Research on Flexural Capacity of RC Beam Strengthened with Hybrid Fiber Sheets

2012-06-19WangXiaomengAiJunZhouChuweiTaoPeng

Wang Xiaomeng Ai Jun Zhou Chuwei Tao Peng

(College of Aeronautics and Astronautics,Nanjing University of Aeronautics and Astronautics,Nanjing210016,China)

0 Introduction

With the rapid development of the national economy,transportation has become much more important.However,some bridges are facing a wide variety of problems because of the lower design load,aging materials and insufficient capacity.Now they become a potential risk of transport development[1].If bridges like these are not allow to rebuilt,they need to be properly reinforced.So an effective,durable,simple-used reinforcement technology and high-tech material is required.

There are several methods of concrete structure reinforcement:Increased Cross-section Reinforcement,Steel Reinforcement,Steel-bonded,Glass fiber reinforced,Shooting Concrete Technology and Fiber Reinforced Polymer(referred to as FRP)Reinforcement.The Fiber Reinforced Polymer Reinforcement is a new and effective reinforcement meth-od.It has been widely used in recent years because of its good durability and easy-usage.Prestressed FRP reinforcement technology has been widely studied,and progress has been made continuously.Tests show that the prestressed FRP reinforcement technology can improve the performance of the structural and inhibit the crack propagation in a significant effective way.

Carbon fiber(CFRP),glass fiber(GFRP)and aramid fiber(AFRP)are the most widelyused fiber reinforced polymer materials.Carbon fiber has a tensiler strength and higher elastic modulus.Besides,it's more stable and durable.According to related natural and accelerated exposure test,the tensile strength and bond strength of the concrete beam reinforced by CFRP do not change in 50years[2].The disadvantage of CFRP is its low elongation and high price.

In order to increase the plastic components of the reinforced structure and enhance economic efficiency,the carbon fiber and glass fiber or aramid fibers can be mixed in accordance with a certain percentage,which is also called hybrid reinforce method.

1 Characteristics of HFRP fabric and the research of its usage in reinforcenment

1.1 Mechanical characteristics and failure modes

A large number of experiments showed that the change of the stress and strain on the section of the concrete beams reinforced by HFRP can be described as three different stages.The first stage:At the very beginning,the strain of hybrid fiber and steel is very small.The strain of hybrid fiber is slightly larger than the strain of the steel.The second stage:The concrete in compression zone cracks,and gradually withdraw from work.The medium axis is shifting,and the stress of steel and FRP is increasing.The third stage:After steel yielding,the strain of hybrid fiber and steel began to increase very quickly.With the increase of load,the rate of development of hybrid fiber strain is gradually over the rate of steel strain.The different failure modes are described as three categories:(l)Damage with appropriate steel:the steel in tensile zone yield first.Soon FRP is broken.In the end,the concrete in compression zone are crushed.(2)Damage with ultra-bar in certain parts:the steel yield before the concrete in compression zone are crushed.The fiber has not yet reached the limits of strength.(3)Damage with ultra-bar:The concrete in compression zone crush before the steel in tensile zone yield.

A lot of experiments showed that the capacity of reinforced concrete beams has been improved in a certain way.The more FRP in use,the higher the capacity of reinforced concrete beams will be.Beams reinforced by intraply hybrid fiber has a higher ultimate strain than the beams reinforced by the same amount of interlaminar hybrid fiber or single fiber[3-4].This indicates that the intraply hybrid fiber is better than interlaminar hybrid fiber or single fiber.This is mainly because the fiber's fracture is a gradually developing process.When the fibers are in tension,it begins to break from its weak links.As a result,other fibers will have more stress.It will continue like this until all fibers break up.As to intraply hybrid fiber,the additional load that caused by low elongation of carbon fiber breakage can be undertaken by fiber of high elongation.So the micro-crack caused by carbon fiber breakage is inhibited.As a result,the average fracture strain of the fiber is increased.

1.2 Bending capacity of reinforced beams

Existing research results show that:(1)After reinforced by FRP,the yield load and the ultimate load of the beams is increased.This shows that the reinforcement materials have played an important role in the improvement of the flexural carrying capacity of the reinforced beams.(2)The ultimate strength and ductility of the concrete beams reinforced by hybrid fiber are improved.At the same time,it makes full use of the advantages of these two kinds of materials.From the cost point of view,the intraply hybrid fiber is better than interlaminar hybrid fiber.

1.3 The discussion of the durability

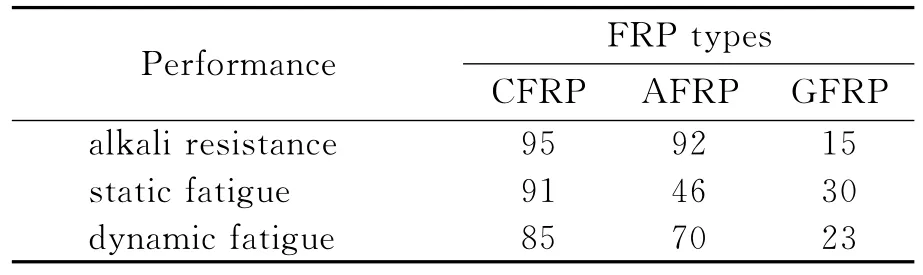

Maybe someone will have the question about the poor durability of glass fiber(Table 1).The tensile strength and elastic modulus of glass fiber is relatively low,besides,it is easy to broke.Existing experimental results show that in the logarithmic decade of time,the static strength values of CFRP,GFRP,AFRP were reduced by 5%to 8%,10%,5%to 6%.If we use aramid fibers which has high strength,high elastic modulus and chemical stability to mix up with carbon fiber to make hybrid fabric instead of glass fiber,the hybrid fiber will be much better.Compared to GFRP(linear expansion coefficient of 6×10-6℃or so),CFRP and AFRP has a similar coefficient of linear expansion(-4×10-6℃or so),so they will work together much better.

Table 1 FRP durability %

2 Concrete beam reinforced by prestressed C/AFRP

2.1 Reinforced concrete beam and the reinforce method

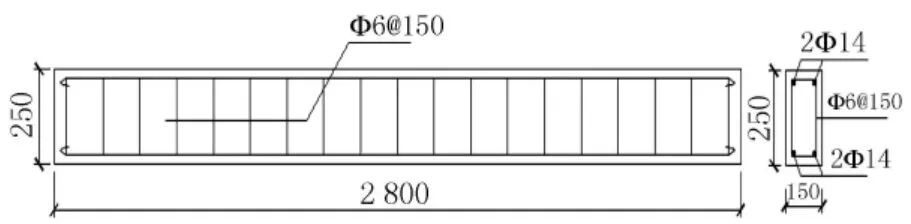

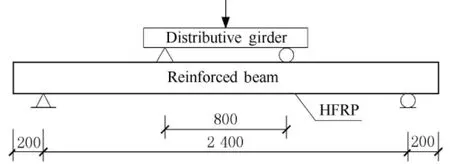

The design size of the beam in this test is 150 mm×250 mm×2800 mm(Figure 1),the standard value of the measured compressive strength of concrete cubes is slightly larger than the strength of C45.The steel bar is 335HRB.Two loads are applied.(Figure 2).Considering the strength,elongation and price factors,the ratio of carbon and aramid in hybrid fiber is 2∶1 and 2∶1are chosen.

Figure 1 Test beam(unit:mm)

Figure 2 Static load test schemes diagram(unit:mm)

2.2 Bending capacity of beams reinforced by HFRP

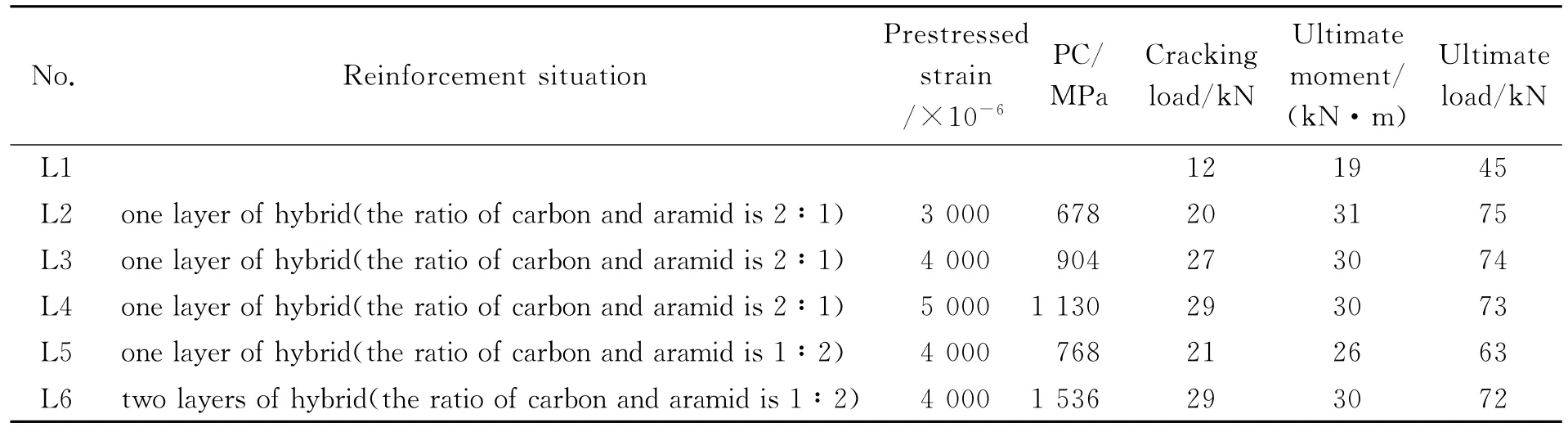

Table 2shows that:

1)The cracking load and ultimate load of the beams reinforced by prestressed hybrid fiber are greatly improved.The cracking load can be increased by nearly 80%,the ultimate load can be increased by nearly 40%.

2) With the increase of prestress,the cracking load of the reinforced concrete beams become higher.It improves the performance of the beam in normal use.But the ultimate load decreased slightly,mainly because the height of concrete in the compression zone is increased with the prestress.Therefore,the suitable prestress for the hybrid fiber cloth should be between 500~1000 MPa.

3)The higher hybrid fiber cloth in carbon content,the more improvement in the bearing capacity of reinforced concrete beam.

4)The flexural capacity of reinforced concrete beams increases with hybrid fiber dosage.With the increase in hybrid fiber cloth layers,the prestress must be large enough to prevent ultra-bar damage.The cracking load of the beams reinforced by two layers of prestressed hybrid fiber can be increased by nearly 140%,the ultimate load can be increased by nearly 60%.However,the amount of capacity growth and the increase in fiber is nonlinear related.The single-layer hybrid fiber cloth is more ecnomical.

Table 2 The reinforced beams Flexural

Table 3shows that:With the increase of prestress,the depth of the concrete compression zone has become higher.As a result,the cracking load is increased and the performance of reinforced beam in normal use is improved.The relative depth of compression zoneξbfbetween appropriate-steel damage and ultra-bar damage is increased with more prestress.This shows that:compared to non-prestressed HFRP,the beam reinforced by prestressed HFRP can effectively avoid the destruction of super-reinforced forms and make full use of the fiber.Prestressed reinforcement method can improve the performance of the structure in an efficient way.This is because the non-prestressed FRP is almost in a zero-stress state at the beginning,it won't work until extra load is applied to the beam.As time goes by,the beams are broken because of wide cracks while the stress of FRP is still in a low level.It is a waste of FRP.The prestressed hybrid fiber cloth already has a certain strain at the very beginning,thus it can greatly improve the bearing capacity of reinforced concrete beams.

Table3 The depth of compression of the reinforced beams

2.3 Ductility research

It is important to calculate the ductility of the structure reinforced by hybrid fiber in a practical project.When a non-expected load is applied,such as accidental overloading,reverse load,temperature or foundation settlement caused by additional internal forces such cases,good ductility will ensure a withstand strong component.In addition,the structures with good ductility will have less damage under the dynamic action,because it can reduce the inertia force and absorb more kinetic energy[5].

μcfis the ductility ratio of a reinforced beam,μcis the ductility ratio of a not-reinforced beam.Statistical results of the related experiments shows:Φ=0.8[7].

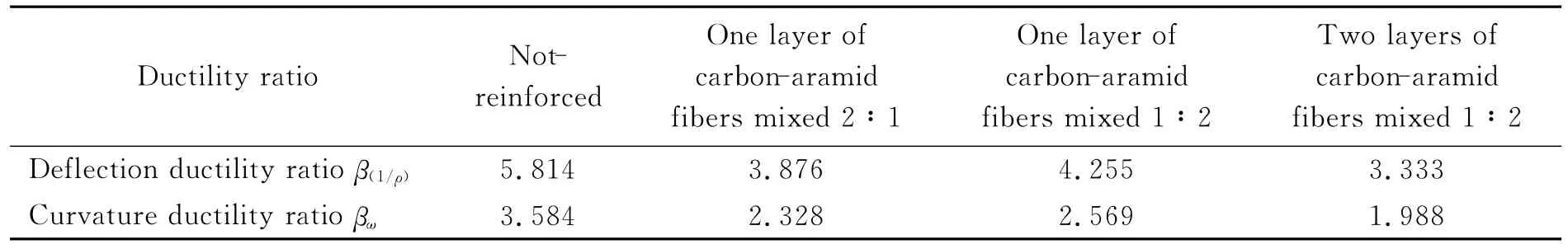

Table 4 Deflection ductility ratio and Corner ductility ratio

The ductility reduction factor can be used in calculations of flexural capacity of FRP reinforced concrete beams.

Experiments shows that:Under the same strain,the curvature ductility reduction factor of the beam reinforced by prestressed CFRP is 0.56[8],while the curvature ductility reduction factor of the beam reinforced by prestressed C/AFRP is 0.73.Compared with CFRP,the curvature ductility of the beam reinforced by prestressed C/AFRP is significant increased.

To ensure the ductility of the reinforced structure,the proper ratio of carbon fiber and aramid hybrid fiber is between 0.5and 2.

3 Conclusion

1)The method of using prestressed hybrid fiber to reinforce concrete structure to increase the flexural capacity is effective.When the hybrid fiber cloth is pasted,the cracking load and ultimate load of the reinforced beams have been significantly improved,while the increase of the cracking load is more obervious.However,the amount of capacity growth and the increase in fiber is nonlinear related.

2)The beam reinforced by prestressed hybrid fiber can not only resist the live load but also the effect of weight resistance.It changes“passive reinforcement”into “active reinforcement”,the internal stress can be re-adjustments to the original state.Some or all of the structural deformation is restored,the ultimate bearing capacity of concrete structures has been improved.It takes the full advantages of lightweight,high strength of the HFRP cloth.The most important thing is,prestressed hybrid fiber can be used to close the cracks or reduce the width of cracks and delay the launching of small cracks,thus improving the durability of the structure.

3)Prestressed intraply hybrid fiber is more cost-effective than single fiber or interlaminar hybrid fibers.Besides,the beam reinforced by prestressed intraply hybrid fiber also has a good ductility.The intraply hybrid fiber is an ideal reinforcement material,with significant economical and social benefits.

4)According to the test result,the proper ratio of carbon fiber and aramid hybrid fiber is 2∶1or 1∶1.Large amount of data shows that:Single FRP have been gradually replaced by HFRP.Nowadays HFRP plays an outstanding performance in space,high altitude and harsh environment of the marine.It is considered as the leading material of 21st century.HFRP will be more and more widely used in real projects.

[1]Aiello M A,Leone M,Ombres L.Modeling of the behavior of conerete tension members reinforced with FRP rods[J].Mechanics of Composite Materials,2003,39(4):283-292.

[2]Shao Xudong,Hu Jianhua.Bridge design hundred Q[M].Beijing:China Communications Press.2005.

[3]Yu Lin.Bending performance of concrete beam reinforced by hybrid FRP[D].Nanjing:Hohai University,2005.

[4]Yu Lin,Jiang Linhua,Chu Hungkeung.Flexural performance of concrete beams reinforced by hybrid FRP[J].Building Materials,2006(3):274-275.

[5]Guo Zhenhai,Shi Xudong.Reinforced concrete theory and analysis[M].Beijing:Tsinghua University Press,2003.

[6]Wang Wenwei.Concrete structures reinforced by FRP[M].Beijing:China Building Industry Press:2007.

[7]Wang Wenwei.Bending performance of concrete beam reinforced by FRP[D].Dalian:Dalian University of Technology,2003.

[8]Tian Anguo.Tests and design method of reinforcement by prestressed FRP[D].Nanjing:Southeast University,2006.