A texture-modified dessert with high nutritional value designed for people with dysphagia: effect of refrigeration and frozen storage

2024-02-16MarCartagenaLarisaGiuraDianaAnsorenaIciarAstiasaran

María Cartagena ,Larisa Giura ,Diana Ansorena, *,Iciar Astiasaran

a Department of Nutrition,Food Science and Physiology,Faculty of Pharmacy and Nutrition,Universidad de Navarra,C/Irunlarrea s/n,Pamplona 31008,Spain

b Center for Nutrition Research,University of Navarra,c/Irunlarrea 1,Pamplona 31008,Spain

c Instituto de Investigación Sanitaria de Navarra,IDISNA,C/Irunlarrea s/n,Pamplona 31008,Spain

d National Centre for Food Technology and Safety (CNTA)—Technology and Knowledge for Food Sector Competitiveness,Navarre,Crta-Na 134-km 53,San Adrian 31570,Spain

Keywords:Malnutrition Texture-modified-food Hydrocolloids Viscoelastic properties Food texture

ABSTRACT Dysphagia is commonly associated with malnutrition and an increased choking risk.To overcome these complications,food designed for people with dysphagia should have an appropriate texture and a high nutritional value.In this study,six formulations of a strawberry dessert enriched in protein (calcium caseinate)and fiber (wheat dextrin or inulin) were developed using different hydrocolloids (xanthan gum,carboxymethyl cellulose or modified starch) to provide desirable texture and stability.Nutritional value was calculated and total phenolic content and antioxidant activity of the samples were analyzed.Back-extrusion test,rheological measurements and sensory analysis were performed in refrigerated and frozen samples to characterize their textural and viscoelastic properties.The high content in protein (14.7 g/100 g) and fiber (7.9–8.7 g/100 g)made possible to use the claims “high protein” and “high fiber”.Phytochemicals supplied by strawberries contributed to the antioxidant properties of the dessert.Loss tangent ranged 0.28–0.35 for all the formulations,indicating a weak gel behavior,which could be considered safe to swallow.The formulations with dextrin in combination with carboxymethyl cellulose or xanthan gum seemed to be less susceptible to structural changes during frozen storage.This work provides insights for the development of a nutrient-dense dessert that meets the requirements of people with dysphagia.

1. Introduction

Dysphagia is a clinical symptom characterized by the difficulty or inability to prepare or transfer the food bolus from the oral cavity to the stomach that it is associated to an increased risk of choking and aspiration of food or saliva into the airways,which may cause pneumonia and even death[1,2].Although dysphagia affects people of all ages,the prevalence increases with age,occurring in approximately 11%-33% of independent-living older people and in 40%–51%of institutionalized elderly[2].Dysphagia may be caused by agerelated changes or by certain diseases,such as Alzheimer’s disease,Parkinson’s disease,stroke,or local structural lesions associated with head and neck cancers or with side-effects of endotracheal intubation,tracheostomy or mechanical ventilation[2,3].

Due to a decline in food intake and other underlying conditions that negatively affect nutritional status,such as dementia,stroke or cancer,people with dysphagia are at higher risk of malnutrition,as reported by a 5-year multicenter study[4].An optimal intake of protein could prevent sarcopenia in older people,which could affect swallowing function[5].Other nutrients and bioactive compounds,such as dietary fiber,carotenoids and polyphenols,could also reduce the risk of cardiovascular diseases and neurodegenerative disorders that could trigger dysphagia[6,7].For these reasons,increasing the consumption of dietary proteins by functional foods and enriching their composition by adding beneficial nutrients may represent an adjuvant therapy for patients with impaired ability to feed properly[8].

On the other hand,texture modified food (TMF) is one of the most common strategies applied in dysphagia management.To increase swallowing safety and effectiveness,TMFs should be soft,moist,cohesive and not sticky or adhesive,nor leave residues in the oropharynx that could be aspirated after swallowing[9].However,texture modification generally affects nutrient-density and palatability,resulting in food refusal and lower nutrient intake[10,11].Therefore,providing swallow-safe,palatable and nutrient-enriched TMFs represents a major challenge for the food industry[12].Moreover,according to the needs of healthcare institutions,which usually have difficulties to provide freshly made food,TMFs should also be stable during storage.In this regard,although some studies have investigated the stability of these products during storage[13-15],no literature was found about the effect of frozen storage on TMFs.

Addition of hydrocolloids may contribute to achieve the desirable texture in the formulation of TMFs[16].Hydrocolloids are high molecular weight polymers that improve the rheological and textural properties of liquids and semiliquid foodstuffs for their ability to gel and/or bind water[17,18].Moreover,hydrocolloids may contribute to improve product stability during storage,inhibiting syneresis and ice crystal formation in frozen food products[19].However,the effects of hydrocolloids on textural,viscoelastic and sensory properties and stability of TMFs depends on several factors,including food matrix,the concentration of hydrocolloid and the type of hydrocolloid[20].Among hydrocolloids,modified corn starch is the most commonly used in TMFs because it is more affordable and easily available.However,the use of gums in TMFs has gained importance in the last years because they are proven to be safer,more stable and more sensorially accepted than MS[21].

The aim of this work was to develop a texture-modified dessert made with fruit (strawberries),and enriched in protein (calcium caseinate) and fiber (wheat dextrin or inulin).Three hydrocolloids of different nature (xanthan gum,carboxymethyl cellulose or modified starch) were added to achieve the desirable texture and try to improve stability during storage.Textural,viscoelastic and sensory parameters were assessed under refrigeration and frozen storage to study the effect of storage conditions.

2. Materials and methods

2.1 Materials

18 kg of strawberries (Fragaria x ananassaDuch) was purchased in a local retail store in Pamplona,Spain.Wheat dextrin (81% fiber,Deliplus,Alcoy,Spain) and granulated refined sugar (Azucarera,Madrid,Spain) were purchased in local supermarkets.Inulin (89%fiber) was obtained from Guinama (La Pobla de Vallbona,Spain).Calcium caseinate (96% protein) and modified pregelatinized waxy corn starch (MS) were obtained from Harrison Sport Nutrition(Albolote,Spain).Xanthan gum (XG) and Carboxymethyl cellulose(CMC) were obtained from Dayelet (Piera,Spain).All ingredients used were food grade.

2.2 Formulations design

Six formulations were prepared with different combinations of a dietary fiber source (wheat dextrin or inulin) and hydrocolloids (XG,CMC or MS),as shown in Table 1.The concentration of strawberry pulp (50.0%,m/m),calcium caseinate (15.0%,m/m),fiber (8.5%,m/m)and sugar (2.5%m/m) used to prepare the formulations remained constant for all the formulations.The content in protein and fiber were set considering the amounts needed to meet the criteria for the“high protein” and “high fiber” claims,according to the European Community Regulation No.1924/2006 on nutrition and health claims made on foods.The concentration of each hydrocolloid was established according to preliminary formulation assays using different concentrations within the ranges suggested by the manufacturers to be used as thickeners.The final concentrations were established so that the desserts would meet the International Dysphagia Diet Standardisation Initiative (IDDSI) requirements for level 4 (pureed and extremely thick foods)[22].Thus,XG and CMC were used at a concentration of 0.2% (m/m),whereas MS was added at a concentration of 4.0% (m/m).

Table 1 Formulations of the strawberry dessert enriched in protein (calcium caseinate)and fiber (dextrin or inulin) and added with hydrocolloids (XG=xanthan gum,CMC=carboxymethylcellulose,MS=modified starch).

2.3 Dessert samples preparation

All the samples were prepared as follows: after removing damaged and immature fruits,strawberries were washed with tap water,hulled,cut into 1 cm by 1 cm pieces and blended (Solac BA5603 PRO 800 Chef,Vitoria-Gasteiz,Spain) to obtain the pulp.Subsequently,water and all the powdered ingredients (protein,fiber and the hydrocolloid) were added to the strawberry pulp according to the amounts described in table 1 for the 6 formulations and were homogenized into a homogeneous paste during 15 min (Ultra-Turrax®T25basic) gradually increasing the speed of mixing from 13 000 r/min up to a maximum of 22 000 r/min.Procedure was carried out at room temperature.

Samples of each type of formulation were divided into two halves:one half was stored under refrigeration for a maximum of three days at(4 ± 1) °C and the other one was frozen at (-18 ± 3) °C for at least 15 days.Frozen samples were thawed at (4 ± 1) °C one day before the analyses.

2.4 Nutritional characterization

The nutritional composition of fresh strawberries was obtained from the National nutrient database for standard reference (https://fdc.nal.usda.gov/fdc-app.html#/food-details/167762/nutrients,accessed on March 21,2021) giving the following results (g/100 g): 7.7 carbohydrates (4.9 sugars),2.2 fiber,0.2 fat (0 saturated),0.7 protein and 0 salt.The energy value was 32 kcal/100 g.

The nutritional value of the desserts was determined using the nutritional information of the ingredients included in each formulation.

2.5 Total phenolic content and antioxidant activity

Total phenolic content (TPC) and antioxidant activity (AA)were experimentally determined in the strawberry pulp (SP) and the resulting value was taken into consideration to obtain TPC and AA in the desserts.

2.5.1 Sample extraction

Lyophilized strawberry pulp were extracted with three different solvents (70% aqueous acetone,60% aqueous methanol and 60% aqueous ethanol),in accordance with the method described by Kähkönen[23]with slight modifications.Briefly,2 500 mg of lyophilized strawberry pulp were extracted with 50 mL of solvent and homogenized (Ultra-Turrax® T25basic) for 1 min.The mixture was centrifuged (3 000 r/min,15 min) and the residue was re-extracted with another 50 mL of solvent.The supernatants obtained were combined and evaporated by rotation at 40 °C and then lyophilized.The lyophilized extracts were stored at (-30 ± 2) °C until analyzed.

2.5.2 Determination of total phenolics

Total phenolic content (TPC) was determined by Folin-Ciocalteu method[24].1 185 μL distilled water were mixed with 15 μL sample,distilled water (blank) or standards and 75 μL Folin-Ciocalteau reagent.After 2 minutes,225 μL of 25% sodium carbonate was added.The mixture was vortexed and incubated 2 h at room temperature in the dark.Absorbance was measured at 765 nm with a Fluostar Omega microplate reader (BMG Labtech,Germany).TPC of the sample was calculated on the basis of the calibration curve of gallic acid(5–2 000 μg/mL).Results were expressed as gallic acid equivalents(GAE),mg per 100 g sample.

2.5.3 ABTS assay

An ABTS solution was prepared by mixing a 7 mmol/L ABTS aqueous solution with 2.45 mmol/L potassium persulfate (final concentration).The mixture was incubated in the dark for 12 to 16 h for the generation of ABTS cation radical.Then,the ABTS cation radical solution was diluted with 5 mmol/L sodium phosphate buffer at pH 7.4 to an absorbance value of (0.700 ± 0.020) at 741 nm.18 μL sample or sodium phosphate buffer (as a control) were placed in a microplate.Subsequently,182 μL of prepared ABTS cation radical solution was added.The mixture was incubated for 6 min and the absorbance was measured at 741 nm with a Fluostar Omega microplate reader (BMG Labtech,Germany).The inhibition percentage of ABTS cation radical was calculated with the following equation[25]:

WhereACwas the absorbance of the control andASwas the absorbance of the sample.A calibration curve of Trolox (0–1 000 μmol/L)was used to calculate the Trolox equivalent antioxidant capacity.Results were expressed in μmol of Trolox equivalent (TE) per 100 g sample.

2.5.4 DPPH assay

A 0.04 mg/mL DPPH solution was prepared by diluting 2 g DPPH in ethanol to obtain an absorbance value of (0.7 ± 0.02) at 516 nm.750 μL sample and 750 μL DPPH solution were mixed and incubated in the dark for 30 min.Control was prepared using methanol to replace the sample.The blank only contained methanol.In addition,a blank sample was prepared replacing the DPPH solution by methanol.200 μL of the mixture were placed in a microplate and absorbance was measured at 516 nm with a Fluostar Omega microplate reader(BMG Labtech,Germany).The inhibition percentage of DPPH radical was calculated using the following equation:

WhereACwas the absorbance of the control,ABthe absorbance of the blank,ASthe absorbance of the sample andABSthe absorbance of the blank sample.A calibration curve of Trolox (0–10 μg/mL)was used and the results were expressed in μmol of Trolox equivalent (TE) per 100 g sample.

2.5.5 Oxygen radical absorbance capacity assay (ORAC)

40 μL sample were placed in a microplate and mixed with 120 μL of 135 nmol/L fluorescein were added.The initial fluorescence was measured at 37 °C with a Fluostar Omega microplate reader (BMG Labtech,Germany).Subsequently,the reaction was started by adding 40 μL of 0.3 mol/L AAPH solution.Immediately,fluorescence was measured every 45 s (F1,F2,F3,...,Fi) for 3 h.A blank with 10 mmol/L sodium phosphate buffer and five standard solutions of Trolox (12.5–200 μmol/L) were used in each assay.Two solutions of 40 and 125 μmol/L Trolox were also used as quality control (QC).The area under the curve (AUC) was calculated with the following equation[26]:

WhereF1was the fluorescence reading at cycle 1;F0was the initial fluorescence;Fiwas the fluorescence reading at cyclei;andCTwas cycle time in minutes (0.75 min).The net AUC was calculated subtracting the AUC of the blank from the AUC of the sample.Oxygen radical absorbance capacity was calculated on the basis of the standard curve for Trolox and results were expressed in μmol of Trolox equivalent per 100 g sample.

2.6 Instrumental texture measurements

Textural parameters were determined by back extrusion test using a Texture Analyzer (TA-XT 2i,Stable Micro Systems,United Kingdom).100 g of sample was transferred into a container of 50 mm internal diameter and compressed with a 40 mm diameter probe(A/BE40).

Testing was done at a test speed of 1.0 mm/s to a maximum penetration depth of 20 mm below the surface of the sample.Pre-test speed and post-test speed were set at 1.0 and 10 mm/s,respectively.Trigger force was set at 0.10 N.All measurements were done in triplicate at consumption temperature (10 ± 1 °C).The forcetime curves obtained were analyzed using Texture Expert Exceed software (Stable Micro Systems,United Kingdom).The parameters measured consisted of firmness (maximum force in compression,N),consistency (area under the curve up to this point,Ns),cohesiveness(maximum negative force,N) and work of cohesion or viscosity index(negative area under the curve,Ns)[27].

2.7 Rheological measurements

The rheological properties of the dessert samples were determined in a discovery HR-1 Hybrid Rheometer (TA Instruments) equipped with a Peltier system to ensure temperature control.A serrated plate geometry of 40 mm diameter was used at a 1 mm gap and 1.5 mm for the formulation with inulin and MS.Before testing,samples were left between the plates for 5 min equilibration time to allow stress relaxation and temperature equilibration.The analyses were performed under constant temperature of 10 °C.

An oscillation amplitude sweep test was performed at a frequency of 1 Hz within a strain ranging from 0.01% to 300% to determine the limits of the linear viscoelastic region (LVR).The changes in elastic modulus (G’) and viscous modulus (G’’) were recorded.The yield strain (%),yield stress (Pa) and flow point (Pa) values were obtained according to the standard ISO 6721-10[28].The yield strain was determined as the strain value at which theG’ value was reduced a 5% of the value within the LVR.The yield stress was considered as the stress value at whichG’ was reduced a 5% of its value within the LVR,whereas the flow point was the value of stress at whichG’=G’’.

Frequency sweep analyses were conducted within the LVR with a frequency ranging from 0.01 to 10 Hz to assess the viscoelastic parameters of the samples.Storage modulus (G’),loss modulus(G’’),complex modulusand loss tangent(tanδ=G’’/G’) were recorded.

2.8 Sensory analysis

Sensory analysis was conducted by a 17-trained member panel.All panelists were professionals with experience in dysphagia management,such as speech-language pathologists,physiotherapists,physicians,psychologists,social workers,occupational therapists,caregivers and cooks.Although no specific training sessions were performed before the sensory analysis,all the panelists had great experience assessing products for people with dysphagia.The objective of the test was to determine the degree of suitability of the samples for being ingested by people with dysphagia.For that purpose,the panelists were asked whether they would offer the sample on a menu for people with dysphagia through a yes or no question.Moreover,they were encouraged to leave comments and observations about the sample.

Prior to the sensory analysis,the panelists were instructed to rinse their mouths with mineral water between each sample.During the sessions,approximately 25 g of each sample at 10 °C was served to the panelists.Each panelist evaluated 12 samples in two separate sessions.The samples were presented in random order to avoid carryover effects and were coded with random three-digit numbers.This procedure was approved by University of Navarra Ethics Research Committee (number 2021.175).

2.9 Statistical analysis

All analyses were performed in triplicate.Mean and standard deviation of the replicates are shown in the tables.A three-way analysis of variance (ANOVA) with interactions was applied to evaluate the effect of the three factors studied-fiber source (wheat dextrin or inulin),hydrocolloid type (XG,CMC or MS) and storage conditions (refrigerated or frozen storage)-on the viscoelastic and textural parameters of the dessert formulations.In presence of interactions,a new grouping variable “formulation” combining both fiber and hydrocolloid was generated and a one-way analysis of variance (ANOVA) followed by Tukey post hoc test was applied on both refrigerated and frozen samples to evaluate significant differences among the six formulations developed.

For each formulation,at-Student test was applied to study significant differences between refrigerated and frozen samples.Statistical significance was set atP<0.05 for all the tests.Statistical analyses were performed with Stata® software,version 15.0 (College Station,Texas,USA,http://www.stata.com).

3. Results and discussion

3.1 Nutritional aspects

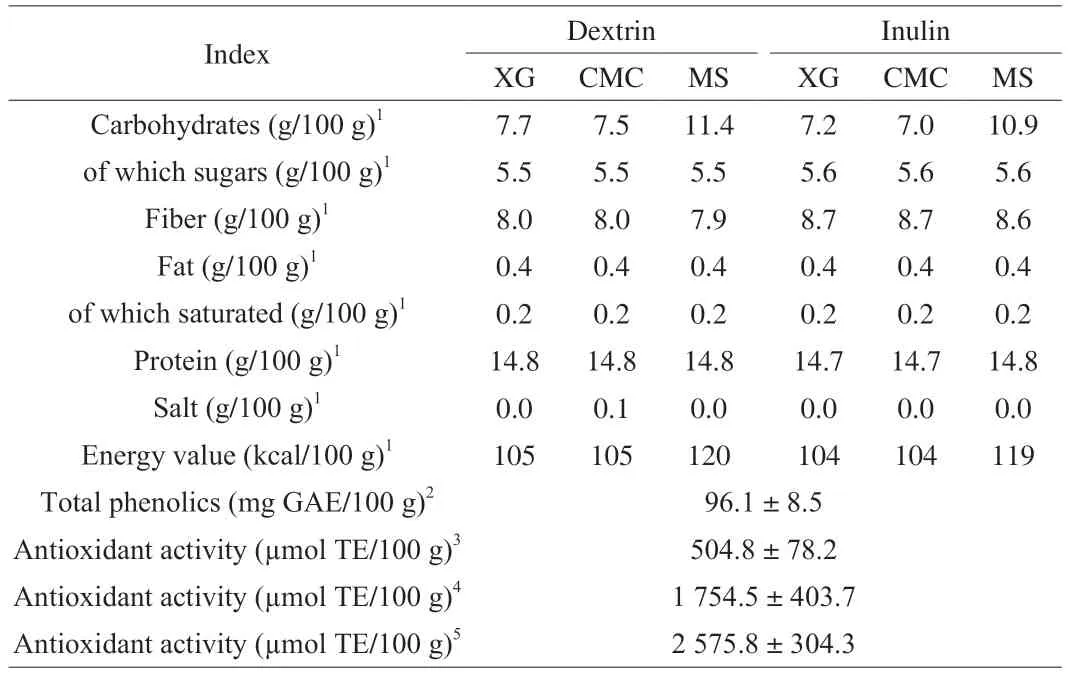

The developed formulations are nutrient-dense products and fruitive foods,with no need for heat treatment and that could be provided as a dessert.Table 2 shows the nutritional composition of the six developed formulations.

Table 2 Nutritional and energy value of the dessert formulations.

The high protein content (14.7%) supplied by calcium caseinate contributed to a 60%–70% of the energy value of the product.Since this value was higher than 20%,the strawberry dessert would meet the criteria for the claim “high protein” established by the Regulation (EC)No 1924/2006[29].The supply of fiber was also highly interesting.The sum of the fiber content of dextrin (81.0 %) or inulin (89.0%)and the fiber from the strawberry pulp (2.0%),probably in form of pectin,made also possible to use the claim “high fiber”,as the product contained at least 6 g of fiber per 100 g or 3 g of fiber per 100 kcal.The energy value ranged from 103 to 120 kcal per 100 g,which may be considered to be quite low.The content of fat,saturated fat and sugars also seemed to be adequate based on the Dietary Reference Intakes (DRIs) for these nutrients[30].

Moreover,the addition of strawberry pulp at 50% contributed with phytochemicals,which could confer many health benefits.Strawberry phenolic compounds are known for their antioxidant and anti-inflammatory actions as well as for their cardiovascular,antiproliferative,and neurologic benefits[31].Total phenolic compounds (TPC) and antioxidant activity (AA) of strawberry pulp were measured in extracts prepared with different solvents (methanol 60%,ethanol 60%,acetone 70%).The results obtained are shown in Table S1 (Supplementary Material).

Depending on the extraction method,the TPC values of strawberry pulp were 175–209 mg gallic acid equivalents/100 g FW,which are similar to those obtained by Kähkönen et al.[23]and Meyers et al.[32].According to these authors,flavonoids (mainly anthocyanins,but also flavonols and flavanols) are the major phenolic compounds in strawberry,followed by ellagitannins.Additionally,AA values were 905-1 189 µmol Trolox equivalents (TE)/100 FW with DPPH assay;2 812-4 393 µmol TE/100 FW with ABTS assay;and 4 665-5 834 with ORAC assay.These values were similar to those obtained in other works in strawberries[33-36],confirming the high antioxidant properties of this fruit.

The mean data obtained in the strawberry pulp by the three solvents was taken into consideration to estimate the antioxidant activity of the dessert formulations,since only a mild mechanical procedure was applied to homogenize the mixtures,and no modification of TPC or AA would have occurred.Thus,TPC of the dessert formulations ranged from 88.0 to 104.9 mg gallic acid equivalents/100 g FW.Similar results had been obtained in other foods containing phytochemicals designed for seniors with swallowing disorders,such as a soymilk-based banana blueberry puree and a chicken-sweet pumpkin-puree[37,38].Regarding the antioxidant activity,values of ABTS,DPPH and ORAC could be considered as significant[39-41].

3.2 Textural and rheological properties

The effect of the fiber type,hydrocolloid type and storage conditions on the textural and viscoelastic parameters of the strawberry dessert were studied.The developed formulations contained various types of macromolecules,which can affect their textural and rheological properties.Strawberry pulp pectin,calcium caseinate,fibers and hydrocolloids form a complex structured network with multiple interactions among them and with water[42,43].Additionally,interactions of many of these compounds with water may limit ice crystals formation during freezing,and thereby offer protection against the deleterious effect of freezing and thawing[44].Since the amounts of strawberry pulp and calcium caseinate remained constant for all the formulations,only the differences attributed to the type of fiber and the hydrocolloids used were discussed.

A three-way ANOVA was applied to analyze the interactions among the three variables: type of fiber (wheat dextrin or inulin),type of hydrocolloid (XG,CMC or MS) and storage condition (refrigeration or frozen storage) (see Table S2 in Supplementary Material).The results showed significant interactions among them for each parameter(except for loss tangent in the case of storage conditions).This means that the effect of each variable analyzed was dependent on the others.Therefore,we assessed separately the effect of the type of fiber and the type of hydrocolloid for each storage condition (ANOVA),and also the effect of the different storage conditions for each type of formulation (t-Student).

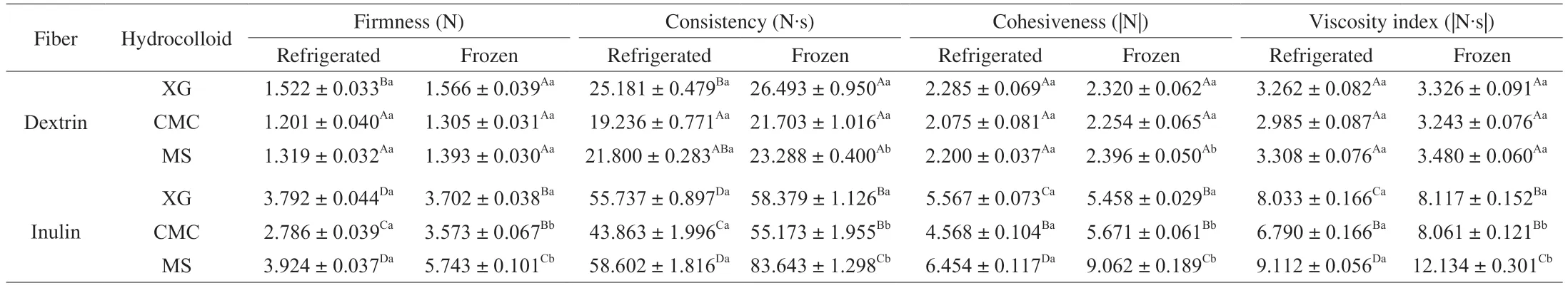

3.2.1 Textural properties

Parameters related with textural properties are shown in Table 3.Significantly higher values of firmness,consistency,cohesiveness and viscosity index were observed in the three inulin-containing formulations when compared to their wheat dextrin counterparts,for both refrigerated and frozen samples.Giri et al.[45]also reported a significant increase in firmness and work of shear in processed cheese spread with the addition of 8% inulin.Similarly[46],observed a significant increase in firmness and consistency in low-fat yoghurts containing inulin at a similar concentration (6%).They observed an increase in the textural parameters caused by the addition of inulin,which could be attributed to its ability to form a particle gel network where water is trapped[47].

Table 3 Textural parameters of the dessert formulations.

Regarding refrigerated samples with dextrin,XG was the hydrocolloid giving the highest firmness,whereas no noticeable differences were observed for the rest of the parameters and hydrocolloids.In the case of refrigerated samples elaborated with inulin,those with CMC showed the lowest values for all parameters.No differences were observed in firmness and consistency between XG and MS-containing samples.

It is known that freezing can change textural properties due to damages in macromolecular structures and water loss caused by ice crystal formation[48].In products elaborated with dextrin,freezing only affected with slight increases in consistency and cohesiveness in samples with MS.In products with inulin,freezing gave rise to significant increases in every parameter in samples with CMC and MS.It is worthy to note that the cryoprotective effects of hydrocolloids depend on their physic-chemical properties and also on the synergistic effect with other ingredients during freezing and frozen storage[18].

In this study,frozen storage gave rise to significant increases in all textural parameters in the formulations with inulin,except for those with XG.However,in products elaborated with dextrin,freezing only caused slight increases in consistency and cohesiveness in the samples with MS.These results could be attributed to the competition of inulin and hydrocolloids for the water,especially when MS is used.It has been described that inulin may limit the swelling ability of starch granules due to its greater affinity for water[49].According to these authors,the higher affinity for water of inulin leads to weaker bonds than when is bound to MS,which could result in a higher susceptibility to freezing and frozen storage.

Moreover,among hydrocolloids,XG was the most effective against the deleterious effects of frozen storage,since even the formulation with inulin showed no significant differences after frozen storage.These results could suggest the ability of XG to inhibit ice crystal formation and growth,as previously reported by Downey[48].Conversely,MS was no effective in both inulin and dextrin-containing formulations,probably due to syneresis and starch retrogradation[50].

So we can conclude that inulin provided higher firmness,consistency and cohesiveness than dextrin,whatever the hydrocolloid was used.However,during frozen storage,dextrin gave more stability to the textural properties,except when MS was used.

3.2.2 Viscoelastic properties

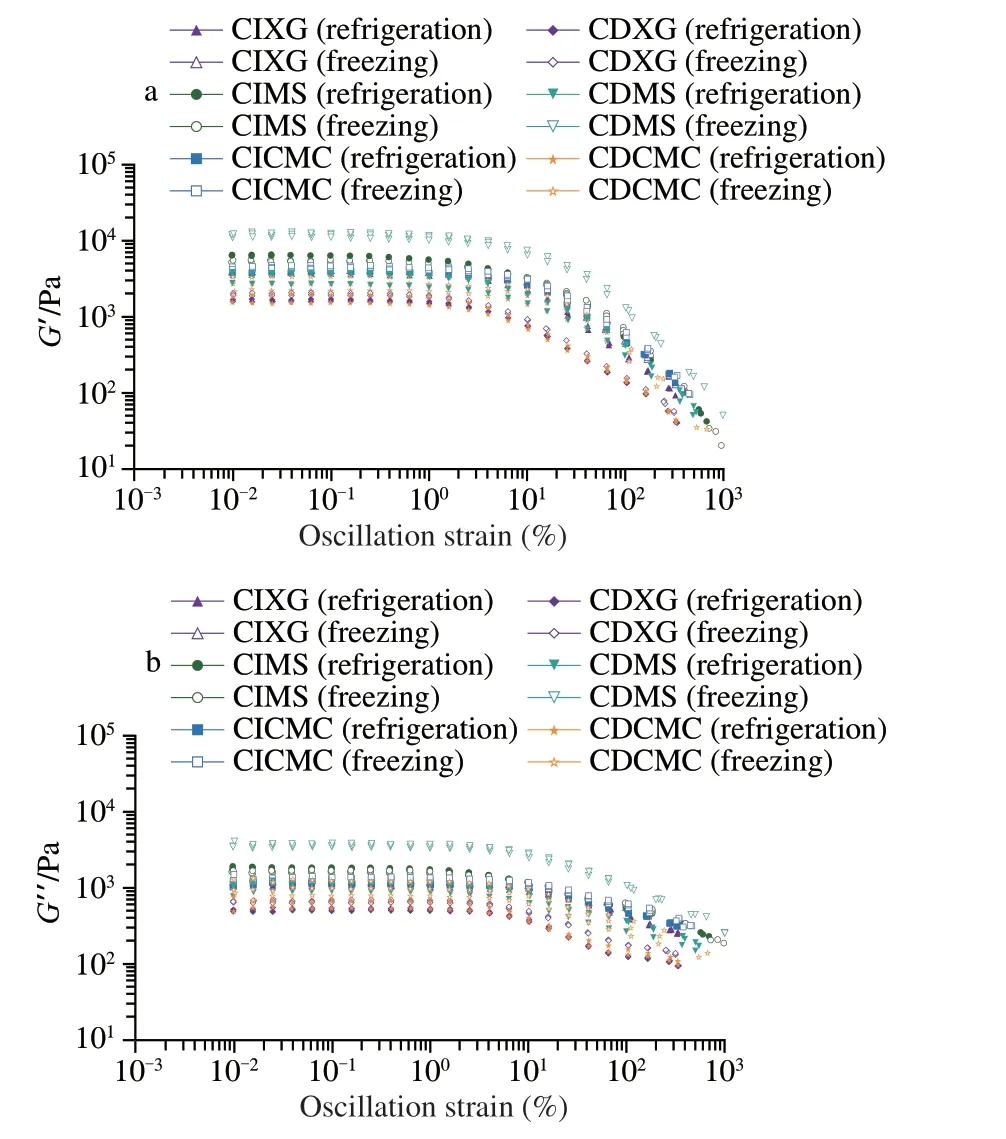

3.2.2.1 Oscillation amplitude sweep tests

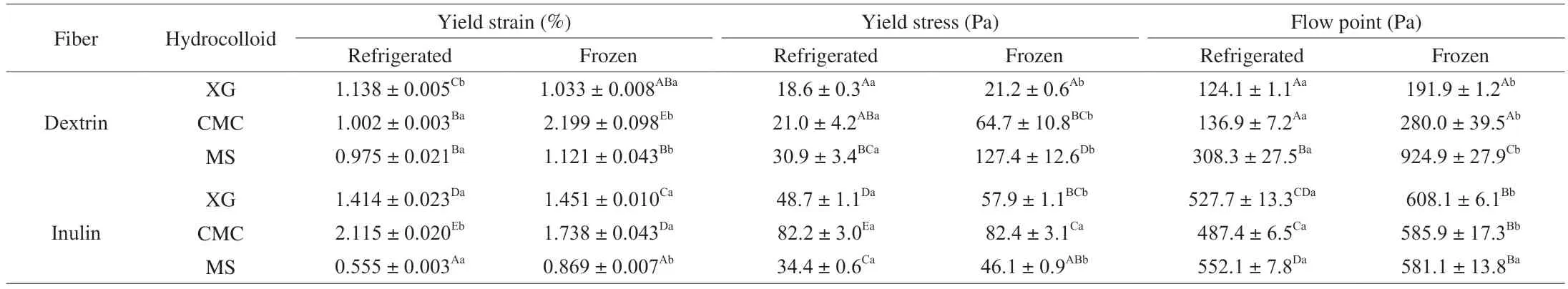

The linear viscoelastic region (LVR) of the samples was determined through the strain sweep test.Fig.1 shows the amplitude of the LVR of the dessert formulations.It can be seen that the extent of the LVR was similar for all the formulations.Values of yield strain,yield stress and flow point are shown in Table 4.

Fig.1 Change of (a) storage modulus (G’) and (b) loss modulus (G”) as a function of strain for the dessert formulations (CIXG=formulation with inulin and XG,CIMS=formulation with inulin and MS,CICMC=formulation with inulin and CMC,CDXG=formulation with dextrin and XG,CDMS=formulation with dextrin and MS,CDCMC=formulation with dextrin and CMC).

Table 4 Viscoelastic parameters of dessert formulations obtained with the strain sweep test.

Refrigerated samples with inulin showed a higher yield strain than the samples with dextrin,except for those with MS.Indeed,the lowest strain for the onset of the non-linear viscoelastic region was obtained when inulin was used in combination with MS.On the contrary,the formulation with inulin and CMC was the most resistant to strain,which could be associated with a greater flexibility of the formulation[51].Refrigerated samples elaborated with inulin also showed significantly higher yield stress than those with dextrin,whatever the hydrocolloid used,which was in accordance with the results obtained in the texture analysis with the back extrusion test.The lowest values of yield stress were recorded in the formulations elaborated with dextrin and XG or CMC,which began to flow under 18.6 and 21.0 Pa of applied stress,indicating a lesser elasticity of these samples[51].Flow point values were generally quite high for all the formulations when comparedto those obtained by Sharma et al.[52]in thickened carrot purees and by Talens et al.[51]in thickened pea cream samples at pudding-thick level.

The formulations with inulin and XG or MS showed the highest flow point values (552.1 and 527.7 Pa,respectively),followed by the formulation with inulin and CMC (487.4 Pa),whereas lower flow point values were obtained in the formulations with dextrin.According to Sharma et al.[52],these results indicate a high resistance of the samples to flow,especially when inulin was used,which could be attributed to the presence of entangled networks of inulin as an additional structure within the gel system[53].

The significant effect of MS on flow point value was worthy to note among the samples with dextrin.These results are in accordance with those obtained by Sharma et al.[52]and Talens et al.[51],who recorded the highest flow point values in samples thickened with starch-based thickeners.However,the high effect of MS on flow point value was not observed in the formulations with inulin.In this case,no significant differences were observed between the formulations with MS and those with XG.

As regards of the effect of frozen storage,interestingly,all the formulations showed a significant increase of yield stress,except for the one with inulin and CMS.The highest increases were observed in dextrin samples elaborated with CMC and,particularly,with MS,which reached the highest yield stress values (924.9 Pa).Therefore,frozen storage seemed to increase the stability of the structure in samples elaborated with dextrin and CMC or XG,since a greater stress would be needed to deform the material structure so that it begins to flow[54].These data agree also with those obtained with the back extrusion test.Frozen storage also led to significant increases in flow point values in all the formulations,except for those with inulin and MS.

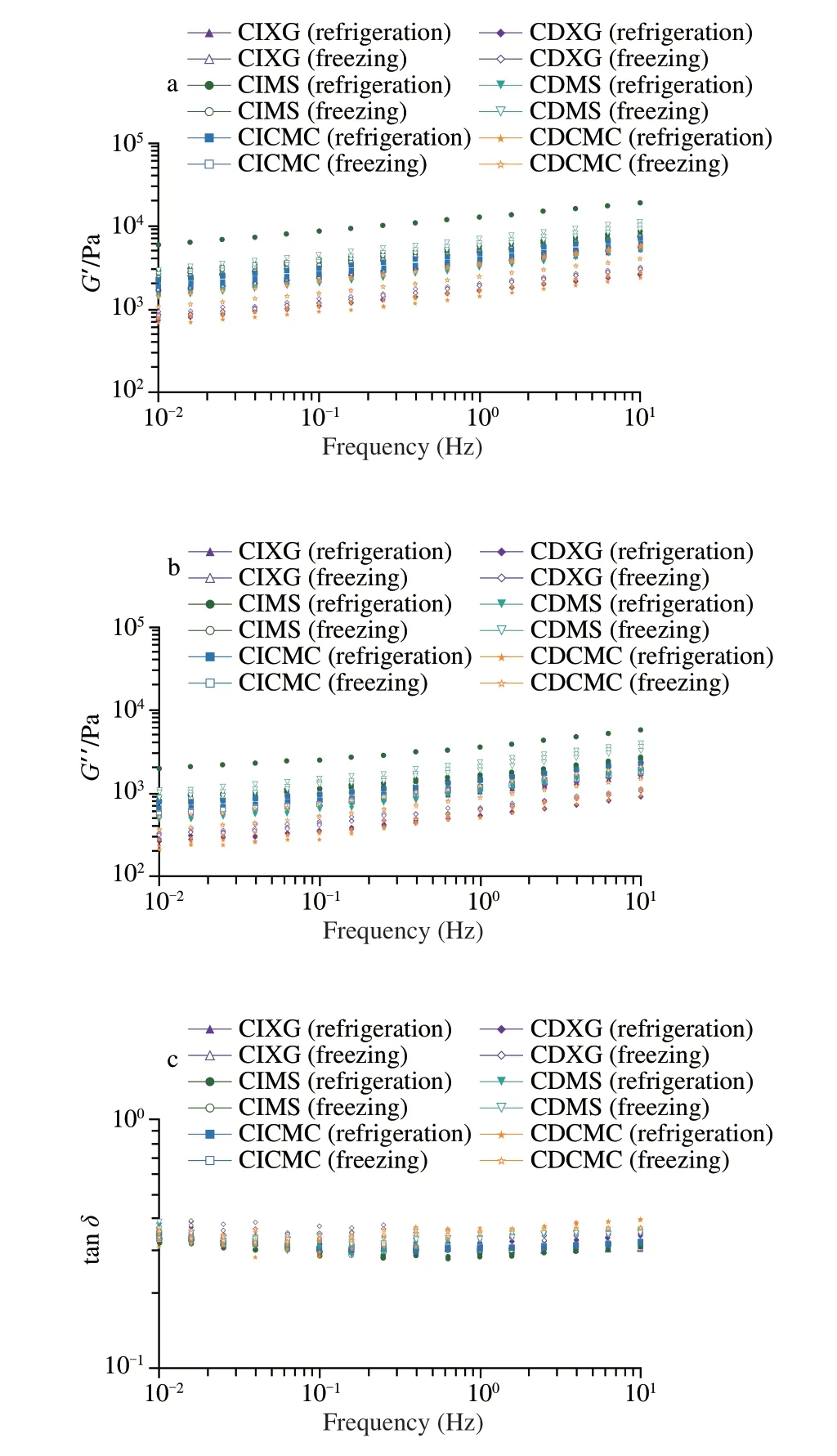

3.2.2.2 Oscillation frequency sweep tests

Results of the frequency sweep test on storage modulus (G’),loss modulus (G’’) and loss tangent (tanδ) are shown in Fig.2.All the samples exhibited similar frequency dependence.Values obtained at a frequency of 1 Hz are shown in Table 5.Values ofG’were much higher than those ofG’’,showing that their behavior was predominantly elastic rather than viscous.When comparing among samples with the same hydrocolloid,those with inulin showed much higher values ofG’ than those with dextrin,indicating a stronger elastic component and consequently,a higher consistency,which is in accordance with the high values of firmness and consistency obtained in this formulation with the back extrusion test.MS was the hydrocolloid giving rise to the highestG’ andG’’ values for both samples with dextrin and inulin.Moreover,it can be seen that frozen samples with dextrin and CMC or MS had a higher standard deviation ofG’ andG’’ than the rest of the samples,which could be attributed to a higher syneresis.

Fig.2 Frequency dependence of (a) storage modulus (G’),(b) loss modulus(G”) and (c) loss tangent (tan δ) of the dessert formulations (CIXG=formulation with inulin and XG,CIMS=formulation with inulin and MS,CICMC=formulation with inulin and CMC,CDXG=formulation with dextrin and XG,CDMS=formulation with dextrin and MS,CDCMC=formulation with dextrin and CMC).

Table 5 Viscoelastic parameters of dessert formulations obtained at 1 Hz with the frequency sweep test.

The loss tangent (tanδ),which is a useful indicator of the relative contributions of the elastic (G’) and viscous (G’’) components to the viscoelastic properties of a material[50],ranged from 0.28 to 0.35,corresponding the lowest values to inulin samples.Since these values are between 0.1 and 1.0,which indicates a weak gel structure,it could be considered that all the formulations were adequate for dysphagia[55].Although inulin samples showed a greater firmness and consistency evidenced by the back extrusion test,they seemed to have a weaker gel structure than those with dextrin.

Frozen storage did not show a significant effect on the loss tangent for most of the samples,with only a very slight increase in dextrin-XG and inulin-MS products.This finding might indicate that samples maintained their internal structure.

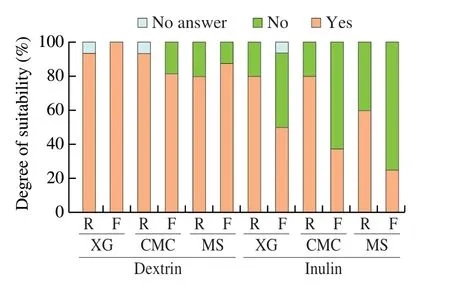

3.3 Sensory analysis

People with dysphagia may show a great diversity of swallowing disorders,especially depending on the buccal and oropharyngeal anatomy and the force of the tongue.Therefore,the degree of texture modification required for safe and efficient swallowing should be in accordance with the severity of dysphagia[56].Thus,while thinner fluids could be suitable for mild dysphagia,more severe cases of dysphagia will require a higher increase consistency,making it somehow difficult to develop a product which could be universally suitable for all dysphagia-affected people.

The dessert developed in the present work showed textural and rheological properties that could be theoretically compatible with those required for people with dysphagia.To confirm this hypothesis,a sensory analysis was performed by a panel of therapists specialized in dysphagia management.They were invited to taste the different products and asked to answer if they would offer them to people with dysphagia (Fig.3).Products with dextrin showed a higher degree of suitability than those with inulin,since all of them were recommended by at least 80% panelists.Among all the formulations,those with dextrin and XG showed the highest degree of suitability,probably because the presence of XG imparts creaminess to the product[57].Moreover,the suitability of this formulation was not affected by frozen storage,evidencing the high effectiveness of XG as a cryoprotectant.On the contrary,the panelists found more problems in the formulations with inulin,especially when they were stored under frozen conditions.An excessive consistency was reported in these samples,which could lead to a higher difficulty to swallow,since they require more force on the tongue and pharynx during swallowing[58].A grainy texture and a decrease in viscosity in the mouth were referred in both samples with MS,leading to a lower degree of suitability than those with XG and CMC.Similar results were obtained in other sensory analyses of different food matrixes thickened with starchbased thickeners[59,60].

Fig.3 Degree of suitability of the dessert formulations,represented as the% of panelists that answered positively to the question “Would you offer this dessert formulation on a menu for people with dysphagia?” (R=Refrigerated samples,F=Frozen samples).

These results were in accordance with the back extrusion test,pointing out a good correlation between back extrusion parameters and sensory consistency,as suggested by Peh et al.[61].

4. Conclusions

The nutritional characterization of the formulations revealed that the protein and fiber content in the strawberry dessert were high enough to be claimed as “high protein” and “high fiber” products.Their content in phytochemicals can also be considered as significant.Therefore,the developed dessert could contribute to the prevent malnutrition and its consequences in dysphagia affected people.

Products elaborated with inulin met the rheological criteria for safe-swallowable foods for people with dysphagia,but were considered not quite adequate by a high number of panelists due to its excessive gel strength.In addition,these formulations,especially the one containing MS,were more susceptible to changes during frozen storage,with significant increases of all textural parameters as well as a decrease in sensory suitability.Unless when MS was used,products elaborated with dextrin seemed to have more adequate textural and rheological properties than those with inulin.Moreover,these formulations showed a higher stability to frozen storage when CMC and especially XG were used.

Conflicts of interest

The authors declare no conflicts of interest.

Acknowledgements

We are grateful to Gobierno de Navarra (Proyectos Estratégicos para Navarra 2020) and the FEDER program for the financial support of project NUTRI+.L.Giura would also like to thank Gobierno de Navarra for the grant given to conduct a Ph.D.(Ayudas para la contratación de doctorandos y doctorandas: Doctorados industriales 2020,Project Deglusen).The authors also wish to thank CAIDIS Infanta Elena (DomusVI),Adacen and Hospital Universitario de Navara for their participation in the sensory analysis.

Appendix A.Supplementary data

Supplementary data associated with this article can be found,in the online version,at http://doi.org/10.26599/FSHW.2022.9250040.

杂志排行

食品科学与人类健康(英文)的其它文章

- Modifications in aroma characteristics of ‘Merlot’ dry red wines aged in American,French and Slovakian oak barrels with different toasting degrees

- Effect of different drying methods on the amino acids,α-dicarbonyls and volatile compounds of rape bee pollen

- Dynamic changes in physicochemical property,biogenic amines content and microbial diversity during the fermentation of Sanchuan ham

- A comparison study on structure-function relationship of polysaccharides obtained from sea buckthorn berries using different methods:antioxidant and bile acid-binding capacity

- Yolk free egg substitute improves the serum phospholipid profile of mice with metabolic syndrome based on lipidomic analysis

- Underlying anti-hypertensive mechanism of the Mizuhopecten yessoensis derived peptide NCW in spontaneously hypertensive rats via widely targeted kidney metabolomics