Investigation on taste characteristics and sensory perception of soft-boiled chicken during oral processing based on electronic tongue and electronic nose

2024-02-16XuXinmingZengPengWngXingChenXinglinXuMinyiHn

N Xu,Xinming Zeng,Peng Wng,,Xing Chen,Xinglin Xu,,*,Minyi Hn,d,*

a College of Food Science and Technology,Nanjing Agricultural University,Nanjing 210095,China

b National Center of Meat Quality and Safety Control,Nanjing Agricultural University,Nanjing 210000,China

c State Key Laboratory of Food Science and Technology,Jiangnan University,Wuxi 214122,China.

d Wens Foodstuff Co.,Ltd.,Yunfu 527400,China

Keywords:Oral processing Chicken Electronic tongue Electronic nose

ABSTRACT The sensory perception of food is a dynamic process,which is closely related to the release of flavor substances during oral processing.It’s not only affected by the food material,but also subjected to the individual oral environment.To explore the oral processing characteristics of soft-boiled chicken,the sensory properties,texture,particle size,viscosity,characteristic values of electronic nose and tongue of different chicken samples were investigated.The correlation analysis showed that the physical characteristics especially the cohesiveness,springiness,resilience of the sample determined oral processing behavior.The addition of chicken skin played a role in lubrication during oral processing.The particle size of the bolus was heightened at the early stage,and the fluidity was enhanced in the end,which reduced the chewing time to the swallowing point and raised the aromatic compounds signal of electronic nose.But the effect of chicken skin on chicken thigh with relatively high fat content,was opposite in electronic nose,which had a certain masking effect on the perception of umami and sweet taste.In conclusion,fat played a critical role in chicken oral processing and chicken thigh had obvious advantages in comprehensive evaluation of soft-boiled chicken,which was more popular among people.

1. Introduction

As a specific traditional low-temperature marinated dish of China,soft boiled chicken (baiqieji) was famous for the appearance brighter and yellow color,crisp skin,tender meat,and original umami taste,which can be cut and eaten at will and is the favorite product of Chinese consumers.It enjoys a reputation as good as Beijing roast duck[1].The chicken skin had high fat content[2],which will produce emulsification under the action of tooth chewing and saliva lubrication after imported into oral cavity.It had an important influence on the formation of chicken bolus as well as lead to the release and perception of unique taste substances[3].Therefore,its presence in soft-boiled chicken consumption plays a crucial role in the oral processing.

Food oral processing is a very complex dynamic multi-stage process.It is the first step of food digestion and the key for food to provide energy and essential nutrients for humans[4].Firstly,the food was broken into small particles through chewing movements such as squeezing of the teeth and the peristaltic action of the tongue,which were fully combined with saliva in the mouth to form a food bolus[5].After that,when the structure and lubrication degree of food boluses reach a certain value,swallowing can be triggered.The fragmentation of food particles,the formation of food boluses,the infiltration of saliva,the release of flavor and the generation of perception are synchronous[6].The particle size and moisture content of the food bolus are the decisive factors for smooth swallowing[7].The release and perception of food flavor is a comprehensive process from the food entering the mouth and chewing to the disappearance of the flavor[8].Various foods undergo different physical,chemical and biological changes in the mouth,which have an impact on human physiology and psychology,mainly including taste,smell,touch and hobby[9],corresponding to sensory attributes such as taste,aroma,texture and mouthfeel.It depends on many factors,including food composition,chewing parameters,saliva secretion,interaction between food and saliva,individual physiological differences and so on[10,11].Therefore,the oral processing process,especially the influence of chewing and saliva,is particularly crucial for the formation of food flavor and taste perception.At present,many scholars have investigated the texture changes and taste perception of foods such as bread[12],fresh and roasted salmon[13],stewed pork with brown sauce[14],blackAngus semitendinosusmuscles[15],cream cheese[11]during oral processing.Understanding the relationship between the structure of food and their oral processing is essential to improve texture and taste of food and other health-related factors such as weight management or dysphagia[16].

As the most consumed meat in the world,chicken has the characteristics of high protein and low fat[17],which is an important protein supplement for fitness people.It is widely accepted that lipids greatly contribute to the sensory properties of foods and consequently to the enjoyment of eating[18].The perception of fat in solid food was more complicated with solid lipids melting in the oral cavity,lubricating the food and facilitating swallowing during mastication[19].Glumac et al.[20]explored thein vitrosimulation and oral processing of rapeseed oil (pure oil) and pork belly (fat food),found that saliva acted as an emulsifier,which could be an important mechanism for the oral processing of oil/fat.A large number of studies have been conducted on mouthfeel of oiliness,the release of fat in emulsion gel,fat content and preference differences[21-24].Chicken skin,as a part of chicken,has relatively high fat content,and its role in chicken oral processing cannot be ignored.At present,there are many researches on the quality and flavor of chicken,while there are relatively few studies on the oral processing of chicken.

Chicken breasts and thighs are the most popular parts among consumers with many studies focus on taste-related compounds which contribute to meat flavor[25-28].But there have been no previous studies on the oral processing of chicken.From the perspective of the preparing method of soft-boiled chicken,the whole chicken was cut into regular small pieces,in which the chicken breasts and thighs occupy the most.Combined with chicken skin,4 fixed type of chicken samples were employed to compare the dynamic changes of chewing parameters and taste values of sensory evaluators.To characteristic the changes of chicken boluses,the texture,particle size,apparent viscosity,the response values of electronic tongue and electronic nose were all determined.On one hand,the exploration about the influence of chicken skin on the formation of food bolus in the oral processing could provide guidance and reference for better consuming methods of soft-boiled chicken,on the other hand,it will lay a theoretical foundation for elucidating the effect of fat addition on the food characteristics,taste perception and flavor release of food during oral processing.

2. Material and methods

2.1 Materials and chemicals

Thirty soft-boiled chickens were provided by Guangdong Wens Jia Wei Foodstuff Co.,Ltd.(Yunfu,Guangdong,China),which manufactured from Qingyuan partridge yellow-feather chickens with body weights 1.0−1.1 kg.The chicken was cooked as follows: the whole carcasses were stewed in 2.0% brine at 85 °C for 65 min after bleached in water bath (90 °C) within 60 s after cleaning the carcass,then the chickens were immediately transferred to a 0−4 °C icy water for 25 min and air-cooled for 20 min to reduce the moisture.After vacuum packaging,the products were kept at 4 °C cold chain transportation to Nanjing Agriculture University,which were stored in the −18 °C freezer for a short period of time no more than one month and thawed at 4 °C cold storage before preparing the sample.Three chickens were used for the determination of chewing parameters in the preliminary sensory training,and the remaining chickens were divided into 3 groups of 9 chickens for the preparation of oral chewing samples for 12 sensory evaluation subjects.Potassium chloride was provided by Nanjing Rongshengda Experimental Instrument Co.,Ltd.(Nanjing,Jiangsu,China).Silver chloride was purchased from Nanjing Jingge Chemical Technology Co.,Ltd.(Nanjing,Jiangsu,China).Sodium glutamate,L-tartaric acid and other reagents were obtained from Nanjing Maibo Biotechnology Co.,Ltd.(Nanjing,Jiangsu,China).Sodium inosinate and glutamate used for sensory evaluation were of food grade,and other chemical reagents were of analytical pure grade.

2.2 Oral processing and sensory evaluation

The experimental protocol has been approved by the Institutional Review Board (School of Food Science and Technology,Nanjing Agricultural University).The sensory questionnaires were at the end of the supplemental material.According to the sensory group screening method of[29,30]with slight modifications,32 sensory panelists were preliminarily recruited by means of differential test including basic color discrimination,taste and smell recognition,and intensity discrimination by three-point test and ranking methods.In order to stimulate saliva production and facilitate collection,chewing gum was used to complete the test,ignoring its impact on taste temporarily.Finally,12 sensory panelists with saliva quality and pH value around the median of the sample interval were selected and trained on the basic knowledge and ability of food sensory evaluation.In order to prevent food digestion from affecting sensory subjects’chewing,swallowing and taste perception,the evaluation subjects were required not to eat within 90 min before sensory experiment.

The soft-boiled chicken was treated in the way of white cut,and each piece of chicken was similar to the finished product on the plate,which have a palatable long strip shape (about 3 cm × 1 cm × 1 cm in length,width and height).The samples were divided into four categories: chicken breast (CB),breast+skin (CBS),chicken thigh(CT),and thigh+skin (CTS).During the 3 training experiments,the sensory panelist chewed one of aforementioned samples,recorded the number and time of chewing before swallowing.All the food boluses were spitted out,weighted and calculated to determine the related parameters for sensory evaluation of chicken oral processing.According to the method of Zhuang et al.[31]with slight modifications,three concentration gradients of salty,sweet and umami solutions were prepared with sodium chloride,sucrose and sodium glutamate respectively,the sodium chloride solution of 1.0,3.0 and 5.0 g/L,sucrose solution of 1.0,4.0 and 8.0 g/L,sodium glutamate solution of 0.1,1.0 and 3.0 g/L were prepared,which was conducted in the sensory scale score training in combination with pure water,corresponding to 1,5 and 9 points from low to high concentration,respectively.

2.3 Bolus collection and pretreatment

According to the chewing parameters,4 different chicken samples were prepared: 5 g chicken breast,4 g chicken breast+1 g chicken skin,5 g chicken thigh,4 g chicken thigh+1 g chicken skin.The oral processing methods were as follows: 12 sensory panelists chewed the above 4 samples in turn,each sample was chewed 6 times,each time for 5,10,15,20,25,30 s,respectively.During the 6 oral processing stages,the main food bolus was spit out.The taste characteristics of umami,salty,sweet and chewing times of the food boluses were recorded.The oral cavity was not cleaned during the chewing of the same type of samples to avoid the affection of drinking water and mince residue in the oral cavity on salivary secretion and sensory sensation.And a total of 288 groups of food boluses were collected with a rest time of 5 min between evaluation of various samples.The 12 food boluses at each chewing point of each sample were gently stirred and mixed with a glass rod,obtaining a total of 24 large food boluses.Each large bolus was divided into 3 parts for subsequent analysis.

2.4 Texture analysis of the chicken

Physical characteristics of chicken boluses during oral processing were measured by the texture profile analysis (TPA) method by TA-XT Plus analyzer (Stable Micro System,Godalming,UK)using a stainless steel cylinder probe (50 mm in diameter,P50) to induce chicken bolus to 50% deformation at the speed of 1.00 mm/s referring to Peyron et al.[32].The speed before and after the probe test was 2.00,1.00 mm/s,respectively.The food bolus was collected in a cylindrical plastic container with a diameter of 25 mm and a height of 10 mm and the surface of the bolus was relatively smooth by pressing lightly with a small spoon,after which it was buckled upside down on the texture analyzer measuring plate fitted with a 200 g load cell.The lift-up height was 20 mm equipped with the trigger force at 5 g and the test interval at 5 s.According to the force-time curve obtained with the TPA test,the hardness,springiness,cohesiveness,chewiness and resilience values were calculated.Hardness is the maximum force value of first compression,the unit is the unit of force,such as g,kg,N.After the TPA test of TA-XT Plus analyzer,the instrument derived the unit of hardness as g.The springiness,cohesiveness and resilience have no units.The unit of chewiness was also g.

2.5 Determination of chicken bolus viscosity

The rheological properties of chicken boluses were determined using a physical MCR301 rheometer (MCR301,Anton Paar GmbH,Graz,Austria) equipped with a parallel plate (diameter 25 mm,sandblasted) with the temperature fixed at 37 °C simulating the oral environment.All measured heights were adjusted to 2 mm according to the size of the boluses.Viscosity,as a measure of the resistance to flow or the internal friction[33],was recorded as the shear rate that linearly increased from 0.01 s−1to 100 s−1with 29 data points.

2.6 Particle size analysis of chicken bolus

According to method of Liu et al.[14]with a slight modification,2 g of vomited chicken bolus was transferred to a 100 mL transparent centrifuge tube,50 mL ultrapure water was added and vortexed 30 s on the mini vortex mixer (VM-300,Joanlab Equipment Co.,Ltd.,Ningbo,Zhejiang,China).Before the determination,the suspension was stirred with a plastic dropper to keep the particles of the bolus in a dispersed state.Malven Mastersizer 3000 laser particle size analyzer(Malven Co.,Ltd.,Malvern,UK) was used to determine the size and particle distribution of the bolus particles in the diluted chicken bolus emulsion.The instrument parameters were set as follows: the real part of the material refractive index was 1.52,the imaginary part was 0.10,the medium refractive index was 1.33,the dispersant was deionized water,and the shading index ranged from 8 to 20.D(4,3),D(3,2)andD(50)were recorded.The particle size distribution and viscosity of chicken bolus at different stages of food oral processing were important physical characteristics,which can help to explain the trigger mechanics of swallowing[14].

2.7 Electronic tongue analysis

The most effective model for predicting human perception is based on humans themselves,through sensory evaluation research conducted with trained or untrained panelist[34].However,there are many complicated factors in sensory measurement.The electronic tongue is one of the main methods of quickly assessing food,which can be used as intelligent sensors to reproduce complex and comprehensive taste by transforming molecular information into taste qualities[35].The sensors of the electronic tongue are immersed in the sample to measure soluble components and the overall characteristic response signal,which are then sent to a processing system using pattern recognition for analysis to produce characteristic taste value corresponding to the human sense of taste.

The SA402B electronic tongue (Insent Co.,Ltd.,Tokyo,Japan)was used to evaluate the taste characteristics of different chicken food boluses formed during oral processing[36].The instrument was equipped with 6 potential chemical film sensors (AAE stands for umami,CT0 for saltiness,CA0 for sourness,C00 for bitterness,AE1 for astringency and GL1 for sweetness).The basic taste membrane sensors were soaked in the reference solution (30 mmol/L KCl solution containing 0.3 mmol/LL-tartaric acid) for at least 24 h.The sweetness of sample was determined separately from the other tastes with GL1 sensor,which was pretreated in the sweet soaking solution at least 48 h before analysis.Chicken bolus (20 g) was mixed with deionized water (100 mL),statically extracted at 40 °C for 20 min,and then centrifuged at 8 000 ×gfor 10 min.The supernatant was vacuum-filtered by 0.45 μm filter membrane for electronic tongue measurement.Before sample testing,the sensor of electronic tongue was self-checked and calibrated,which was carried out at room temperature of 25 °C.The 5 basic tastes were measured 4 times and the sweetness was repeated 5 times.The measured values of the first and last time were deducted respectively during data processing,and the three response values in the middle were taken as valid data[37].

2.8 Discrimination by electronic nose analysis

Electronic nose analysis was a method to detect volatile components and sensory attributes quickly,which can simulate human senses through a sensor array system[38].There are many significant features of electronic nose,such as relatively fast headspace evaluation,quantitative representation or signature of gas,and cheap sensors that can be easily integrated into the current production processes[39].The main applications of electronic nose in food industry include quality evaluation,spoilage identification,detection of freshness,off-flavors and adulteration[40].The different chicken boluses were distinguished by PEN3 portable electronic nose (Win Muster Airsense Analytics Inc.,Schwerin,Germany),which was equipped with 10 sensors (W1C,W5S,W3C,W6S,W5C,W1S,W1W,W2S,W2W,W3S) sensitive to various compounds as shown in Table S1.The sensor was heated metal oxide sensor array.Before the test,1 g of chicken boluses was added into 20-mL sealed headspace vial and incubated at 40 °C for 5 min.During the test,a syringe needle was used to penetrate the sealed vial and absorb volatile gases from the headspace at a constant rate.It was supplemented by a second hollow needle with a charcoal filter after the volatile gas was replaced by clean air.The measurement time was 120 s with a 180 s standby procedure to flush with clean air until the sensor signals returned to baseline level.

2.9 Statistics analysis

The experimental data was summarized and sorted by Excel 2016(Microsoft) software.A significant difference (P<0.05) was analyzed by two-factor (chicken type,oral processing time) analysis of variance(ANOVA) and Duncan’s multiple comparison were applied for post-hoc using SAS software (SAS 8.1,SAS Inst.Inc.,NC,USA).The electronic nose signal was analyzed by principal component analysis (PCA) to reduce the dimensionality and visualize the dataset with SIMCA 14.1 (Sartorius Stedim Data Analystics AB,Sweden).The inputs of PCA from signal of E-nose was the name of the sensor,and the features were extracted according to the system data analysis.There were 24 groups of samples in total,and each group of samples was repeated in 3 parallels and 3 repeats.The correlations analysis between the dynamic taste perception (results of sensory evaluation) and the texture properties of bolus during oral processing were performed by partial least squares regression (PLSR) with SIMCA 14.1 (Sartorius Stedim Data Analystics AB,Sweden).X-variable is the corresponding signal of texture,particle size,electronic tongue,and electronic nose,andY-variable is sensory data.A largeQ2(Q2>0.5) indicates good predictively.

3. Results and discussion

3.1 Chewing parameters screened by sensory evaluation

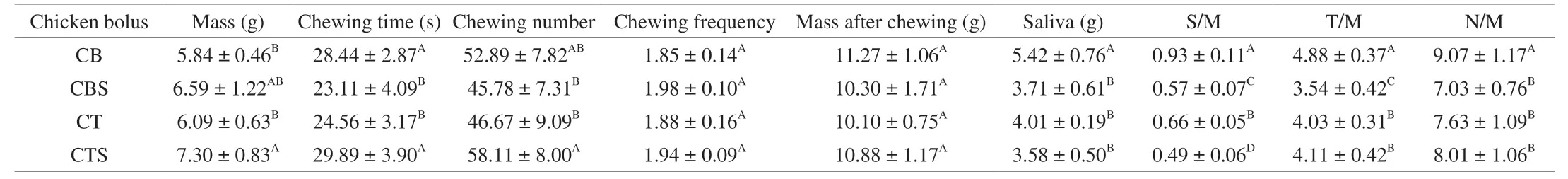

In the sensory evaluation training experiment,the oral processing experiment was carried out on chicken breast and chicken thigh samples.It can be found from Table 1 that the amount of saliva produced by chewing samples without skin was much greater than that with skin,which was much higher in chicken breast than that of chicken thigh.It may be related to the high fat content in chicken skin[41]and thigh[42],which play a lubricating effect similar to saliva in oral processing[43].Although different panelists had variance chewing frequencies,there was no significant difference in the chewing frequency between soft-boiled chicken samples,indicating that the chewing parameters of sensory group had certain similarity.The result was similar to the study of Chen et al.[44],in which chewing frequency did not differ vastly between consumers and was independent of product type.The swallowing point is the state in which food could be swallowed during chewing[45].The mass of each piece of chicken sample ranges from 5.84 g to 7.30 g,the total chewing time before reaching the swallowing point was within 30 s,and the proportion of saliva to chicken was between 0.49−0.93.The ratio of the number and times of chewing to the sample mass was the highest in chicken breast.In order to facilitate calculation and processing,5 g chicken sample (5 g meat,4 g meat+1 g skin) was selected for each treatment group,with a total chewing time of 30 s(5,10,15,20,25,30 s) to ensure complete oral processing (adequate chewing and full release of flavor).The food boluses formed during the oral processing of the 4 types of chicken were shown in Fig.1.Each row from top to bottom represents CB,CBS,CT,CTS,with each column corresponding to 5,10,15,20,25,30 s from left to right.It is obvious that the bolus particles continue to decrease,and the structure gradually become uniform.

Table 1 Chicken chewing parameters of 12 sensory subjects during oral processing.

Fig.1 Food boluses formed during the oral processing of different chicken samples.CB,CBS,CT,CTS represent chicken breast,chicken breast and chicken skin,chicken thigh,chicken thigh and chicken skin,respectively.

3.2 TPA of chicken boluses

Although there were no standards for the setting of TPA procedure with hardly comparing in result,it may help to indicate the overall bolus texture and understand the relationship between sensory perception and bolus texture[46].Table 2 suggested that the longer ofthe oral processing time,the lower of hardness of the 4 soft-boiled chicken boluses,among which,the hardness of the CB was the highest at (966.198 ± 92.571) g,and that of CTS was the lowest at(717.660 ± 83.913) g.Comparing the samples with and without skin,it was found that the hardness and chewiness of the skin samples are significantly reduced at the initial chewing period (P<0.05).There was no significant difference in the hardness of the CT within 15 s of mastication (P>0.05),while the hardness of the CTS after chewing for 10 s was significantly lower than that of 5 s (P<0.05).It may be concluded that the fat of the chicken skin played an important role in reducing the hardness of the sample and the energy required for mastication[47].There was also no obvious difference in chewiness between samples during oral processing for 25 and 30 s,which further revealed that the swallowing point of the sample was basically reached after chewing for 25 s,and the 30 s ensured the completeness of the oral processing of the sample.

Table 2 Texture profile of different soft-boiled chicken sample during oral processing.

During oral processing,the springiness of the chicken bolus also showed a trend of decreasing with time except that the springiness of CT for 10 s and CTS for 20 s rebounded slightly.Although the springiness values of CB and CT were higher than those of corresponding skin samples in the early stage of oral processing,chicken skin had a remarkable effect on maintaining the springiness state of soft-boiled chicken for a long time during oral processing due to the relatively high values of skin samples in the later stage(P<0.05).The resilience of CB and CT enhanced slightly at chewing for 15 and 20 s,respectively,but there was no prominent difference with the samples before and after (P>0.05),and this phenomenon was not observed in the samples with skin.The possible reason is that the chicken skin fat had been dissolved in the mouth during this oral processing stage,which combined with the chicken sample to increase its lubricity and reduce the resilience of the chicken bolus[48].In addition to the relatively high cohesiveness of 0.691 ± 0.026 in the CT at 10 s,the cohesiveness of the other samples declined during oral processing,with lower values in the samples with skin than that of corresponding CB and CT.It manifested that during oral processing of soft-boiled chicken,the contents of saliva continues to boost with dissolved chicken skin fat,which improve the fluidity and lessen the cohesiveness.

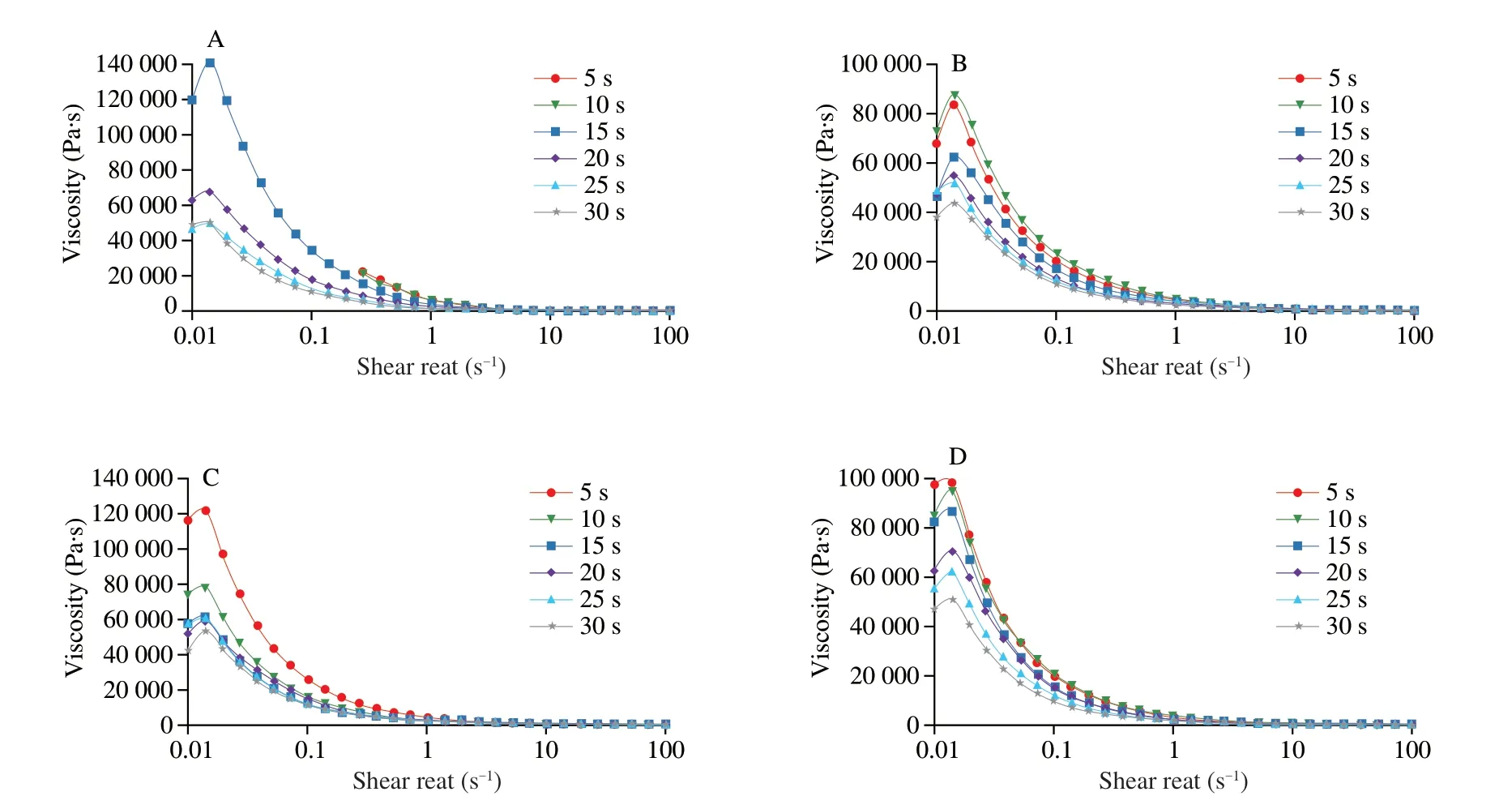

3.3 Viscosity of chicken boluses

As shown in the Fig.2,all samples displayed similar changes:the viscosity of the second data point (shear rate of 0.013 9 s−1)was slightly higher than the first one,which may be affected by the startup of the instrument.After the second data point,with the ascending of shear rate,the viscosity dropped by degrees,which is the pseudoplastic characteristic of shear thinning in non-Newtonian fluid[49].Food bolus,as a mixture of solid and liquid,the greater the deformation rate,the smaller the apparent viscosity and the better the flow,which was a characteristic of most polymer solutions and emulsions[50].

Fig.2 Apparent viscosity of various chicken bolus during oral processing.CB (A),CBS (B),CT (C),CTS (D) represent chicken breast,chicken breast and chicken skin,chicken thigh,chicken thigh and chicken skin,respectively.The same below.

The viscosity of CB sample chewing for 5 and 10 s cannot be measured at a low shear rate due to poor rheology,which can be detected only after 0.268 s−1.Generally,it displayed that with the extension of chewing time,the viscosity of the bolus declined and the rheology raised,which had a strong similarity between the samples chewed for 25 and 30 s.The CBS for 10 s had higher viscosity ranged from 72 850 Pa·s to 33.90 Pa·s and worse fluidity than the sample for 5 s ranged from 67 500 Pa·s to 29.45 Pa·s during the shear rate variation between 0.01 to 100 s−1,which may be related to the interaction between high protein chicken breast and skin fat in the oral cavity at the early stage of chewing.The combination of protein and fat molecules improved the cohesiveness of boluses.With the continuous increase of chewing time,the particle size of boluses declined and the content of saliva improved gradually[47,51].At the same time,the binding of protein and fat molecules may be destroyed,brought about the debasing of viscosity and strengthen of fluidity,which was better than CB.The viscosity of CT was lower than that of CB and higher than that of CBS.Within 20 s,the viscosity of CT gently fell which may be related to the general ascend of saliva content at this stage.The viscosity of first two data points of CT at 25 s ranged from 57 400 Pa·s to 60 025 Pa·s was slightly higher than 51 750−58 650 Pa·s at 20 s,and then dropped to the lowest value from 42 450 Pa·s to 52 850 Pa·s at 30 s,indicating that 20−30 s may be the key period in the oral processing of CT.Tendon fat in CT may release and bind to protein molecules after 20 s,resulting in the slight improvement.For CTS samples,at the initial chewing time of 5 s,the higher fluidity and lower viscosity (116 150−21.75 Pa·s) than CT(97 800−13.45 Pa·s) may be owing to the lubrication effect of chicken skin.Meanwhile,the viscosity at the remanent chewing stage was higher than CT,which might be related to full interaction and binding of chicken thigh protein,tendon fat and chicken skin[52].

3.4 Chicken bolus particle size distribution

The particle size and rheology of a food bolus was very different from that of food prior to oral processing[53],which were closely related to chewing frequency and saliva content.During oral processing,the particle size changes of different chicken boluses were shown in Table 3.D(4,3)andD(3,2)are the volume average particle size and surface area average particle size.respectively[54].D(50)is the median particle size,which is the particle size when the cumulative volume of particles accounts for 50% of the total volume and can reflect the average particle size in the food bolus[55].When chewing for 5 s,D(50)of CTS bolus was the largest at (1 563.3 ± 26.2) μm,while there was no significant difference between CT and CBS(P>0.05),and it was the smallest at (1 150.0 ± 14.1) μm in CB.During the processing stage,D(50)of chicken thigh was larger than that of chicken breast,and the addition of chicken skin augmented bolus size further.At the stage of chewing to 10 s,D(50)of the CB was the largest at (976.7 ± 7.6) μm,while CBS and CTS were relatively small,indicating that the chicken skin played an critical role in food particle crushing at the stage of 5−10 s oral processing.The fat of the chicken skin began to dissolve,which improved the lubricity of the food,as well as accelerated the release of flavor components and the combination of small molecule components.It was the key period for the oral processing of chicken samples with skin.In the oral processing stage after 10 s,D(50)of the CB bolus was the smallest and that of CT was the largest.

Table 3 Changes in the particle size of different types of chicken boluses during oral processing.

In chicken thigh samples with relatively high content of tendon and intermuscular fat,a small amount of fat can play a favorite role in lubrication,reduce chewing resistance,time and particles,enhance the uniformity of food bolus.In the chicken breast samples with low fat content,the adding fat magnified the bolus size formed during chewing.AlthoughD(50)of the bolus declined continuously,there is no significant difference among the chicken samples after chewing for 20 s with the value less than 300 μm,indicating that the chicken can be swallowed when median maximum bolus size was not more than 300 μm,which was similar to the average particle size of the lean layer during the oral processing of braised meat[14].It can also be found that when chewing for 5 s,the value ofD(4,3)was the highest at (1 416.7 ± 23.6) μm in CTS bolus,followed by CT,CBS and CB.At the chewing stage for 10 s,D(50)of CB was the largest.During a series of oral processing,the change trend ofD(4,3)in chicken bolus was similar toD(50),which can also be used to characterize the change of the particle size of the bolus.Comparing the particle size of cooked wooden chicken breast after oral processing reported by Zhang et al.[56],it can be revealed that theD(50)of chicken thigh before swallowing point was (213.7 ± 3.4) μm,which was higher than that of severely wooden chicken breast boluses of (201.10 ± 8.94) μm.D(50)of CTS was between mild and moderate wooden chicken breast,with CBS between normal and mild grade,CB lower than the normal,which further illustrated that the chicken made of Qingyuan partridge was more delicate.

Fig.S1 revealed the particle size distribution of different chicken boluses during oral processing.The abscissa was the particle size of food bolus,and the ordinate was the percentage of particles with the corresponding particle size in the total volume of particles.TheD(50)distribution of 4 chicken boluses presented multi peak form,most of which were bimodal.This may be related to the changes in the internal structure of the chicken bolus and the uneven local distribution of saliva during oral processing[57].The other samples chewed for 5 and 10 s showed 3 peaks,of which the first peak ranged from 92.0 μm to 118.8 μm except chicken breast meat samples.With the prolongation of oral processing time,the peak value gradually shifted to the left,and the volume density at the peak generally heightened,corresponding to CB,CBS,CT and CTS from high to low.The second peak value showed a large difference between 374.8 and 549.8 μm,which also had a phenomenon of left shift,and displayed a trend of gently augment in CB,CBS,CT and CTS.The third peak appeared at 1 970.5 μm for chewing for 5 and 10 s,and there were still large particles larger than 3 283.6 μm that could not be measured by instruments.

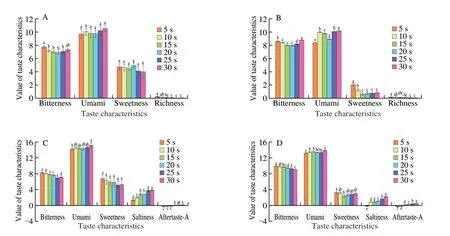

3.5 Changes in the electronic tongue taste characteristics during oral processing

The taste characteristics of the four chicken boluses (CB,CBS,CT,and CTS) during oral processing determined by electronic tongue are shown in Table 4.The transformed taste characteristic value was meaningless when it is less than 0[58].It can be seen that bitterness,umami and sweetness are the common taste characteristics of chicken food boluses formed in oral processing.Fig.3 illustrated the taste characteristics changes of the electronic tongue in the chicken bolus more intuitively.The bitterness characteristic value of the CTS was the highest,with CB bolus the lowest.The addition of chicken skin significantly improved the bitterness characteristic of the chicken.In addition,with the extension of the oral processing time,the bitterness characteristic value of each type of food bolus showed a trend of gradual downward in 20 s,which increased slightly in the last 10 s in chicken breast samples.It is possible explanation was that the chicken breast sample had been chewed completely within 20 s,and the saliva produced afterwards magnified the bitterness characteristics.

Table 4 Electronic tongue taste characteristics of chicken bolus during oral processing.

Fig.3 Electronic tongue taste characteristics of different chicken bolus.Different lowercase letters of the same taste characteristic indicate significant differences (P <0.05).

During the oral processing,the umami taste improved firstly in 10 s,then declined in 20 s,and enhanced again at the end of 10 s.Compared with the chicken bolus without skin,the umami characteristic value of the chicken boluses with skin were significantly different in all stages of oral processing,which was the highest in CT and the lowest in CBS.Therefore,the addition of chicken skin reduced the umami of each chicken bolus,in which the chicken thigh samples dropped the most obviously.The sweetness characteristic values of CB and CT were relatively higher almost without notable difference in the process of chewing,but the corresponding sweetness of CBS and CTS were significantly reduced and showed a tendency of gradually fall within 15 s and a slightly rising after adding chicken skin.It can be concluded that for chicken breast samples with low fat content,the addition of chicken skin will seriously affect the release and perception of sweet substances in chicken breast.There was no prominent difference in richness between CB and CBS,which reduced evidently with the prolongation of oral processing time,indicating that with the secretion of saliva,the perception of richness(umami aftertaste) was diluted.Both the salty and aftertaste-A of CT and CTS boosted observably with the extension of oral processing with conspicuous higher salty and fewer aftertaste-A in CT.On the one hand,the change trend of saltiness showed that saliva promoted the delivering of salty taste in the chicken thigh samples.On the other hand,the salty characteristic value of the chicken breast sample was lower than 0,declining that the chicken thigh was easier to taste than the chicken breast during stewing.The addition of chicken skin reduced the release and perception of salty molecules and enhanced the perception of aftertaste-A in chicken thigh sample.Comprehensive analysis of various taste characteristics found that chicken thigh samples had obvious tasteful characteristic over chicken breast,especially CT,which had the highest umami and sweet taste values at all stages.

3.6 Electronic nose analysis of volatile substances in food bolus during oral processing

Observing the Fig.4,it can be found that the W1W and W2W sensor signals are relatively high when chewing for 5 s in chicken samples.On the one hand,both WIW and W2W sensors are related to sulfur compounds,on the other hand,the content of cysteine in chicken skin was relatively high,and the sulfhydryl group in cysteine was the main source of sulfur containing volatile gases[59],so it is inferred that sulfides increases gradually.In the subsequent chewing process,the signal intensity of two types of sensors in CB bolus decreased the most,followed by CBS and CTS,with minimal declines in CT.The change indicated that on the one hand,the addition of chicken skin promoted the release of sulfur-containing substances in chicken breast samples and the opposite trend in chicken thighs.The content of sulfur-containing compounds (thiophenes and furan mercaptans) in chicken thigh,skin and breast may be from high to bottom.On the other hand,the raising of saliva will mask the release of sulfide,which may be related to mucin and other components in saliva[20].In addition,the signal intensity of the CBS on the W1S sensor,which was more sensitive to methane and other alkanes,gradually dropped with the prolongation of chewing time.It may be that the combination of chicken breast and skin promoted the release of alkane volatile substances.

Fig.4 Radar chart of electronic nose data form chicken bolus during oral processing.

The signal intensity of W1C,W3C and W5C sensors of different chicken bolus increase with the extension of chewing time except the chicken breast bolus chewed for 10 s,which indicated that CBS,CT and CTS boluses continuously released aromatic substances with the extension of oral processing time due to the high sensitivity of the three sensors to aromatics.The signal intensity of the three sensors was the highest in CB samples chewed for 10 s,which may be due to the low fat content of chicken breast leading to entire liberation in a short time,while the remaining samples with relatively high fat concentration causing slowly delivering of during the chewing process,in which fat was the main source of aromatic compounds[60,61].

As shown in Fig.5,the remaining samples were similar after chewing for 20 s except for CT samples,which basically reached the swallowing point and was in consistent with sensory evaluation(Section 3.7).The higher the contribution percentage is,the better the principal components can reflect the original multi-index information[52].In the PCA of 24 chicken boluses,although the accumulative variance contribution percentage of principal components 1 and 2 was only 69.6% (PC1 45.4%,PC2 24.2%),the overall degree of differentiation between all samples were relatively obvious,CB and CBS in the late stage of chewing were mainly concentrated in the third quadrant,with CT and CTS near the positive semi-axis.The food boluses in the early stage of chewing were mainly distributed around the ellipse.Through comprehensive analysis,different chicken bolus can be distinguished by electronic nose based on the 5 sensors including W1W,W2W,W1C,W3C,and W5C.

Fig.5 Principal component analysis (PCA) scatter plots of electronic nose during oral processing in different types of chicken.The number on the right represents chewing time.

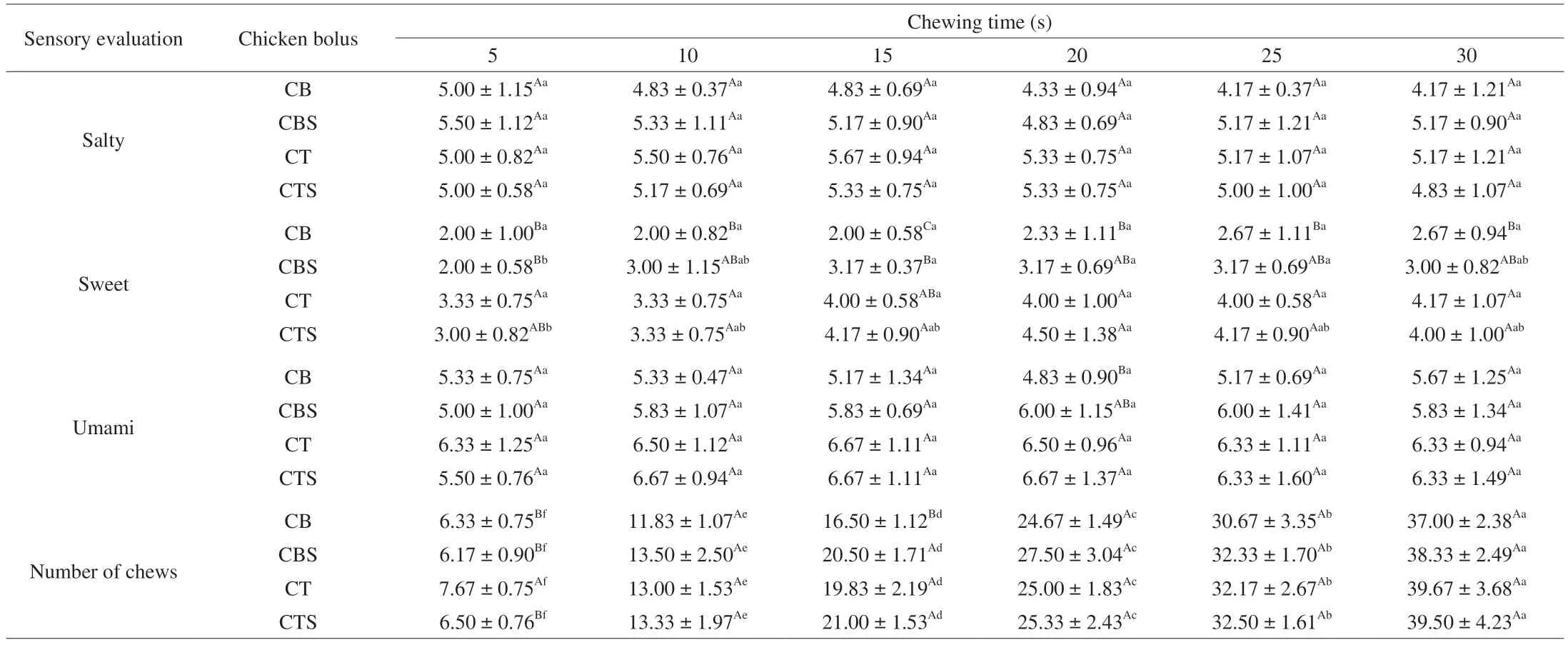

3.7 Sensory evaluation

From the perspective of chicken bolus samples,the saltiness and umami scores of CB went down with the gain of chewing time,while the sweetness accelerated incrementally (Table 5).The sweetness score of the 30 s sample was the same as that of the 25 s sample,while the umami score improved slightly without remarkable difference.The saltiness of CBS descended initially to 20 s and then raised.The points of sweetness and umami indicated an upward trend with significant difference in sweetness,and both dropped slightly at 30 s.In addition,the chewing numbers of CBS were higher than CB with a significant difference only at 15 s of mastication.The scores of umami,salty and sweet tastes changed in a similar pattern in CT and CTS,which enhanced initially and then declined moderately during oral processing.The number of chewing were similar excepted expressively higher value at 5 s of CT and a marginally higher value at 15 s of CTS.Although there was no significant difference,it can be inferred from the combination of CB and CBS that around 15 s was the critical period for oral processing of chicken samples with skin.In terms of different stages of oral processing,there was no significant difference in the saltiness of different chicken food groups.Although the saltines characteristic value of the CB and CBS measured by the electronic tongue was less than 0,which did not contribute to the overall sensory characteristics.Sensory panelists could not evaluate the differences in saltiness of different chicken.The umami score of the chicken thigh samples was higher than that of the chicken breast at all stages of oral processing,with a significant difference only at 20 s of chewing.It may be that various samples have reached the swallowing point after 20 s with complete mastication and flavor releasing.The sweetness scores of the chicken thigh samples were higher than the breast during oral processing,which may be the reason why chicken thigh was more popular.The bitterness value of the electronic tongue in different soft-boiled chicken boluses were all greater than 0.But the bitter taste was not be perceived during the mastication of the soft-boiled,so the bitterness was not listed in Table 5.It is shown that there were still some differences between electronic sense and human perception.It is one of the directions that could be considered in the future to perfect the apparatus of electronic sensory and establish the actual connection between them.

Table 5 Sensory evaluation of soft-boiled chicken during oral processing.

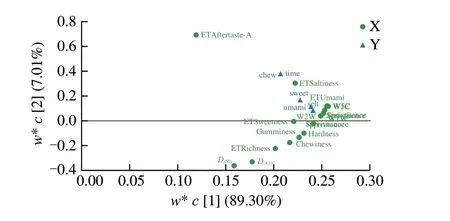

3.8 Correlation analysis by PLSR

In the PLSR model,the internal logical relationship was considered in advance,X-variables include the results of texture,particle size,electronic tongue,and the electronic nose,Y-variables is for the sensory evaluation.Besides,PLSR analysis had the advantage that it could conduct regression modeling under the condition of multiple correlation of independent variables,which contained all the original variables[62].The correlation loadings scatter plot (based on the first and second components) of texture,particle size,electronic tongue,electronic nose and sensory perception among 24 different chicken boluses were shown in Fig.6,in whichw* andcare the loading weights ofX-variables andY-variables,respectively.The cumulatedQ2was 0.948 (>0.5),indicating that the PLSR model and predictive ability was reliable[63].It can be found that there was a close relationship between chewing time and number.The sensory perception of umami,sweet and salty taste was intimately related to the cohesiveness and springiness in texture characteristics,the W1C,W3C,W5C,W1W,W2W signals of electronic nose,the umami and bitterness taste of electric tongue.The result was similar to the variable importance for the projection (VIP) plot as shown in Fig.7,which summarizes the importance of variables both to explainXand to correlate toY.The VIP value greater than 1 indicates important variable,while the value less than 0.5 indicates unimportant[64].The gray area is between 0.5 and 1,where the importance level depends on the size of the data set.The VIP of all variables was greater than 0.8,demonstrating that each index had a certain impact on the sensory quality of the food bolus,with 11 indicators including aftertaste-A,W3C,W5C,W1C,umami bitterness and saltiness of electronic tongue,W1W,cohesiveness,W2W,springiness larger than 1.The regression coefficients in Fig.8 indicated that the salty and umami taste were similar,in which the regression coefficients of each index were all positive,and the chewing time was consistent with the chewing number,which was relatively affected by aftertaste-A.It was regarded as the largest VIP value of all indexes and only detected in CT and CTS,further illustrating that the chicken thigh sample was better than the breast in the sensory evaluation process on the whole.

Fig.6 Loadings scatter plot between sensory perception and basic index of chicken boluses.

Fig.7 VIP (variable importance for the projection) plot.

Fig.8 Overview of regression coefficients.

4. Conclusion

After the food is ingested,it gathers into bolus and triggers swallowing through a series of oral processing processes such as tooth chewing,tongue peristalsis and saliva secretion.It was found that the bolus particles gradually decrease with the progress of oral processing through the determination of particle size of CB,CBS,CT,CTS.The hardness,cohesiveness,springiness,chewiness and resilience of texture declined from the early stage to the late stage of the chewing on the whole.The apparent viscosity also dropped with the enhancement of fluidity.Combined with electronic nose,electronic tongue,PLSR analysis were also used to determine the taste and correlation of food boluses.The swallowing point of chicken breast samples was reached at 20 s,while that of chicken thigh samples at 25 s.The inclusion of chicken skin can significantly reduce the viscosity of bolus,increase the fluidity,facilitate swallowing,and enhance the flavor release of aromatic compounds,but has a negative effect on the perception of umami and sweet taste.The composition of soft-boiled chicken before first bite,the chewing process all affect the perception of the good quality of soft-boiled chicken.Especially in the mastication of chicken breast,it is recommended to eat with chicken skin to enhance the tenderness and taste of the sample.In general,there are certain differences in taste perception of different types of soft-boiled chicken combinations.Whether in terms of taste or texture,the indicators of the chicken thigh samples are the best.Meanwhile,the incorporation of fat associated with the formation and characteristics taste perception of food bolus during oral processing.

Statement

All subjects have obtained informed consent for the sensory evaluation experiment in the article.We promise that all sensory experiments related to humans were carried out in accordance with the Code of ethics of the World Medical Association (Declaration of Helsinki),and always abide by the privacy right of human subjects.

Competing interests

There was no conflict of interest.

Acknowledgement

The research was supported by China Agriculture Research System of MOF and MARA (CARS-41) and Wens Fifth Five R&D Major Project (WENS-2020-1-ZDZX-007).We are slao grateful for the cooperation of the sensory subjects to the experiment.

Appendix A.Supplementary data

Supplementary data associated with this article can be found,in the online version,at http://doi.org/10.26599/FSHW.2022.9250026.

杂志排行

食品科学与人类健康(英文)的其它文章

- Modifications in aroma characteristics of ‘Merlot’ dry red wines aged in American,French and Slovakian oak barrels with different toasting degrees

- Effect of different drying methods on the amino acids,α-dicarbonyls and volatile compounds of rape bee pollen

- Dynamic changes in physicochemical property,biogenic amines content and microbial diversity during the fermentation of Sanchuan ham

- A comparison study on structure-function relationship of polysaccharides obtained from sea buckthorn berries using different methods:antioxidant and bile acid-binding capacity

- Yolk free egg substitute improves the serum phospholipid profile of mice with metabolic syndrome based on lipidomic analysis

- Underlying anti-hypertensive mechanism of the Mizuhopecten yessoensis derived peptide NCW in spontaneously hypertensive rats via widely targeted kidney metabolomics