Psychoacoustic Study on Contribution of Fan Noise to Engine Noise

2012-01-20ZHANGJunhongLIUHaiBIFengrongNIGuangjianZHANGGuichangLINJieweiandYUHanzhengnan

ZHANG Junhong,LIU Hai,BI Fengrong*,NI Guangjian,ZHANG Guichang,LIN Jiewei,and YU Hanzhengnan

State Key Laboratory of Engines,Tianjin University,Tianjin 300072,China

1 Introduction

Customer's perception to diesel engine noise is receiving more attention since the noise emitted from an operating diesel engine is stronger than a spark ignition engine[1-3].Over the past decades,manufacturers have focused their design efforts on reducing the noise of engine components.Unfortunately,the significance of these characters is mostly overrated,which causes the misinterpretations of sound quality.Although certain noise properties are reduced which have contributed to mask disturbing noise patterns,the annoyance may even increase despite of the overall level reduction.Diesel engine noise is a composition of relevant components noise.Subjective and objective evaluation methods are applied to analyze main cause of the annoyance of engine noise,and to identify target noise sources and components.In order to obtain the best composition of the components' noise,acoustic design of engine components is utilized efficiently to improve the sound quality of overall emitted noise.

Fan noise is one of the main sources of diesel engine noise,which is composed of rotational noise and eddy noise[4].In research of cooling fan,acoustic pressure measurement expressed in dBA is the main parameter used to characterize acoustic comfort for customer.WANG,et al[5],used acoustic pressure testing to analyze the engine with and without fan,and concluded that the fan noises are mostly broadband noises.JIN,et al[6],studied the spectrum of noise signal and found that different analysis bandwidth made a significant difference in the passing frequency component value of blade.

The sound quality criterion has been recently applied to evaluate the fan noise,to deal with the noise perception by human hearing,and to establish relationship between stimuli and hearing sensation.LIU[7],applied jury testing to evaluate the fan noise using phase modulation and psychoacoustic theories,and reached a conclusion that increased phase modulation may not improve the sound quality.SOTTEK,et al[8],established the hearing model to evaluate the spectrum and temporal patterns of fan noise,and emphasized all relevant signal components concerning human auditory perception:tonal and transient signals.RINAUDO,et al[9],used significant psychoacoustic parameters to qualify and classify the noise of cooling fan,and established the correlation between subjective annoyance and psychoacoustic metrics.In conclusion,psychoacoustic criteria have been recently applied to the research of fan noise,but contribution of fan noise to an engine overall noise has not been considered.

Main focus of this paper will be on contribution of fan noise to diesel engine overall noise.First,the psychoacoustic theory[10]is applied to quantify variation of the engine sound quality caused by different cooling fans.Meanwhile,subjective evaluation experiment will be carried out by several experienced listeners to assess change of diesel engine sound quality.Next,a combined psychoacoustics and spectrum analysis is be used to analyze physical reason of engine noise change.Finally,which parameters are more important for engine sound quality and how to optimize the engine noise via fan acoustic design are depicted.

2 Experiment Preparation

Four-cylinder in-line diesel engines are widely used on vehicles.A representative diesel engine is chosen as research subject,which works at calibration condition (105 kW/2 500 r/min).The experiment is based on the microphone recording of real engine noise collected in engine anechoic chamber.In the experiment,the intake and exhaust noises are eliminated.The sampling frequency is 10 kHz and the sampling time is 10 s.During the experiment the microphones are placed at a distance of one meter aside and at a height of one meter above the engine.Test point 2 is close to the cooling fan side,as shown in Fig.1.

The locations of the test points are placed according to the international standard (ISO 6798:1995) and the precedent researches[11-12].Among the 4 test points,the point 2 is closest to the cooling fan,and the influence of variation is most obvious,so test data from the point 2 is collected in following engine noise annoyance analysis.Sound pressure signals of the 4 test points are applied in the objective and subjective evaluation.

In order to analyze the diesel engine sound quality characteristics caused by different cooling fans,objective evaluation is applied and is verified by the subjective evaluation in this paper.The experienced listeners who have long been involved in engine or engine related research fromState Key Laboratory of Engines of theTianjin Universityare chosen to complete the evaluation tasks.

3 Engine Noise Annoyance Analysis

When processing the sound signals,auditory system can be considered to act as a set of overlapping constant percentage bandwidth filters.The human hearing system processes perceived sound in non-equal width sub-band which is called critical bands.In each critical band,sound is analyzed independently.Each band corresponds to an equivalent section of cochlea.The critical bands have important implications for sounds composed of multiple components,considering the sound masking effect.Critical band width differs within the frequency range,the human's hearing thresholds of 20 Hz-16 kHz range is divided into 24 sub-critical bands[13],which is convenient to establish the relationship between sound physical quantities and subjective hearing impressions.

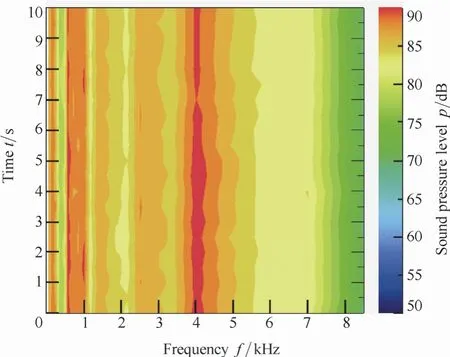

The critical band as a basic unit of hearing is suitable to study the response of human observers to the bands of noise and other complex sounds[14].As the diesel engine sources are complex,the critical band theory is suitable to depict diesel engine sound quality.Critical band map is a direct reflection of human reaction to sound,which is used to describe the sound quality of the engine prototype without cooling fan at point 2,as shown in Fig.2.

Fig.2.Critical band map of engine without fan at point 2

From Fig.2,we can find that the noise spectrum contains strong tonal or narrow band content at about 4 100 Hz,the sound pressure level in this region is larger than other regions,which causes the annoyance of engine noise.

4 Cooling Fans Selection Based on Critical Band Theory

The cooling fans noise,as one of the main noise sources of diesel engine,has an important influence on engine sound quality.In order to reduce the impact of the fan on engine sound quality,critical band method is applied to analyze variation of the engine sound quality after installing different cooling fans which have different fan blades in number and diameter.

Different fans generate complex noise signatures which are related to their frequency of rotation.In order to improve sound quality,five different fans with different blades in number and diameter are utilized on the diesel engine.

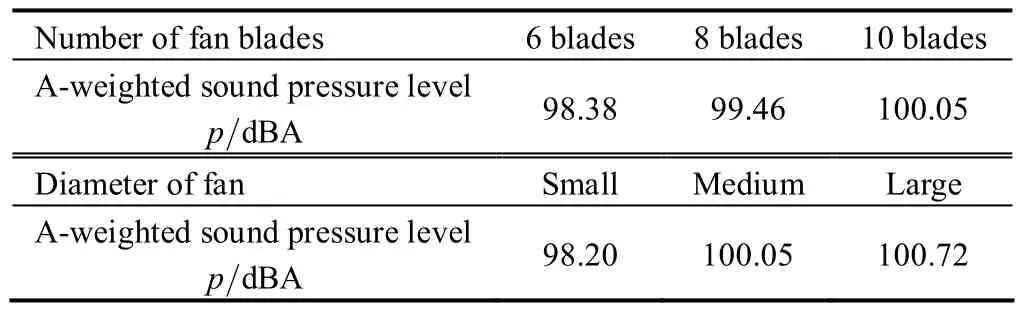

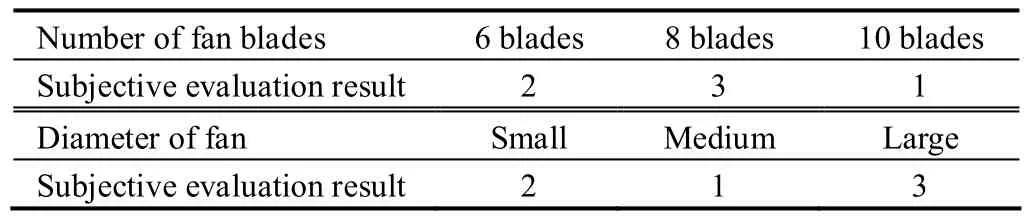

Firstly the engine overall noise are tested with A-weighted sound pressure level and then a comparative analysis of the effects of different fans by chosen listeners,the results are shown in Tables 1 and 2.modulation effect of human hearing organ on the acoustical signal.

Table 1.A-weighted sound pressure level

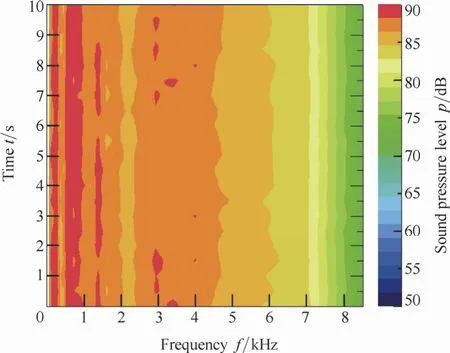

Fig.3.Critical band map with cooling fan at point 2

Table 2.Subjective evaluation results

Experienced listeners are invited to evaluate the sound quality of diesel engine with different cooling fans.The method of rank order[15]is applied in subjective evaluation.Subjects are asked to order sounds from 1 to 3(where 3 is the number of sounds) based on preference criteria,the smaller number stands for better sound quality.The sounds are presented sequentially,the results is shown in Table 3.

Table 3.Loudness of engine with different fans

Comparing noises of engine with different cooling fans,it is found that the noise level of engine with 10-blade fan in medium diameter is not the least,the sound quality is the best however.Selecting the proper cooling fan can improve the sound quality of the diesel engine.

Fig.3 shows that with 10-blade fan in medium diameter,the strong tonal content around 4 kHz attenuates a lot in the critical band map,the noise spectrum becomes smoother and the subjective feeling to the diesel engine noise becomes better.Then the psychoacoustic method will be used to analyze the noise changes of engine with different cooling fans.

Psychoacoustic analysis,not only considers masking effect of sound signals[10],but also accurately simulates the

5 Psychoacoustic Analysis

The noise emitted from an operating diesel engine tends to vary much more in time than a spark ignition engine.Evaluating diesel engine noise data only based on overall noise level does not fully correlate with the subjective evaluation[16-17].

Psychoacoustics is a science of the relationship between physical quantities of sound and listeners' preference.The goal of psychoacoustic research is to quantify the perceptual attributes of diesel engine sounds,and to eliminate individual influence.The psychoacoustic features including loudness,sharpness,roughness,and tonality,have been applied to evaluate and predict the engine noise widely[18-21].

The mathematical software-MATLAB is used to simulate the human auditory perception of the variation of the engine overall noise caused by different cooling fans.

5.1 Loudness

Loudness of a sound is a perceptual parameter to measure the effect of the sound energy content on the ear.It's related to,not only the distribution of critical frequency bands,but also the masking effects.So the value of the loudness is not only determined by the value of the amplitude of sound waves,but also influenced by frequency.Compared to A-weighted sound pressure level,loudness is preferable to reflect the pitch of the sound.Generally,the larger the value of loudness is,the more annoying the sound is.

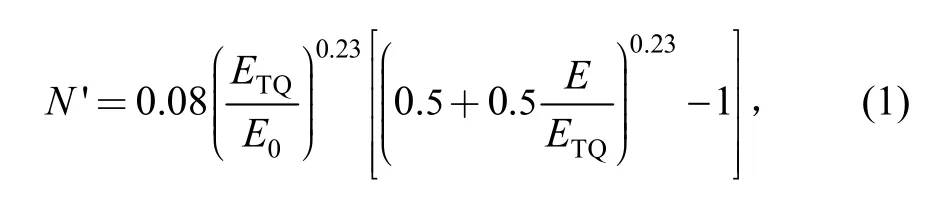

The unit of loudness is sone.1 sone corresponds to a pure tone at a center frequency of 1 kHz with a level of 40 dB[10].The specific loudness can be expressed as follows:

whereN' is the specific loudness,Eis the excitation level,ETQis the excitation at threshold in quiet andE0is the excitation that corresponds to the reference intensity.

The calculation of total loudness is a summation of all the specific loudness across all the critical bands,as seen in Eq.(2):

whereNis the loudness,Cis the critical band rate,Bark is the unit of the critical band rate.

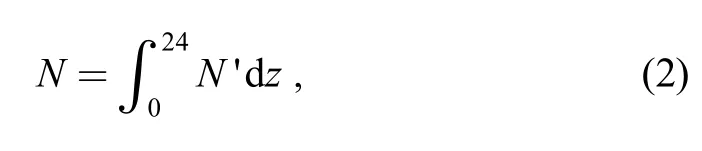

In order to describe the value of the loudness vary with frequency domain,the Zwicker loudness theory is used to obtain the loudness of engine with cooling fans.The loudness of the point 2 is shown in Table 3.After installing proper cooling fan,the specific loudness of diesel engine is shown in Fig.4.

Fig.4.Specific loudness at point 2

From Table 3,one important conclusion is that the loudness of diesel engine increases with the number and diameter of fan blades within a given range.

After installing the 10-blade medium cooling fan,the loudness at point 2 increases from 45.87 sone to 49.19 sone,and the loudness at points 1,3,4 increases by 0.37,2.38 and 0.74 sone respectively.Obviously the noise generated by cooling fan contributes to the overall noise of diesel engine.The result is consistent with the other research[5].Installing the proper cooling fan,the magnitude of the noise has turned larger,but it does not mean that the quality of noise has deteriorated,because auditory system is not only sensitive to the acoustic pressure level of a sound but also its amplitude density,spectrum composition and time structure[8].

After analyzing the Fig.4,it is found that the fundamental frequency of the cooling fan with 10 blades is about 410 Hz about 4.5 Bark,so 4 100 Hz is the 10th harmonic frequency.It is also found that the fan eddy noise belongs to continuous broadband spectrum,so the fan noise has masked the engine noise annoyance content (around 4 100 Hz).Finally the engine noise spectrum structure has become smoother,which provides valuable design data that if the tones in the Bark range can be controlled,the sound quality of the engine can be improved.

5.2 Sharpness

Sharpness is a measurement of high frequency energy content of a sound.Therefore,sharpness determines the spectrum weight of higher frequency components.The diesel engine emitted noises contain many high frequency contents,especially at high speed.Sharpness is reasonably to describe the weighting functions of high frequency contents in noise spectrum and the sensory pleasantness depends mostly on sharpness[10].

FASTL and ZWICKER[10]defined a sound of sharpness 1 acum as“a narrow band noise one critical band wide at a centre frequency of 1kHz having a level of 60 dB”.

The model for sharpness is simply a weighted first moment of the critical band rate distribution of specific loudness as shown in Eq.(3):

whereSis the sharpness,g(z) is an additional factor which depends on critical band rate.

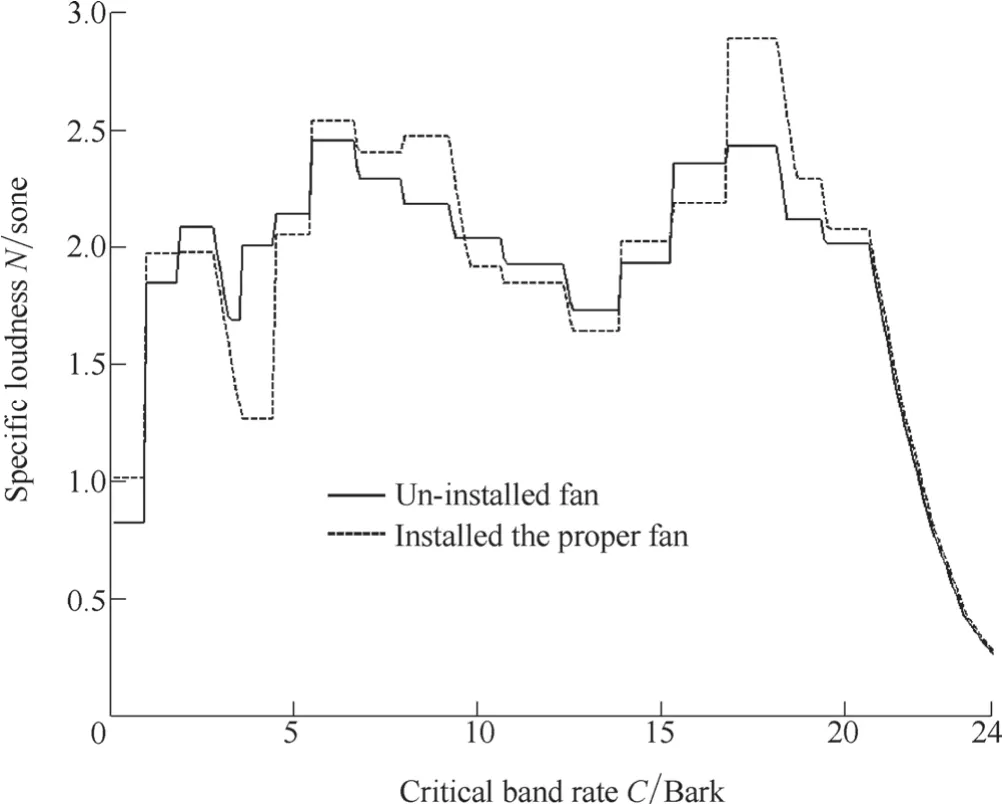

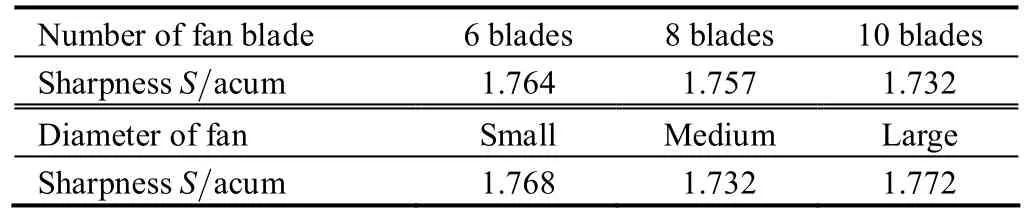

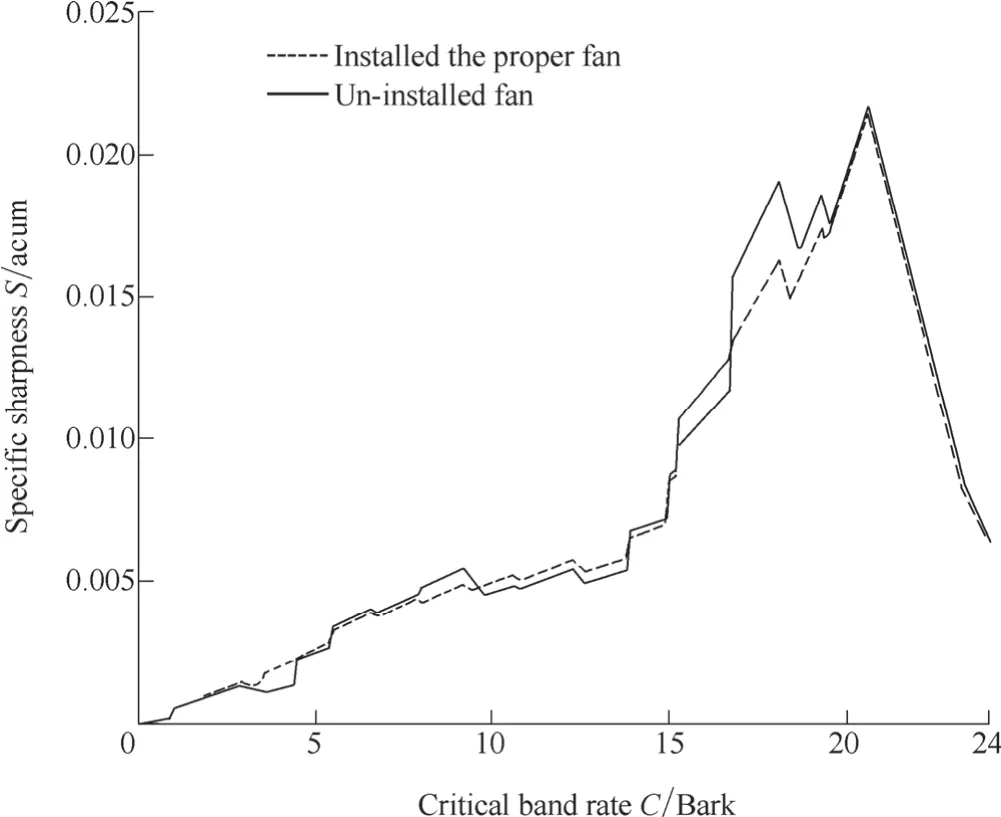

The sharpness is calculated to obtain the specific sharpness of the diesel engine with different cooling fans,as shown in Table 4.After installing proper cooling fan,the specific sharpness of diesel engine is shown in Fig.5.

Table 4.Sharpness of engine with different fans

Fig.5.Specific sharpness at point 2

From Table 4,the sharpness at point 2 is 1.978 acum without cooling fan and reduced to 1.732 acum when the medium cooling fan with 10 blades is installed.The sharpness at the other points 1,3,4 decreases by 0.102,0.052 and 0.010 acum respectively,is indicating that the overall sound quality is improved.However,if an improper cooling fan is installed,the sharpness turns larger,and the sound quality is deteriorated.

Fig.5 shows that with proper cooling fan,the specific sharpness changes obviously,especially from 15 Bark to 20 Bark.The components of fan noise are mostly broadband noise,and the high harmonic frequencies have masked other frequency contents.The results make the ratio of high frequency level to overall level lower and a better spectrum envelope is obtained.Several experienced listeners are chosen to discerning the nuances of diesel engine noise,the results show that with a proper cooling fan the engine overall noise sounds smoother,and the sound quality is improved significantly.

5.3 Roughness

The roughness parameter is used for the subjective judgment of sound impressions and for sound design.With the increase of the roughness,engine emitted noise is perceived increasingly noticeable and usually increasingly aggressive and annoying,even if the loudness or the A-weighted sound pressure level remains unchanged.The engine roughness is suitable to analyze engine orders.

The unit of roughness is asper.1 asper is defined as the roughness produced by a 1 kHz tone of 60 dB which is 100% amplitude modulated at 70Hz[10].

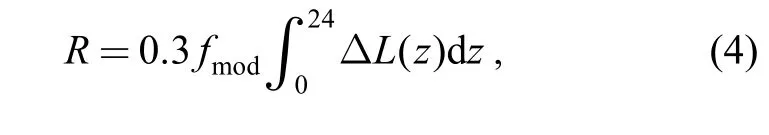

The roughness,R,of a sound is simply a weighted first moment of the critical band rate distribution of specific loudness as follows:

wherefmodis the modulation frequency,ΔLis the temporal masking depth.

The roughness is calculated to obtain the specific sharpness of the diesel engine with different cooling fans;the specific roughness of the diesel engine is shown in Fig.6.

Fig.6.Specific roughness at point 2

Fig.6 shows that the specific roughness has changed obviously.After installing a proper cooling fan,the values around 5,10,14,17,19,20 Bark have decreased effectively.The specific roughness at point 2 is reduced by 0.096 asper,the roughness at the other points 1,3,4 are reduced by 0.003,0.031,and 0.029 asper respectively.After analyzing the reason,it is found that the fan noise contains several periodic modulation frequencies,and the modulation frequencies in the region between 20 Hz and 300 Hz has effects on the overall noise.The noise is perceived smoother and more consonant after installing a proper fan.

5.4 Tonality

Tonality is concerned with the tonal prominence of a sound.The tonality of this sound can be estimated by comparing the relative magnitudes of the tones and the broadband noise.

The magnitude of tonality can be estimated from a comparison in amplitude of the“noise floor”verses the pear amplitude of the tone.This estimate is expressed in Eq.(5),as the ratio of amplitudes of the tone to that of broadband noise[22-23]:

whereATis the amplitude of tone,AFis the amplitude of noise floor.

After analyzing the tonality metric of engine sound quality with different fans,the results are relatively similar.Therefore,it does not significantly influence the sensory pleasantness results.

Each of the psychoacoustic parameters only represents an approximation about how auditory system responds,such as sound signal strength,high frequency excitation,duration and spectrum distribution.However,the human auditory perception processing which considers both the acoustical and psychological characteristics relies on each psychoacoustic parameter,so the sensory pleasantness index is applied to meet the requirement.

5.5 Sensory pleasantness

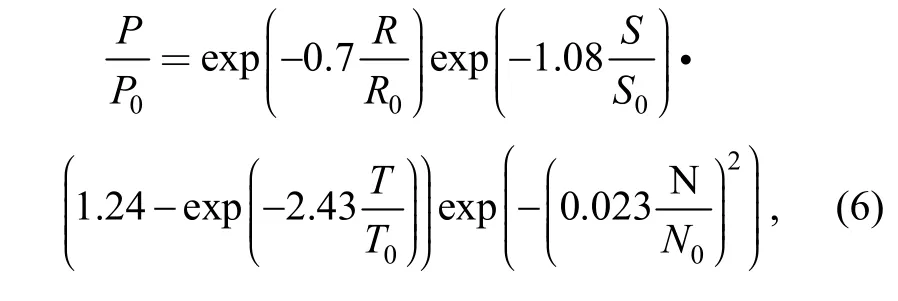

Whether the sound is readily accepted is not only determined by the physical characteristics of sound,but also by the subjective feeling of listeners.The psychoacoustic model does not only consider auditory system characteristics but also the physical characteristics of the sound[10].The relationship between sensory pleasantness and the sensations of loudness,sharpness,roughness,fluctuation and tonality can be modeled based on relative values of each metric.As proposed by FASTL and ZWICKER[10]is as follows:

wherePis the sensory pleasantness,the parametersP0,N0,S0,R0,andT0are references.In other words,this model is a model of relative sensory pleasantness measured against a benchmark sound.

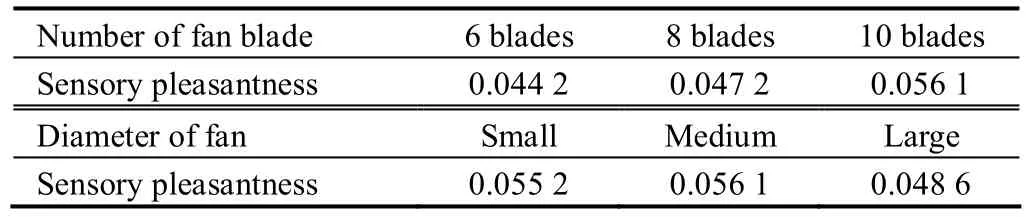

5.6 Psychoacoustics results

As mentioned above,all of the psychoacoustic metrics are calculated at the declared working condition.Sensory pleasantness is computed based on psychoacoustic metrics,and a single overall rating of the sound quality for each point is given.To reiterate,for all of the metrics except sensory pleasantness a lower value is desired.For sensory pleasantness,the larger value indicates a more appealing sound.Table 5 shows the sensory pleasantness index of the diesel engine with different fans at point 2.

Table 5.Sensory pleasantness of engine with different fans

Table 5 shows that the sensory pleasantness has improved from 0.050 8 to 0.056 1 after installing a medium cooling fan with 10 blades at point 2,therefore,an optimum combination of engine components can improve the sound quality of engine significantly.

Table 6 shows the changes of sound quality after installing the proper cooling fan at each point.

Table 6.Comparison of the sensory pleasantness

Table 6 shows that after installing the medium fan with 10 blades the sensory pleasantness has increased significantly,especially at point 1 the value has increased by 26.65%.Although the loudness increases obviously,the roughness and sharpness decrease,so the sensory pleasantness at each point is increased significantly and the overall engine sound quality is improved obviously.The fan noise has optimized the spectrum structure of overall noise,which makes engine noise spectrum structure more reasonable,so the sound became more acceptable.The conclusions can be drawn that optimizing the engine components can improve the overall noise of a diesel engine,however the sound quality is not decided by the physical variables or psychoacoustic variables,but a comprehensive reflection of the objective variables.

The results of subjective evaluation show that,after installing the proper cooling fan,the noise near the test points is more easily accepted by most listeners.The jury test results are verified by the mathematical metrics.This illustrates that the psychoacoustic analysis of noise is effective.The establishment of the quantitative relationships between listeners' subjective feelings and the physical properties of noise proves the reliability of the psychoacoustic analysis.

6 Spectrum Analysis

From the psychoacoustic results,the change of engine sound quality (sensory pleasantness) is obvious,which is consistent with subjective evaluation results.1/3 octave band methodology can depict the hearing impressions directly.

1/3 octave band spectrum analysis is used to analyze the spectrum energy distribution of the human auditory audible threshold (20 Hz-8 kHz),and to establish the relationship between physical quantities of sound and subjective hearing impressions.In order to observe the engine overall noise changes directly with and without proper cooling fan,1/3 octave band methodology is used to analyze the reason that changes engine sound quality by calculating the relationships between psychoacoustic results and physical characters.

Fig.7 shows the 1/3 octave frequency spectrum chart of the engine noise with and without proper cooling fan at point 2.

Fig.7.1/3 octave frequency spectrum at point 2

From the chart,it is clear that the energy spectrum distribution is more reasonable after installing a proper cooling fan.Before installing a proper fan,some inharmonious frequency contents including 40 Hz,80 Hz and 315 Hz deteriorate the engine sound quality,and the overall energy spectrum distribution is lack of balance,which is the major reason for the poor sound quality.With a proper fan,the energy distribution is more reasonable,such as 21.5 Hz,31.5 Hz,50 Hz,100 Hz,200 Hz,315 Hz and 400 Hz,the proportion of the high frequency content has declined,the spectrum structure is more reasonable,so the engine overall noise sounds more comfortable.

7 Conclusions

(1) Psychoacoustic method is able to discriminate the auditory response to diesel engine sound quality.The sensory pleasantness metrics are suitable to reflect the listeners' preference and the different level of sound quality,which is proved by the listening jury test.

(2) After optimizing the fan structure,the rational spectrum allocations can be obtained,which leads to an improvement of the overall sound quality of diesel engine.

(3) A-weight sound pressure and loudness increase with increasing the number and diameter of cooling fan blade in a certain scope.

(4) The combined psychoacoustic and spectrum analysis is useful and effective for analyzing engine sound quality,and can provide an independent check on engine sound quality design.

[1]GENUIT K.Product sound quality of vehicle noise-a permanent challenge for NVH measurement technologies[G].SAE Paper,2008-36-0517,2008.

[2]ZHANG J H,YU Y L,HAN B.Identification of diesel front sound source based on continuous wavelet transform[J].Chinese Journal of Mechanical Engineering,2004,17(2):268-271.

[3]YAO C D,SHAO Y P,ZHANG C R,et al.Flow characteristics of wall-flow diesel particulate filter system with reverse pulse air regeneration[J].Chinese Journal of Mechanical Engineering,2005,18(3):439-441.

[4]PANG J,CHEN G,HE H.Automotive noise and vibration principle and application[M].Beijing:Beijing Institute of Technology Press,2006.(in Chinese)

[5]WANG B,WU J W,CHEN Z J.Influence of fan noise on engine noise[J].Chinese Internal Combustion Engine Engineering,2004,25(6):52-54.(in Chinese)

[6]JIN P,WANG T Q.Bandwidth influence on frequency spectrum analysis of high speed fan noise[J].Journal of Aerospace Power,2006,21(5):909-913.(in Chinese)

[7]LIU E.Evaluation of fan noise using phase modulation and psychoacoustic theories[D].Ohio:The Ohio State University,2007.

[8]SOTTEK R,GENUIT K.Sound quality evaluation of fan noise based on advanced hearing-related parameters[J].Noise Control Engineering Journal,2009,57(4):384-390.

[9]RINAUDO S,SANON A,DUPUTEL P,et al.The sound quality of cooling fan systems[G].SAE Paper,980587,1998.

[10]FASTL H,ZWICKER E.Psychoacoustics-Facts and Models[M].New York:Springer,1990:257-261.

[11]SCHIFFBÄNKER H,BRANDL F K,THIEN G E.Development and application of an evaluation technique to assess the subjective character of engine noise[G].SAE Paper,911081,1991.

[12]HUSSAIN M,GÖLLES J,RONACHER A,et al.Statisticalevaluation of an annoyance index for engine noise recordings[G].SAE Paper,911080,1991.

[13]FLETCHER H.Auditory patterns[J].Reviews of Modern Physics,1940,12 :47-65.

[14]SCHARF B.Complex sounds and critical bands[J].Psychological Bulletin,1961,58(3):205-217.

[15]OTTO N,AMMAN S,EATON C,et al.Guidelines for jury evaluations of automotive sounds[G].SAE Paper,1999-01-1822,1999.

[16]KHAN M S,JOHANSSON O,LINDBERG W,et al.Annoyance of idling diesel engine noise evaluated by multivariate analysis[J].Noise Control Engineering Journal,1995,43(6):197-208.

[17]GONZALEZ A,FERRER M,DIEGO M D.Sound quality of low-frequency and car engine noises after active noise control[J].Journal and Sound and Vibration,2003,265(3):663-679.

[18]BISMARCK G.Sharpness as an attribute of the timbre of steady sounds[J].Acoustica,1974,30:159-172.

[19]AURES W.The sensory euphony as a function of auditory sensations[J].Acoustica,1985,58:282-290.

[20]AURES W.A Procedure for calculating auditory roughness[J].Acoustica,1985,58:268-281.

[21]SOTTEK R.Modeling engine roughness[G].SAE Paper,2009-01-2153,2009.

[22]HASTINGS A L.Sound quality of diesel engines[D].Indiana:Purdue University,2004.

[23]CHATTERLEY J J.Sound quality analysis of sewing machines[D].Utah:Brigham Young University,2005.

Biographical notes

ZHANG Junhong,born in 1962,is currently a professor and a PhD candidate supervisor atState Key Laboratory of Engine,Tianjin University,China.She received her PhD degree fromTianjin University,China,in 2004.Her research interests include noise and vibration control,reliability analysis and structure optimal design.

Tel:+86-22-27 892182;E-mail:zhangjh@tju.edu.cn

LIU Hai,born in 1980,is currently a PhD candidate atState Key Laboratory of Engines,Tianjin University,China.He received his master degree fromHebei University of Technology,China,in 2009.His research interests include vibration and noise control of engine.

E-mail:liuhai725@tju.edu.cn

BI Fengrong,born in 1965,is currently a professor atTianjin University,China.He received his PhD degree fromTianjin University,China,in 2003.His main research interests include vibration and noise control of vehicle/engine.

E-mail:fr_bi@tju.edu.cn

ZHANG Guichang,born in 1981,is currently a PhD candidate atState Key Laboratory of Engines,Tianjin University,China.He received his master degree fromTianjin University,China,in 2009.His research interests include noise and vibration control.

E-mail:zhangguichang@tju.edu.cn

LIN Jiewei,born in 1984,is currently a PhD candidate atState Key Laboratory of Engine,Tianjin University,China.He received his master degree fromTianjin University,China,in 2007.His research interests include noise and vibration control,fatigue and reliability analysis.

E-mail:linjiewei@tju.edu.cn

杂志排行

Chinese Journal of Mechanical Engineering的其它文章

- Tool Wear in Turning of Titanium Alloy after Thermohydrogen Treatment

- Reconstruction of Emission Coefficients for a Non-axisymmetric Coupling Arc Based on MALDONADO's Method

- Modeling of Fatigue Crack Growth Closure Considering the Integrative Effect of Cyclic Stress Ratio,Specimen Thickness and Poisson's Ratio

- Characterizing the Spheroidization Grade and Strength of 15CrMo Steel through Determining Fractal Dimension

- Influence of Deposition Temperature and Pressure on Microstructure and Tribological Properties of Arc Ion Plated Ag Films