Analysis of Volatile Compounds of Jinmudan Oolong Tea by Different Wrapping-Twisting

2013-12-13QingWeiYingWuFeiLongCuiJingZhuHuiJingXuLingYunZhang

Qing Wei,Ying Wu,Fei-Long Cui,Jing Zhu,Hui-Jing Xu,Ling-Yun Zhang*

1.College of Horticulture,South China Agricultural University,Guangzhou 510642,China.

2.Yinzhou district forestry technology management service station,Ningbo 315000,China.

1.Introduction

Jinmudan was bred by cross breeding method by Tea Research Institute of Agricultural Science Institute of Fujian province.It was bred from 1978 to 2002,which is as Tieguanyin for female parent and Huangdan for male parent[1].It won the national identification of varieties in 2010[2].It has the characteristics of high cutting reproductive rate,high survival rate,drought resistance,cold resistance and great adaptability[3].It is good for producing oolong tea.

Wrapping-twisting is a key procedure to form granular shape for oolong tea,which has an important influence on the aroma and taste of tea[4,5].Wrapping-twisting for long time seems to decrease the content of jasmine lactone,methyl jasmonate and indole,to significantly increase the content of α-farnesene and nerolidol[6].As previous reports,wrapping-twisting made the total essential oil lower[7].There is no in-depth study about the volatile compounds by wrapping-twisting.Therefore,the aim of the present study was to research the effect of the time of wrapping-twisting for volatile compounds.

2.Materials and methods

2.1.Samples and reagents

The fresh leaves were picked in Yinzhou district Zhangshui Yongjie tea garden with the standard in one bud and three or four leaves in October 2012.The sample was made by the way of Minnan Oolong tea processing as follow:fresh leaves→withering→making of green leaves→de-enzyming→wrapping-twisting→hert energy dehydration→semifinished tea.There were four groups of experimental treatment,numbered from 1 to 4,wrapping-twisting for 5 times,10 times,15 times and 20 times respectively,and other processes were the same.

The following chemicals were used:diethyl ether,sodium sulphate anhydrous and ethyl decanoate were purchased from CongYuan instrument Co.,Ltd(Guangzhou,China).

2.2.Simultaneous steam distillation and extraction(SDE)

A Likens-Nickerson type SDE apparatus was used to extract volatile compounds[8-10].For SDE extraction,20.0 g of the sample were transferred to 1000 ml round bottom flask mixed with 450 ml of distilled water,to which 100 μg of internal standard ethyl decanoate was added.The extraction was performed for 1 h at 100℃.As the extraction solvent,50 ml of diethyl ether was used.Obtained extracts were dried over sodium sulphate anhydrous and concentrated to approximately 1 ml.The concentrated extract was stored at 4℃ until further analysis was performed.

2.3.GC – MS analysis

Analyses were carried out by a TRACE GC-2000 GC-MS(Thermo Finnigan)using a DB-1(100%dimethyl polysiloxane)column(30 m ×0.32 mm).Helium was used as the carrier gas at a flow rate of 1.0 ml/min.Thermal desorption of the compounds from the column was carried out in the GC splitless injector at 230℃.The oven temperature was programmed to increase from 50℃ (2 min)to 110℃ (2 min)at a rate of 3℃ /min.The temperature was then raised to 170℃ (2 min)at a rate of 5℃ /miin,and then to 230℃ (1 min)at a rate of 10℃ /min.Aroma compounds were analyzed by MS with electronic impact(EI)70 eV quadripolar filters.The mass range for this acquisition is 35-335 amu.

2.4.Identification

All compounds were identified by comparison to NIST library(including Wiley,Mainlib and Replib)spectral data bank.Only compounds whose similarity is more than 800 were reported here.Quantitative analysis was based on the ratios between the peak area of a particular component in the powder of Jinmudan Oolong tea and the total peak area of all components in the powder.

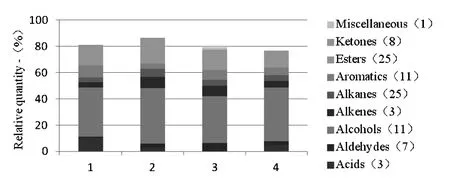

Fig.1.Aroma components of different treatments

3.Results and discussion

3.1.Volatile composition of Jinmudan Oolong tea

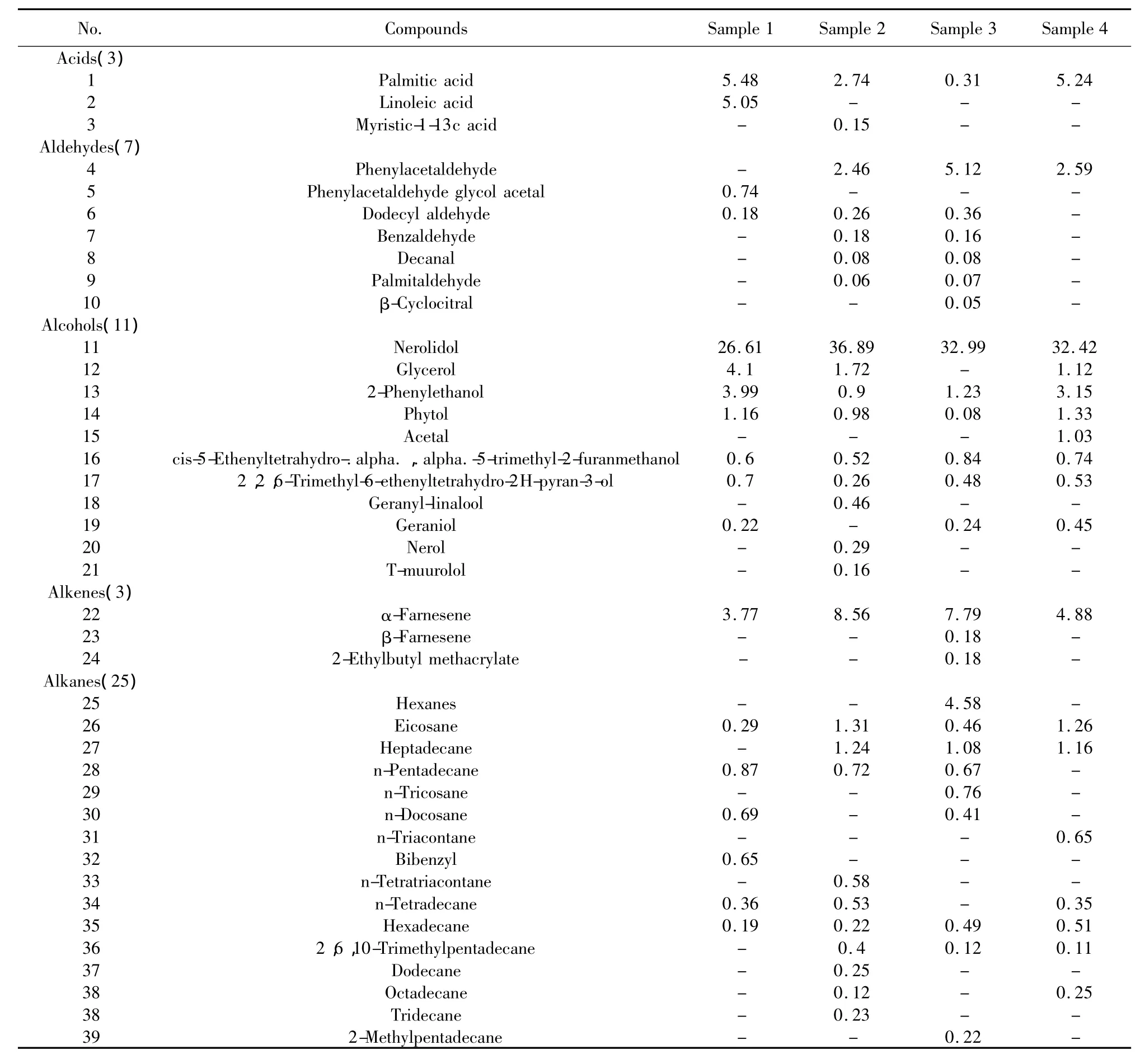

The volatile compounds identified in Jinmudan Oolong tea are listed in Table1.A total of 93 volatile components were identified,46 for sample 1,56 for sample 2,45 for sample 3 and 30 for sample 4,which included acids(3),aldehydes(7),alcohols(11),alkenes(3),alkanes(25),aromatics(11),esters(25),ketones(8)and miscellaneous(1).Alcohols and esters were the most dominant volatiles in the four samples(Fig.1).Nerolidol was the highest aroma compound,which was thought to be the role volatile for oolong tea.

3.1.1.Aldehydes

As for aldehydes,sample 1 was less than others.When the time of wrapping-twisting was 20,the variety of the aldehydes got least.When the time of wrapping-twisting was more than 5, there were amount of phenylacetaldehyde forming,which is fruity smells.Therefore a suitable wrapping-twisting time is benefit for the formation of aroma.

3.1.2.Alcohols

Alcohols were the dominating aromas in the four samples.Among the higher alcohols(Table1),the highest concentrations in nerolidol.While as previous reports,nerolidol was decrease for long time wrapping-twisting[7].In our study,when the wrapping-twisting time exceeded 5,it supported the point.However when the wrappingtwisting time 5,the content of nerolidol was the lowest among the four samples.Thus,the decrease of nerolidol may happen when the wrapping-twisting time surpasses a certain time.When we process the Jinmudan Oolong tea,wrapping-twisting 10 times may be a good way.

3.1.3.Aromatics

Aromatics changed a lot in the four samples.A short time(5 times)wrapping-twisting generated more aromatics,while a long time that got less.It is intriguing that Jinmudan Oolong tea was abound of indole.While the fresh leaves were lower of indole[11-12].As the tea process,especially for oolong tea,the content of indole sharply increased[13-16].As a consequence,wrapping-twisting may contribute on forming indole.

3.1.4.Esters

Esters had a wide variety in the samples.β-phenethyl hexanoate,diisobutyl phthalate,methyl palmitate,benzoic acid,2-phenylethyl ester were all in the samples.Other components have no obvious change.

3.1.5.Ketones

Tetrahydro-6-(cis-2-pentenyl)-2H-pyran-2-one and cis-jasmone were the highest concentrations in the components of ketones.They were both the dominating aromas in oolong tea.As the time of wrapping-twisting altered,the changes of the two were not obvious.

The other groups of volatile compounds identified in the samples were acids, alkenes, alkanes and miscellaneous.

Table1.Relative content of aroma components in the tea samples.

No. Compounds Sample 1 Sample 2 Sample 3 Sample4 40 n-Heptacosane---0.21 41 2-Methyltridecane-0.21--42 Pristane 0.2-- -43 Nonadecane-0.17--44 2-Methyl-3-dioxolane---0.16 45 2-Methyltetradecane-0.13--46 Phytane 0.12-- -47 2,6-Dimethylnonane-0.03--48 n-Heneicosane 0.03-- -Aromatics(11)49 Indole 5.65 3.95 5.07 5.74 50 2,4,6-Cycloheptatriene-1-carbonitrile-- 2.38 -51 Allyl benzyl ether 1.74-- -52 Phenylacetonitrile 1.38-- -53 1,3-Bis(2-oxazolidinyl-2-yl)benzene 0.85-- -54 2,4-Di-tert-butylphenol-- 0.31 -55 Benzyl isocyanide 0.13-- -56 n-Propylbenzene-0.13--57 Benzothiazole-- 0.06 -58 o-Benzylhydroxylamine hydrochloride-0.04--59 o-Xylene-0.03--Esters(25)60 Methyl linolenate-6.75 2.92 -61 Methyl eicosanoate-- 6.3 -62 Methyl linolenate---4.61 63 Isobutyl acetate-3.07--64 Methyl dihydrojasmonate 1.02 0.58-1.21 65 Butanoic acid,2-methyl-,2-phenylethyl ester 0.94-- -66 2-Phenylethyl 2-methylbutyrate-0.9 0.78 -67 Isopropyl acetate 0.85-0.01 -68 β-Phenethyl hexanoate 0.74 0.63 0.45 0.56 69 Diisobutyl phthalate 0.55 0.27 0.11 0.24 70 δ-Decanolactone 0.36 0.53 0.27 -71 Phenprobamate 0.49-- -72 Methyl palmitate 0.45 0.41 0.11 0.27 73 Phenethyl isobutyrate 0.28 0.35 0.36 -74 Methyl stearate 0.36-- -75 Benzoic acid,2-phenylethyl ester 0.35 0.24 0.07 0.16 76 1,1-Ethanediol diacetate-0.32--77 Dibutyl phthalate 0.26 0.12--78 cis-3-Hexenyl benzoate-0.26--79 Hexyl hexanoate-- 0.15 -80 Methyl palmitoleate 0.12 0.13--81 2-Phenylethyl acetate 0.1-- -82 Methyl salicylate 0.08 0.05--83 Linalyl propionate-0.03 0.07 -84 Methyl 2-methylvalerate-- 0.06 -Ketones(8)85 Tetrahydro-6-(cis-2-pentenyl)-2H-pyran-2-one 4.54 3.37 2.91 4.23 86 cis-Jasmone 1.96 1.26 0.99 1.28 87 2-Acetonaphthone 1.69-- -88 Perhydrofarnesyl acetone-0.38-0.18 89 2(5H)-furanone 0.16-- -90 Geranyl acetone 0.08-- -91 Methyl isohexenyl ketone-0.05--92 3-Hydroxy-3-methyl-2-butanone-0.04--Miscellaneous(1)93 Oleamide-- 1.7 -Total 81.13 86.7 84.03 76.62

3.2.Comparative analysis of volatile composition in the samples

Since wrapping-twisting 10 times,there was a decrease in the amount of essential oil,which was consistent with the previous research[7].Tea twisting or not,will affect the aroma.The leaves which were not twisting,were easier to form the aroma[17].As for oolong tea,we need to twisting to develop the shape.In our study,it is suggested to wrapping-twisting 10 times for producing Jinmudan Oolong tea.

Twisting affects the percentage cell disruption of tea[18].The activity of some enzymes change in the process,such as glycosidase,which can hydrolyse the glycosidic body to release the tea alcoholic aroma[19-21].It may impact wrapping-twisting,then different wrapping-twisting time got a much different amount.Long time twisting leads to more percentage cell disruption,it may influence the conversion of the aroma.So the aroma total amount increase first and then decrease,as the time of wrapping-twisting increase.

In summary,the volatile components of Jinmudan Oolong tea by different wrapping-twisting were quite different.Some volatile components were changed in different wrapping-twisting,but we do not know how it alters.Thus,we need to do more about it.On the basis of these results,we can point out that the characteristics aromas of Jinmudan Oolong tea should include nerolidol,cis-Jasmone and indole.

Acknowledgements

This work was supported by the rural science and technology innovation fund project of technology division from Ningbo city science and technology bureau(No.201001C8002011,201002C1011003).We thank the Ningbo city Yinzhou district Zhangshui Yongjie Tea Company for helping in the preparation of tea samples.

1.Guo JC,Yang RX,Zhang WJ,et al.Selection and application of Camellia Sinensis Hybrids:Jinmudan and Huangmeigui.The National Conference on Science and Technology of Tea,2007,31-37.

2.Wang RJ,Guo JC,Yang J,et al.Analysis of the characteristics and cultivation techniques of Camellia Sinensis Hybrids:Jinmudan.Tea in Fujian,2010:20-24.

3.Guo JC,Yang RX,Zhang WJ,et al.The economic characters of oolong tea varieties in different regions.Tea in Fujian,2002,4:4-6.

4.Chen C,Hu JC,Zhu XM.Manufacture of Tea.Chinese Agricultural Press:Beijing,China,2007.

5.Zheng PC.Anhui oolong tea processing technology research.Journal of Anhui Agriculture University,2009,36(1):34-37.

6.Zhang WT,Zhang LZ,Wang DL.The effect of processing technology of oolong tea aroma components research.Chinese Tea,2010,(04):10-13.

7.Miao AQ,Shu AM,Wu XY,et al.Changes of aroma components of Oolong tea processing.Chinese Tea,2003,(04):8-10.

8.Lee S,Ahn B.Comparison of volatile components in fermented soybean pastes using simultaneous distillation and extraction(SDE)with sensory characterisation.Food Chemistry,2009,114(2):600-609.

9.Li N,Zhang FP,Chen HT,et al.Identification of volatile components in Chinese Sinkiang fermented camel milk using SAFE,SDE,and HS-SPMEGC/MS.Food Chemistry,2011,129(3):1242-1252.

10.Majcher M,Jeleń H H.Comparison of suitability of SPME,SAFE and SDE methods for isolation of flavor compounds from extruded potato snacks.Journal of Food Composition and Analysis,2009,22(6):606-612.

11.Cao PR,Liu KB,Liu CY,et al.Studies on the induction of aromatic constituents in fresh leaves of Lingtou dancong tea by low temperature stress.Journal of Tea Science,2006,26(2):136-140.

12.Zheng PC,Ye F,Gao SW,et al.Effect of spreading time on aroma components in fresh tea leaves.Chinese Agricultural Science Bulletin,2011,27(04):334-338.

13.Zhang LY,Wei Q,Wu Y,et al.Effect of different drying technologies on qualities of Jinmudan oolong tea.Modern Food Science and Technology,2013,29(8):1916-1920.

14.Yao Y,Feng L,Yang J,et al.Aroma composition analysis of Tieguanyin using GC-MS.Southwest China Journal of Agricultural Sciences,2013,26(2):524-530.

15.Ye NX,Yang RX,Yang G,et al.Effects of vacuum freezing dry on the aroma quality of oolong tea.Journal of Tea Science,2006,26(3):181-185.

16.Guo YQ,Zhan ZJ,Jin XY,et al.Formation and changes of aromas during the leaf processing under different conditions in Meizhan tea.Chinese Agricultural Science Bulletin,2007,23(5):115-119.

17.Chen YQ,Ni DJ.A study on formation of flavor in famous green tea.Journal of Huazhong Agricultural University,1997,16(1):91-96.

18.Qian TS,Kang ML,Ling JG,et al.Progress of the Research on Rubs Twists in the Tea Processing Research Development.Academic Periodical of Farm Products Processing,2008,145(8):48-50.

19.Takeo T.Production of linalool and geraniol by hydrolytic breakdown of bound forms in disrupted tea shoots.Phytochemistry,1981,120(9):2145-2147.

20.Guo WF,Yamaguchi K,Watanabe N,et al.A primeverosidase as a main glycosidase concerned with the alcoholic aroma formation in tea leaves.Bioscience,Biotechnology,and Biochemistry,1995,59:962-964.

21.Guo W F,Ogawa K,Yamaguchi K,et al.Isolation and characterization of aβ-primeverosidase concerned with alcoholic aroma formation in tea leave.Bioscience,Biotechnology,and Biochemistry,1996,60(11):1810-1814.

杂志排行

茶叶的其它文章

- Analysis of the Volatile Chemicals of Longjing Tea from Different Production Locations Using Electronic Nose

- Effects of Tannic Acid on Active Aluminum Species Distribution in Various Tea Soils

- The 30-Day Oral Administration Studies of Liposoluble Tea Polyphenols in Rats

- Oxidative Stability of Green Tea Extract-Enriched Rice Bran Oil During Storage

- A Study on Physiological Character of Fresh Tea Leaves in Different Cold-Resistant Varieties

- Stability of Tea Catechins and Antioxidant Properties of Green Tea Extracts as Affected by Boiling-treatment