Metamorphic Manipulating Mechanism Design for MCCB Using Index Reduced Iteration

2013-03-01XUJinghuaZHANGShuyouZHAOZhenandLINXiaoxia

XU Jinghua, ZHANG Shuyou, ZHAO Zhen, and LIN Xiaoxia

State Key Laboratory of Fluid Power Transmission and Control, Zhejiang University, Hangzhou 310027, China

1 Introduction

Moulded case circuit breaker(MCCB), namely low voltage(less than 1 kV) circuit breaker, is an automatically operated electrical switch designed to protect an electrical circuit from damage caused by overload, short circuit,under voltage and phase failure. Its basic function is to detect a fault condition and, by interrupting continuity, to immediately discontinue electrical flow. MCCB is widely used in power distribution branches, such as electric power locomotive, CNC machine tools and complete sets of electromechanical equipments.

The metamorphic manipulating mechanism is crucial to the current-limiting interrupting performance of MCCB. A metamorphic mechanism has the property that the effective number of DOF changes during the movement of the device under complicated working conditions. This means the kinematic structural representation of a metamorphic linkage has different forms in which vertices and edges combine depending on the configuration of the device[1–2].

In recent years, many scholars have studied the mechanism or product design and proposed many design methods[3–9]. DAI, et al[10], analyzed the difference between metamorphic mechanism and deployable mechanism,kinematotropic mechanism and discontinuity mobility mechanism. ZHANG, et al[11–12], proposed kinematic reverse design, product structure modeling method for mechanism and product design. Ref. [13] uses the equation of motion to analyze the dynamic response of the spring type manipulating mechanism. In Ref. [14], direct numerical simulation of the first three milliseconds following ignition of the arc in a low-voltage circuit-breaker is proposed using a computationalfluid-dynamics code adapted for electric-arc modeling. In Refs. [15–16], multiobjective constrained optimal synthesis of mechanisms is realized using a new evolutionary algorithm. In Ref. [17], constraint analysis on mobility change of a novel metamorphic parallel mechanism is realized. In Ref. [18], the effect of different vent configurations including middle vent and side vent on the interruption performance is investigated based on a simplified model of arc chamber with a single break, which can be opened by the electro-dynamics repulsion force automatically. Ref. [19] proposes a Bayesian methodology to assess the performance of circuit breaker utilizing its control circuit data. Ref. [20] uses improved empirical mode decomposition energy entropy and multi-class support vector machine to diagnose fault for high voltage circuit breaker. In Ref. [21], the evaluation of time measurements in case of different failures is carried out for two circuit-breaker solutions, i.e. with spring and hydraulic drive. Ref. [22] presents the results of the degree of irreversible changes of dielectric properties of vacuum circuit breakers with CuCr and CuBi contacts before and after short-circuit breaking operations. Ref. [23] uses the constraint graph of computational geometry rather than the traditional topological graph to characterize a metamorphic linkage in order to simplify the representation of configuration changes. In Ref. [24], degree of motion constraint and its algorithm are put forward to add motion constraints among parts automatically for a MCCB multibody system. LIN, et al[25], focused on the application of asymmetric distributed loads on parts based on the eigenfunction distribution of FEM. ZHAO, et al[26], focused on the efficiency when the step small enough to guarantee the solution stability and precision of MCCB.

The above methods promote the design quality of mechanism or product design. However, it is difficult to obtain the instantaneous and short time breaking characteristics of flexible metamorphic mechanism because of inaccuracy during small step iteration. Therefore, a metamorphic manipulating mechanism design method for MCCB using IRI is put forward which mainly contains:current-limiting interrupting process of metamorphic manipulating mechanism of MCCB; rigid-flexible coupling multi-body dynamics resolution of metamorphic manipulating mechanism for MCCB based on IRI;metamorphic manipulating mechanism design process via multiobjective optimization. The independent prototype design system has been developed to verify the proposed method.

2 Current-Limiting Interrupting Process of Metamorphic Manipulating Mechanism of MCCB

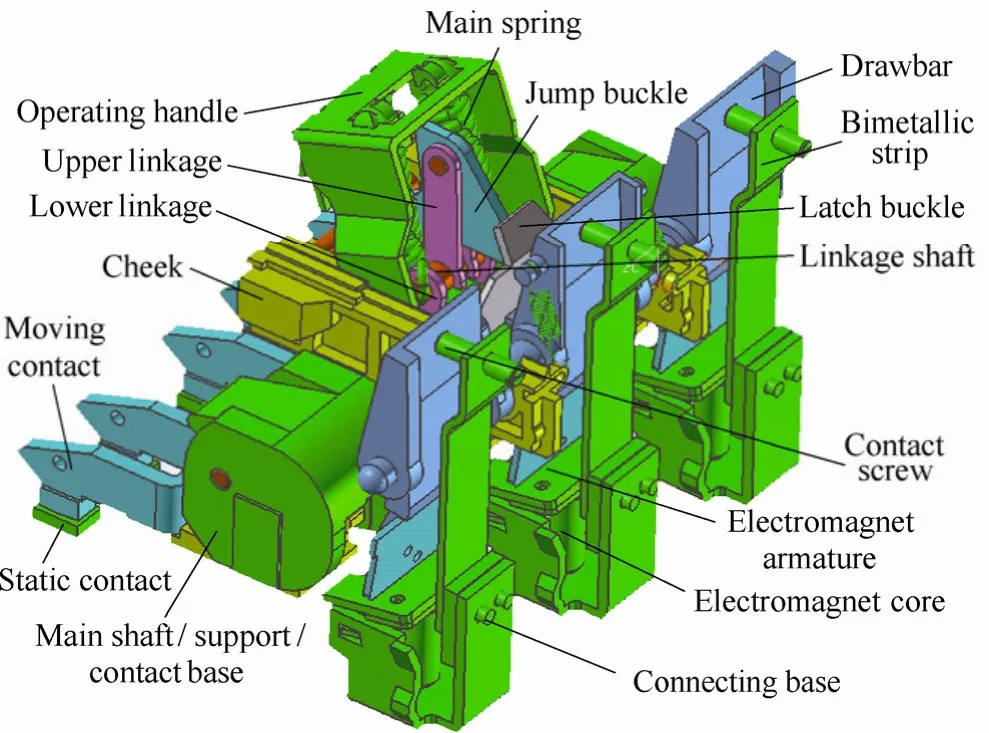

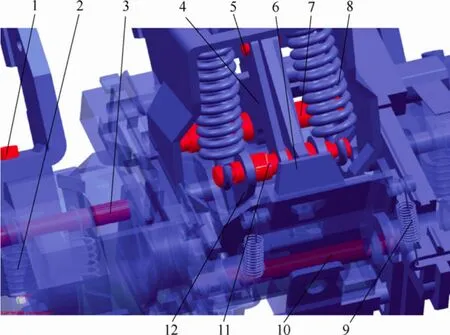

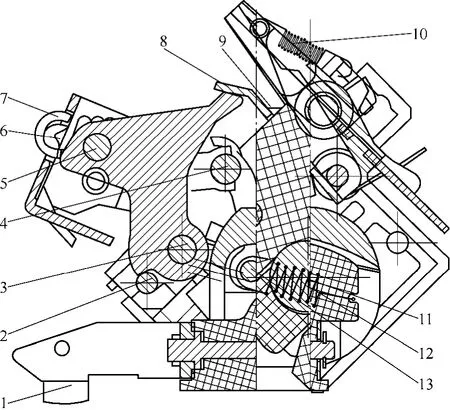

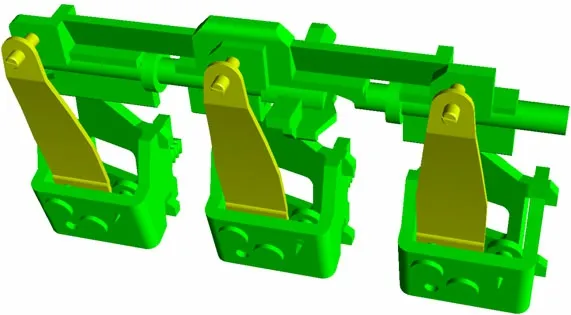

The DOF of main switch connector changes, therefore,the manipulating mechanism of MCCB can be considered as a kind of metamorphic mechanism. Miniature low-voltage circuit breakers (rated current not more than 100 A) use air alone to extinguish the arc. It avoids the contact floating or bouncing at closure and during any inrush current under short circuit conditions. The MCCB is shown as Fig. 1–Fig. 3.

Fig. 1. Geometric assembly model of metamorphic mechanism

Fig. 2. Metamorphic manipulating mechanism of MCCB

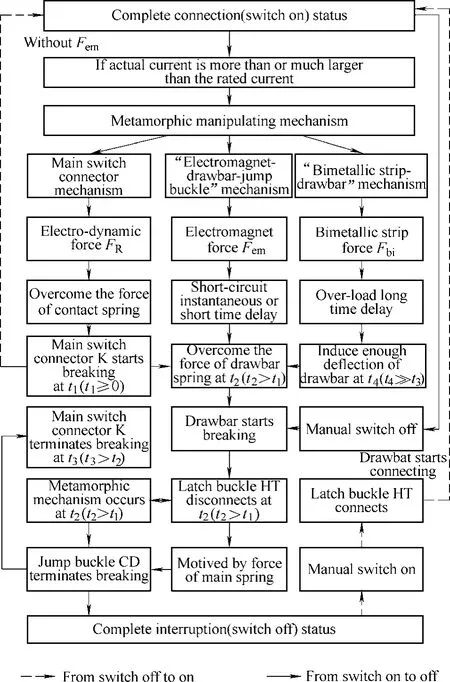

Fig. 4 shows the interruption process of MCCB. If the actual current is more than or much larger than the rated current, the jump buckle CD will execute action, Lock catch HT will turn which results in the freedom of T, then,Jump buckle CD will rotate around point C under the action of the spring JB, the point D becomes active point, the upper linkage BD and the lower linkage AB have no constraints, the mechanism becomes five-bar linkage from four-bar linkage. The DOF of MCCB is changing from one to two, so the circuit is protected.

Fig. 3. Two dimensional full section view of MCCB

Fig. 4. Current-limiting interrupting process of metamorphic manipulating mechanism of MCCB

If we want to switch on manually, push the operating handle, let it rotate around point O. Then the main spring JB turns with the handle JO and stores mechanical energy because of tensile strain. When the force direction of the main spring JB is the same with upper linkage BD, the spring has the maximum mechanical energy. Once the main spring JB passes across the upper linkage BD, point B will move under the action of the main spring JB, then, the lower linkage AB pushes the main switch connector K to close. After the thorough close of K, the upper linkage BD and the lower linkage AB are all at the dead center position.

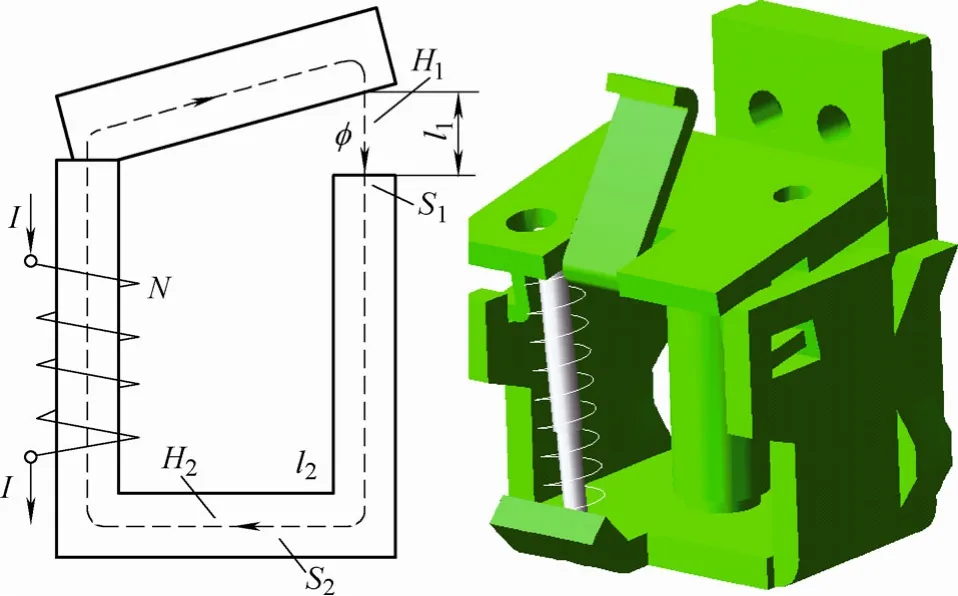

The metamorphic manipulating mechanism of MCCB is decomposed into three mechanisms: main switch connector mechanism, electromagnet-drawbar-jump buckle mechanism,and bimetallic strip-drawbar mechanism which is respectively described by electro-dynamic force,electromagnet force, and bimetallic strip force which are shown as Fig. 5–Fig. 7.

Fig. 5. Electromagnet trip break mechanism

Fig. 6. Bimetallic strip break mechanism

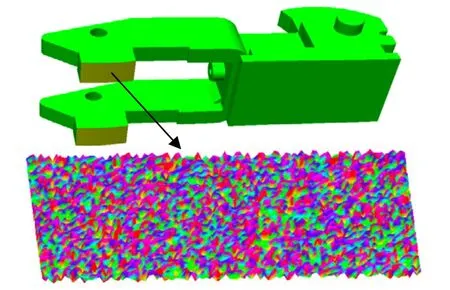

Fig. 7. Main switch connector mechanism

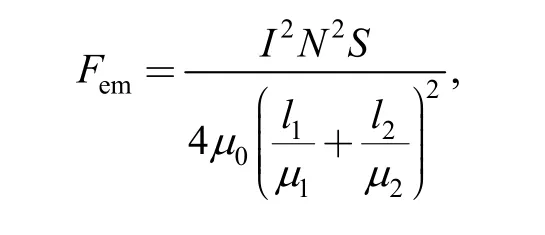

The attraction force of electromagnet trip mechanism Femcan be obtained by Maxwell formula and Ampere’s circuital law:

where I—Actual current,

S—Cross sectional area of electromagnetic iron-core,

μ1,μ2—Magnetic permeability,

μ0—Permeability of vacuum,

l—Magnetic flux path,

N—Coil turn.

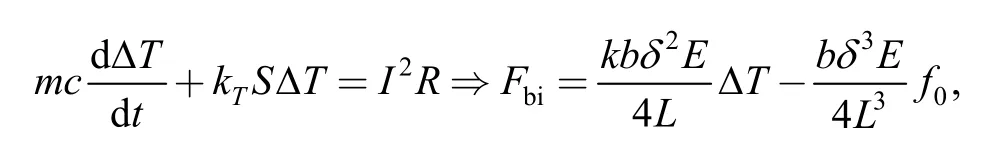

The pushing force of bimetallic strip Fbican be obtained by thermodynamic energy equation:

where m—Mass of bimetallic strip,

S—Surface heat transfer area,

R—Electrical resistance of heating body,

c—Specific heat capacity of bimetallic strip,

k—Specific thermal deflection,

b—Width of bimetallic strip,

δ—Thickness of bimetallic strip,

L—Length of bimetallic strip,

E—Young’s modulus of elasticity,

Δ T—Temperature rise.

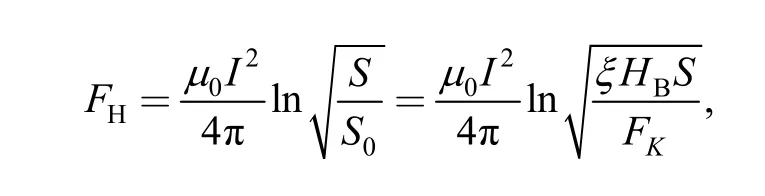

The electro-dynamic repulsion force FRcontains the Holm force FHand the Lorentz force FL.

The contact area is far less than the contact surface area because the contact surface is always rough in microscopic scales shown in Fig. 7. Then, the current elements shrink at the contact point which leads to repulsion force. The Holm force FHis caused by current constriction and skin effect which exists only during contact process of the main switch connector K:

where S—Cross sectional area of contact point K,

S0—Effective contact area,

ξ—Contact coefficient which is about 0.3–1,

HB—Brinell hardness of contact point (N/mm2),

FK—Contact force of contact point K.

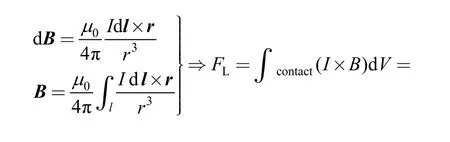

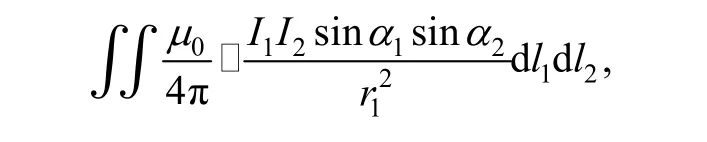

The Lorentz force FLcan be obtained by Biot-Savart law which exists till electric arc extinguishing. FLdepends on current and contact angle of K:

where dB—Magnetic flux density due to Id l,

α—Vector angle of current element,

r—Position vector from dI l to point P.

3 Rigid-flexible Coupling Multi-body Dynamics Resolution of Metamorphic Manipulating Mechanism for MCCB Based on IRI

The parts with large deformation should be considered as flexible body rather than rigid body, such as long linkage type, long shaft type. Index reduced iteration(IRI) means converting the higher order differential equations into lower order differential equations to improve iteration stability in each integration step.

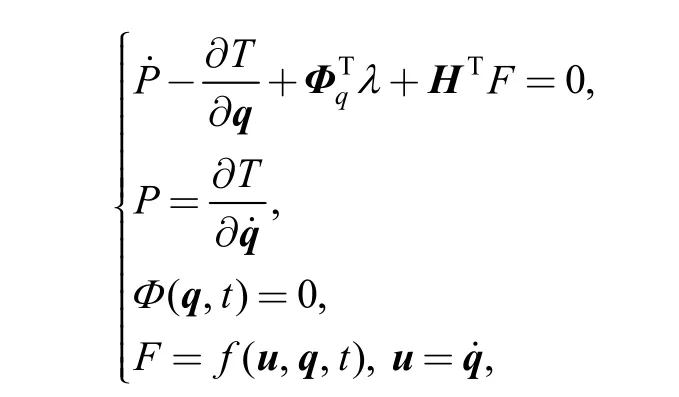

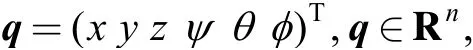

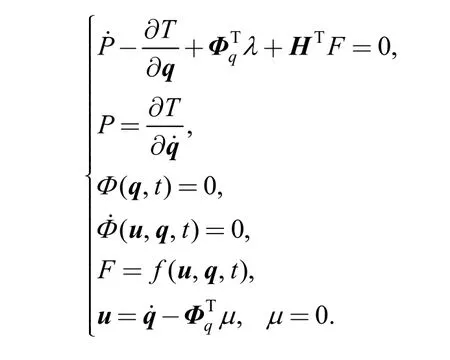

The differential order refers to derivation number, neither matrix size nor power exponent. The dynamics questions are expressed with differential algebraic equations(DAEs),which are also called Euler-Lagrange Equations. For dynamics questions, the inputs are the constraints of the kinematic pairs, the preset initial generalized coordinates of each rigid body, while the outputs are the generalized coordinates (position, velocity and acceleration) of each rigid body at any time in global coordinates system. The DAEs are as follows:

(x y z) —Cartesian coordinates of mass center of rigid body,

(ψ θ )φ —Euler angles of rigid body,

t—Time coordinate,

T—Kinetic energy of the system,

P—Generalized momentum of the system,

H—Coordinates transformation matrix of external force,

λ—Lagrange multiplier for constraint equations,λ ∈Rm,

Φ —Constraints of the kinematic pairs,m,Φ ∈R

where m—Number of constraints, number of the kinematic pairs,

n—Number of rigid and flexible body,

6n—Number of generalized coordinates.

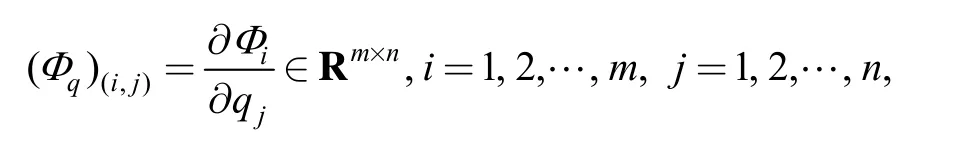

The generalized coordinates q of rigid body can be decomposed into independent coordinates and nonindependent by full rank factorization of matrix of constraints Φ of the kinematic pairs. The independent coordinates are solved by integration iteration while the non-independent coordinates are solved by non-linear algebraic equations resolution.

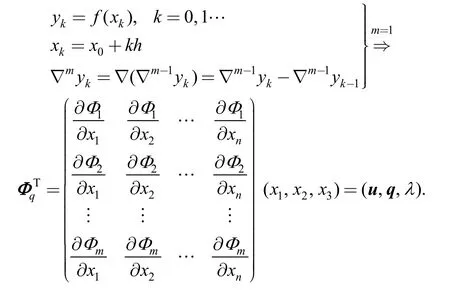

Jacobian matrix of constraint equationscan be obtained by derivation of ( u q λ ) through m order backward differentiation formula (m=1):

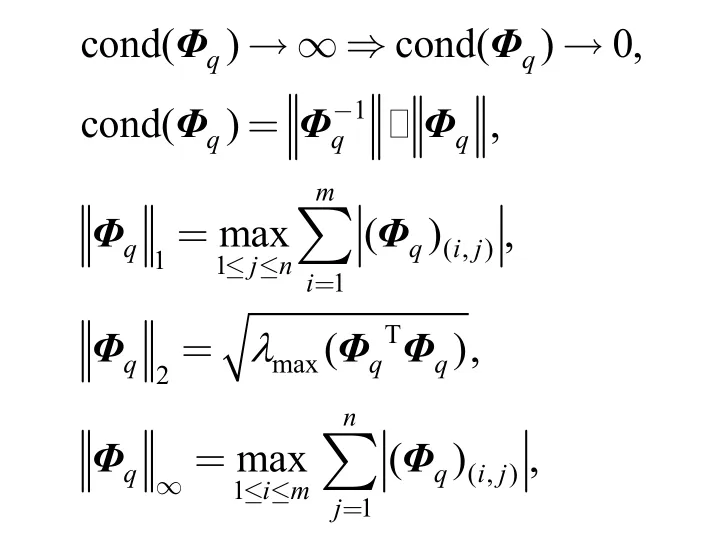

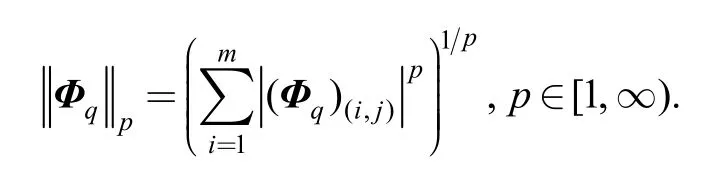

The nonlinear algebraic equationsare solved by improved Newton-Raphson iteration algorithm. When the integration step approaches zero, Jacobian matrixbecomes into ill-conditioned matrix, therefore,an IRI method is applied to analyze metamorphic manipulating mechanism:

After using IRI method, condition number cond(Φq)calculated by normof Jacobian matrixdecreases from +∞ to zero. There is no violation during calculating Φ and Φ˙.

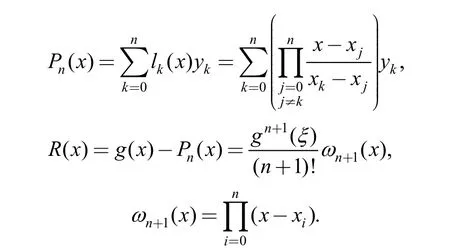

After obtaining generalized coordinates q of rigid body,the n order interpolation polynomialis constructed to obtain the derivative of the function g (x):

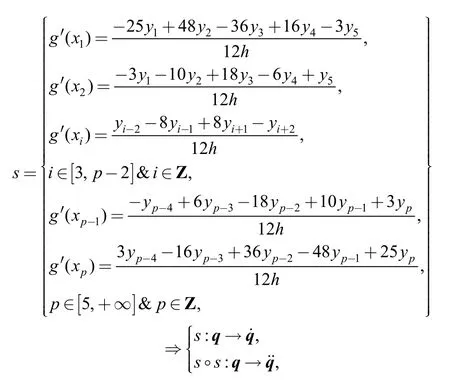

R (x) represents truncation error. When k= 5, we can get the numeric differential expression with five discrete points based on Lagrange interpolation polynomial. Thus,if we get the resultant displacement of main switch connector, we can use Lagrange interpolation polynomial rules s to obtain the velocity and acceleration[27]:

where ◦ stands for composite mapping.

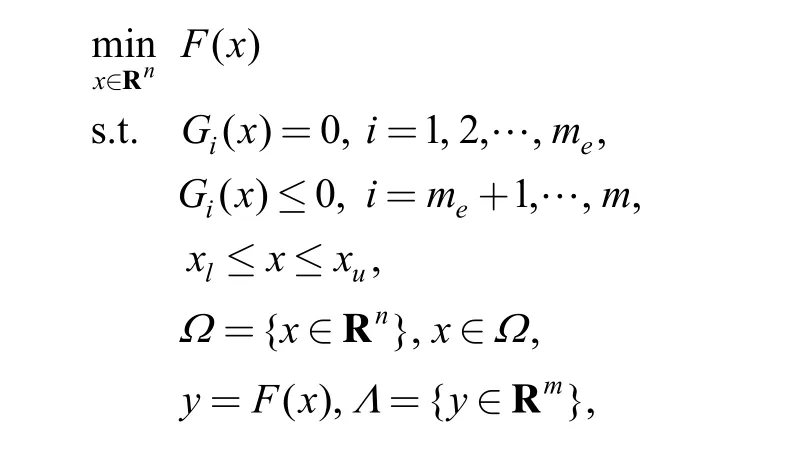

4 Metamorphic Manipulating Mechanism Design Process via Multiobjective Optimization

Metamorphic manipulating mechanism design for MCCB can be converted into a multiobjective optimization model:

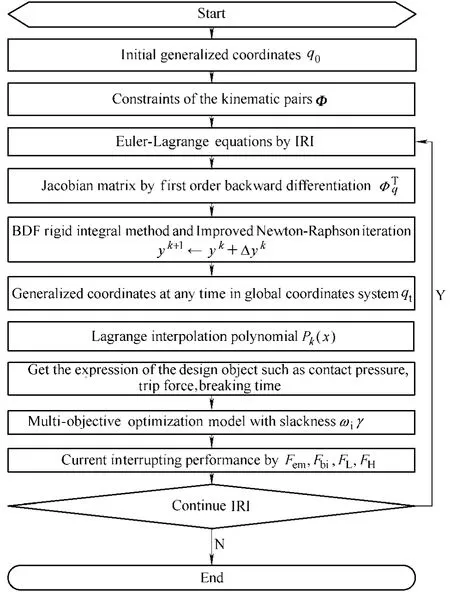

The flowchart of the metamorphic mechanism synthesis is shown in Fig. 8.

Fig. 8. Metamorphic manipulating mechanism design process via multiobjective optimization

5 Example of Metamorphic Manipulating Mechanism Design for MCCB

The independent prototype design system using ACIS R13, HOOPS V11.0 and Visual C++.NET 2003 has been developed to verify the proposed method. The break velocity of the manipulating mechanism of the MCCB means the average velocity during the process from tripping to thoroughly breaking off. The more quickly the break velocity is, the shorter the breaking time is. We make the maximum break angular velocity as the main desired design object during the process from the dead center position to extreme position. The status when MCCB completely closed is taken as initial condition.

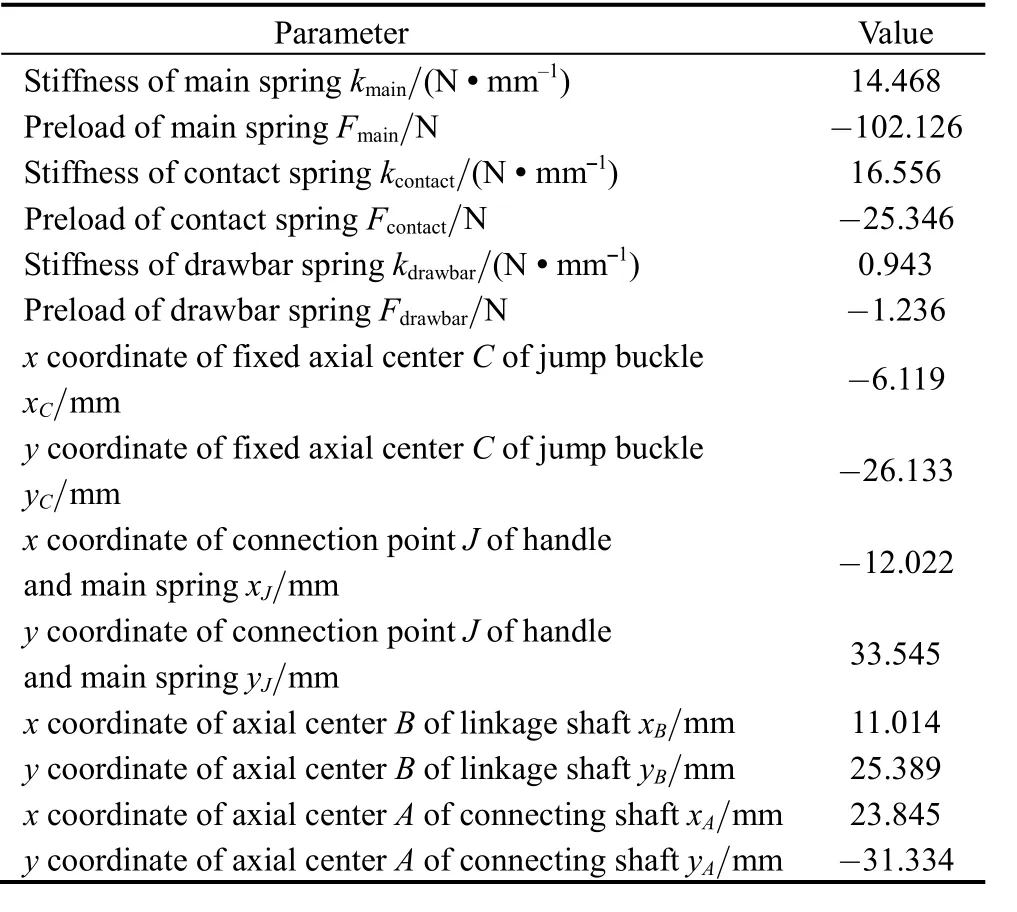

The key known parameters of metamorphic mechanism are shown in Table 1.Kθ stands for opening angle of main switch connector K, means the angle between moving contact and fixed contact across the main shaft. IfKθ is too small, it will cause electric arc reignition.KL stands for opening resultant displacement of main switch connector K, means the motion resultant displacement of the centroid of main switch connector in global coordinate system. vKstands for linear velocity of main switch connector K, means the resultant velocity of the moving connector in global coordinate system. aKstands for linear acceleration of main switch connector K, means the resultant acceleration of the moving connector in global coordinate system. Ftripmeans the minimum trip force which is enough to trigger tripping automatically of latch buckle.

Table 1. Key parameters of metamorphic mechanism when MCCB completely closed

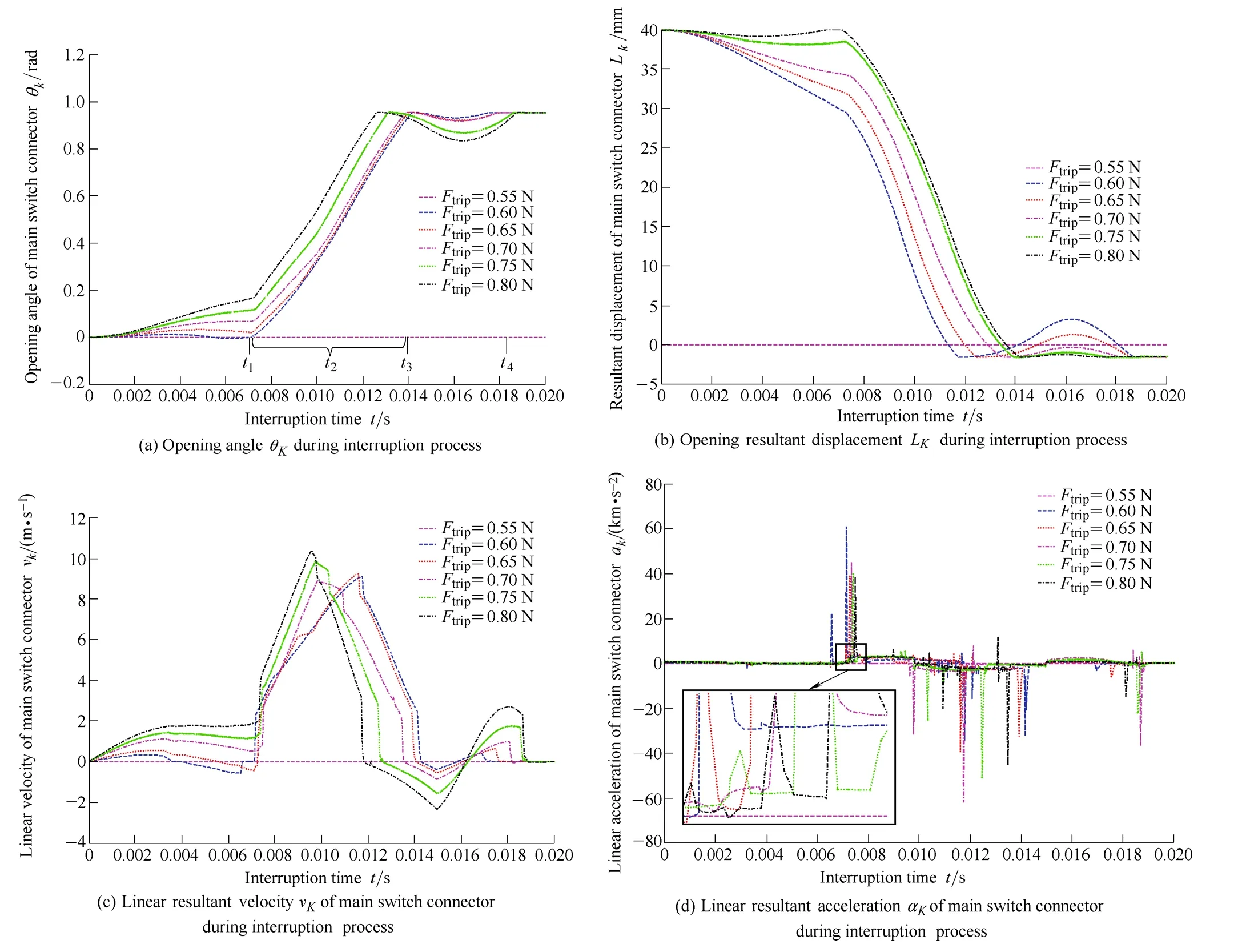

The breaking performance obtained by IRI is shown in Fig. 9 and Table 2. From Fig. 9(a), we can know that main switch connector K starts breaking due to electro-dynamic repulsion forceRF or pushing force of bimetallic strip Fbiat t1. The metamorphic mechanism occurs just when the latch buckle HT disconnects at t2, concurrently, the jump buckle CD/CT starts breaking due to electromagnetic force Fem, manipulating mechanism becomes five-bar linkage from four-bar linkage. The metamorphic manipulating mechanism endures impact vibration at t3. The jump buckle terminates breaking and K breaks thoroughly at t4.

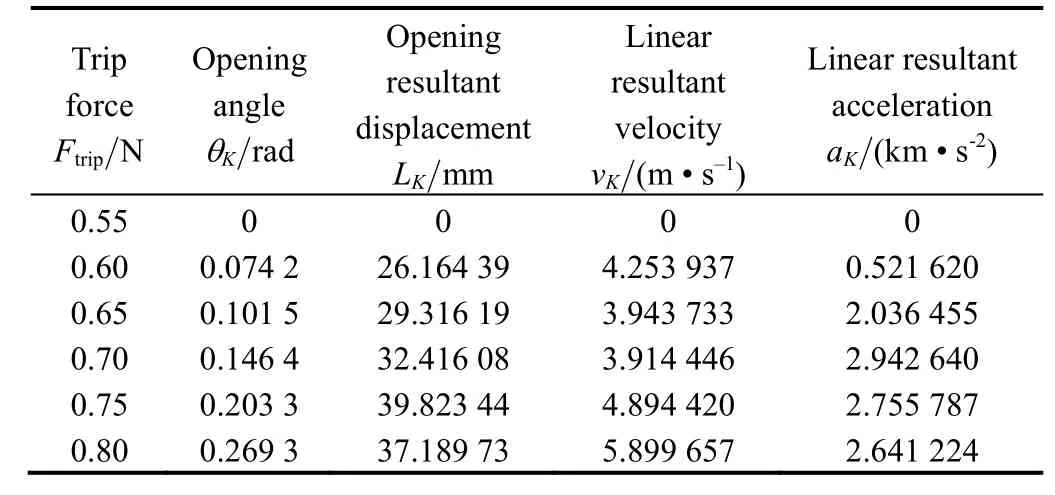

If we want to determine the precise minimum tripping force, we can first divide the rough interval 0.5–0.8 N into six trial force and calculate the opening angle, opening resultant displacement, linear resultant velocity, linear resultant acceleration, based on these values, we can further determine that the minimum tripping force is 0.55–0.60 N.If we want to know the more precise minimum tripping force, we use Index Reduced Iteration method and repeat the process whose results are shown in Table 2. The metamorphic mechanism analysis can’t be precededwithout IRI method, because the step size h of Newton-Raphson iteration reduces to zero and condition number of Jacobian matrix approaches plus infinity

Fig. 9. Breaking performance verified by ADAMS simulation

Table 2. Parameters of MCCB during interruption process at a given time using IRI

The parts of the metamorphic mechanism have more than one functional direction of strains and stress. The three principal stresses are labeled σ1, σ2, and σ3. The principal stresses are ordered so that σ1is the most positive (tensile)and σ3is the most negative (compressive). The Von Mises or equivalent stresseσ is employed to determine the combined strength analysis:

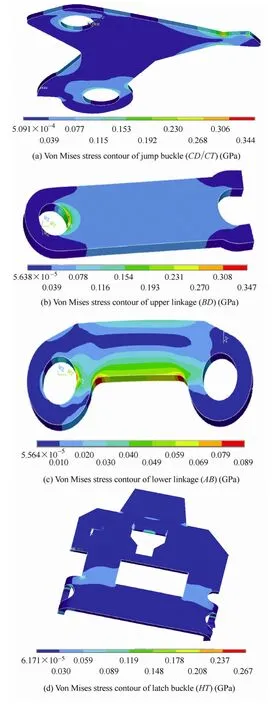

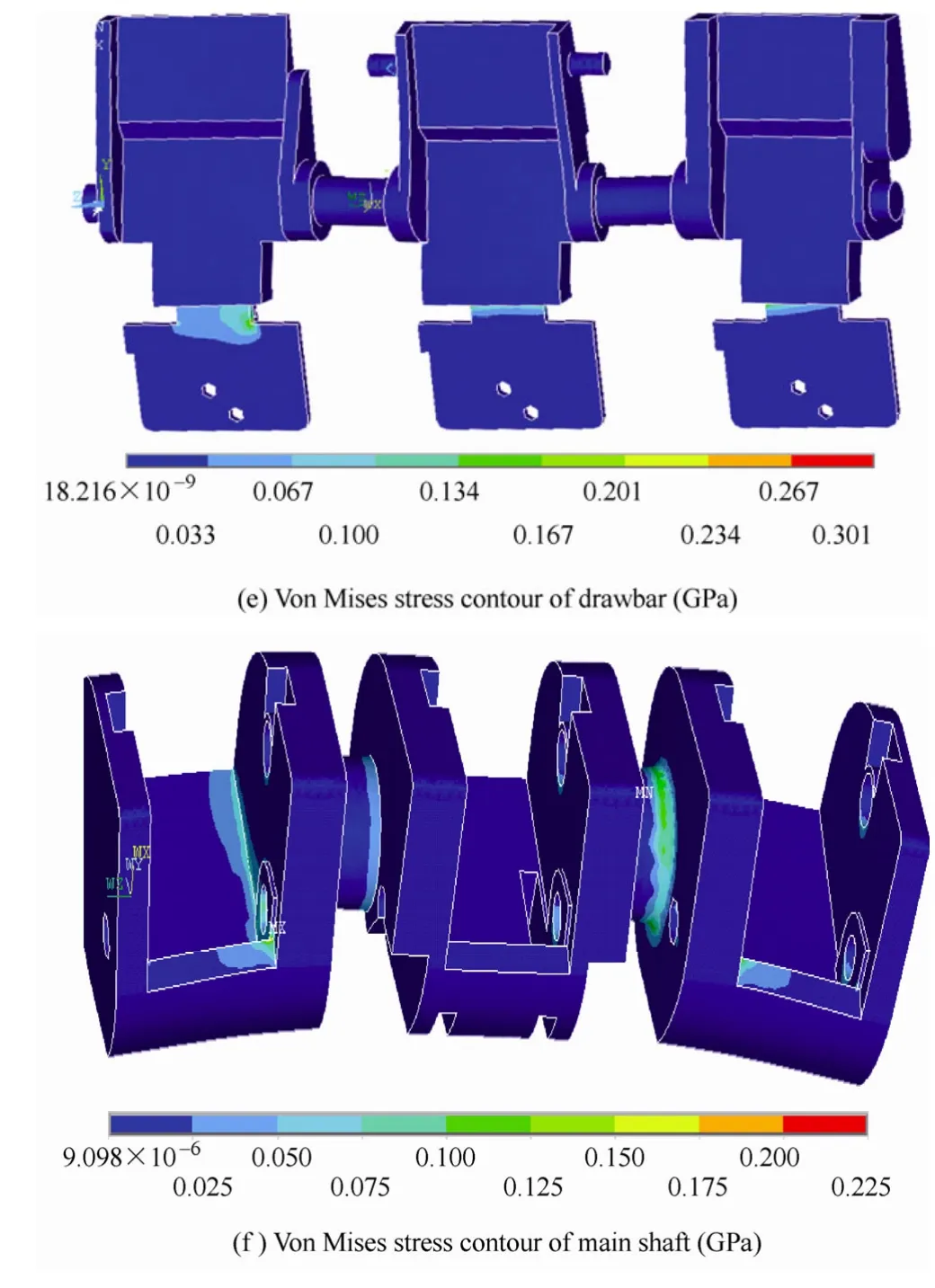

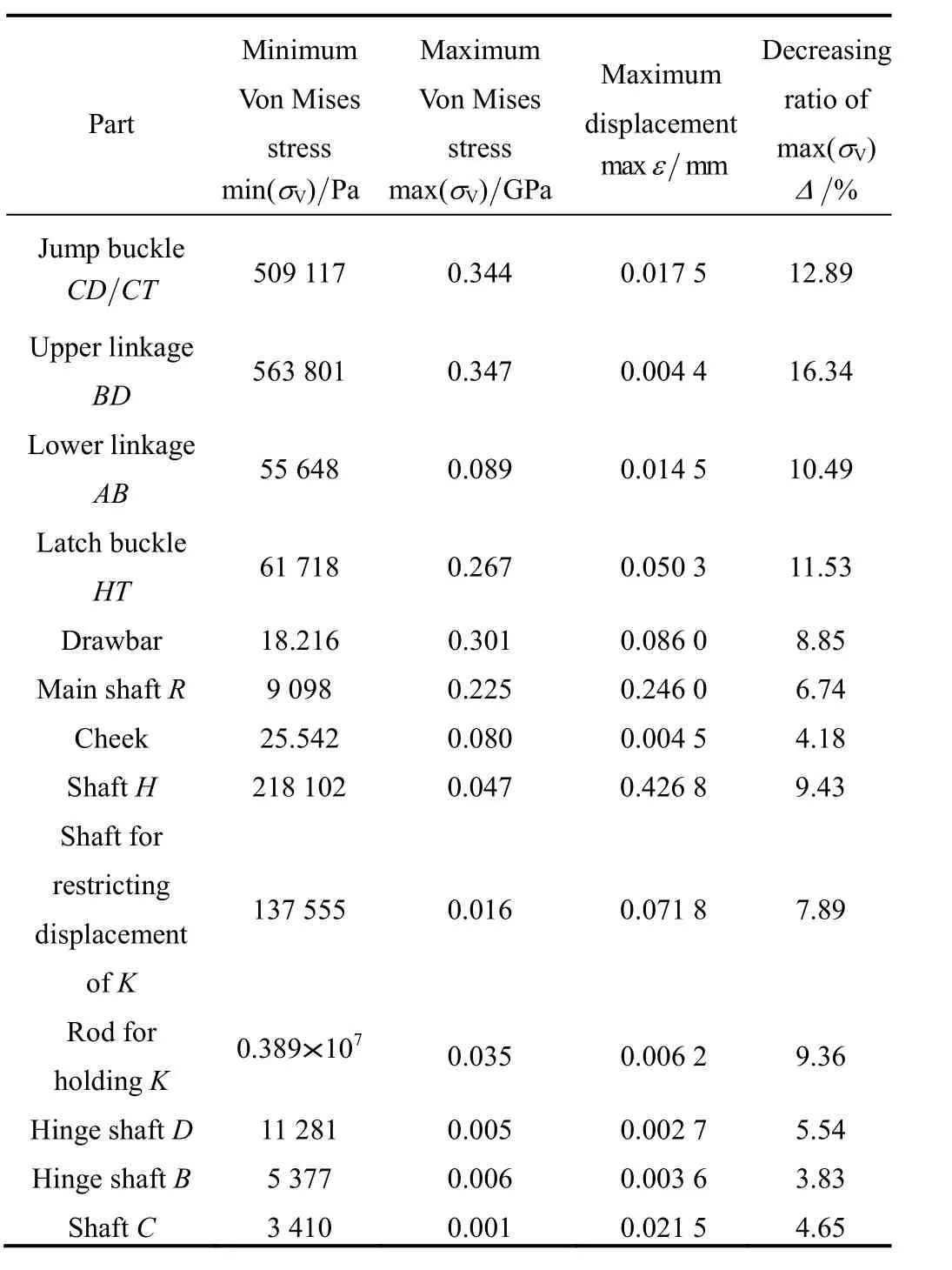

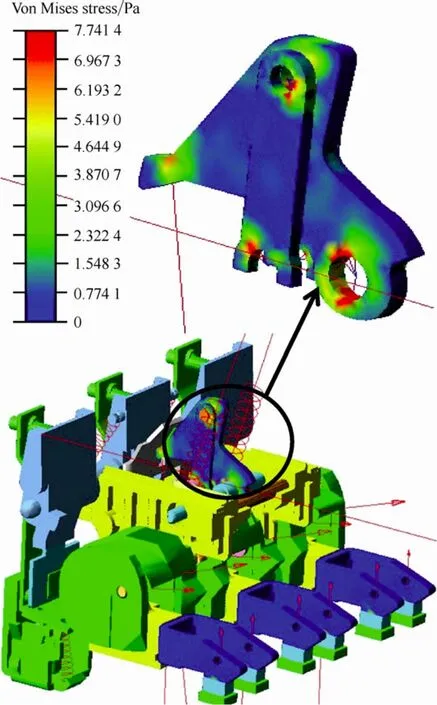

The strength analysis of improved metamorphic mechanism is shown in Fig. 10 and Table 3. From Fig. 10 and Table 3, we can know that the jump buckle and upper linkage have larger deformation under a certain working condition. Therefore, defining the jump buckle and upper linkage as rigid body is suitable. The rigid-flexible coupling metamorphic mechanism of MCCB under a certain working condition which is taken jump buckle and upper linkage as flexible body is shown as Fig. 11.

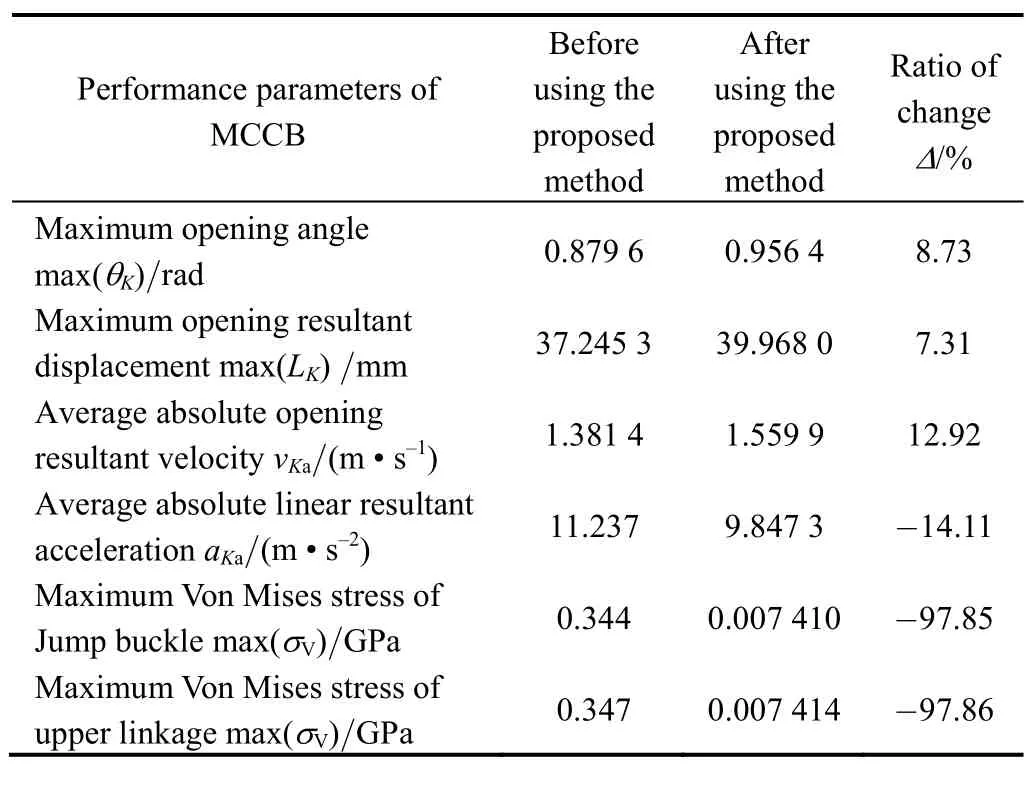

The key parameters of metamorphic mechanism are optimized by rigid-flexible coupling multi-body dynamics design using IRI shown as Table 4.

By using the proposed method, the maximum opening angle and maximum opening resultant displacement of main switch connector K are increased by shape parameters optimization to eliminate electric arc reignition. The average absolute opening resultant velocity is increased to enhance current-limiting interrupting performance. The average absolute linear resultant acceleration is decreased to weaken the impact vibration to arm of the moving contact and frame of MCCB. The maximum equivalent stress of jump buckle and upper linkage are decreased to improve the reliability of MCCB.

Fig. 10. Strength analysis of improved metamorphic mechanism

Table 3. Von Mises stress of improved metamorphic mechanism under a certain working condition

Fig. 11. Rigid-flexible coupling metamorphic mechanism of MCCB under a certain working condition

Table 4. Current-limiting interrupting performance comparison of the original and improved mechanism

6 Conclusions

(1) IRI is proposed to realize the multi-body dynamics of flexible metamorphic manipulating mechanism of MCCB.Index reduction makes the resolution of DAEs more stable,furthermore, the very small iteration in integration step help us obtain the instantaneous and short time breaking characteristics of metamorphic mechanism.

(2) The dummy part (virtual rigid) without moment of inertia and mass is employed as intermediate to join the flexible body and rigid body. The precision of nonlinear dynamics calculation of MCCB is improved by getting micro element deformation of metamorphic manipulating mechanism.

(3) The independent prototype design system has been developed to design the geometric structure of MCCB. The proposed method enhances the current-limiting interrupting performance of MCCB.

[1] LI Duanling, ZHANG Zhonghai, MCCARTHY J M. A constraint graph representation of metamorphic linkages[J]. Mechanism and Machine Theory, 2011, 46(2): 228–238.

[2] WEI Guowu, DAI J S. Geometric and kinematic analysis of a seven-bar three-fixed-pivoted compound-joint mechanism[J].Mechanism and Machine Theory, 2010, 45(2): 170–184.

[3] MEIER S D, MOORE P J, COVENTRY P F. Radiometric timing of high-voltage circuit-breaker opening operations[J]. IEEE Transactions on Power Delivery, 2011, 26(3): 1 411–1 417.

[4] PHILIPP S. A complete circuit breaker model for calculating very fast transient voltages[C/CD]//Conference Record of IEEE International Symposium on Electrical Insulation, San Diego, CA,United states, June 6–9, 2010.

[5] GEORGE E, JOSEPH E. Performance of HRC fuse and MCCB in low voltage distribution network[C/CD]//IEEE/PES Power Systems Conference and Exposition, Phoenix, AZ, United states, March 20–23, 2011.

[6] PARK S K, PARK K Y, CHOE H J. Flow field computation for the high voltage gas blast circuit breaker with the moving boundary[J].Computer Physics Communications, 2007, 177(9): 729–737.

[7] MATSUMURA T, HIRATA S, CALIXTE E, et al. Current interruption capability of H2-air hybrid model circuit breaker[J].Vacuum, 2004, 73(3–4): 481–486.

[8] ROODENBURG B, EVENBLIJ B H. Design of a fast linear drive for (hybrid) circuit breakers—Development and validation of a multi domain simulation environment[J]. Mechatronics, 2008, 18(3):159–171.

[9] LEE J C, KIM Y J. The influence of metal vapors resulting from electrode evaporation in a thermal puffer-type circuit breaker[J].Vacuum, 2007, 81(7): 875–882.

[10] DAI Jiansheng, DING Xilun, WANG Delun. Topological changes and the corresponding Matrix operations of a spatial metamorphic mechanism[J]. Chinese Journal of Mechanical Engineering, 2005,41(8): 30–35.

[11] ZHANG Shuyou, YI Guodong, XU Xiaofeng. Reverse design approach for mechanism trajectory based on code-chains matching[J]. Chinese Journal of Mechanical Engineering, 2007,20(3): 86–90.

[12] ZHANG Shuyou, YI Guodong, XU Xiaofeng. Modeling method for product structure mapping based on the reverse solving of trajectory and motion[J]. Chinese Journal of Mechanical Engineering, 2007,20(5): 114–119.

[13] CHEN Fuchen. Dynamic response of spring-type operating mechanism for 69 kV SF6 gas insulated circuit breaker[J].Mechanism and Machine Theory, 2003, 38(2): 119–134.

[14] PIQUERAS L, HENRY D, JEANDEL D, et al. Three-dimensional modeling of electric-arc development in a low-voltage circuitbreaker[J]. International Journal of Heat and Mass Transfer, 2008,51(19–20): 4 973–4 984.

[15] CABRERA J A, NADAL F. Multiobjective constrained optimal synthesis of planar mechanisms using a new evolutionary algorithm[J]. Mechanism and Machine Theory, 2007, 42(7):791–806.

[16] CABRERA J A, ORTIZ A, NADAL F, et al. An evolutionary algorithm for path synthesis of mechanisms[J]. Mechanism and Machine Theory, 2011, 46(2): 127–141.

[17] GAN Dongming, DAI J S, LIAO Qizheng. Constraint analysis on mobility change of a novel metamorphic parallel mechanism[J].Mechanism and Machine Theory, 2010, 45(12): 1 864–1 876.

[18] CHEN Degui, LI Xingwen, DAI Ruicheng. Effect of different vent configurations on the interruption performance of arc chamber[J].IEICE Transactions on Electronics, 2010, E93-C(9): 1 399–1 403.

[19] NATTI S, KEZUNOVIC M. Assessing circuit breaker performance using condition-based data and Bayesian approach[J]. Electric Power Systems Research, 2011, 81(9): 1 796–1 804.

[20] HUANG Jian, HU Xiaoguang, GENG Xin. An intelligent fault diagnosis method of high voltage circuit breaker based on improved EMD energy entropy and multi-class support vector machine[J].Electric Power Systems Research, 2011, 81(2): 400–407.

[21] BARTOSZ R, GERD B, MARTIN H, et al. Timings of high voltage circuit-breaker[J]. Electric Power Systems Research, 2008, 78(12):2 011–2 016.

[22] DRAGAN M, PREDRAG O, KOVILJKA S, et al. Dielectric characteristics of vacuum circuit breakers with CuCr and CuBi contacts before and after short-circuit breaking operations[J].Vacuum, 2011, 86(2): 156–164.

[23] LI Duanling, ZHANG Zhonghai, MCCARTHY J M. A constraint graph representation of metamorphic linkages[J]. Mechanism and Machine Theory, 2011, 46(2): 228–238.

[24] XU Wenliang, ZHANG Shuyou, YI Guodong, et al. Motion constraint recognition and its application oriented to multibody simulation[J]. Chinese Journal of Mechanical Engineering, 2008,44(6): 137–142. (in Chinese)

[25] LIN Xiaoxia, ZHANG Shuyou, CHEN Jing, et al. Method for asymmetric distributed loads on curving areas in products simulation analysis[J]. Chinese Journal of Mechanical Engineering, 2010,46(1): 122–127. (in Chinese)

[26] ZHAO Zhen, ZHANG Shuyou. Method of step self-adaptive sequential-interaction and application in problem of transient fields coupling[J]. Computer Integrated Manufacturing System, 2011,17(7): 1 404–1 414. (in Chinese)

[27] XU Jinghua, ZHANG Shuyou, YI Guodong, et al. Object variation oriented kinematics optimization design for manipulator[J]. Journal of Zhejiang University (Engineering Science). 2011, 45(2): 209–216.(in Chinese)

杂志排行

Chinese Journal of Mechanical Engineering的其它文章

- High Efficient Methods of Content-based 3D Model Retrieval

- Innovative Group-Decoupling Design of a Segment Erector Based on GF Set Theory

- Sewerage Force Adjustment Technology for Energy Conservation in Vacuum Sanitation Systems

- Simulation Research on the Effect of Cooled EGR, Supercharging and Compression Ratio on Downsized SI Engine Knock