降低变速器、车桥和转向系统的功率损失(二)

2013-07-06F.-J.JOACHIM,J.BIJRNER,N.KURZ

6 传动系统的近期发展

6.1 电动转向器

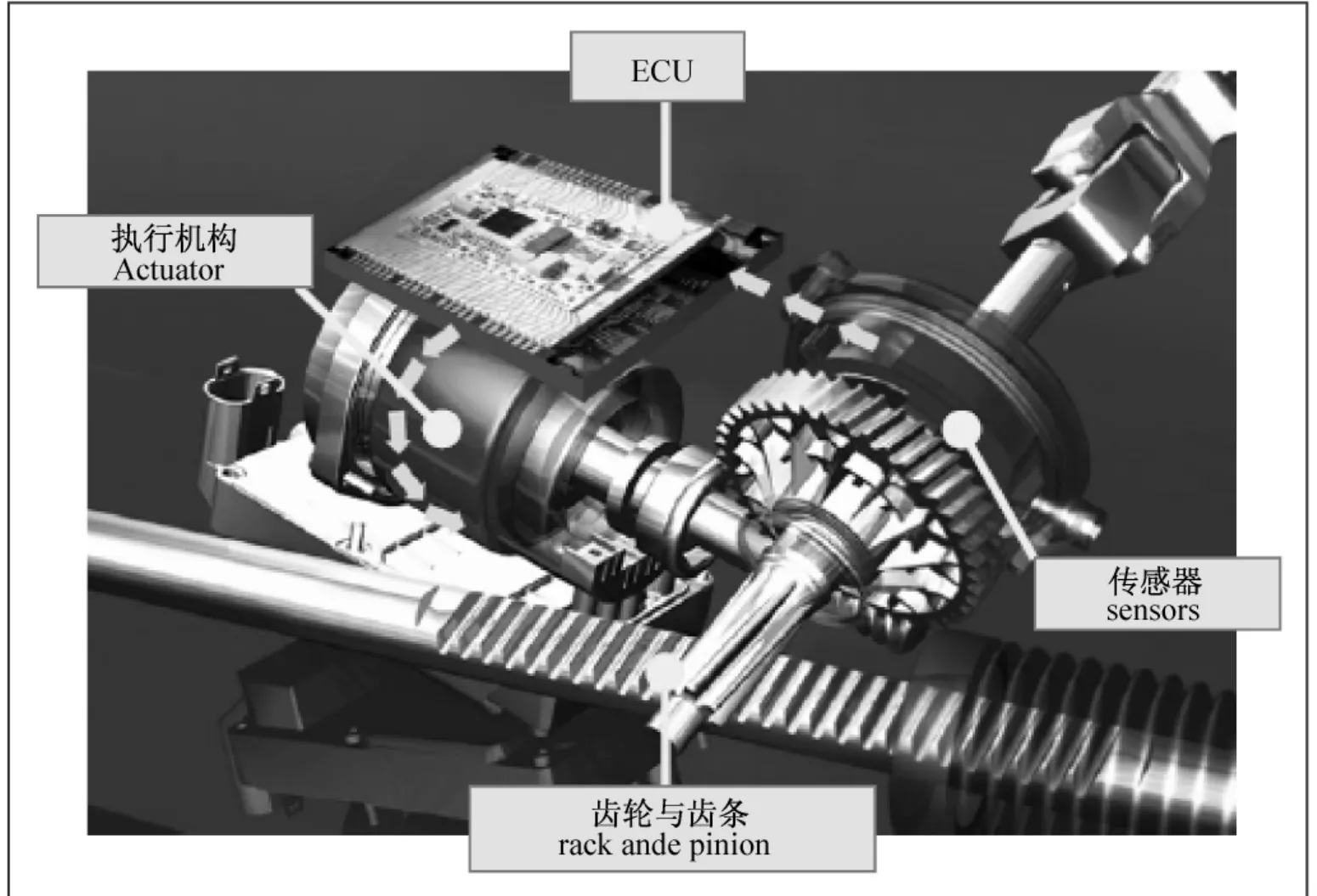

近年来,电动转向器取代了中小型汽车常用的液力转向器。这里采用了不同的设计,即所谓的“双主动齿轮”转向器或管柱型转向器。在设计中,伺服作用通过第二主动齿轮与齿条啮合。其结构详见图18。转向力由驾驶员经转向盘传递给齿轮和齿条。

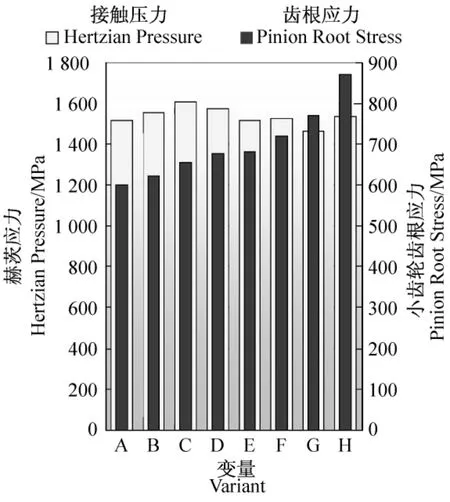

电动机由传感器装置激活,而后者利用一个交叉轴螺旋齿轮对主动齿轮提供支撑。与液力转向器相比,电动转向器无需使用常设能源,相反能源仅在转向时提供。这将明显降低油耗。图1 9是电动转pressure angle was increased additionally at some side steps.Increasing the number of teeth is most effective.Reduced addendum and increased operating pressure angle have less influence.Traces of noise excitation level versus load range of 10to 100%of nominal load are plotted in Fig.15for some examples from Fig.14.Differences are clearly visible and they have to be considered in optimizing gears for low power loss.Improvements can be achieved with adjusted tooth modifications in doing so.Maximum stresses in case of nominal load are shown in Fig.16.Hertzian pressure is nearly constant for all variants.A distinctive increase of root stresses appears over decreasing loss factor from variant A to H.So an inadequate load-carrying capacity can be a result of minimizing power losses by changing tooth geometry.Finally the load distribution along the line of action is also influencing the level of power losses.Tooth loads at begin and end of contact can be reduced by increased tip relief,which decreases their large proportion to overall power loss as shown in Fig.17.Means of relieving start and end of contact for increased load-carrying capacity are also helpful for minimizing power losses of meshing gears.

图17 齿端修缘对功率损失的影响Fig.17 Influence of tip relief on gearing power loss

6 Recent transmission developments

6.1 Electromechanical power steering

图18 一个高度复杂的机电一体化的电动转向器结构图[4]Fig.18 Electromechanical power steering assemblies as a highly complex mechatronic system[4]

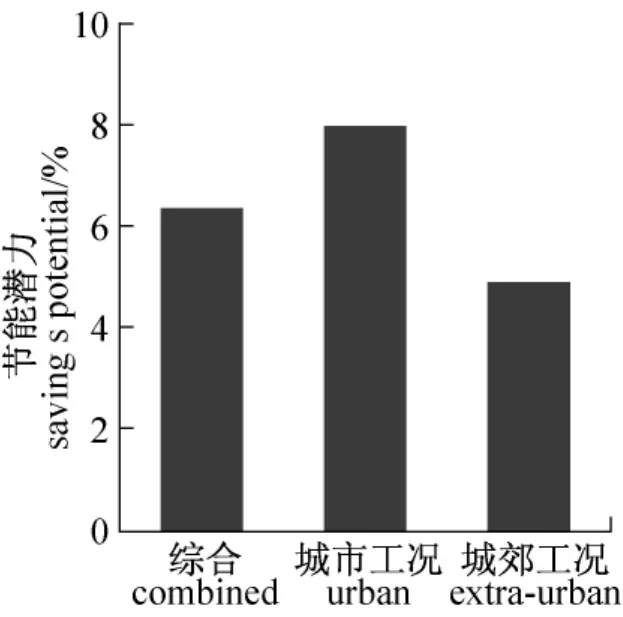

In recent years,hydraulic power steering for向系统在NEDC循环试验中的测量结果。采用电动转向器后可节约6%的油耗。采用一千万套电动转向器共可减少CO2排放930万吨[4]。

6.2 自动变速器

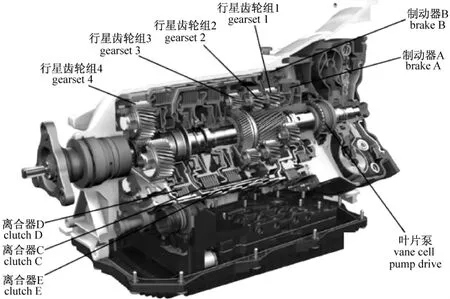

为满足不断增加的降低油耗和CO2排放的要求,ZF公司开发了用于标准传动的8档自动变速器[5]。新一代变速器的目标是为用户带来效益。图20所示的8档变速器具有5套换档机构和4个行星排。传动比范围是7.05。理想的速比范围、高效的齿轮传动效率、平衡的旋转速度以及转矩分流等特点造就了一个高效和紧凑的设计。small and mid-sized vehicles was replaced by electromechanical power steering.There are different designs,so-called“dual pinion”steering system or a column type steering.In this design the servo effect is brought to the rack via a second pinion.Another configuration is presented in Fig.18.The steering impulse is carried from the driver via the steering wheel to a steering pinion and the steering rack.

The electric motor is activated via a sensor unit,which gives the steering support to a steering pinion via a crossed helical gear transmission.In contrast to all hydraulic steering systems,the electric power steering system does not use permanent energy;rather,energy is only used when it is steered.This leads to significant fuel consumption economization.Fig.19shows measurement results with an electrical steering system for a NEDC driving cycle.This subsequently leads to fuel consumption economization of approx.6%through use of the EPS(electric power steering)in comparison to a hydraulic steering system.The use of 10million such steering systems would lead to reductions of approx.9.3million tons of

图19 电动转向系统的节能潜力(NEDC、1 400kg轿车、2l发动机)Fig.19 Conservation potential with electro-mechanical steering systems(New European Driving Cycle,car 1 400 kg,2lengine)

图20 8HP70自动变速器剖视图[5]Fig.20 Transmission section 8HP70[5]

6.2 Automatic transmissions

In order to meet the continually rising requirements in fuel consumption economization and CO2reduction,ZF decided to develop a new 8-speed automatic transmission model range for standard drives[5].Each new generation of transmissions has come with new goals,which bring an improved benefit to the customer compared with the previous generation.The 8-speed transmission,Fig.20,is based on a gear set system with 5shifting elements and 4planetary gear sets.The overall gear spread is 7.05.The harmonic transmission ratio series,the good gear set efficiency as well as balanced ro-tational speed and torque splitting within the transmission provides the conditions for a compact construction as well as good internal efficiency.

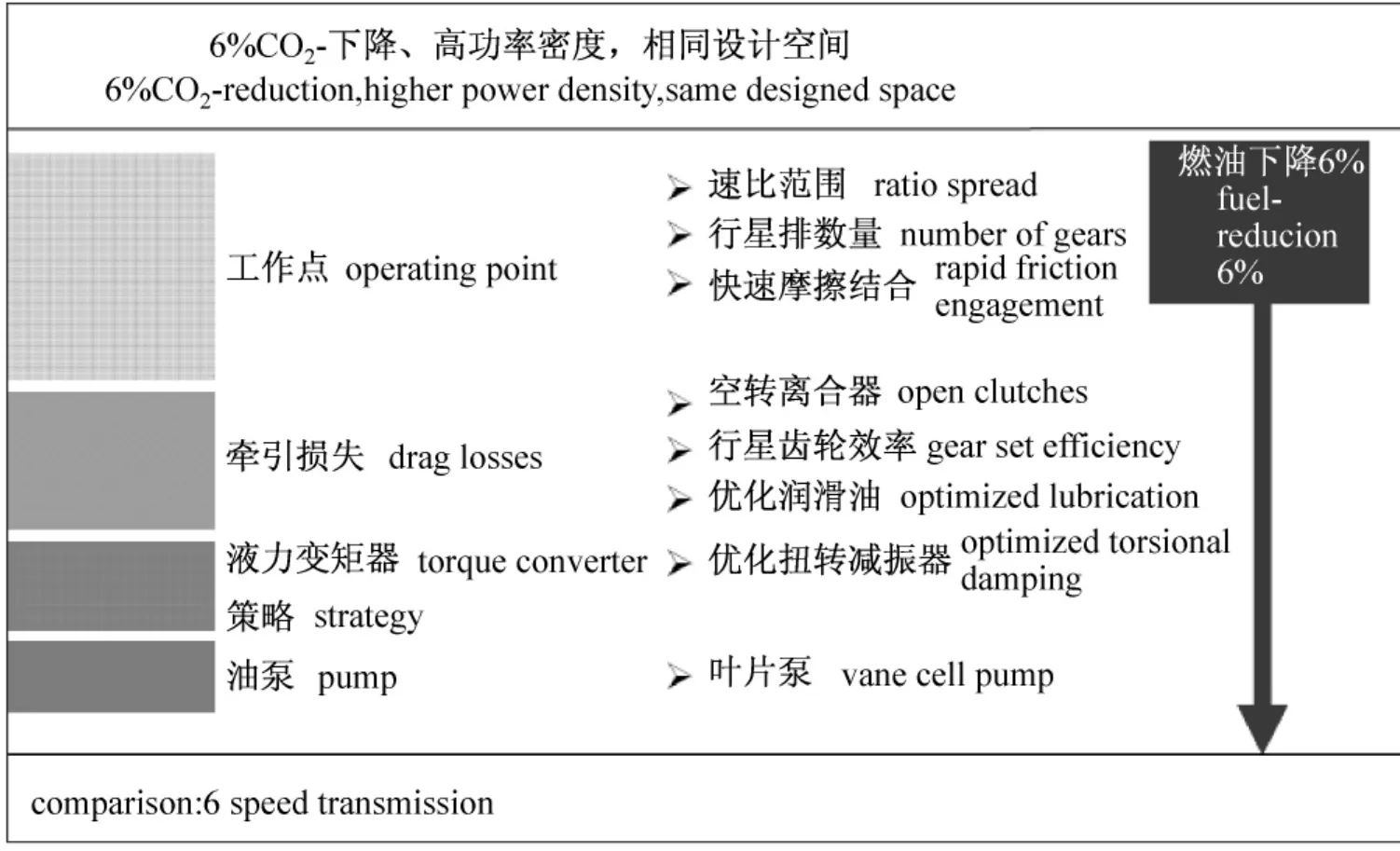

每个行星排具有两个轴类零件。设计空间与上一代6HP28相仿;采用轻量化结构后重量甚至有所降低。变速器采用了一个三相变矩器,其锁止离合器独立调节。根据文献[5],多工况扭转减振器安装在壳体内,对传动系统实施最优调整。为降低油耗,锁止离合器在齿轮起步后能够立即锁止。供油的叶片泵采用平行轴设计,紧靠控制单元,并通过滚子链传动。制动器与离合器的空间和重量最轻,并能以多种方式根据发动机转矩加以调整。变速器壳体只是耐久性的一个方面,壁厚被减少了3 mm。塑料油底壳采用的是上一代变速器的产品。停车锁采用久经考验的锥/爪系统;可采用增强型满足重型车辆或牵引需求。随着能源成本的增加和降低CO2排放,减少油耗自然成为最主要的开发目标。与第二代变速器相比,新变速器能够节省6%的油耗。6%的油耗主要依靠更大的速比范围、更多的行星排、内部牵引转矩减少、高效油泵和离合器切换转速低等因素,详见图21.由于传动系统采用平行开发模式,许多产品可采用相同或相似的部件。变速器可配备不同的起步系统和四轮驱动技术。不考虑尺寸的话,还可集成各种混合动力装置;变速器因而可作为今后的传动系统。这里,车辆起停系统还能节约5%的油耗。当发动机停车时液压蓄能器可通过液压泵驱动变速器。

图21 ZF8档自动变速器的节油途径Fig.21 Measures by ZF to reduce fuel consumption in 8-speed automatic transmissions[2]

This is additionally supported by just two open shift elements per gear.The design space is comparable to the 6HP28forerunner transmission;the weight was reduced even further with a lightweight construction.A new triple-line converter is used in the transmission,with the lock-up clutch regulated by a separate line.According to[5],various torsion damper systems are available in the building set,in order to enable an optimal adjustment to the particular driveline.For consumption reasons,the luck up clutch can be closed immediately after the start-up operation.For the oil supply,a vane cell pump was developed parallel to the axle,lying close to the control unit and powered via a roller chain.Wheel sets and clutches are constructed with optimized design space and weight,and can be adjusted to the engine torque in various configurations.The transmission housing is one-sided because of rigidity,and the wall thickness was reduced locally to 3mm.The plastic oil pan was largely carried over from the forerunner transmission.The parking lock is based on the proven cone/catch system;a strengthened version is available for heavy vehicles or trailing loads.In these times of increasing energy costs and requirements for lower vehicle CO2emissions,the reduction of fuel consumption was naturally one of the primary development goals.A significant value was achieved,with a contribution of 6%as compared with the 2nd generation 6-speed transmissions Approx.6%better fuel consumption results from the larger transmission-ratio spread and greater number of gears,the reduced internal drag torque,the efficiency-optimized pump and the low converter clutch rpm connections Fig.21.Because of the parallel development of transmissions within the model range,many synergies can be exploited by using similar or identical parts.The transmissions can be equipped with different starting systems and 4WD technologies.Regardless of the dimensions,micro hybrid,mild hybrid and hybrid systems can be integrated;the transmission is therefore well equipped even for future drivelines.Meanwhile,there is also a start/stop function that leads to a fuel consumption reduction of approx.5%.A hydraulic impulse accumulator provides the transmission with hydraulic oil while the engine is still at a standstill.

6.3 商用车自动变速器

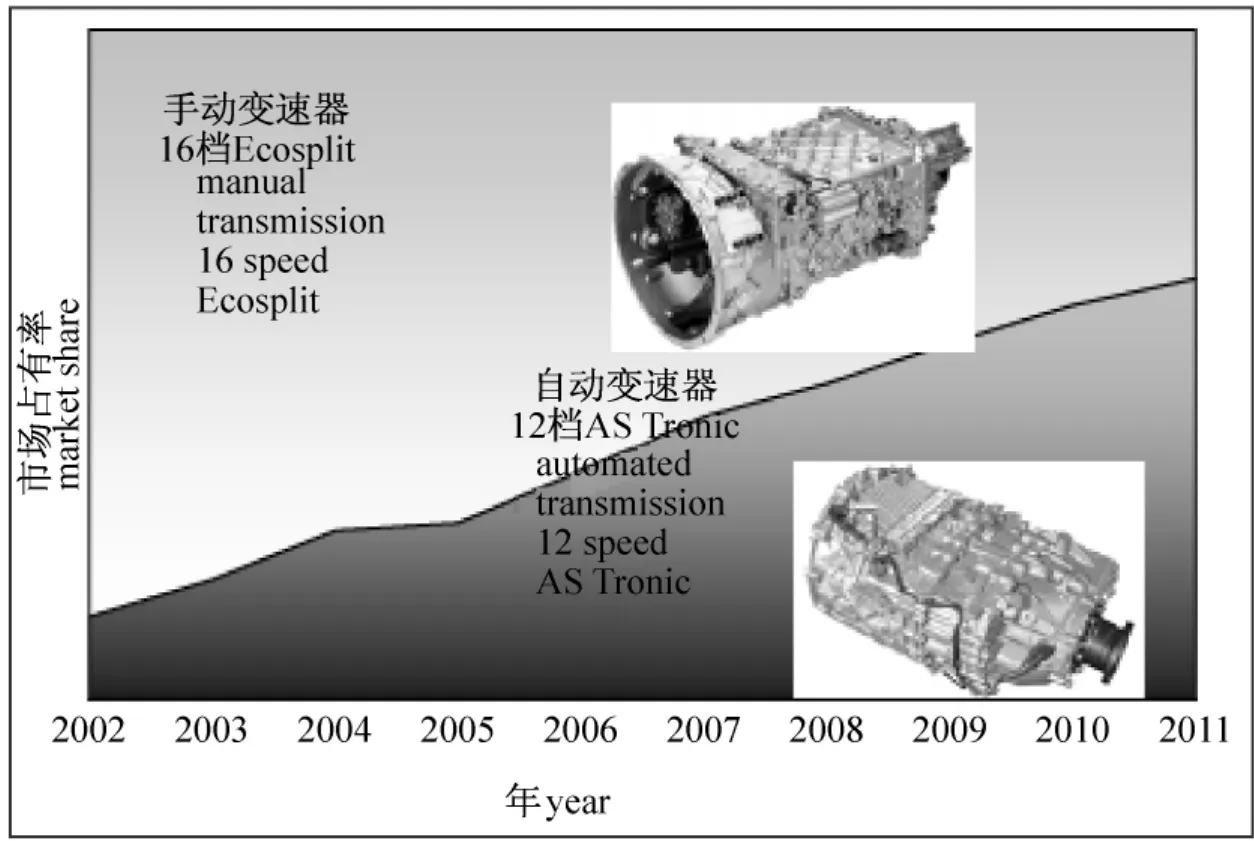

商用车发动机的平均驱动转矩增长相当迅速。其主要原因是发动机技术的提高。汽缸容积相同时输出转矩/功率均增加。由于运输量和运输效益的提升,也要求提高车速。这些都要求增加输出转矩。随地区和应用场合不同,平均转矩每年增加20至30Nm[6]。随着EURO6标准发动机在2014年的启用,转矩大于3 000Nm将变得可能。是否所有种类的变速器都需要满足顶层要求。显然手动变速器除去,主要依靠AS Tronic自动变速器。在欧洲自动变速器的份额约为50%,详见图22。自动变速器的应用场合是多样化的。

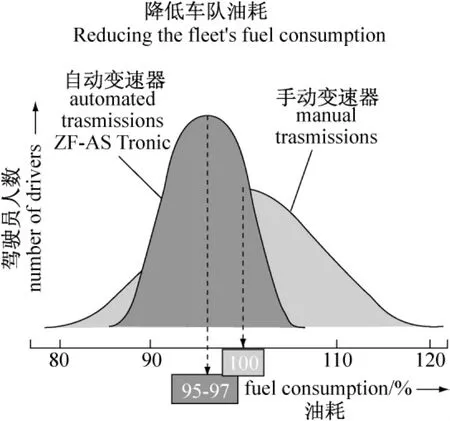

虽然在德国轿车CO2排放应下降11%而商用车仅需下降5%,ZF公司仍然发现了为此作出贡献的需求和机会。相关的措施有减轻变速器重量、优化车辆和变速器相互影响、智能化行驶策略以及进一步优化已相当高的变速器效率(约99%,MT/AT直接档)等。根据文献[6],紧凑和高效的AS Tronic系列自动变速器具有转矩/重量高、智能化行驶功能以及与车辆、发动机最优共同工作等特性,相比手动变速器能够节省3-5%的油耗。通常一个优秀的驾驶员即便使用手动变速器也有很好的效果。但是作为一个车队的平均值,从星期一工作到星期五,自动变速器在任何情况下都有一个满意的结果,见图23。驾驶员能够不受繁忙的交通所累。变速器可提供如同轿车那样的舒适性。同时还能改善道路安全性。还可利用扩大传动比实现油耗和CO2排放的进一步改善(40吨货车的变速器传动比可达17:1或更高)。相对于所谓的超速档变速器(OD),ZF通常采用直接档(DD)传动。在长距离行驶时,90%采用最高档传动。直接档作为最高档传动时可节省额外的0.4-0.5l/100km油耗。重要的是具有足够的档位数以降低油耗,这样发动机能够总是工作在最佳油耗点。这里货车是先驱者,通常有12档或16档。

图22 AS Tronic在欧洲重型商用车自动变速器的市场占有率Fig.22 Market development for automatic transmissions for heavy commercial vehicles in Europe with the example of AS Tronic

图23 自动变速器降低车队的油耗[3]Fig.23 Reduced fleet consumption with automatic transmissions[3]

6.3 Automated commercial vehicle transmissions

The median driving torque of commercial vehicle engines is growing steadily.The reasons for this are advances made in engine technology.More torque/power is achievable from the same piston displacement.Because of the rising transport volume and the pressure on the transport efficiency,possible speeds are also rising,where permitted.This pushes drive torque up.The median torques have risen up to now,according to region and application,between 20and 30Nm per year[6].With EURO 6engines starting in 2014,torque of significantly more than 3 000Nm will be possible.It remains to be seen whether all transmission types will be desired for the top transmission segments.It is conceivable to do without manual transmissions in these segments and to rely on automatic AS Tronic transmissions.The market share in Europe for automatic transmissions is almost 50%,Fig.22.The applications of automatic transmissions are extremely versatile.

Although 11%of CO2emissions in Germany come from passenger cars and only 5%from commercial vehicles,ZF sees the need and the opportunity to make an appropriate contribution.These relate,among others,to the reduction of the transmission weight,the optimal interplay of vehicle and transmission,an intelligent driving strategy,as

图24 驱动桥降低CO2排放的潜力[2]Fig.24 Possibilities for CO2reduction with rear axle transmissions[2]