Characterizing the Spheroidization Grade and Strength of 15CrMo Steel through Determining Fractal Dimension

2012-01-20LIUChangjunDONGLeiyunandJIANGXiaodong

LIU Changjun*,DONG Leiyun,and JIANG Xiaodong

Key Laboratory of Safety Science of Pressurized System of Ministry of Education,School of Mechanical and Power Engineering,East China University of Science and Technology,Shanghai 200237,China

1 Introduction

Since Mandelbrot's[1-2]pioneering work on fractal of fractured surface,the fractal analysis has been widely applied to describe various irregular phenomena in nature.For instance,the qualitative fractograghy has been extensively used to describe the effect of the microstructure on the fracture mechanics.However,since the qualitative fractography was unable to distinguish fracture surfaces with very similar features,fractal characterization becomes an increasingly important method in fractography analysis[3-7].In spite of the fractured surface,the real surfaces of materials are fractal,i.e.,self-similar or self-affine over a wide range of scales.Hence,a lot of efforts have been devoted to correlating the fractal dimension (FD) of surfaces with mechanical properties of materials,such as impact energy[8-9],fracture toughness[10-11],fatigue crack propagation[12-13],etc..

The evaluated value of the FD is strongly depended on the method used in the fractal analysis.A number of methods that can be used to evaluate the fractal dimension were reviewed by MANDELBROT[2].Among these methods,slit-island and box-counting methods[2]have been most widely used.Slit-island method (SIM)is widely applied to calculate the fractal dimension of engineering surfaces.Generally,for anomalistic topography with fractal character,the relation of the perimeterPand areaSis described as follows[14]:

whereDis the fractal dimension.The surface FD is obtained by fitting the slope of the line on the double logarithm chart ofPandS.The box-counting method(BCM) is an appropriate method of fractal dimension estimation for images with or without self-similarity.In this method,each image is covered by a sequence of grids with descending sizes.For each grid,two values are recorded,i.e.,the number of square boxes intersected by the image,N(s),and the side length of the squares,l.The regression slopeDof the straight line formed by plotting lg(N(s)) against lg(1/s) indicates the value of FD[15].

Carbon steel with a pearlitic microstructure is the most commonly used material for high-temperature components in thermal power plants due to its high strength,low cost and good wear resistance.However,as a result of the two-phase microstructure,pearlite is susceptible to softening at higher temperature due to the spheroidization of cementite phases[16].The spheroidization may have obvious influence on the degradation of properties of pearlitic steel,such as tensile strength and impact energy.A lot of models for description of the the mechanism of spheroidization have been proposed[17].In Chinese national standard DL/T 787-2001[18],the spheroidization grade of the used pearlitic steels is generally evaluated through comparison between the observed carbide morphology and the carbide morphology in standard.However,in such a case,the spheroidization grade can only be qualitatively determined.The aim of this paper is to characterize the spheroidization grade and strength of pearlitic steel,15CrMo,by using FD method.

2 Determination of FD

2.1 Material

The material used for the FD analysis is a low carbon steel which has been widely used in pressure vessels and piping structures for several decades (with Chinese designation 15CrMo).Its chemical composition is following as:C 0.12-0.18,Mn 0.40-0.70,Si 0.17-0.37,Cr 0.80-1.10,Mo 0.40-0.55,S 0-0.03,and P 0-0.03 wt%.

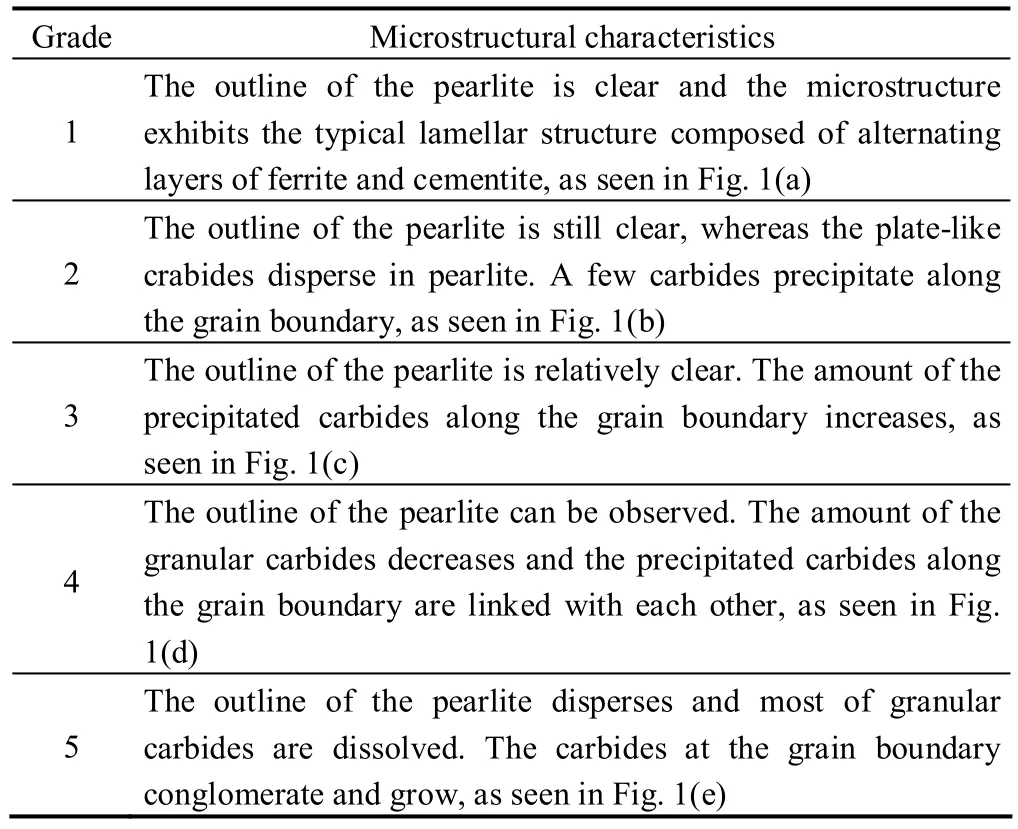

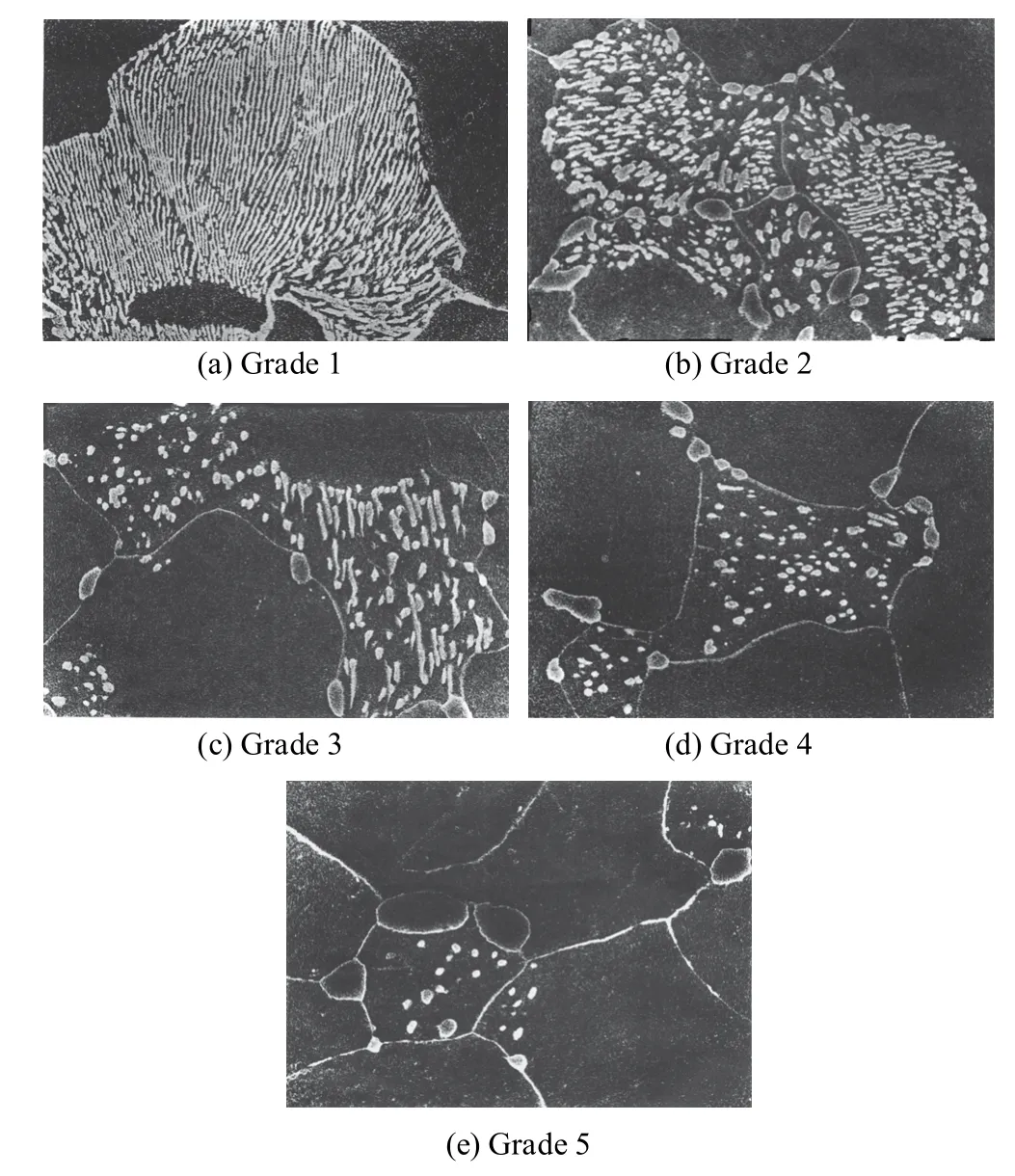

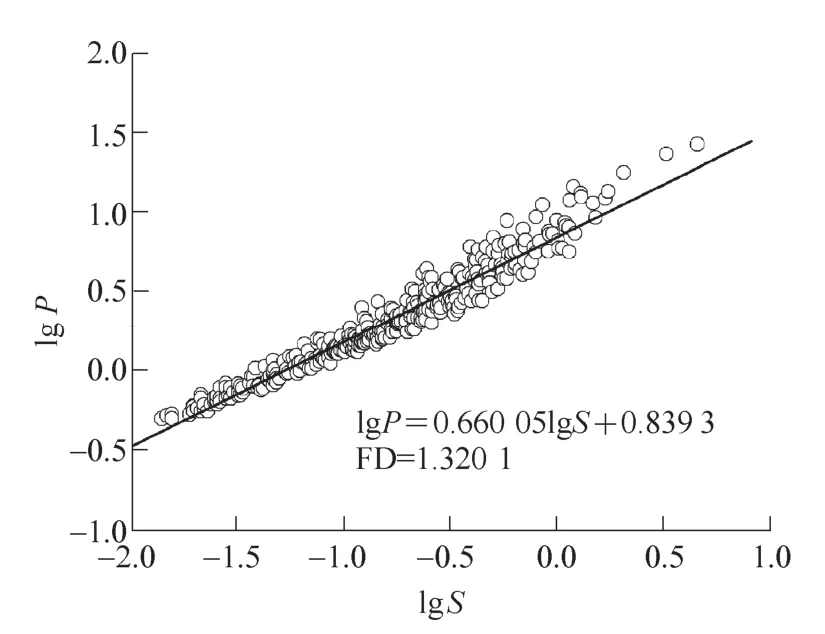

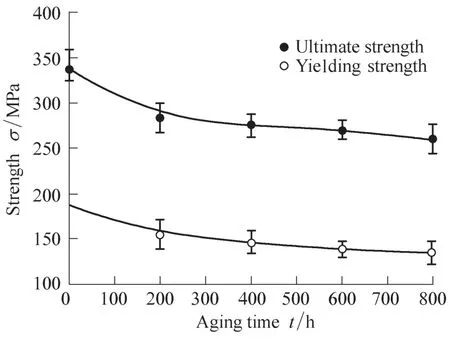

In Chinese national standard DL/T 787-2001[18],five spheroidisation grades are classified,as seen in Table 1,and the corresponding morphologies of cementite phase observed by scanning electron microscope (SEM) are shown in Fig.1.As expected,the yielding strength and the ultimate strength of the material at 550℃ and room temperature (i.e.,25℃),decrease with the spheroidisation grade,as shown in Fig.2.When the spheroidisation grade changes from 1 to 2,the yielding strength and the ultimate strength decrease sharply.

Table 1.Five spheroidisation grades classified on the basis of microstructural characteristics.

Fig.1.Microstructure of cementite phase in 15CrMo steel corresponding to different spheroidization grades

Fig.2.Variations of yielding strength and ultimate strength of 15CrMo steel at 550 ℃ and 25℃ along with spheroidisation grade

2.2 Evaluation of FD

The FD of the cementite phase in 15CrMo steel is evaluated by using 2-D SEM images shown in Fig.1.Before FD analysis,the input image should be pre-processed.In this work,the pre-processing of the image was carried out by using the image analysis method which was developed by ZHANG,et al[19-20].The procedure used in the proposed image analysis method can be divided into four steps,i.e.,gray level transformation,fuzzy enhancement of image,binary segment of image,and removing the impurities and pores.Using Fig.1b as an example,the image after pre-processing is shown in Fig.3.

Two methods,i.e.,SIM and BCM,are used for calculation of FD.When the SIM method is used,the FD value can be determined by using the image analysis software,OPTIMAS6.0.When the BCM method is used,the FD of digital image is calculated basedon the analysis of pixels.The detailed process for the FD evaluation can be divided into seven steps.

Step 1:Inputting a binary image matrixAm×n.

Step 2:Settingi=0,whereiis a decreasing scale factor.

Step 3:DividingAinto 2i-1submatrix and representing the number of submatrix covering the pearlites with variablen.

Step 4:Setting variablesxi=lg(1/2i) andyi=lgn,wherexiandyiare the elements of vector variablesX,Yrespectively.

Step 5:Settingi=i+1.

Step 6:Repeating steps 3-5 untiln<2i.

Step 7:Based on the data ofXandY,the relationship,Y=aX+bcan be estimated in a least-squares regression.The slopeais the FD.

Fig.3.Pre-processed image of Fig.1b

2.3 Experimental

In order to investigate the relationship between FD and yielding strength as well as ultimate strength of 15CrMo steel,the microstructure and mechanical properties of the aging-treated specimens with different aging time are evaluated.The specimens are cut from the low-pressure boiler tube serviced at around 550 ℃.The aging temperature is kept to be 650 ℃ in the heating furnace.Totally five specimens are used in the aging treatment.The time for aging treatment ranged from 0 to 800 h.

The microstructure of cementite phase in the agingtreated specimens is examined by using SEM.Prior to observation,the specimens are mounted in the epoxy resin.The cross-sectional surface for SEM observation is wet-ground with 400,600,800 and 1 200 grit SiC paper.The samples are ultrasonically cleaned in acetone between each grit paper.Before the microstructural examination,the specimens are chemically etched by using the natal solution.To get a representative FD value,five SEM images with a magnification of 6 000 are obtained for individual specimens.The high magnification images allow a closer view of the cementite phase.The strength of the aging-treated 15CrMo steel is evaluated by using tensile testing at 550 ℃.Five parallel specimens are used to get the representative value of strength.

3 Results and Discussion

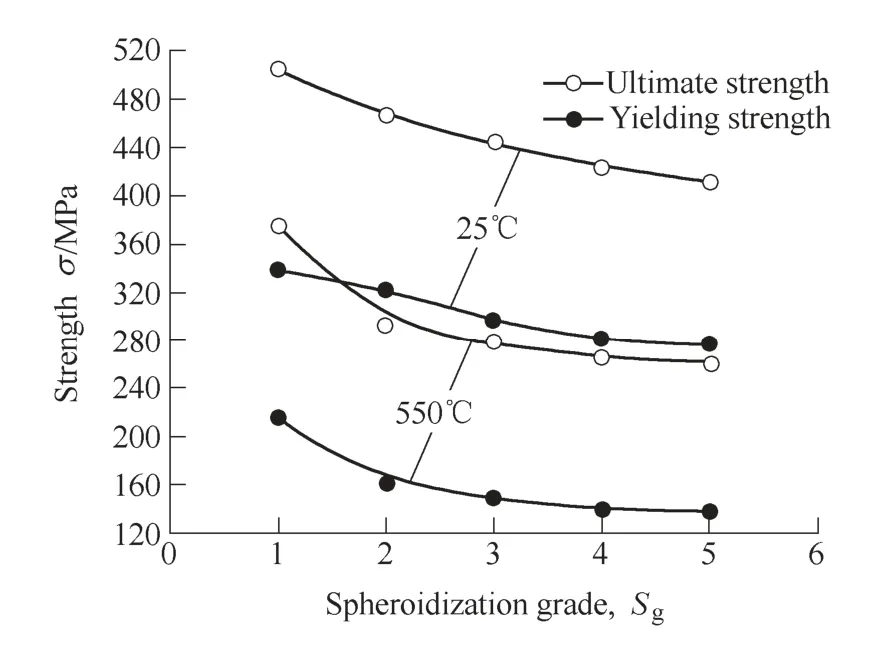

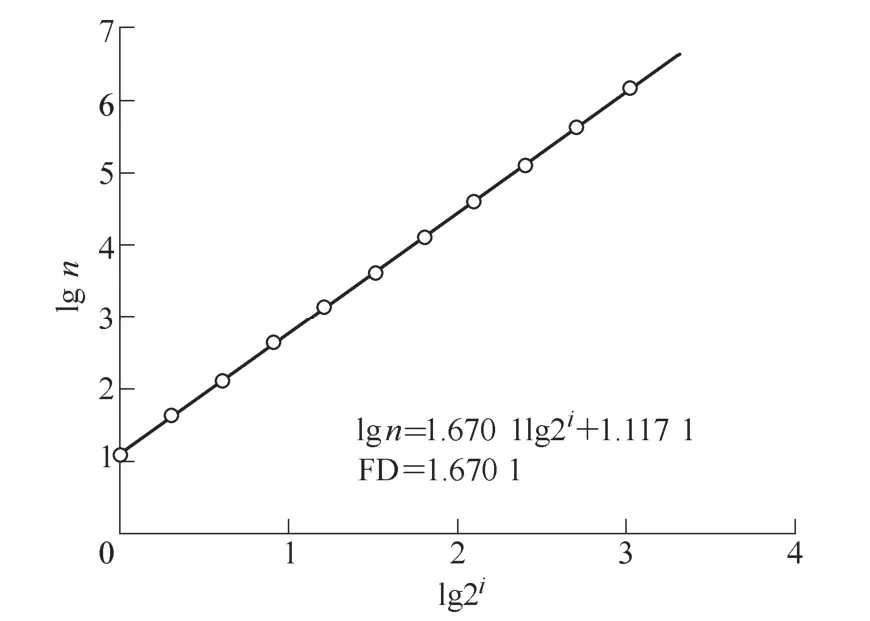

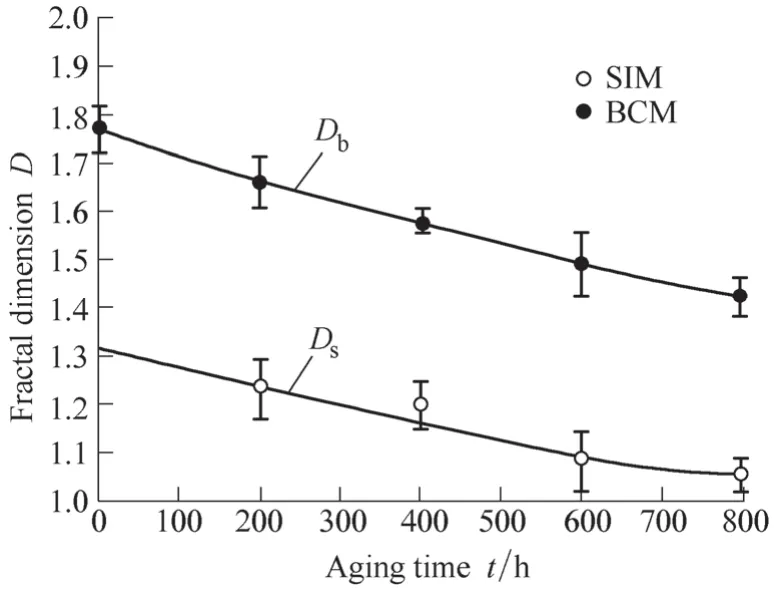

Using SIM to evaluate the FD of Fig.1b,the double logarithm chart of perimeterPand areaSis shown in Fig.4.The value of FD is two times of the value of slope,i.e.,1.320 1.Using BCM,the double logarithm chart ofnand 2iis shown in Fig.5.The value of FD is determined to be 1.670 1.It can be seen that different values of FD may be obtained when different methods are used.Fig.6 shows the variation of FD along with the spheroidization grade,whereDbandDsdenote the FD values determined by using BCM and SIM,respectively,andSgdenote the spheroidisation grade.The FD is evaluated on the basis of the images shown in Fig.1.It is clear that the FD decreases linearly with increasing the spheroidisation grade.

Fig.4.Double logarithm chart of perimeter P and area S in SIM

Fig.5.Double logarithm chart of n and 2i in BCM

Fig.6.Fractal dimension determined by using SIM and BCM as a function of spheroidization

At a given spheroidisation grade,the FD value evaluated by using BCM,Db,is obviously higher thanDsevaluated by SIM.The similar result was also obtained by FUSELER,et al[21].This phenomenon may be due to the difference in the principles used in different methods.The principle of the SIM is measurement of the length of a contour line at several scales from the surface topography.The box-counting principle is based on counting the number of boxes having side length needed to cover the surface of a fractal object and the number of grid boxes occupied by one or more pixels of the image.In general,BCM appears to be more sensitive in determining the degree of disorganization or changes in complexity than SIM.The difference in the values ofDbandDsmay result from the level of thresholding of the images of the 15CrMo steel used in different image analysis software.The apparent greater sensitivity of BEM may result from the very wide range of box sizes used in determining the numbers of boxes that are completely or partially filled with the image to determineDb[21].These conditions may allow for the impurities,such as small inclusions,with very small fragments in the calculations ofDb.In SIM,these small fragments may be averaged during the application of thresholding of the image to determine the area and perimeter values required for the calculation ofDs[21].

From Fig.6,it is interesting to find that the two models applied to determine the FD of the 15CrMo steel generated similarly shaped response curves.The slops between the FD and spheroidization grade are -0.111 and -0.108 when SIM and BCM are used.Hence,when the above two methods are used to determine the FD of pearlite in 15CrMo steel,the relationship between the FD and spheroidization grade can be approximately expressed asD≌-0.11Sg+A,whereAis a constant value which is depended on the evaluation method.

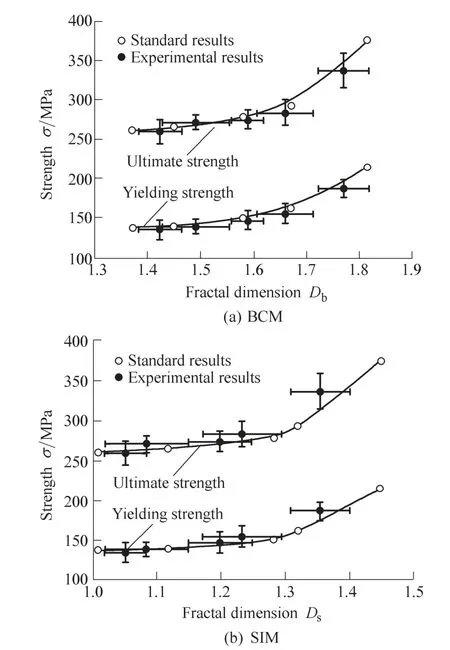

Combing Fig.1 and Fig.6,the relationship between the spheroidization grade and the strength of 15CrMo steel are shown in Fig.7.It can be seen that the yielding strength as well as the ultimate strength increases with increasing the FD.The similar results can be seen elsewhere[22].

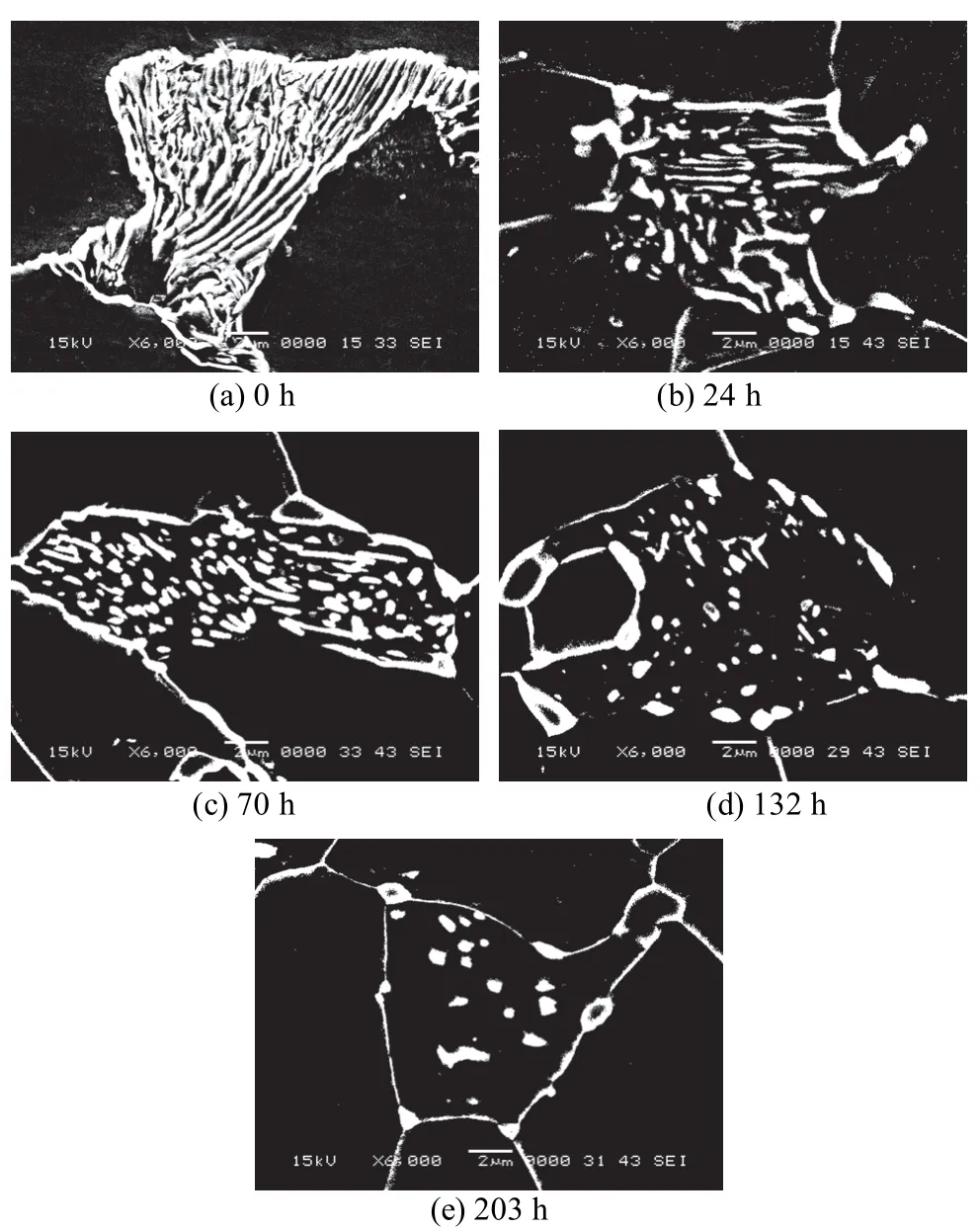

Fig.8 shows the microstructure of the pearlite in 15CrMo steel after aging treatments with different exposure time at 550 ℃.It can be seen that,for the as received 15CrMo steel,the outline of the pearlite is clear and the microstructure exhibits the typically lamellar structure composed of alternating layers of ferrite and cementite,as seen in Fig.8(a).With increasing the aging time,the plate-like crabides are broken and disperse in pearlite.A few carbides precipitate along the grain boundary,as seen in Figs.8(b) and 8(c).When the aging time is further increased,the amount of carbides in the pearlite decreases and the precipitated carbides along the grain boundary are linked with each other,as seen in Figs.8(d) and 8(e).Fig.9 shows the variations of fractal dimension of cementite phase in 15CrMo along with the aging time.Fig.10 shows the effect of aging treatment on the strength of 15CrMo steel.It can be seen that,with increasing the aging time,both the ultimate strength and the yielding strength decrease.However,the decreasing rate decreases with the aging time.

Fig.7.Variation of strength along with fractal dimension determined by BCM and SIM.

Fig.8.Microstructure of cementite phase in 15CrMo steel after aging treatment with different time

Fig.9.Variation of fractal dimension of cementite phase along

Fig.10.Variation of strength of 15CrMo steel along with aging time

On the basis of the FD results in Fig.9 and the strength shown in Fig.10,the relationship between the aging time and the FD of cementite phase in 15CrMo steel is shown in Fig.11,where the results from Fig.7 are also include for comparison.It can be seen that the experimental results agree well with the data from Chinese national standard DL/T 787-2001[18].The result indicates that the there may be a common relationship between the FD of cementite phase and strength of 15CrMo steel.When the FD of cementite phase in 15CrMo steel is determined,the strength of this steel may be evaluated by using Fig.11.

4 Conclusions

(1) Using the microstructural image of cementite phase in 15CrMo steel in Chinese national standard DL/T 787-2001[18],the values of fractal dimension of cementite phase can be evaluated by using slit-island method and box-counting method.

(2) The FD value evaluated by using box-counting method is generally higher than that evaluated by slit-island method.When the above two methods are used,the slopes between spheroidization grade and the FD value are almost same.The values of FD linearly decreases with increasing the grade of spheroidization.

(3) The effect of aging treatment on the fractal dimension of cementite phase and strength of 15CrMo steel are also investigated.It is found that the FD value and strength decreases with increasing the aging time.The ultimate and yielding strength of 15CrMo steel increases with increasing the FD value.The experimental results agree well with the results obtained from Chinese national standard DL/T 787-2001.

Fig.11.Variation of strength of aging-treated 15CrMo steel along with fractal dimension of cementite phase determined by two different methods.

[1]MANDELBROT B B.How long is the coast of Britain[J].Science,1967,156 (3 775):636-638.

[2]MANDELBROT B B.The fractal geometry of nature[M].New York:Freeman WH,1983.

[3]ZHANG S Z,LUNG C W.Fractal dimension and fracture toughness[J].Journal of Physics D:Applied Physics,1989,22(6):790-793.

[4]ANDERSON T L.Application of fractal geometry to damage development and brittle fracture in materials[J].Scripta Metallurgica,1989,23(1):97-102.

[5]WOJNAR L,KUMOSA M.Advanced quantitative analysis of fracture surfaces[J].Materials Science and Engineering,1990,A128(1):45-53.

[6]AZEVEDO C R F,MARQUES E R.Three-dimensional analysis of fracture,corrosion and wear surfaces[J].Engineering Failure Analysis,2010,17(1):286-300.

[7]BIGERELLE M,LOST A.Statistical artefacts in the determination of the fractal dimension by the slit island method[J].Engineering Fracture Mechanics,2004,71(7-8):1 081-1 105.

[8]RAY K K,MANDAL G.Study of correlation between fractal dimension and impact energy in a high strength low alloy steel[J].Acta metallurgica et materialia,1992,40(3):463-469.

[9]KOŇAS P,BUCHAR J,SEVERA L.Study of correlation between the fractal dimension of wood anatomy structure and impact energy[J].European Journal of Mechanics,2009,A28(3):545-550.

[10]HILDERS O A,PILO D.On the development of a relation between fractal dimension and impact toughness[J].MaterialsCharacterization,1997,38(3):121-127.

[11]ISSA M A,ISSA M A,ISLAM M S,et al.Fractal dimension-a measure of fracture roughness and toughness of concrete[J].Engineering Fracture Mechanics,2003,70(1):125-137.

[12]CARPINTERI A,SPAGNOLI A.A fractal analysis of size effect on fatigue growth[J].International Journal of Fatigue,2004,26(2):125-133.

[13]CARPINTERI A,SPAGNOLI A,VANTADORI S,et al.Influence of the crack morphology on the fatigue crack growth rate:A continuously-kinked crack model based on fractals[J].Engineering Fracture Mechanics,2008;75(3-4):579-589.

[14]YUAN C Q,LI J,YAN X P,et al.The use of the fractal description to characterize engineering surfaces and wear particles[J].Wear,255(1-6):315-326.

[15]FOROUTAN-POUR K,DUTILLEUL P,SMITH D L.Advances in the implementation of the box-counting method of fractal dimension estimation[J].Applied Mathematics and Computation,1999,105(2-3):195-210.

[16]CVETKOVSKI K,AHLSTRÖM J,KARLSSON B.Thermal softening of fine pearlitic steel and its effect on the fatigue behavior[J].Procedia Engineering,2010,2(1):541-545.

[17]WANG Y T,ADACHI Y,NAKAJIMA K,et al.Quantitative three-dimensional characterization of pearlite spheroidization[J].Acta Materialia,2010,58(14):4 849-4 858.

[18]China Electric Power Industry Standard DL/T 787-2001,The gradational standard of spherular pearlite for 15CrMo steel used in fossil power plant[S].Beijing:China Electric Power Press,2001.(In Chinese)

[19]ZHANG X C,XU B S,XUAN F Z,et al.Porosity and effective mechanical properties of plasma-sprayed Ni-based alloy coatings[J].Applied Surface Science,2009,255(8):4 362-4 371.

[20]ZHANG X C,XU B S,XUAN F Z,et al.Microstructural and porosity variations in the plasma-sprayed Ni-alloy coatings prepared at different spraying powers[J].Journal of Alloys and Compounds,2009,473(1-2):145-151.

[21]FUSELER J W,MILLETTE C F,DAVIS J M,et al.Fractal andimage analysis of morphological changes in the actin cytoskeleton of neonatal cardiac fibroblasts in response to mechanical stretch[J].Microscopy and Microanalysis,2007,13(2):133-143.

[22]LI T,ZHU Z,WANG D S,et al.The strength and fractal dimension characteristics of alum-kaolin flocs[J].International Journal of Mineral Processing,2007,82(1):23-29.

Biographical notes

LIU Changjun,born in 1972,is currently a professor atKey Laboratory of Safety Science of Pressurized System,Ministry of Education,East China University of Science and Technology,China.He received his bachelor degree fromQingdao Institute of Chemical and Technology,China,in 1994.His research interests include safety evaluation of important components and nuclear power engineering.

Tel:+86-21-64 251623;E-mail:cjliu@ecust.edu.cn

DONG Leiyun,born in 1972,is currently an associate professor atKey Laboratory of Safety Science of Pressurized System,Ministry of Education,East China University of Science and Technology,China.He received his bachelor degree fromEast China University of Science and Technology,China,in 1995.His research interests include safety evaluation of important components and nuclear power engineering.

Tel:+86-21-64 253181;E-mail:lyd@ecust.edu.cn

JIAN Xiaodong,born in 1960,is currently an associate professor atKey Laboratory of Safety Science of Pressurized System,Ministry of Education,East China University of Science and Technology,China.He received his bachelor degree fromEast China Institute of Chemical Technology,China,in 1983.His research interests include safety evaluation of important components and nuclear power engineering.

Tel:+86-21-64 253181;E-mail:jxd@ecust.edu.cn

杂志排行

Chinese Journal of Mechanical Engineering的其它文章

- Influence of Deposition Temperature and Pressure on Microstructure and Tribological Properties of Arc Ion Plated Ag Films

- Modeling of Fatigue Crack Growth Closure Considering the Integrative Effect of Cyclic Stress Ratio,Specimen Thickness and Poisson's Ratio

- Psychoacoustic Study on Contribution of Fan Noise to Engine Noise

- Reconstruction of Emission Coefficients for a Non-axisymmetric Coupling Arc Based on MALDONADO's Method

- Tool Wear in Turning of Titanium Alloy after Thermohydrogen Treatment