KEY PROBLEMS ANALYSIS ON CO2 DISPLACEMENT AND GEOLOGICAL STORAGE IN LOW PERMEABILITY OIL RESERVOIR, CHINA

2011-02-20ZHAOHongjunLIAOXinwei

ZHAO Hong-jun, LIAO Xin-wei

(MOE Key Laboratory of Petroleum Engineering, China University of Petroleum, Beijing 102249, China)

0 Introduction

According to the third hydrocarbon resources evaluation in 2004, the Chinese petroleum resource is 1 086×108t (excluding Taiwan and China south sea), including low permeable resources for 537×108t, accounted for total resources of 49%, more than 80% of the low permeable oil resources distribute in Cenozoic continental sediments[1]. The largest low permeability reservoir geological reserves is Xinjiang region, the rest in turn for Daqing, Shengli, Jilin, Liaohe, Dagang, Zhongyuan, Yanchang, Changqing, Tuha, Huabei oilfields etc in China[2]. How to scientifically and effectively explore low permeability reservoirs, and will make a great strategic significance for China′s energy supply and security.

China′s low permeability reservoir mainly adopts water flooding way, as a result of “low holes, low permeability, and low pressure” features, which result in the lower water injectivity, pressure conduction slowly, water injection and the oil wells production ability difficult. The average water drive recovery ratio is only 20%, compared with water flooding, CO2oil displacement has absolute advantage. First, since the good liquidity, make CO2can well mixed with oil, inject ability greatly improved, second, because of low viscosity generally low permeability reservoirs has low minimum miscible pressure (MMP), so that it is easier to form miscible of CO2and crude oil, accordingly can obtain higher crude oil recovery. In addition, in the process of CO2oil displacement, due to CO2dissolution, bound and other forms of trapping in reservoir[3-6], which make CO2buried in reservoir for a long time, it provides favorable conditions for energy conservation and greenhouse gas emissions reduction, and the goal of green oilfield achievement. Especially for China, the economy is still underdeveloped, CO2oil displacement and storage technology is an important measure to realize the sustainable energy supply and climate abatement.

1 Geological Characters of Low Permeability Reservoir in China[7]

1.1 Petrography characteristics

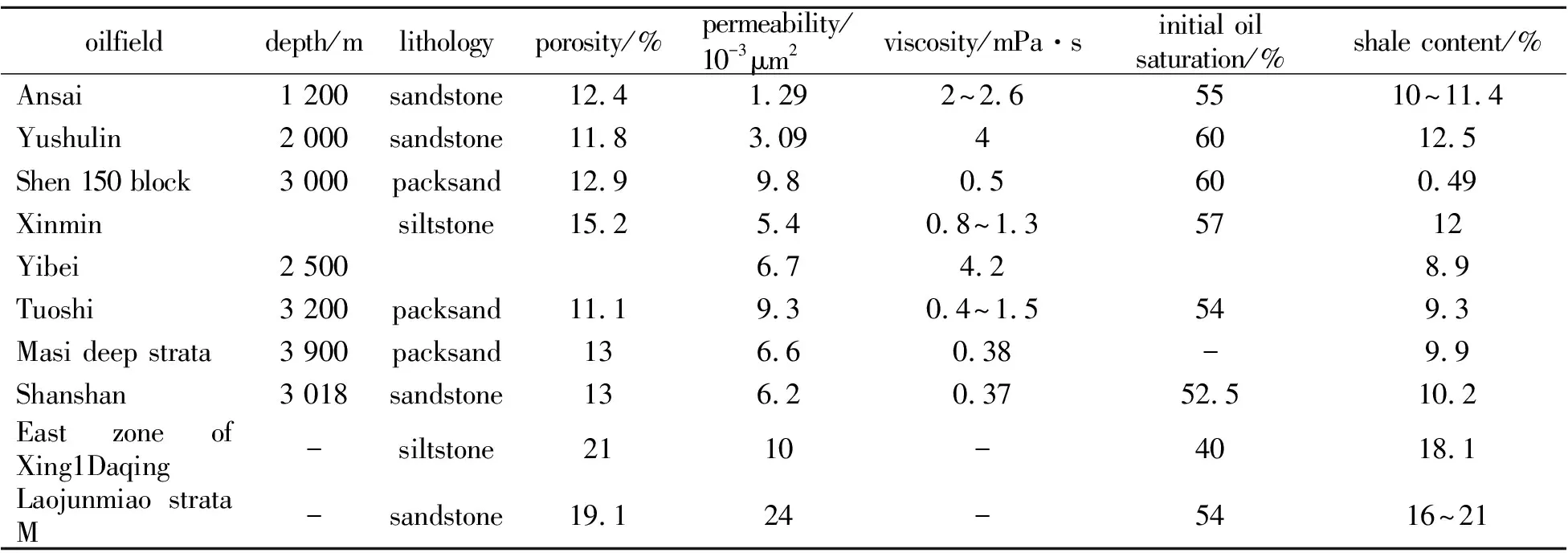

The most significant difference of continental low permeable reservoir is low sediments maturity. Mainly difference is manifested in the higher feldspar and lithic content of clastic constituents (Tab.1), mostly feldspar sandstone and lithic sandstone. This is totally different from Marine reservoir characteristics of rich in quartz.

Tab.1 The parameters of low permeability sandstone reservoir, China

1.2 Pore structure characteristics

The most essential characteristic of low permeability sandstone reservoir is small pore throat, high capillary pressure, the median radius generally less than 1 μm.

1.3 Strata scaling damage

After water flooding, usually because of reservoir temperature and pressure change or incompatibility ionic water-dividing mix, then precipitation were generated, forming a dirty deposit, reduce reservoir permeability, which make some effects on the kinds of oilfield development, especially low permeability oilfield, once dirty deposit blocked its pore throat it will make more serious influence on oilfield development. At present, some relevant research about scaling mechanism and anti-scaling measures have already undertaken in Jilin and Changqing oilfield. In addition, the feldspar content in sandstone reservoir is always higher in China, it is easy for feldspar to dissolution of rocks during acidification process, which result in structural damage, and form lots of clastic particle and clay to plug throat, to causes more damage in reservoir.

1.4 The role of natural fractures

Almost all of the diagenetic sandstone reservoirs develop natural fractures, but only in low permeability reservoirs, fractures will generate obvious influence on reservoir performance. The influence of fractures should be fully considered, using its advantageous side, avoiding adverse side, the key is to slow down the gas coning speed into wells along the fractures and expand gas injection sweep volume.

2 Several Key Problems Analysis on CO2 Displacement and Storage

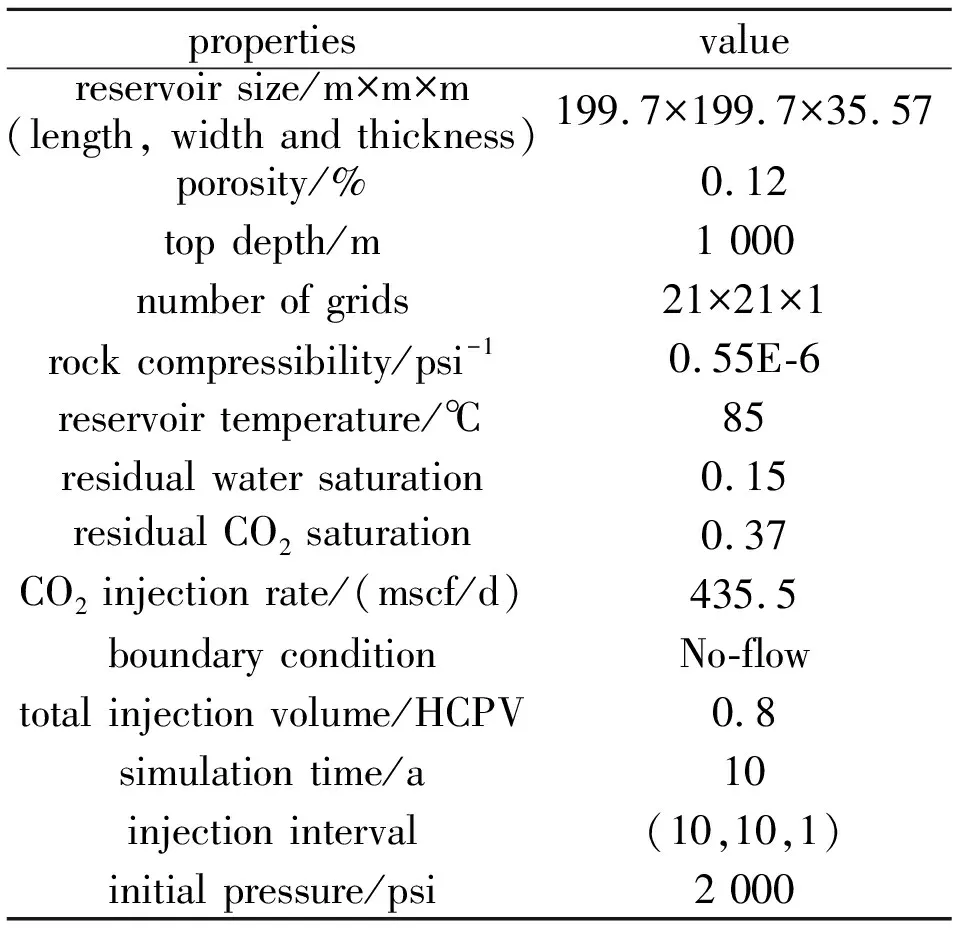

Theoretically, CO2recovery ratio in oil reservoir can reach 90%. However, the actual recovery often is not high under the effects of geological characteristics, fluid property and injection technology conditions and so on. A number of factors affect oil displacement and CO2storage efficiency; several key problems are analyzed as follow through theoretical analysis and numerical simulation methods to explain these effects. A five-spat pattern model was used in numerical simulation, an injection wells is located in the central, and four production wells are located in the four corners of the model. In order to simulate low permeability reservoir, the simulations presented an oil reservoir with a horizontal permeability of 1 mD, vertical and horizontal permeability ratio for 0.1, Tab.2 summarizes the base case input parameters including reservoir parameters and injection conditions. The main substances to be taken into account when describing flow and transport during CO2flooding and sequestration are CO2, irreducible water, and reservoir oil, of course, the rock matrix that forms the porous medium.

Tab.2 Summary of the reservoir properties and injection conditions

2.1 Viscous fingering

Because of the large viscosity difference between oil and gas, injected CO2can′t completely mix with oil and cause the gas coning of displacement front, namely viscous fingering phenomenon. In order to consider the fingering effect in black-oil model, the model introduces an empirical parameter,ω, amended the viscosity calculation model. A value ofω=1 results in a piston-like displacement of oil by the injected solvent. Ifω=0 the displacement is similar to an immiscible displacement (except for the treatment of relative permeability). An intermediate value ofωresults in a continuous solvent saturation increase behind the solvent front. The different values ofωwere used to illustrate the viscosity fingering and the effect on oil recovery and CO2storage efficiency.

Fig.1 shows the effect of viscous fingering on the oil recovery. Simulation results show that more oil produced from reservoir as the viscous fingering effect strengthens. Mixed parameter changed from 1 to 0, means that CO2displacement was from miscible displacement completelyto immiscible flooding. As viscous fingering effect became more serious, the poorer CO2mixed with crude oil, the faster gas displacement front coning, resulting in CO2oil displacementefficiency decrease and smaller recovery. We can also draw from the results that the immiscible displacement had the earlier gas breakthrough time, the less storage volume (Fig.2). In the case of miscible flooding, CO2can well mixed with crude oil, gas driving efficiency greatly increased, breakthrough seldom happened, the output volume is less.

2.2 Anisotropy

We just considered the different vertical to horizontal permeability ratio from 0.01 to 1 to (the horizontal permeability is 1 mD) explain the anisotropy effect. It should be pointed out that the amount of oil recovery and CO2storage increases with lowKv/Khvalue (Fig.3, Fig.4). The difference is significantly related with the upward migration. The lower vertical permeability (i.e. lowKv/Khvalue) prevents CO2from migrating up to the cap rock, and CO2can contact with crude oil completely. Simulation results showed that the lowKv/Khthe vertical to horizontal permeability ratio is beneficial to CO2flooding and geological storage.

Fig.1 Effect of the viscosity fingering on oil recovery with time Fig.2 Effect of the viscosity fingering on time development of storage volume

Fig.3 Effect of Kv/Kh on oil recovery with time Fig.4 Effect of Kv/Kh on time develop-ment of storage volume

Fig.5 Cross-section of distribution of free CO2 plume in oil reservoir (Left: immiscible; Right: miscible) for different simulation times

2.3 Gravity segregation

In order to clearly observe gravity segregation existing in CO2-oil system, a three dimensional model was presented on the basis of two-dimensional model as above, grid dimension was 21×21×5. Simulation injection time was 10 years, total simulation time for 40 years, other model parameters and injection parameters as mentioned above. All of the five wells adopted completely completion. Fig.5 shows the changes of CO2saturation profile with time (1, 20, 40 years) for miscible and immiscible displacement respectively.

It can be seen from above saturation distribution profile that CO2tend to migrate upward with the extension of time under buoyancy effect. Especially, after injection termination, gravity segregation became more apparent, however, immiscible displacement is more serious than miscible flooding, and CO2is easier to reach the top layer. In the process of immiscible displacement, much of CO2cannot effectively mix with crude oil existing as free phase in reservoir; therefore, the vertical migration happened easier. By comparing the distribution of CO2saturation, miscible displacement is favorable to CO2geological storage, reducing the risk of CO2leakage.

2.4 The reservoir heterogeneity[8]

Reservoir heterogeneity is one of the most dominant factors affecting the performance of CO2flooding and its expected oil recovery. Most of the low permeability reservoirs in China belong to continental deposition in complicated diagenetic environment, the interlayer heterogeneity is very serious, and the difference of permeability can reach several times, even thousands of times in the same reservoir. Especially, the low permeability reservoir has a development of natural fractures; the connected fractures constitute the channeling-path of injected water and gas. Most reservoirs have formed the connected channeling-path after decades of water flooding.

2.5 The minimum miscibility pressure (MMP)

MMP depends not on the purity of CO2and the reservoir temperature, but depends on crude oil components; the more heavy components (eg the above C5 components) into crude oil, the higher MMP. The outstanding characteristic of China′s reservoir has high viscosity, wax and high colloid content; these properties determine the most Chinese reservoirs have the high MMP. According to the preliminary evaluation results of China oilfield, characterized high proportion in western reservoir, and the low proportion in the east. In conclusion, most oil reservoirs is not suitable for CO2miscible flooding, immiscible displacement will play a dominant role in China.

Through the above analysis, we can conclude that many factors and problems comprehensive effect on the efficiency of oil displacement and CO2storage in low permeability oil, especially viscous fingering, gravity segregation and reservoir heterogeneity. Aiming at these problems, some technical ideas have been reported for improving CO2sweep efficiency in literature. Nestor L, Bai Betal.[9,10]published a technique-water alternating gas, to improve oil-water viscosity ratio, expand sweep efficiency, Zhu T[11]proposed CO2-foam flooding, by adding foam agents into CO2, increased CO2flow resistance, thus improving sweep efficiency; Heller, J.P, Xu Jianhang[12,13]introduced gas thickening technology, namely CO2mix with high molecular weight polymer, thus increase viscosity of CO2to reduce mobility ratio. All of these technical ideas based primarily on the same mechanism, namely lower mobility ratio and controlling CO2viscous fingering. In the future, we should be aimed at low permeability reservoirs in China, and focus on suppressing gas channeling and improving sweep efficiency in related research.

3 Conclusions

Because of the particularity of the China′s crude oil and reservoir conditions, CO2displacement and geological storage technique still has many technical challenges for implementation on a large scale. As the high MMP of CO2-oil generally; immiscible displacement gives priority to EOR and CO2geological storage in China.

Through the above analysis, we can get the following understanding:

(1)China has huge low-permeability reserves, low-permeability reservoirs will become the main place for oil and gas development and CO2storage in future.

(2)Many factors have the effect on oil displacement and CO2storage efficiency, the key factors include viscous fingering, gravity segregation, reservoir heterogeneity and miscible condition; should pay more attention in the process of CO2injection.

(3)Water alternating gas injection, CO2foam or gas thickening technology should be investigated further for field application.

(4)Aimed at low permeability reservoirs in China, the related research should focus on suppressing gas channeling and improving sweep efficiency in future.

With the coming of “post-Kyoto world” in 2012, China will inevitably become the focus in the global performance for greenhouse gas emissions. So the CO2displacement and geological storage technique will make positive contribution for China′s energy supply and emission reduction.

[1] Hu Wenrui. The present and future of low permeability oil and gas in China[J]. Engineering Science, 2009,11(8):30.

[2] Wu Bozhi. Theory and Application on High Efficiency Development in Low Permeability Reservoir[M]. Beijing: Petroleum Industry Press, 2009:1.

[3] Ennis-King, J. Paterson, L. Role of Convective Mixing in the Long Term Storage of Carbon Dioxide in Deep Saline Formations[R]. SPE Paper 884344, 2003.

[4] Felett, M., Gurton, R., Taggart, I. The Function of Gas-water Relative Permeability Hysteresis in the Sequestration of Carbon Dioxide in Saline Formations[R]. SPE Paper 88485, 2004.

[5] Holtz M.H. Residual Gas Saturation to Aquifer Influx: a Calculation Method for 3d Computer Reservoir Model Construction[R]. SPE 75502, 2002.

[6] Kumar A, Noh M, Pope G.A.etal. Reservoir Simulation of CO2Storage in Deep Saline Aquifers[R]. SPE 89343, 2004.

[7] Zeng Daqian; Li Shuzhen. Types and characteristics of low permeability sandstone reservoirs in China[J]. Beijing: Petroleum Science, 1994,15(1):41.

[8] Yue Xiang-an, Zhao Renbao, Zhao Fenglan. Technological chanllenges for CO2EOR in China[J]. Science Paper Online, 2007,2(7):487-488.

[9] Bai B, Grigg R B, Liu Y,etal. Adsorption Kinetics of Surfactant Used in CO2-Foam Flooding onto Berea Sandstone[R].SPE95920,2005.

[10] Nestor L. Management of Water Alternating Gas (WAG) Injection Projects[R]. SPE53714, 1999.

[11] Zhu T, Ogbe D O, Khataniar S. Improving the foam performance for mobility control and improved sweep efficiency in gas flooding[J]. Ind. Eng. Chem. Res., 2004,43:4 413-4 421.

[12] Xu Jianhang. Carbon dioxide thickening agents for reduced CO2mobility[D]. Pittsburgh: University of Pittsburgh, 2003.

[13] Heller, J.P., Dandge, D.K., Card, R.J.,etal. Direct Thickeners for Mobility Control of CO2Floods[R]. SPE11789, 1985:679.