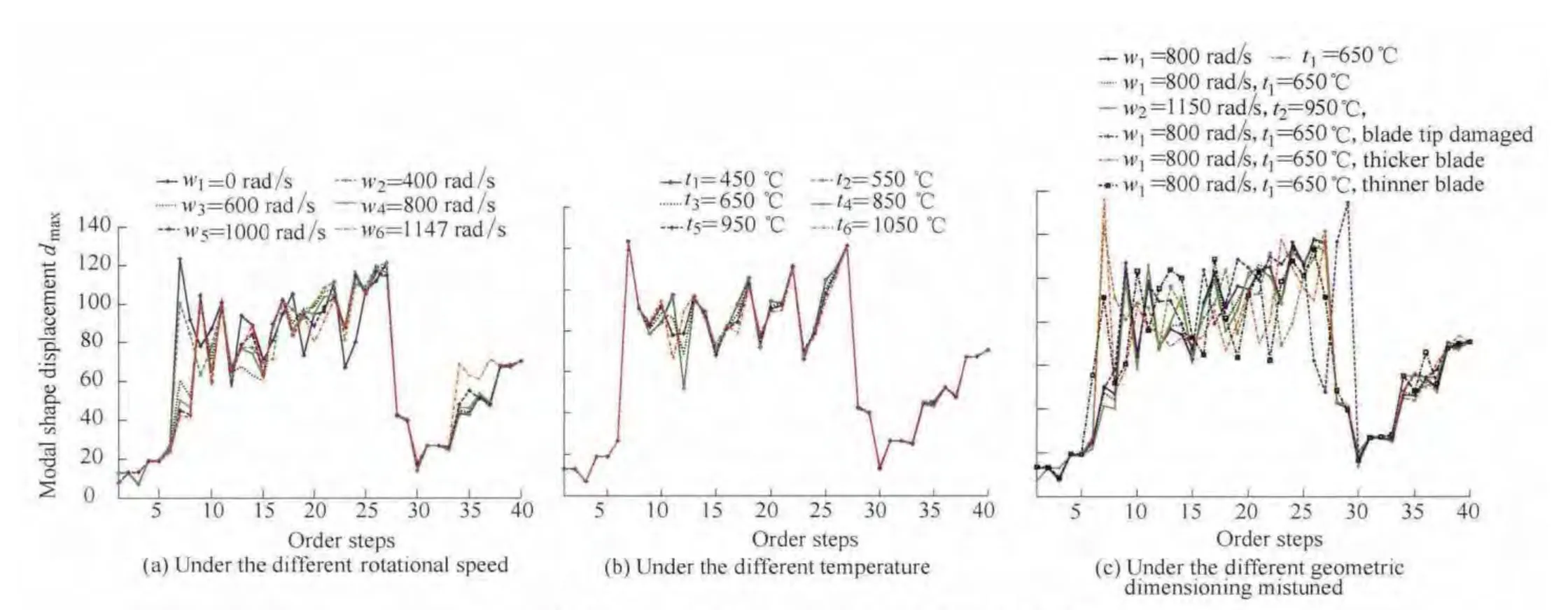

The maximum displacement and the maximum stress of the modal shape for the first forty orders were investigated which are shown in Fig.10-Fig.11 in order to research the influencing of rotational speed,gas temperature,geometric dimensioning on the localization phenomenon of them.

Fig.9.Natural frequencies in the different geometric dimensioning mistuned

Fig.10 Maximum displacement distribution of the blisk

As Figs.10(a)-(b),11(a)-(b)shown,modal shapes are dominated by the vibration of the disk and bending vibration based on the first frequency band.They are also dominated by the vibration of the disk or coupled vibration of the blisk and torsional vibration based on the third frequency band,but it appear bending-torsional-coupled vibration in the 28th,29th order and the localization phenomenon is relatively weak in the first and the third frequency band.The strong localization phenomenon is observed in the second frequency band,such as,the larger mutation of the maximum displacement and the maximum stress are occured in the 7th,27th order and almost all energy focuses on one blade.The main reason lies in the weak coupling between blades,which leads to the mistuned periodic localization.The head and end of each frequency band appear strong localization phenomenon of the maximum displacement and the maximum stress which generate fatigue damage for the blade.Paying close attention to the second frequency band about the vibrational localization problem of the blisk is very important.The 30th order is the head of the torsional vibration in the third frequency band,so the modal shape localization is the most sensitive in the frequency veering,the localization phenomenon is strong in the vibration of the blade,but the localization phenomenon is relatively weak in the vibration of the disk or coupled vibration of the blisk.This is because compared with the blade,the mass and the stiffness of the disk are much larger,resulting in the mistuned of the blade is difficult to producing great influence on the vibration of the disk or the coupled vibration of the blisk.

The influence of rotational speed is greater than the temperature on the maximum displacement and the maximum stress’localization.The localization of the maximum displacement has a reduced trend,especially in the first and the second frequency veering band with the rotational speed increasing.The localization degree of the maximum stress is improved but not much with the rotational speed increasing in the second frequency band.The localization degree of the maximum stress is significantly decreased in the veering of the first and the second frequency band with the rotational speed increasing.The high rotational speed intensifies localization of the maximum displacement when the blisk produces the torsional vibration in the third frequency band.The temperature has a small influence on the maximum displacement and comparative law on the maximum stress and it has a weak trend with the temperature increasing.

It is shown in Fig.10(c)and Fig.11(c)that different geometric dimensioning mistuned has different influence on the localization of the modal shape,such as,the thin blade makes the 7th order displacement increased obviously,blade tip which is damaged makes the 28th order displacement increased obviously and the thicked blade makes the 34th order stress increased obviously.The change rule of every frequency band’s modal shape is different from the geometric dimensioning mistuned.So processing and manufacturing,installation must be considered in the structural design and reasonable measures must be adopted to decrease the blisk’s wear in its working.

8 Conclusions

(1)An improved HISCMSM is proposed and the dynamic equation of the ROM mistuned blisk is inferred by this method which makes the computational efficiency greatly increased with keeping precision.The problem of a large amount of calculation via the classical method is solved.

(2)Natural frequencies of the blisk are obtained by the improved HISCMSM.The efficiency is about 4.46%–10.57%higher than the classical HISCMSM,but the relative error is only 0.002%–0.157% by the improved HISCMSM,so it is feasible to the large and complex structure.

(3)Modal is respectively increased and reduced with the rotational speed and the temperature improving.The low-order modal is influenced larger by the rotational speed and the high-order modal is influenced larger by the temperature,and it is not changed much when the rotational speed and the temperature are both considered.It is hardly influenced by the geometric dimensioning mistuned,so it can be neglected.

(4)The strong localization phenomenon is observed in the second frequency band and it is relative weak in the first and the third frequency band,and it is the most sensitive in the frequency veering.The localization of the modal shape is more serious caused by the geometric dimensioning mistuned.

[1]SHANMUGAM A,PADMANABHAN C.A fixed-free interface component mode synthesis methed for rotordynamic analysis[J].Journal of Sound and Vibration,2006,297(3–5):664–679.

[2]CUI Z Q,YANG R F.Parametric modeling and modal analysis for the complex mechanical structure[J].Chinese Journal of Mechanical Engineering,2008,44(2):234–237.(in Chinese)

[3]RIVAS-GUERRA A J,MIGNOLET M P.Maximum amplification of blade response due to mistuning:localization and mode shape aspects of the worst disks[J].Journal of Turbomachinery,2003,125:442–453.

[4]MARTEL C,CORRAL R.Asymptotic description of maximum mistuning amplification of bladed disk forced response[J].Journal of Engineering for Gas Turbines and Power,2009,131:022506(1–10).

[5]BAI G C,FEI C W.Distributed collaborative response surface method for mechanical dynamic assembly reliability design[J].Chinese Journal of Mechanical Engineering,2013,26(6):1160–1168.

[6]BECK J A,BROWN J M,SLATER J C,et al.Probabilistic mistuning assessment using nominal and geometry based mistuning methods[J].Journal of Turbomachinery,2013,135(3):051004(1–9).

[7]JUNG C,SAITO A,EPUREANU B I.Detection of cracks in mistuned bladed disks using reduced-order models and vibration data[J].Journal of Vibration and Acoustics,Transactions of the ASME,2012,134(6):061010(1–10).

[8]BLAHD R,PIERRE C,CASTANIER M P,et al.Dynamic response predictions for a mistuned industrial turbomachinery rotor using reduced–order modeling[J].Journal of Engineering for Gas Turbines and Power,2002,124(2):311–324.

[9]SUN G Y,PALAZZOLO A,CARNEY K,et al.An efficient algorithm for blade loss simulations using a high fidelity ball bearing and damper model[C]//Proceedings of the 19th Biennial Conference on Mechanical Vibration and Noise,Chicago,USA,September 6,2003,5:1011–1020.

[10]FEINER D M,GRIFFIN J H.Mistuning identification of bladed disks using a fundamental mistuning model-part I:theory[J].Journal of Turbomachinery,2004,126(1):150–158.

[11]FEINER D M,GRIFFIN J H.Mistuning identification of bladed disks using a fundamental mistuning model Part-II:Application[J].Journal of Turbomachinery,2004,126(1):159–165.

[12]BHARTIYA Y,SINHA A.Reduced order modeling of a bladed rotor with geometric mistuning via estimated deviations in mass and stiffness matrices[J].Journal of Engineering for Gas Turbines and Power,2013,135(5):052501(1–8).

[13]MCGEE III O G,FANG C.Three-dimensional tailored vibration response and flutter control of high-bypass shroudless aeroengine fans[J].Journal of Vibration and Acoustics,2013,135(2):021010(1–26).

[14]LIU M H,ZHENG G T.Improved component-mode synthesis for nonclassically damped systems[J].AIAA Journal,2008,46(5):1160–1168.

[15]LAXALDE D,LOMBARD J P,THOUVEREZ F.Dynamics of multistage bladed disks systems[J].Journal of Engineering for Gas Turbines and Power,2007,129:1058–1064.

[16]YANG T,FAN S H,LIN C S.Joint stiffness identification using FRF measurements[J].Computers and Structures,2003,81(28–29):2549–2556.

[17]MAO K,LI B,WU J,et al.Stiffness influential factors-based dynamic modeling and its parameter identification method of fixed joints in machine tools[J].International Journal of Machine Tools and Manufacture,2010,50(2):156–164.

[18]D’SOUZA K,SAITO A,EPUREANU B I.Reduced-order modeling for nonlinear analysis of cracked mistuned multistage bladed-disk systems[J].AIAA Journal,2012,50(2):304–312.

[19]SUN G Y,PALAZZOLO A,PROVENZA A,et al.Long duration blade loss simulation including thermal growths dual-rotor gasturbine engine[J].Journal of Sound and Vibration,2008,316(1–5):147–163.

[20]MARINESCU O,EPUREANU B I,BANU M.Reduced order models of mistuned cracked bladed disks[J].Journal of Vibration and Acoustics,Transactions of the ASME,2011,133(5):051014(1–9).

[21]BLAHD R,PIERRE C.Component-mode-based reduced order modeling techniques for mistuned bladed disks.part I:theoretical models[J].Journal of Engineering for Gas Turbines and Power,2001,123(1):89–99.

[22]LIM S H,PIERRE C,CASTANIER M P.Predicting blade stress levels directly from reduced-order vibration models of mistuned bladed disks[J].Journal of Turbomachinery,2006,128(1):206–210.

猜你喜欢

杂志排行

Chinese Journal of Mechanical Engineering的其它文章

- Basic Characteristics of a New Flexible Pneumatic Bending Joint

- Effect of Spine Motion on Mobility in Quadruped Running

- Curvature Theory for Point-Path and Plane-Envelope in Spherical Kinematics by New Adjoint Approach

- Fatigue Life Prediction under Service Load Considering Strengthening Effect of Loads below Fatigue Limit

- Stabilizing Mechanism and Running Behavior of Couplers on Heavy Haul Trains

- Modified Pressure Loss Model for T-junctions of Engine Exhaust Manifold