悉尼国际体育中心

2001-07-10

悉尼国际体育中心从设计到施工均由澳大利亚人完成,是钢结构设计和工程实践的范例。钢结构的成功运用代表了澳大利亚在钢结构方面成就。这个出色的钢结构体育建筑,已在2000年吸引了全世界的目光。

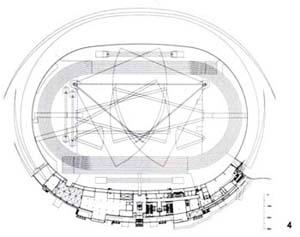

结构的设计主旨是把体育中心融合到场地环境中。钢材可以在大型结构中保持最小的联结点,不仅满足结构需要,也能满足美学需要。曲面屋顶和看台的优美曲线表现出澳大利亚早期的“黄金时代”。

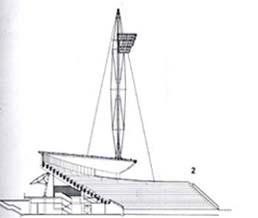

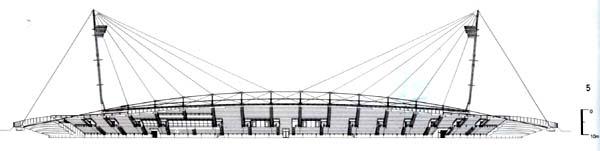

从设计到施工,各方面都渗透着创新精神,尤其是屋面系统。大看台的屋面系统与传统形式非常不同,轻质屋面通过钢缆网悬挂在45m高的钢桅杆上。桅杆支持着屋面前部,各桅杆的六个倾斜前支柱把向下的荷载从铆接在桅杆上带有两个后支柱的椽子上传递到地面。

钢桅杆可承担350t荷载,并保持轻巧外形。与采用7个交错式桅杆结构方案相比,由预张力高强度杆加强的4个钢管构成的核心既能满足美学上的要求,又能满足经济上的要求。

钢桅杆完全在车间中制造组装,这样加快了安装速度并提高了场地安全。前桅支索装配前已系到桅杆上。构件组装前的全面检测和计算机分析显示钢缆的最终位置与预计位置相差不超过25mm。屋面在地面预先组装好,包括屋面梁、屋面系统和天花板、线缆和灯具,而后吊装到位,不需搭建脚手架。

各桅杆基座上的200m长悬索连接到前支柱上,以抵消风的升力。前支柱加入预张力以减小前支柱因自重而下垂。屋面支撑钢桅杆可以安装泛光灯,使此方案的经济性大大提高,场地的两个照明结构可以取消。

钢缆支撑屋面系统的独特之处是屋面向前倾斜,从前沿排水,为观众和官员提供了最大的遮蔽。

屋面的弹性变形模型在莫纳什大学进行了风洞试验,以准确确定风荷载和检测屋面的动态变化。风洞试验得到了一个不寻常结果,可以用一个独特的钢缆结构承担,而不需很大的投资。

由于钢缆的下垂作用,屋面试验的动态分析较为复杂,需同时加载结构的自然频率。

在整个设计阶段应用了艺术工程设计和计算机分析。开发了一个专用计算机程序,用于确定在特定前支柱预张力的作用下钢缆系统的形状和计算钢缆的下垂和总钢缆用量。非线性分析被应用到确定因安装屋面导致的结构几何形状的累积变化上。

结构的耐久性是设计的主要考虑方面,因而开发了一套喷涂系统,铸件完全镀锌,并且设计了一整套自排水和清洁系统,以降低积尘和雨水冲刷。暴露在外的钢结构尽量使用封闭截面的构件,如盒形或桶形,以便于雨水把积尘冲走,并且能减少鸟兽的栖息地。

决定采用钢缆支撑系统经过了广泛的调查,并考察了各种屋面的方案,以及如何有效处理下列问题;结构的效率、投资的效率、美学因素、造型、可建性、用户友好性、环境影响和耐久性。

(水润宇译)

Totally designed, engineered, constructed and developed in Australia by Australians, the Sydney International Athletic Centre is an extraordinary example of innovation and invention in steel design and engineering practice.An ingenious solution to a difficult problem, the use of steel elements throughout the Athletic Centre has provided the people of Australia with a truly remarkable grandstand building.This use of steel has confirmed the appropriateness of the material for a high profile project;a steel structure on which the eyes of the world will be cast come the year 2000. A major design theme flowing through the structure was that the Centre integrate into the landscape and recognise existing landforms.The earth is mounded and modelled to respond to these needs which the built form is designed to grow out of and complement.Steel was specified for its ability to be easily moulded with even the smallest connection examined in great detail to ensure that it not only satisfied strength requirements but fulfilled aesthetic requirements.The catenary cables of the Athletic Centre are in counterpoise to the curved roof and grandstand which are natural extension of the curved berm forming the arena.Paved areas meander between parts of the facility in graceful curves reflecting the earliest images of Australia‘s Dreamtime.Innovation permeates almost every aspect of the design, engineering and construction of the Athletic Centre, in particular its roofing system.In a major departure from conventionally used grandstand roofing systems, an extremely lightweight roof structure was designed which is suspended by a network of cables from two 45m high steel masts at each end of the stand.These masts provide support for the front of the roof and six raking front stays from each mast transfer the downward load from the rafters with two back stays anchoring the masts to the ground. The steel masts had the potentially conflicting responsibility of carrying loads of 350 tonnes yet also provide an aesthetically fine and lightweight structure.A combination of a core of four clustered tubes braced by pre-tensioned high strength rod bracing elements best fulfilled aesthetic and economic requirements when compared to seven alternative structure mast schemes.The engineering of such a mast is at the absolute cutting edge of analysis and design techniques.Relevant Australian safety standards were exceeded as a direct result of the material chosen for the construction of the roof.The masts were entirely fabricated and preassembled in the shop, speeding erection and significantly enhancing site safety.Even the forestay cables were attached to the masts prior to erection.Thorough checking and computer analysis of all elements prior to erection saw the final location of the cables within 25 mm of the predicted position;a truly remarkable result.The roof was prefabricated in panels on the ground including roof girders, roof systems and ceilings, cables and lights and lifted into position without scaffolding.Secured by just four pins, the crane time required to erect each panel was significantly reduced. A 200 m long catenary cable taken over the top of each mast pedestal and connected to the forestays provides resistance to wind uplift.The forestays are pretensioned to tension the catenary cable and to minimise the sag of the stays under self-weight.This is a true tension structure.

The ability to attach floodlights to the roof-supporting steel masts also contributed dramatically to the economy of this scheme as two lighting structures for the arena were able to be deleted.A unique characteristic of the cable-stayed roofing system is that the roof tilts forward due to the double curvature of the roof profile, disposing of roof stormwater at the front edge and allowing maximum protection for spectators and officials.An aeroelastic model of the roof was wind tunnel tested at Monash University to provide an accurate determination of wind loads and to examine the dynamic behaviour of the roof.This wind tunnel testing resulted in very unusual load combinations which the unique behaviour of a cable structure was able to accommodate without significant cost penalty.The dynamic analysis and testing of the roof was complicated by the effect of cable sag which resulted in the natural frequency of the structure being load dependant, a highly unusual situation.State of the art engineering and computer analysis was carried out throughout the design stage.A specially developed computer program was used to determine the shape of the cable system under specified forestay pretensions and to calculate cable sags and total cable mass.Non-linear analysis was undertaken using a purpose written computer program which the building contractor used to determine the progressive changes in the geometry of the structure as the roof panels were erected.Durability of the structure was a major consideration in design.A special paint system was developed, castings were fully galvanised, and self draining and cleaning systems were an integral part of the design to minimise dust build-up and rainwater run-off.Exposed structural steelwork makes extensive use of closed sections, box and circular steel tubes, where dust build-up can be effectively washed away by rain, and to minimise potential roosting places for vermin.The decision to use a cable stayed structure was made after an exhaustive investigation and review of alternative roof schemes and how effectively they met the key criteria - efficiency in structure, cost effectiveness, aesthetics, image, buildability, user friendliness, effect on the environment and durability.The construction of the Sydney International Athletic Centre formed a major part of Sydney‘s bid for the 2000 Olympics and represents an outstanding asset for the people of Sydney of which they can be justifiably proud.The successful use of steel for this structure and the role of steel technology combined with innovative design and engineering techniques was influential in Sydney securing the 2000 Olympics.The structure was completed six months ahead of time and under budget and results in a roof with superior weather protection for the public.Throughout the intense bid process, the Australian steel design and construction industry was the subject of immense international scrutiny with nothing short of exceptional expertise and practice in steel design acceptable.The result is a triumph of what can be achieved with a careful attention to details, world best practice in engineering techniques and pushing technology to its limits in from of the watchful eyes of the world.The Sydney International Athletic Centre rests as evidence of what can be achieved in Australia with steel construction.This stadium represents innovation in the true sense of the work.There is no other stadium like it anywhere else in the world.

国际体育中心景观图 |  剖面图 |

钢桅杆 |  国际体育中心平面图 |

国际体育中心立面图