Absorption Characteristics of Anechoic Coating Embedding Frustum-of-a-cone Cavities

2010-02-27SHANGChaoZHANGJiazhongWEIYingjie

SHANG Chao,ZHANG Jia-zhong,WEI Ying-jie

(School of Astronautics,Harbin Institute of Technology,Harbin 150001,China)

1 Introduction

Rubber sheets embedding air cavities(usually cylindrical),are used as anechoic coatings to reduce the energy of sound waves reflected by underwater structures.Studies on resonance absorption mechanism for such layered configurations began in the forties of the Twentieth Century and are continually under developing[1-10].

Two types of resonance mechanisms are known to be existed in such layered configurations.One is due to the radial motion of the hole-wall and the other is due to the drum-like oscillations of the cover layer.By changing the hardness of the perforated layer for his experiments,Lane[3]put forward that absorption performance was primarily due to the dynamic response of the cover layer vibrating as a diaphragm over the cavity.But Gaunaurd[4]held that the importance of the two types of resonance mechanisms were determined by the cover layer and perforated layer’s relative stiffness.By approximating the varying sectional cylindrical cavity as the structure of layered cylindrical tubes,Tang[5]indicated that the absorption performance of anechoic coating embedding cylindrical cavities with horn shape was better than that of anechoic coating embedding uniform cylindrical cavity.

It is difficult to obtain analytic solution for acoustic characteristics of anechoic coating embedding cylindrical cavities.Thus numerical methods are widely used and finite element method(FEM)has been chosen mostly.By using the finite element method,Hennion[6-7]and Easwaran[8]studied the reflection characteristics of anechoic coatings with a doubly periodic structure.Tan[9]analyzed sound characteristics of the viscoelastic layer containing periodic cavities and presented the numerical results for the base layer with spherical,cylindrical or cone-shaped cavities.

In the present paper,frustum-of-a-cone cavities are introduced,and the absorption characteristics of both single-cavity coating and mix-cavity coating are studied by numerical simulation respectively.Then the influence of coating structure parameters on absorption characteristics is also studied.

2 Theory model

2.1 Acoustic problem of fluid-structure interaction

In order to solve the acoustic problem of fluid-structure interaction,following assumptions are made

(1)The fluid is compressible,but the pressure is limited to a small variation with respect to the mean pressure;

(2)The fluid is stationary and inviscid(that is,viscosity causes no dissipative effects);

(3)Uniform mean density and mean pressure,with the pressure solution being the deviation from the mean pressure,not the absolute pressure.

Then the momentum equation can be simplified as follows:

where:{U }is the displacement vector of the structure at the interface;{n }is the unit normal vector of the interface S,from fluid to solid.

By using the Galerkin method,the complete finite element discredited equations for the fluid-structure interaction problem are written in assembled form as:

where[R]is a ‘coupling’ matrix that represents the effective surface area associated with each node on the fluid-structure interface.

2.2 Sound absorption of viscoelastic material and fluid boundary

Anechoic coating usually uses viscoelastic materials(e.g.rubber)as the substrate,but for viscoelastic solid,its Lame constant is complex and the imaginary part represents the existence of material loss factor.Then its elastic material parameters should be in complex number form,too.Elastic modulus E can be expressed as a complex number:

where,η is the loss factor.Then the stiffness matrix is transformed to a complex stiffness matrix:

The damping matrix[C]can be expressed by the stiffness matrix[K]and the loss factor η:

where ω is the circular frequency.

The expression for the fluid damping matrix[Cf]is

where,c is the sound speed in fluid;α is the absorption coefficient for the fluid boundary;{}N is the shape function of the sound pressure.

If set α=1,the fluid boundary becomes the non-reflecting boundary which can be used to simulate the infinite flow field.

2.3 Reflection coefficient and absorption coefficient

When plane harmonic waves incident vertically upon the contact interface,the sound pressure reflection coefficient R can be calculated by:

where Z0=ρ0c is the impedance of incident plane wave medium;Zbis the mechanical impedance of absorbing surface per unit area.Zbis usually a complex number:

where,p is the pressure at nodes of fluid,v is the normal velocity at nodes of solid.

After obtaining the reflection coefficient R,the absorption coefficient α is expressed as

3 Anechoic coating model

The construction of a typical resonant sound absorber is shown in Fig.1.Acoustic coating(rubber layer embedding double periodic cylindrical air cavities)is laid on the plate,which is with the air backing.Plane harmonic waves incident normally from water.The relevant parameters are,for rubber:density ρ=1 100kg/m3,Young’s modulus E=1.4e8N/m2,Poisson’s ratio υ=0.49,loss factor η=0.23,for steel,ρ=7 800kg/m3,E=2.07e11N/m2,υ=0.3,and for water,ρ=1 000kg/m3,wave velocity c=1 489m/s.The thicknesses of cover layer,perforated layer,base layer and steel layer are t1=0.002m,t2=0.046m,t3=0.002m and t4=0.005m,respectively.

Fig.1 Sketch of structure mod el

It is known that different structures with the same perforation rate have different absorption performance.In Ref.[10],it has been indicated that structure with four small cylindrical cavities around a bigger cylindrical cavity had better absorption performance.Fig.2 shows the cross-sectional view of unit cell of the structure model,which was established by adopting 8-node hexahedron units,and the maximum mesh size is 2.5mm.Case 1 is a singlecavity coating and Case 2 is a mixed-cavity coating.

In order to improve the absorption performance of the anechoic coating,frustum-of-acone cavity,which is a type of varying sectional cylindrical cavity,is introduced.

Fig.2 Cross-sectional view of unit cell of the section A-A of Fig.l

4 Results and discussion

The analytic solution of no-cavity coating is calculated.Fig.3 shows the comparison of FEM solution and analytic solution with the thickness of water layer tw=0.007 5m and tw=0.07 5m respectively.It can be seen that the FEM solution agrees well with the analytic solution.And less finite elements are used to simulate the infinite flow field under the non-reflecting boundary.

Fig.3 Comparison of FEM solution and analytic solution

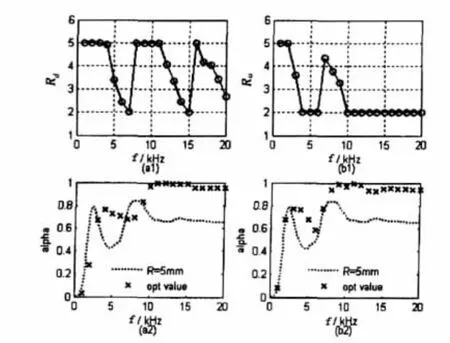

Fig.4 The optimization result of single-cavity structure

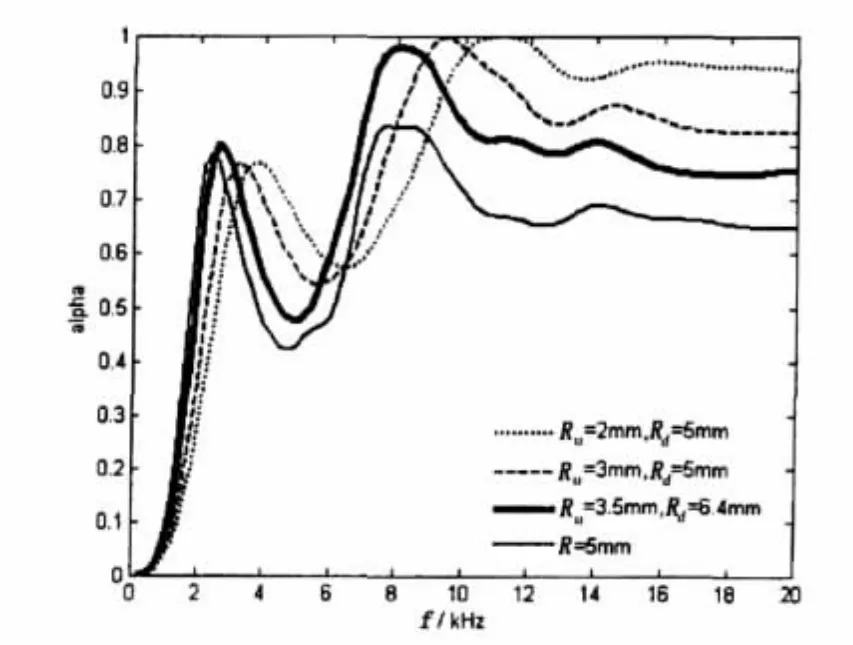

Fig.5 Curves of absorption coefficient of case 1 with different cavity shapes

Fig.4 and Fig.5 are the simulation results for the coating with single-cavity structure.Fig.4 shows the optimization result with the radii of the frustum-of-a-cone as variable.Here,Ruis the radius of the frustum-of-a-cone at top of perforated layer;Rdis the radius of the frustum-of-a-cone at bottom of perforated layer.Fig.4(a1)and Fig.4(b1)show the optimal values of Rd,Ruwith the change of frequency,when Ru=2mm,Rd=5mm,respectively.Fig.4(a2)and Fig.4(b2)show their optimal values of absorption coefficient accordingly and the solid line is the curve of absorption coefficient of coating with R=5mm cylinder cavity.The absorption performance of coating is better with smaller Ruat high frequency and with larger Ru,Rdat low frequencies.Fig.5 shows the comparisons of absorption performance among three types of frustum-of-a-cone cavities coating and a cylinder cavity coating.The last two cases have the same perforation rate.As shown in the figures,with the Ruincreased,curves of absorption coefficient shift to low frequency and shift down at high frequencies.Under the condition of same perforation,the absorption performance of frustum-of-a-cone cavities coating is more attractive than that of cylinder cavity coating.

Absorption performance of Case 2 with different frustum-of-a-cone cavities shapes is shown in Fig.6.Where,the radii(R0u,R0d,R1u,R1d)of Case 2-a,2-b,2-c and 2-d are(1.5,3,2,5)mm,(2,3,2,5)mm,(2,3,3,5)mm,(2,4,3,5)mm,respectively.It is shown that curves of absorption coefficient shift to low frequency with the radii increase and the bandwidth of sound absorption becomes narrow.Case 2-d,which has the largest radii,has the best absorption performance at low frequencies.Case 2 with frustum-of-a-cone cavities can keep its absorption coefficient above 0.8 at high frequencies.Fig.7 shows absorption performance of Case 1 and Case 2 with same perforation rate.Before the first-peak response frequency,the four cases have the similar absorption performance.After the first-order peak response frequency,mixcavity coating has better absorption characteristics obviously.The curves of absorption coefficient of frustum-of-a-cone cavities coating shift to low frequency related to cylinder cavity coating.Case 2-d has the largest peak absorption coefficients at every order response frequency in the whole band and its second-order peak absorption coefficient has reached 0.998 at 7kHz.

Fig.6 Curves of absorption coefficient of Case2 with different cavity shapes

Fig.7 Absorption performance of Case 1 and Case 2 with same perforation rate

Fig.8 shows the vibration modes of case d at 7kHz.The strenuous drum-like oscillations of the cover layer over the cavities occurred,which is helpful to the absorption of sound energy.And the radial motion of the whole cavity-wall is considerable,which would play a leading role in absorbing the sound energy.

Fig.8 The vibration modes of case d at 7kHz

The numerical results show that the bigger perforation rate,the lower resonance vibration frequency is.Then the curve of absorption coefficient of coating shifts to low frequency,and the first peak value of absorption coefficient increases.However,with the top radius of cavity increasing,more high frequency sound waves are reflected.Relating to single-cavity and cylindrical cavity respectively,mixed-cavity and frustum-of-a-cone cavity have more surface area and smaller top radius of cavity under the condition of same perforation rate.On the whole,the absorption performance of coating embedding mixed frustum-of-a-cone cavities is better than that of the others at all-band frequency.

5 Conclusions

The absorption characteristics of anechoic coating embedding frustum-of-a-cone cavities with air backing have been studied,and the following conclusions can be drawn:

(1)At low frequencies,the larger top radius or larger bottom radius of frustum-of-a-cone cavities results in the higher absorption coefficient.

(2)At high frequencies,it is an effective way to increase the absorption coefficient by reducing the top radius of frustum-of-a-cone cavities.

(3)After the first-order peak frequency,mix-cavity coating has better absorption characteristics than single-cavity coating obviously.

(4)Under the condition of same perforation rate,coating embedding mixed frustum-ofa-cone cavities has more surface area and smaller top radius of cavity.On the whole,its absorption performance is better than that of others at all-band frequency.

[1]He Zuoyong,Wang Man.Investigation of the sound absorption of homogeneous composite multiple-layer structures in water[J].Applied Acoustics,1996,15(5):6-11.

[2]He Zuoyong,Wang Man.Investigation of the sound absorption of non-homogeneous composite multiple-layer structures in water[J].Applied Acoustics,1996,15(5):12-19.

[3]Lane R.Absorption mechanisms for waterborne sound in Alberich anechoic layers[J].Ultrasonics,1981,19(1):28-30.

[4]Gaunaurd G C.Comments on ‘Absorption mechanisms for waterborne sound in Alberich anechoic layers’[J].Ultrasonies,1985,23(2):90-91.

[5]He Shiping,Tang Weilin,He Lin,Tang Zhiyin.Analysis of acoustic characteristics of anechoic coating containing varying sectional cylindrical cavity[J].Journal of Ship Mechanics,2006,10(1):120-127.

[6]Hennion A C,Bossut R,Decarpigny J N.Analysis of the scattering of a plane acoustic wave by a periodic elastic structure using the finite element method:Application to compliant tube gratings[J].J Acoust.Soc.Am.,1990,87(5):1861-1870.

[7]Hennion A C,Decarpigny J N.Analysis of the scattering of a plane wave by a double periodic structure using the finite element method:Application to Alberich anechoic coatings[J].J Acoust.Soc.Am.,1991,90(6):3356-3367.

[8]Easwaran V,Munjal M L.Analysis of reflection characteristics of a normal incidence plane wave on resonant sound absorbers:A finite element approach[J].J Acoust.Soc.Am.,1993,93(3):1308-1318.

[9]Tan Hongbo,Zhao Hong,Xu Haiting.Sound characteristics of the viscoelastic layer containing periodic cavities by the finite element method[J].ACTA Acustica,2003,28(3):277-282.

[10]Shang Chao,Zhang Jiazhong,Cao Wei.Study of the absorption characteristics of Alberich anechoic coating based on the finite element method[J].Journal of Ship Mechanics.Accepted,2010.

杂志排行

船舶力学的其它文章

- Modeling and Simulation of Cavitating Flow over Underwater Vehicle with Large Angle of Attack

- Hydrodynamic Analysis of 3-D Hydrofoil under Free Surface in Time Domain

- Hydroelastic Analysis of SWATH Ship Wave Loads

- Applicability of the Improved Crack Growth Rate Model for a Wide Range of Alloys under Constant Amplitude Load

- Vulnerability Evaluation of Aircraft Guarantee System by Improved Fuzzy Petri Net

- Optimum Design of Cylindrical Shells under External Hydrostatic Pressure