致密储层极限渗透率的计算及其应用

2025-02-13刘志楠张贵才葛际江杜勇

摘要:致密储层渗透率是决定水驱开发方式为驱替、渗吸或是驱替-渗吸联合使用的重要参数。分析不同渗透率下动态压差和渗吸压差的变化规律,提出致密储层极限渗透率的存在并对其定义,即极限渗吸渗透率(ki)、极限驱替渗透率(kd)和极限驱替开发渗透率(ku)。基于极限渗透率的定义,阐明各极限渗透率对于水驱的意义,提出一种计算水湿(弱水湿)致密储层ki、kd和ku的方法,并对中国典型致密储层极限渗透率计算。结果表明:当渗透率降低至某一数值时,动态压差(渗吸压差)的数值变为零;渗吸动力在驱动力中的比例随储层渗透率降低而增加,而动态压差与渗吸压差随渗透率升高而增大;ki是致密储层可采渗透率的下限,kd是驱替开发渗透率的下限,ku是驱替在开发过程起主导作用的渗透率下限;驱替-渗吸作用渗透率大于渗吸作用渗透率。

关键词:致密储层; 极限渗透率; 渗吸; 驱替; 驱替-渗吸; 水驱开发

中图分类号:TE 122.2""" 文献标志码:A

引用格式:刘志楠,张贵才,葛际江,等.致密储层极限渗透率的计算及其应用[J].中国石油大学学报(自然科学版),2025,49(1):136-144.

LIU Zhinan, ZHANG Guicai, GE Jijiang, et al. Calculation and application of ultimate permeability for tight reservoirs[J].Journal of China University of Petroleum(Edition of Natural Science),2025,49(1):136-144.

Calculation and application of ultimate permeability for tight reservoirs

LIU Zhinan1, ZHANG Guicai1, GE Jijiang1, DU Yong2

(1.School of Petroleum Engineering, China University of Petroleum(East China), Qingdao 266580, China;

2.SINOPEC Shengli Oilfield, Dongying 257001, China)

Abstract: The permeability of tight reservoirs is an essential parameter that""" determines whether the water flooding development mode is displacement, imbibition or a combination of displacement-imbibition. By analyzing the variation pattern of dynamic and static differential pressure at different permeability, the ultimate permeability was proposed to exist and defined, namely the ultimate imbibition permeability (ki), the ultimate displacement permeability (kd) and the ultimate displacement development permeability (ku). Based on the definition of ultimate permeability, the significance of each ultimate permeability for water flooding for water-wet (weakly water-wet) tight reservoirs was elucidated, and a method for calculating ki, kd and ku was proposed as well. And the ultimate permeability of typical tight reservoirs in China was calculated. The results indicate that the permeability decreases to a certain value, the value of the dynamic pressure difference (imbibition pressure difference) becomes zero.

The proportion of imbibition dynamic force relative to the driving force increases as reservoir permeability decreases,while the dynamic pressure difference and the imbibition pressure difference increase with increase of permeability. ki represents the lower limit of recoverable permeability in tight reservoirs, kd denotes the lower limit of permeability for effective displacement development, and ku indicates the lower limit of permeability where displacement becomes the dominant mechanism in the development process. The permeability of displacement-imbibition effect is greater than that of imbibition.

Keywords: tight reservoirs; ultimate permeability; imbibition; displacement; displacement-imbibition; water flooding development

收稿日期:2024-08-28

基金项目:中国石油天然气集团有限公司科技计划专项(ZD2019-183-007-033)

第一作者:刘志楠(1990-),男,博士研究生,研究方向为提高采收率与采油化学。E-mail:fslzn1990@163.com。

通信作者:张贵才(1966-),男,教授,博士,博士生导师,研究方向为提高采收率与采油化学。E-mail:zhanggc@upc.edu.cn。

文章编号:1673-5005(2025)01-0136-09""" doi:10.3969/j.issn.1673-5005.2025.01.014

开发致密油藏是解决能源需求日益增长的一种方法[1-4]。水驱较CO2驱、泡沫驱以及混相驱具有成本低的优点,但致密储层特征为基质物性差[5]、低渗透率[6]和低孔隙度[7-8],致密储层可开采的渗透率下限已有大量研究[9-10]。Xiao等[11]发现水膜厚度和渗透率呈现L型曲线,其平坦段对应的束缚水膜厚度是孔喉半径下限,而L型曲线拐点是可采渗透率下限。研究结果发现大庆和长庆致密储层可采渗透率分别为0.08×10-3 μm2和0.03×10-3μm2。进一步研究[12]发现当纳米孔隙占总孔隙65%以上时,对应的渗透率是该储层可开采渗透率下限。Jiang等[13]根据可动流体百分数对致密储层分为3类并确定可采渗透率下限。张世铭等[14]通过可动流体与束缚流体的分离点确定孔喉下限,并通过孔喉-渗透率关系曲线确定可采渗透率下限。现有计算致密储层可采渗透率下限的方法没有区分驱替和渗吸的极限渗透率,笔者基于流体在基质中流动状态,从渗吸和驱替机制出发,定义极限渗吸渗透率(ki)、极限驱替渗透率(kd)以及极限驱替开发渗透率(ku)的概念,并提出计算方法。以玛湖百口泉组,姬源长6段,马岭长8、延10段和榆树林扶杨油层为例,计算各致密储层的极限渗透率,对结果进行分析。

1" 致密储层极限渗透率定义

致密储层水驱开发由驱替[15-17]和渗吸[18-19]两部分组成。多数学者认为,致密储层开发是驱替-渗吸双重机制的结果[20-22]。亲水储层驱替动力等于储层压力梯度与毛管力之和[23],渗吸动力为毛细管力[24],即渗吸动力是驱替动力的一个组成部分[25]。

1.1" 极限渗透率的提出

基于达西渗透率公式,将多孔介质视为等半径的均一平行毛细管束,其数值与多孔介质的喉道半径成正比[26-27],获得平均喉道半径r[28]:

r=207kφ .(1)

式中,k为渗透率,10-3 μm2;φ为孔隙度。

根据Laplace方程,计算毛细管中油水界面两侧的压力差(pc)[29]为

pc=2σcosθr.(2)

式中,σ为油水界面张力,mN/m;θ为润湿角,(°)。

流体在基质流动时,与基质或其上附着的薄膜层之间产生相对运动,流体分子在流动过程的黏滞力(Fη)[30]为

Fη=8μ0Lqπr4=8μ0Lνr2 .(3)

式中,μ0为流体黏度,mPa·s;L为流体移动距离,m;q为流体流量,mL/s;v为驱替速度,m/s。

绘制启动压力梯度-渗透率的关系曲线,回归得到启动压力梯度(pλ)与渗透率关系表达式[31]为

pλ=ak-b.(4)

式中,a和b为常数。

对于亲水(弱亲水)致密储层,驱替动力(Fu)是储层压力梯度与毛细管力之和,数学表达式为

Fu=Δp+pc.(5)

单位距离的驱替动力与阻力共同构成动态压差(pu),即

pu=Δp+pc-pλ-Fη .(6)

对于亲水(弱亲水)致密储层,渗吸过程中毛细管力提供渗吸动力(pi),即

Fi=pc.(7)

与动态压差类似,单位距离的渗吸动力与阻力之差为渗吸压差:

pi=pc-pλ-Fη .(8)

式(5)和(7)说明毛细管力即渗吸动力是驱替动力的一部分,因此渗吸动力和驱替动力不可完全分割,均为水驱过程中的动力,如图1所示。

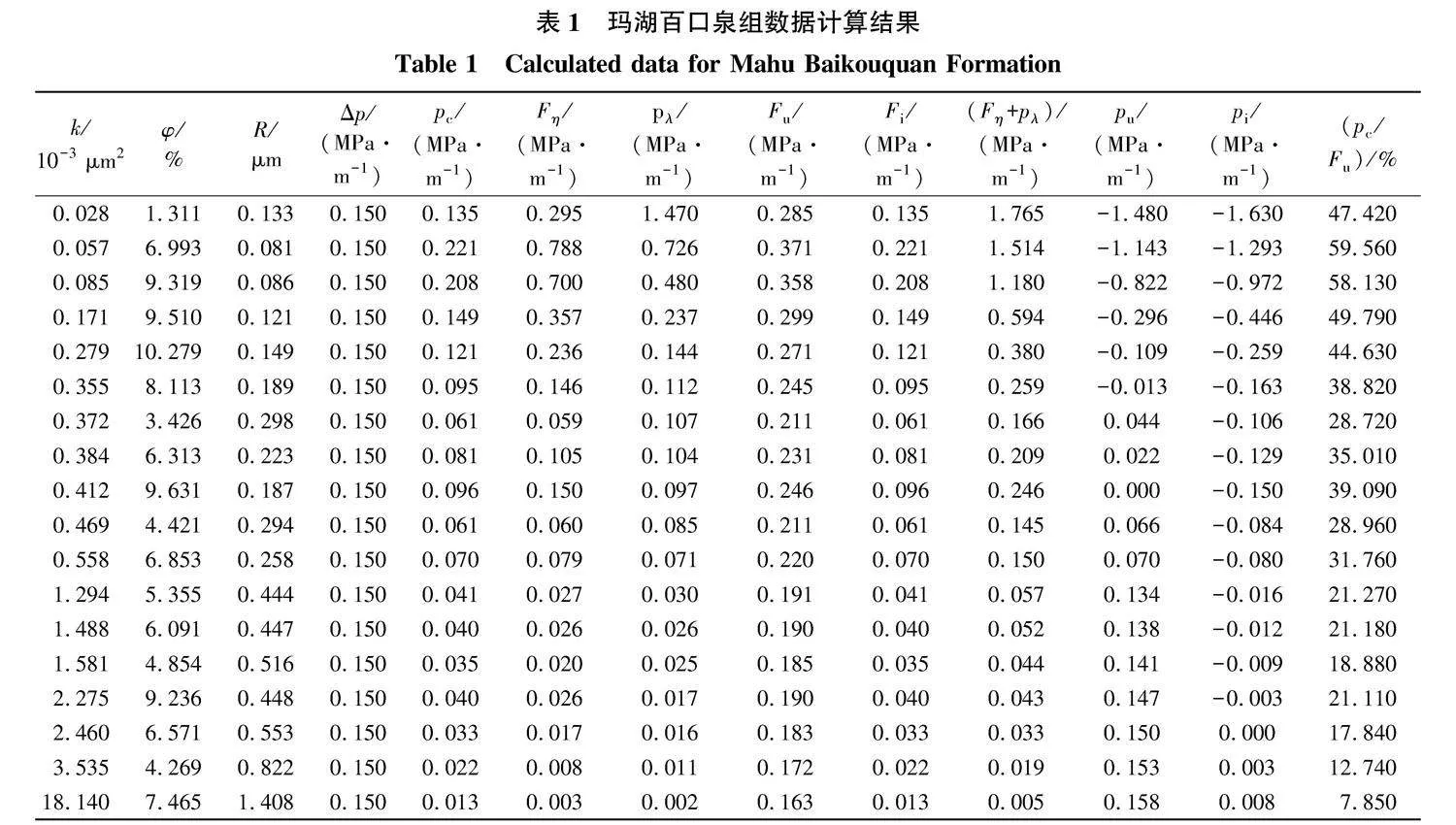

设定:Δp=0.15 MPa[32];L=1 m;θ=60°;油水界面张力σ=18 mN/m;流体流动速度v=0.0001 m/d=1.157×10-9 m/s,玛18井区原油黏度0.43 mPa·s,艾湖井区原油黏度0.70 mPa·s,平均地下原油黏度0.565 mPa·s[33],因此取黏度μ0=0.565 mPa·s。假设岩心绝对均质,岩心中所有孔喉完全一致。按照公式(1)~(8)计算玛湖百口泉组[34]相关数据,结果见表1。

由表1可得:随着储层渗透率降低,毛细管力(渗吸动力)在驱替动力中所占比例增加;随着储层渗透率升高,动态压差与渗吸压差增大;当渗透率大于0.37×10-3" μm2时,动态压差大于0 MPa/m,这表明储层流体在0.15 MPa/m储层压力梯度下可以流动,即理论上玛湖百口泉组可以有效驱替的最小渗透率为0.37×10-3" μm2;当渗透率大于2.54×10-3" μm2时,渗吸压差大于0 MPa/m,表明储层流体在仅为毛细管力作用下可以流动,此时渗吸和驱替完全统一,动态压差成为储层流体流动的主要动力,也就是理论上2.54×10-3" μm2是玛湖百口泉组高效驱替的最小渗透率。

1.2" 极限渗透率的定义

对玛湖百口泉组致密储层的分析发现,致密储层驱替开发存在一个渗吸可以忽略、驱替为主的渗透率下限(极限驱替开发渗透率ku)和驱替可以发生的渗透率下限(极限驱替渗透率kd),因此也应该存在一个渗吸可以发生的渗透率下限(极限渗吸渗透率ki)。

当致密储层渗透率降低至某临界值时,岩石孔隙中所有喉道部位岩石表面分子与流体分子间作用力均大于流体流动的剪切力,喉道部位流体全部束缚于岩石表面,孔隙结构中流体失去流动性,此时渗吸和驱替均不能发生,因此渗吸同样存在一个极限渗透率(极限渗吸渗透率ki),小于该渗透率的储层属于不可开发储层,极限渗透率如图2所示(根据玛湖百口泉组储层计算数据,ki=0.011 7×10-3" μm2, kd=0.37×10-3" μm2,ku=2.54×10-3" μm2)。

在致密储层研究过程中,由于渗透率的极限值定义较为模糊,现对致密储层各极限渗透率定义如下。

(1)极限渗吸渗透率(ki)。当渗透率降低至某一数值时,岩石孔隙中所有喉道部位岩石表面分子与流体分子间作用力均大于流体流动的剪切力(即喉道半径小于等于束缚水膜厚度Rt≤hsw,图3),流体全部束缚于喉道部位岩石表面(即孔隙结构中流体失去流动性),此渗透率称为极限渗吸渗透率(ki),它是储层可采的渗透率下限。对于某一储层,驱替压力梯度、岩石润湿性和流体极性都会对极限渗吸渗透率产生一定的影响。

(2)极限驱替渗透率(kd)。随渗透率降低,流体渗流阻力增加、动态压差下降,当动态压差pu≤0时,多孔介质中流体停止流动,此渗透率为可以驱替的最小渗透率,称为极限驱替渗透率(kd),它是储层驱替开发的渗透率下限。对于某一储层,极限驱替渗透率是一个可变值。驱替介质和被驱替介质黏度越低、驱替压力梯度越大、储层润湿性越向亲水转变,极限驱替渗透率越小。

(3)极限驱替开发渗透率(ku)。渗透率越大,动态压差、渗吸压差同时增加,当渗透率提高至某一数值时,渗吸压差大于零(pi≥0),此时正向渗吸作用在驱替方向全程发生,渗吸动力成为驱替动力的一部分,动态压差成为储层流体流动的主要动力,此渗透率称为极限驱替开发渗透率(ku),它是驱替作用在储层原油开发过程起到了绝对主导作用的渗透率下限。对于某一储层,储层流体黏度越低、岩石越亲水,极限驱替开发渗透率越小。

2" 致密储层极限渗透率理论

2.1" 极限渗吸渗透率计算方法

可动流体饱和度是影响储层渗流能力的重要原因[35]。根据致密储层孔隙度(φ)和可动流体饱和度(Smw),计算出可流动流体孔隙度(φm)[36]为

φm=φSmw.(9)

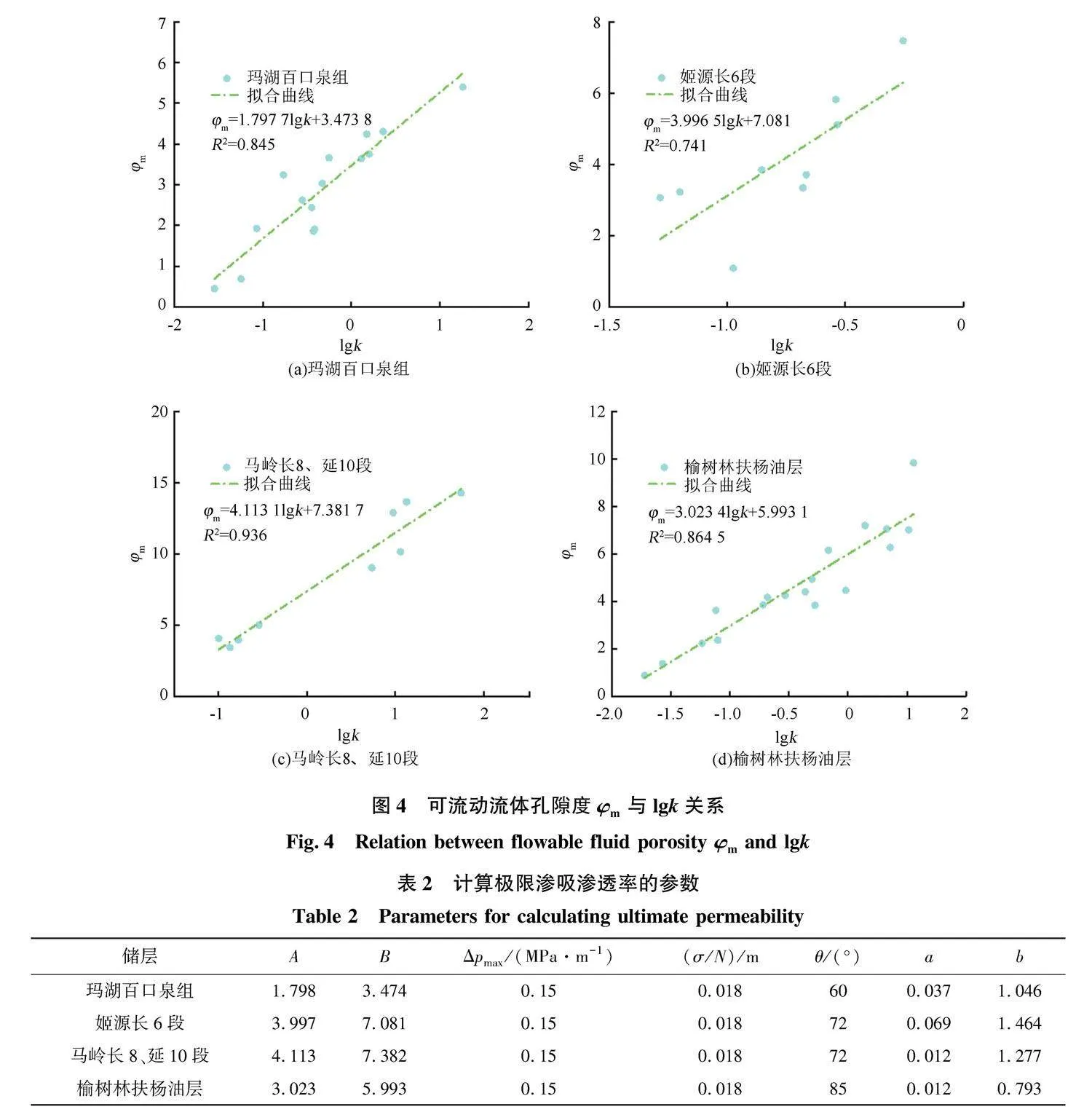

将渗透率的对数值与可动流体饱和度作lgk-φm曲线,结果表明,该曲线呈正相关,回归得到关系式为

φm=Algk+B.(10)

式中,A和B为常数。

如图3所示,由于储层是亲水性(弱亲水性),靠近岩石边缘有一束缚水膜层,当孔径小到一定程度后,束缚水膜层厚度等于喉道(孔隙)半径,可动流体饱和度为零,此时对应的渗透率为极限渗吸渗透率,即极限可采渗透率下限,由式(10)得

ki=10-BA .(11)

2.2" 极限驱替渗透率计算方法

多孔介质的孔隙和喉道呈正态分布[37],表明致密储层微观孔喉是不均质的,喉道半径决定多孔介质的渗流能力[38]。在一定的驱替压力梯度下,流体可能发生较大孔喉可以流动,小孔喉却不能流动的情况,这与理想的均质储层不同。极限驱替渗透率的定义是所有渗流通道均不能流动,也就是极限驱替渗透率是储层中最大渗流通道失去流动性的最小渗透率。

实际储层驱替作业时的最大驱替压力梯度为

Δpmax=pmaxw-pminoL .(12)

式中,pmaxw为现有技术条件下注水井井底最大流压,MPa;pmino为现有技术条件下采油井井底最小流压,MPa;L为油水井井距,m。

由式(2)得实际储层毛细管力为

pc=2σcosθr=0.7σcosθ1000φk .(13)

由极限驱替渗透率定义可知,当动态压差与渗吸黏滞力为零时,对应的渗透率为极限驱替渗透率,由式(6)得

Δpmax+pc=pλ.(14)

将式(4)和(13)带入式(14)可得极限驱替渗透率,整理后得

Δpmax+0.7σcosθ1000φkd=a(kd)-b.(15)

2.3" 极限驱替开发渗透率计算方法

由极限驱替开发渗透率定义可知,当动态压差与驱替压力梯度为零时,驱替阻力由渗吸黏滞力和启动压力梯度共同构成,而驱替动力为毛细管力,由式(6)得

pc=Fη+pλ .(16)

当渗流速度趋近于零时,流体流动黏滞力亦趋近于零,因此由式(16)得

pc=pλ.(17)

将式(1)、(2)和(4)带入式(17),得出极限驱替开发渗透率,整理后得

0.7σcosθ1000φku=a(ku)-b.(18)

3" 致密储层极限渗透率应用

以玛湖百口泉组、姬源长6段、马岭长8、延10段和榆树林扶杨油层4个典型致密亲水储层为例计算极限渗透率[34,39-43]。

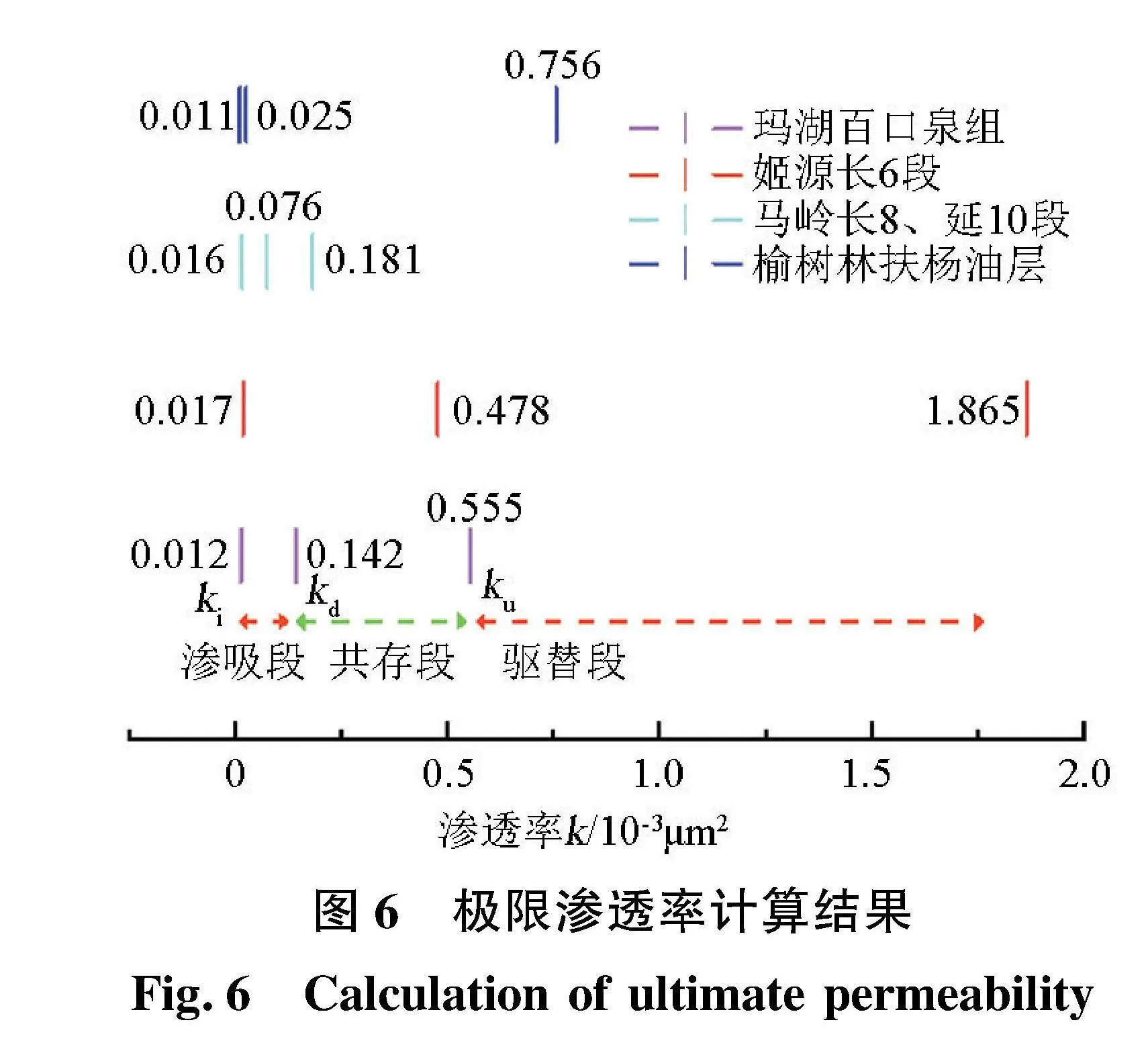

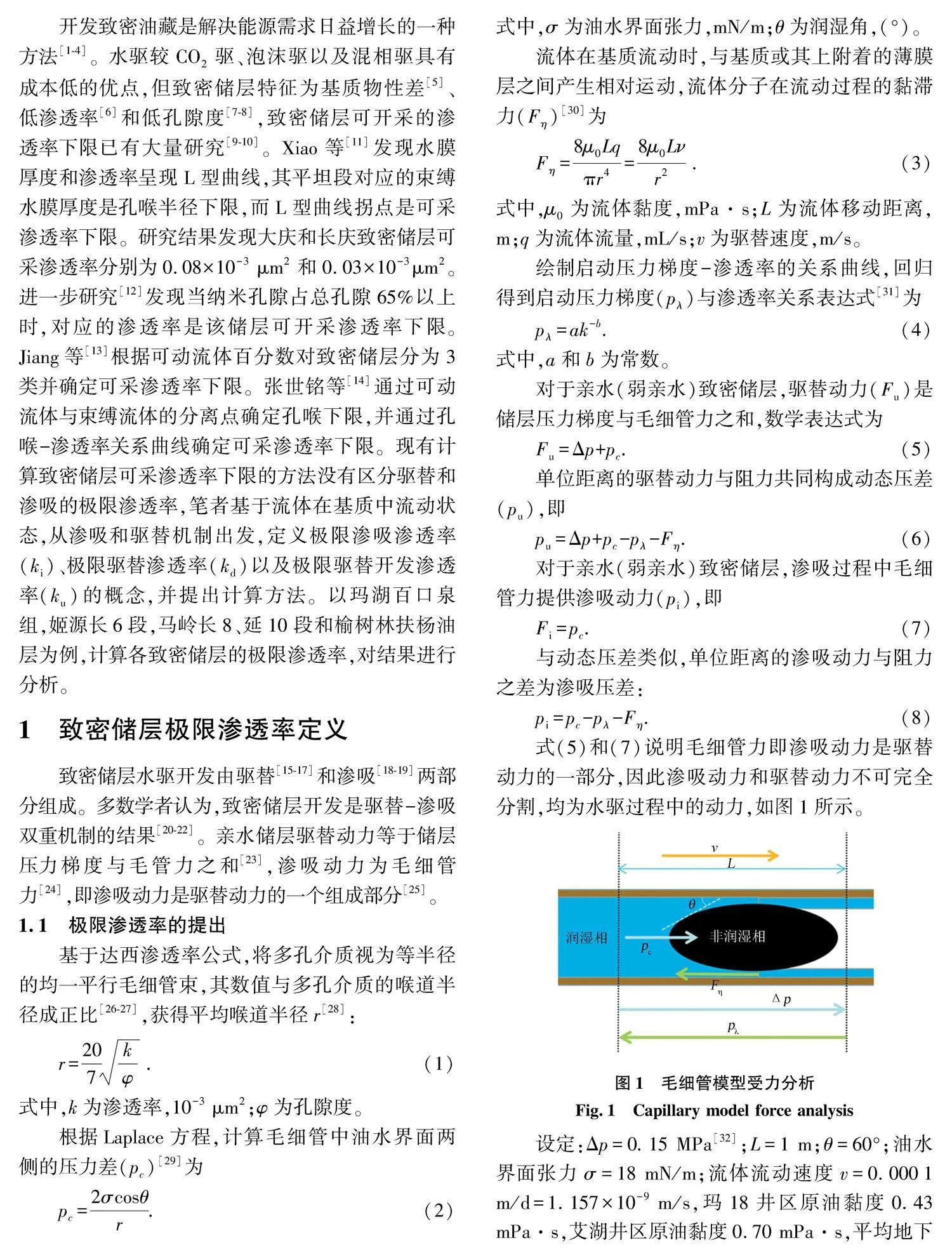

将致密储层基本数据中的孔隙度与可动流体饱和度通过式(9)计算得出可流动流体孔隙度,将φm与lgk绘制曲线后呈现线性关系,如图4所示。通过拟合回归得到φm-lgk关系式,得出公式(10)中A和B的值,列于表2中。此外,通过公式(11)计算得出各个储层的极限渗吸渗透率ki,计算结果见图6。计算结果表明4个储层的可开采渗透率下限相似。此ki为渗吸可发生的渗透率最小值,理论上为储层可开采的渗透率下限。

取Δpmax=0.15 Pa/m,σ=0.018 /m,由于储层润湿性不同,因此θ值也不同,总体为弱水湿性。将启动压力梯度与渗透率拟合曲线如图5所示,拟合回归得出pλ-k关系式,得出式(4)中a和b的值列于表2。通过公式(15)和(18)计算得出kd和ku,计算结果见图6。由于实际岩心渗流通道呈正态分布,因此实际岩心极限驱替渗透率低于理想岩心极限驱替渗透率。与极限驱替渗透率相同,实际岩心驱替开发渗透率也低于理想岩心驱替开发渗透率。

计算得出的ki与张洪等[46]得出的致密砂岩储层内部渗透率下限相近,大于统计法[47]和水膜计算法[48]的渗透率下限。由图6可知,水驱开发过程中驱替-渗吸作用的渗透率范围大于渗吸作用的渗透率范围,在开发致密储层应重视驱替-渗吸联合方式,

榆树林扶杨油层的ki和kd相距较近,更加适合驱替-渗吸联合开发方式。马岭长8、延10段的ku较小,驱替开发方式潜力较大。

4" 结" 论

(1)随着储层渗透率降低,毛细管力(渗吸动力)在驱替动力中的比例升高。随着储层渗透率升高,动态压差与渗吸压差同时增大。

(2)极限渗吸渗透率(ki)是致密储层可采渗透率下限,极限驱替渗透率(kd)是致密储层驱替开发渗透率下限,极限驱替开发渗透率(ku)是驱替作用在致密储层开发过程中起到绝对主导作用渗透率下限。

(3)水驱开发过程中驱替-渗吸作用的渗透率范围大于渗吸作用的渗透率范围,榆树林扶杨油层更适合使用驱替-渗吸开发方式,马岭长8、延10段则具有较大的驱替开发潜力。

参考文献:

[1]" 李阳,赵清民,薛兆杰.新一代油气开发技术体系构建与创新实践[J].中国石油大学学报(自然科学版),2023,47(5):45-54.

LI Yang, ZHAO Qingmin, XUE Zhaojie. Construction and innovative practice of new generation oil and gas development technology system[J].Journal of China University of Petroleum (Edition of Natural Science), 2023,47(5):45-54.

[2]" ZHOU Y, CHEN W, LEI Y. Combustion characteristics of tight sandstone[J]. Energy amp; Fuels, 2018,32(5):6293-6299.

[3]" WU S, ZHU R, YAN Z, et al. Distribution and characteristics of lacustrine tight oil reservoirs in China[J]. Journal of Asian EarthEnces, 2018,178:20-36.

[4]" 王艳忠,宋磊,孟涛,等.济阳坳陷车西洼陷二叠系上石盒子组致密砂岩储层成岩-成藏系统演化[J].中国石油大学学报(自然科学版),2024,48(4):43-56.

WANG Yanzhong, SONG Lei, MENG Tao, et al. Evolution of diagenesis-hydrocarbon accumulation system of tight sandstone reservoirs of Permian Upper Shihezi Formation in Chexi Subsag,Jiyang Sub-basin,China[J].Journal of China University of Petroleum (Edition of Natural Science), 2024,48(4):43-56.

[5]" 黄兴,高辉,窦亮彬.致密砂岩油藏微观孔隙结构及水驱油特征[J].中国石油大学学报(自然科学版),2020,44(1):80-88.

HUANG Xing, GAO Hui, DOU Liangbin. Micro pore structure and water-flooding characteristics on tight sandstone reservoir[J].Journal of China University of Petroleum (Edition of Natural Science), 2020,44(1):80-88.

[6]" 李宾飞,郑磊,柏浩,等.裂缝性致密油藏CO2吞吐开采孔隙原油动用特征[J].中国石油大学学报(自然科学版),2023,47(4):119-127.

LI Binfei, ZHENG Lei, BAI Hao, et al. Pore scale crude oil production characteristics during CO2 huff and puff in fractured tight reservoirs[J]. Journal of China University of Petroleum (Edition of Natural Science), 2023,47(4):119-127.

[7]" FA XIANG, YA ZHI, WY A, et al. Classification evaluation criteria and exploration potential of tight oil resources in key basins of China-science direct[J]. Journal of Natural Gas Geoscience, 2019,4(6):309-319.

[8]" 邓文龙,衡勇,冉旭.中江沙溪庙组致密砂岩气藏地层水微观赋存状态及产出特征[J].西南石油大学学报(自然科学版),2024,46(5):19-28.

DENG Wenlong, HENG Yong, RAN Xu. Microscopicoccurrence and production characteristics of formation water in Shaximiao Formation tight sandstone gas reservoir in Zhongjiang[J]. Journal of Southwest Petroleum University(Science amp; Technology Edition), 2024,46(5):19-28.

[9]" FENG Jun, ZHANG Bowei, FENG Zihui, et al. Crude oil mobility and its controlling factors in tight sand reservoirs in northern Songliao Basin, East China[J]. Petroleum Exploration and Development, 2019,46(2):122-132.

[10]" ZHANG L, SONG X, DU Y, et al. The upper and lower limits and grading evaluation of the Shahezi tight gas reservoirs in the Xujiaweizi Rift, northern Songliao Basin:implications from microscopic pore structures[J]. Journal of Petroleum Science amp; Engineering, 2022,212:110224.

[11]" QX A, ZW B, ZYC D, et al. Novel method for determining the lower producing limits of pore-throat radius and permeability in tight oil reservoirs[J]. Energy Reports, 2021,7:1651-1656.

[12]" QX A, ZYC D, ZW B, et al. A full-scale characterization method and application for pore-throat radius distribution in tight oil reservoirs[J]. Journal of Petroleum Science and Engineering, 2020,187:106857.

[13]" JIANG F, ZHANG C, WANG K, et al. Characteristics of micropores, pore throats, and movable fluids in the tight sandstone oil reservoirs of the Yanchang Formation in the southwestern Ordos Basin, China[J]. AAPG Bulletin, 2019,103(12):2835-2859.

[14]" 张世铭,王建功,张永庶,等.柴达木盆地西部地区下干柴沟组湖相白云岩晶间孔型储层物性下限的确定[J].石油学报,2021,42(1):45-55,118.

ZHANG Shiming, WANG Jiangong, ZHANG Yongshu, et al. Determination of petrophysical property cutoffs of lacustrine dolomite intercrystalline pore reservoir in the Xiaganchaigou Formation,western Qaidam Basin[J]. Acta Petrol Sinica, 2021,42(1):45-55,118.

[15]" 查明,苏阳,曲江秀,等.致密储层孔隙介质内石油运移的物理模拟试验[J].中国石油大学学报(自然科学版),2019,43(5):1-10.

ZHA Ming, SU Yang, QU Jiangxiu, et al. Physical simulation experiment of oil migration in porous media of tight reservoir[J]. Journal of China University of Petroleum (Edition of Natural Science), 2019,43(5):1-10.

[16] "谭锋奇,马春苗,黎宪坤,等.储层流体可动性在油田开发中的应用及展望[J].西南石油大学学报(自然科学版),2024,46(1):1-20.

TAN Fengqi, MA Chunmiao, LI Xiankun, et al. Application andprospect of fluid mobility in oilfield development[J]. Journal of Southwest Petroleum University(Science amp; Technology Edition), 2024,46(1):1-20.

[17]" 史伟奇,程宇雄,吴彬,等.表面活性剂对鄂尔多斯盆地致密砂岩储层渗吸采收率影响分析[J].油田化学,2023,40(1):110-116.

SHI Weiqi, CHENG Yuxiong, WU Bin, et al. Effect ofsurfactants on imbibition recovery of tight sandstone reservoirs in Ordos Basin[J]. Oilfield Chemistry, 2023,40(1):110-116.

[18]" 党海龙,王小锋,崔鹏兴,等.基于核磁共振技术的低渗透致密砂岩油藏渗吸驱油特征研究[J].地球物理学进展,2020,35(5):1759-1769.

DANG Hailong, WANG Xiaofeng, CUI Pengxing, et al. Research on the characteristics of spontaneous imbibition oil displacement with the low permeability tight-sandstone oil reservoir using the nuclear magnetic resonance (NMR) technology[J]. Progress in Geophysics, 2020,35(5):1759-1769.

[19]" 石立华,魏登峰,常毓文,等.基于微流控模型的致密油藏微观渗吸机制试验[J].中国石油大学学报(自然科学版),2024,48(2):99-108.

SHI Lihua ,WEI Dengfeng ,CHANG Yuwen, et al. Experiment on micro imbibition mechanisms of tight reservoirs based on a microfluidic model[J].Journal of China University of Petroleum (Edition of Natural Science), 2024,48(2):99-108.

[20]" WANG X, DANG H, GAO T. Method of moderate water injection and its application in ultra-low permeability oil reservoirs of Yanchang Oilfield, NW China[J]. Petroleum Exploration and Development, 2018,45(6):114-122.

[21]" FENG X, YUE X, AN W, et al. Experimental study of influence of core wettability on imbibition properties[J]. Energies, 2022,15(11):3984.

[22]" 吴可,文守成,邵伟,等.纳米SiO2微乳液对鄂南致密油藏的降压增注效果[J].油田化学,2024,41(2):245-250.

WU Ke, WEN Shoucheng, SHAO Wei, et al. Effect of nano-SiO2 microemulsion on pressure reduction and injection increase in Eunan tight reservoir[J]. Oilfield Chemistry, 2024,41(2):245-250.

[23]" REN X, LI A, WANG G, et al. Study of theimbibition behavior of hydrophilic tight sandstone reservoirs based on nuclear magnetic resonance[J]. Energy amp; Fuels, 2018,32(7):7762-7772.

[24]" JING W, LIU H, QIAN G, et al. Investigations on spontaneous imbibition and the influencing factors in tight oil reservoirs[J]. Fuel, 2019,236:755-768.

[25]" 党海龙,王小锋,段伟,等.鄂尔多斯盆地裂缝性低渗透油藏渗吸驱油研究[J].断块油气田,2017,24(5):687-690.

DANG Hailong, WANG Xiaofeng, DUAN Wei, et al. Study on imbibition flooding in fractured low-permeability reservoir of Ordos Basin[J]. Fault-Block Oil amp; Gas Field, 2017,24(5):687-690.

[26]" YANG M, ZHONG H, HU M, et al. Nonlinear porous flow equation based on pore throat radius sorting of porous media in low-permeability reservoirs[J]. Energy Sources Part A: Recovery Utilization and Environmental Effects, 2022,44(1):1391-1401.

[27]" JIANG L, LIU Y, TENG Y, et al. Permeability estimation of porous media by using an improved capillary bundle model based on micro-CT derived pore geometries[J]. Heat and Mass Transfer, 2017,53(1):79-58.

[28]" 廖万平,王兴建,李卿武,等.基于剖面渗透率估算全岩心孔喉半径[J].物探化探计算技术,2022,44(3):322-328.

LIAO Wanping, WANG Xingjian, LI Qingwu, et al. The entire core pore throat radius was estimated based on the profile permeability[J]. Computing Techniques for Geophysical and Geochemical Exploration, 2022,44(3):322-328.

[29]" WASHBURN, EDWARD W. The dynamics of capillary flow[J]. Physical Review, 1921,17(3):273-283.

[30]" TIAN W, WU K, GAO Y, et al. A critical review of enhanced oil recovery by imbibition: theory and practice[J]. Energy amp; Fuels, 2021,35(7):5643-5670.

[31]" ZAFAR A, SU Y L, LI L, et al. Tight gas production model considering TPG as a function of pore pressure,permeability and water saturation[J]. Petroleum Science, 2020,17(5):1356-1369.

[32]" RAO Y, YANG Z, CHANG L, et al. Influence of reservoir lithology on porous flow resistance of gas-bearing tight oil reservoirs and production forecast[J]. Journal of Petroleum Exploration and Production Technology, 2021,12(2):409-419.

[33]" 李柯.玛湖油田玛18井区三叠系百口泉组油藏精细描述[D].西安:西南石油大学,2019.

LI Ke. Fine description of the reservoir in the Triassic Baikouquan Formation in the Mahu Oilfield Ma 18 well area[D]. Xian: Southwest Petroleum University, 2019.

[34]" 黎宇.玛湖凹陷玛18井区百口泉组致密砂砾岩储层评价研究[D].北京:中国石油大学(北京),2018.

LI Yu. Dense sand conglomerate reservoir evaluation research of Baikouquan in well Block M18, in Mahu Sag[D]. Beijing: China University of Petroleum(Beijing), 2018.

[35]" WANG L, LIU C, JIANG P, et al. Characterization of two-phase flow in porous media using global mobility[J].Journal of Petroleum Science and Engineering, 2019,177:188-197.

[36]" ZOU M, WEI C, HUANG Z, et al. Porosity type analysis and permeability model for micro-trans-pores, meso-macro-pores and cleats of coal samples[J]. Journal of Natural Gas Science amp; Engineering, 2015,27:776-784.

[37]" MI L I, GUO Y, ZHUANGFU L I, et al. Pore-throat combination types and gas-water relative permeability responses of tight gas sandstone reservoirs in the Zizhou Area of East Ordos Basin, China[J]. Acta Geologica Sinica, 2019,93(3):622-636.

[38]" QU Y Q, SUN W, WU H N, et al. Impacts of pore-throat spaces on movable fluid: implications for understanding the tight oil exploitation process[J]. Marine amp; Petroleum Geology, 2021,137:105509.

[39]" 汪艳勇.榆树林油田特低渗透储层分类评价及开发规律研究[D]. 大庆: 东北石油大学, 2016.

WANG Yanyong. Research on the classification evaluation and the development law of extra low permeability reservoir in Yushulin Oilfield[D]. Daqing: Northeast Petroleum University, 2016.

[40]" 黎盼,孙卫,闫健,等.鄂尔多斯盆地马岭油田长81储层不同流动单元可动流体赋存特征及其影响因素[J].石油实验地质,2018,40(3):362-371.

LI Pan, SUN Wei, YAN Jian, et al. Characteristics of movable fluids and controlling factors in different flow units of Chang 81 reservoir in Maling oil field, Ordos Basin[J]. Petroleum Geology amp; Experiment, 2018,40(3):362-371.

[41]" 白云云,孙卫,任大忠.马岭油田致密砂岩储层可动流体赋存特征及控制因素[J].断块油气田,2018,25(4):455-458.

BAI Yunyun, SUN Wei, REN Dazhong. Characteristics and controlling factors of movable fluid in low-permeability and tight sandstone reservoirs in Maling Oilfield[J]. Fault-Block Oil amp; Gas Field, 2018,25(4):455-458.

[42]" 张颀悦,孙卫,尹红佳,等.低渗透储层核磁共振可动流体研究:以姬塬地区长6储层为例[J].石油化工应用,2014,33(8):42-47,52.

ZHANG Xinyue, SUN Wei, YIN Hongjia, et al. NMR movable fluid study of low permeability reservoirs: Chang6 reservoir in the Ji Plateau area[J]. Petrochemical Industry Application, 2014,33(8):42-47,52.

[43]" 师调调,孙卫,何生平.低渗透储层微观孔隙结构与可动流体饱和度关系研究[J].地质科技情报,2012,31(4):81-85.

SHI Diaodiao, SUN Wei, HE Shengping. Relationship between micro-pore structure and movable fluid saturation in low permeability reservoir[J]. Bulletin of Geological Science and Technology, 2012,31(4):81-85.

[44]" 高辉.特低渗透砂岩储层微观孔隙结构与渗流机理研究[D].西安:西北大学,2009.

GAO Hui. Research on micro-pore structure and micro-flow mechanism of ultra low permeability sandstone reservoir[D]. Xian: Northwest University, 2009.

[45]" 王佳杰.马岭油田某区长8特低渗透油藏开发技术政策研究[D].西安:西安石油大学,2014.

WANG Jiajie. A study on chang 8 ultra-low permeability reservoir development technology policy research at Maling Oilfield[D]. Xian: Xian Shiyou University, 2014.

[46]" 张洪,张水昌,柳少波,等.致密油充注孔喉下限的理论探讨及实例分析[J].石油勘探与开发,2014,41(3):369-374.

ZHANG Hong, ZHANG Shuichang, LIU Shaobo, et al. A theoretical discussion and case study on the oil-charging throat threshold for tight reservoirs[J]. Petroleum Exploration and Development, 2014,41(3):369-374.

[47]" 揭君晓,王甘露,苏逊卿.低孔低渗型砂岩储层物性特征及油层物性下限值确定:以塔里木盆地塔河西南为例[J].贵州工业大学学报:自然科学版,2007,36(4):12-15.

JIE Junxiao, WANG Ganlu, SU Xunqing. Research on low porosity and permeability of sandstone oil and gas reservoir performance-take Ta River Southwest of Tarim Basin as the example[J]. Journal of Guizhou University of Technology(Natural Science Edition), 2007,36(4):12-15.

[48]" 吴松涛,邹才能,陶士振,等.鄂尔多斯盆地中生界致密油成藏机理研究:以陕北地区长6油层组为例[C]//第四届中国石油地质年会论文集.北京:中国石油学会,2011:333.

(编辑" 刘为清)