Effects of Potassium Ferrate and Low-Temperature Thermal Hydrolysis Co-Pretreatment on the Hydrolysis and Anaerobic Digestion Process of Waste Activated Sludge

2023-12-21MAYingpengHAODiYAOShuoZHANGDahaiLIXianguoandFENGLijuan

MA Yingpeng, HAO Di, YAO Shuo, ZHANG Dahai, LI Xianguo, and FENG Lijuan

Effects of Potassium Ferrate and Low-Temperature Thermal Hydrolysis Co-Pretreatment on the Hydrolysis and Anaerobic Digestion Process of Waste Activated Sludge

MA Yingpeng, HAO Di, YAO Shuo, ZHANG Dahai, LI Xianguo, and FENG Lijuan*

This study evaluated the effect of potassium ferrate (PF) and low-temperature thermal hydrolysis co-pretreatment on the promotion of sludge hydrolysis process and the impact on acid production in the subsequent anaerobic digestion process. The analytical investigations showed that co-pretreatment significantly facilitated the hydrolysis process of the sludge and contributed to the accumulation of short-chain fatty acids (SCFAs). The pretreatment conditions under the optimal leaching of organic matter from sludge were hydrothermal temperature of 75℃, hydrothermal treatment time of 12h, and PF dosage of 0.25gg−1TSS (total suspended solids), according to the results of orthogonal experiments. By pretreatment under proper conditions, the removal rate of soluble chemical oxygen demand (SCOD) achieved 71.8% at the end of fermentation and the removal rate of total phosphorus (TP) was 69.1%. The maximum yield of SCFAs was 750.3mgL−1, 7.45 times greater than that of the blank group. Based on the analysis of the anaerobic digestion mechanism, it was indicated that the co-pretreatment could destroy the floc structure on the sludge surface and improve organic matter dissolving, resulting in more soluble organic substances for the acidification process. Furthermore, microbial community research revealed that the main cause of enhanced SCFAs generation was an increase in acidogenic bacteria and a reduction of methanogenic bacteria.

waste activated sludge; potassium ferrate; low-temperature thermal hydrolysis; anaerobic digestion; short-chain fatty acids

1 Introduction

Waste activated sludge (WAS) is generated in enormous amounts from sewage treatment by the activated sludge method, which contains many hazardous substances, including heavy metals, pathogens, and other pollutants that constitute a significant contamination risk to the environment (Zhang., 2014). Meanwhile, the abundance of organic matter in WAS makes it a potential resource. Anaerobic digestion is particularly meaningful for sludge stabilization since it can minimize pathogens and recover resources including short-chain fatty acids (SCFAs) and methane (Yang., 2015; Choi., 2018; Zhao., 2018). Various studies suggested that the production of SCFAs is more promising due to higher product value, lower cost input, and easier operation and maintenance (Liu., 2018a; Zhang., 2018).

Focusing on the production of SCFAs, numerous strategies including physical, chemical, and biological have been explored to accelerate the anaerobic digestion’s rate-limiting step,.., the hydrolysis process of sludge. These methods promote the release efficiency of intracellular material by cracking extracellular polymeric substances (EPS) (Liu., 2018b; Fang., 2021; Wu., 2021; Xu., 2021). Among these strategies, thermal hydrolysis is an effective approach for releasing the organic materials in the sludge, which primarily consists of soluble protein (SP) and soluble carbohydrate (SC). The performance of anaerobic digestion with thermal hydrolysis pretreatment relies heavily upon pretreatment temperature. Most research concentrated on high-tempe- rature (>100℃) pretreatments, and the cracking effici- ency of sludge cells improved dramatically as treatment temperature increased (Carrere., 2008; Choi., 2018). However, a prominent disadvantage of high-tem- perature pretreatment is the high energy input, which affects the profitability of the anaerobic fermentation process. Furthermore, high temperatures might lead to the development of hazardous chemicals (Pilli., 2015). It has been recently reported that by pretreating sludge with low-temperature thermal hydrolysis (<100℃) in the ran- ge of 70℃ to 90℃, the efficiency of leaching substances from sludge was greatly improved thus the subsequent anaerobic digestion for SCFAs production was also facilitated. Zhao(2020) found that 80℃ was a more appropriate thermal hydrolysis temperature for sludge biodegradation due to the maximum total organic carbon (TOC) solubility. Furthermore, Xiao. (2020) reported on the synergistic effect of low-temperature thermal hydrolysis and chemical pretreatments, stating that the addition of certain alkaline substances allowed for a lower pretreatment temperature, saving a significant amount of energy. Lu. (2008) evaluated the energy balance under low-temperature thermal hydrolysis pretreatment and found that the energy of anaerobic digestion products was greater than that consumed by pretreatment, and there was an energy surplus of 2.17kJd−1.

PF can effectively oxidize some organic and inorganic substances in sludge owing to its strong oxidation ability. It has been demonstrated that the ferric ion (Fe3+) produced in the process of oxidation by PF has a beneficial flocculation effect on various pollutants (Wu., 2015). Based on the excellent characteristics, the role of PF in the production of SCFAs by anaerobic digestion has been widely explored. It has been pointed out that on the eighth day of anaerobic digestion, the yield of SCFAs increased from 475mg CODL−1of the control to 2835mg CODL−1in 0.9gg−1VSS PF pretreated condition, and the enrichment of acidogenic microbe is an important explanation for the rise in SCFAs production (Li., 2018b). He. (2019) found that the optimal production of SCFAs was acquired at a PF dosage of 56mg Fe(VI)g−1TSS. However, PF concentrations above a particular point will result in the production of harmful particles, which will damage the subsequent anaerobic digestion process of sludge (Guo., 2021), and it also raises the cost of sludge treatment. Based on these research backgrounds, it is necessary to combine PF pretreatment with other pretreatment strategies to enhance the effectiveness of anaerobic digestion and decrease the amount of PF, which will help to better sludge disposal and prevent the release of hazardous materials.

The proper co-treatment methods can improve the synergistic of two different pretreatment methods and overcome the defects of various single pretreatment methods in sludge reduction and anaerobic digestion. The target of this work, therefore, is to investigate the optimal combination of PF and low-temperature thermal hydrolysis pretreatment and determine how PF and low-temperature thermal hydrolysis co-pretreatment affect solubilization of sludge and SCFAs generation in the process of anaerobic digestion. We studied various combinations of hydrothermal temperature, hydrothermal time, and PF dosage to improve the process of hydrolysis and enhance the synergy of two different pretreatment options. The change law of SCFAs contents during anaerobic digestion was determined at the optimal combined pretreatment conditions. Aside from those, the removal rate of soluble chemical oxygen demand (SCOD) and total phosphorus (TP) was evaluated to explore the role of anaerobic fermentation in sludge harmlessness. Moreover, by analyzing the changes in relevant microbial communities, the mechanism of increased SCFAs production was discus- sed.

2 Materials and Methods

2.1 Experimental Materials

The WAS used in this experiment was obtained from the secondary sedimentation tank of an urban sewage treatment plant in Qingdao. It was stored in a plastic container at 4℃ after being collected. Its main characteristics were as follows: total phosphorus (TP) 5.2mgL−1, ammonia nitrogen (NH4+-N) 246.4mgL−1, soluble chemical oxygen demand (SCOD) 4635.2mgL−1, soluble protein (SP) 12.7mgL−1, soluble carbohydrates (SC) 21.3mgL−1. PF was purchased from Shanghai Aladdin Bio-Chemtech- nology Corporation.

2.2 Pretreatment Conditions

The pretreatment experiments were divided into two parts. Part-I explored the effect of three single factors, which were pretreatment temperature, time, and dosage of PF on sludge organic matter leaching. The results of part- I were analyzed and the orthogonal experiment in part-II was designed based on the results of the part-I to determine the optimal co-pretreatment conditions:

Part-I: Single-factor pretreatment experiments were performed in multiple identical reactors. Each reactor received 50mL WAS, and then single-factor pretreatment experiments were performed under different conditions. To investigate the effect of temperature on the organic matter leaching, the reactors were pretreated for 6h in a 45, 60, 75, and 90℃ water bath after the sludge was added to the reactors and stirred uniformly. The sludge was treated to pretreatment at 60℃ under water bath heating for 3, 6, 9, 12, and 15h to analyze the impact of the pretreatment period. PF was added to six sludge reactors at the amounts of 0.05, 0.15, 0.25, 0.35, 0.45, and 0.55gg−1TSS each, then the reactors were pretreated with constant stirring (400rmin−1) at room temperature for six hours to determine the optimum PF dosage.

Part-II: The orthogonal experiment was designed with a dosage of PF, pretreatment temperature, and pretreatment time as factors and set three levels for each factor based on the consequence of Part-I. The factors and levels of orthogonal experiments are listed in Table 1. The method of orthogonal experiment was the same as part-I, and the sludge was sampled and tested after the pretreatment was completed.

2.3 Experimental Setup of Anaerobic Digestion

Two batch reactors with 500mL working volume were operated. One of the reactors was charged with 300mL of un-pretreated sludge and the other reactor was filled with an equal amount of sludge treated in an optimal combined pre-treatment manner. Inoculum sludge was then added to each reactor to a total volume of 400mL in each reactor. Both reactors afterwards were flushed with nitrogen gas for 5min, then attached to an air collector bag and sealed, kept stirring (150rmin−1) on a blender, and placed in a constant temperature incubator. During the anaerobic digestion experiment, the 20mL of sludge was removed every 24h from each of the two reactors for the determination of parameters, and the 20mL of sludge treated in the same pretreatment manner was re-added to the reactors. The digestion experiments were all run at 25℃ for 20d.

2.4 Analysis Methods

The sludge samples were centrifuged at 5000rmin−1and then filtered through a 0.45μm filter membrane to obtain the supernatant. SCOD and NH4+-N were measured complying with the standard methods (APHA, 2005). TP was determined by the ammonium molybdate colorimetric method (Huang., 2015). In addition, the contents of SP in the supernatant were measured by the Lowry-Folin approach with bovine serum albumin as the standard, and the contents of SC were measured by the anthrone-sulfuric approach with glucose as the standard (Lowry., 1951; Zhao., 2021). A GC-2010 plus equipped with a DB-FFAP column (30m×0.25mm×0.25μm) and a hydrogen ion flame detector were used to analyze the compositions and concentrations of SCFAs, which were considered as the sum of acetic, propionic, iso-butyric,-butyric, iso-valeric and-valeric acids. Besides, the sludge morphology of the experimental and blank groups was investigated by scanning electron microscopy (SEM).

2.5 Microbial Community Analysis

The sludge samples with pretreatment and without pretreatment on the anaerobic digestion were analyzed for the microbial community. The microbial community was measured by Illumina Novaseq platform, following the process of total DNA extraction, polymerase chain reaction (PCR), recovery and purification of amplification products, preparation of sequencing library, fluorescence quantification of amplified products, and high-throughput sequencing. Amplicon release was constructed using bacterial fusion primers 341F (CCTACGGGNGGCWGCAG) and 806R (GGACTACHVGGGTWTCTAAT) for the V3-V4 region of the 16s rRNA gene. The PCR products were detected by 1% agarose gel electrophoresis with 3μL of sample volume. Amplification products were purified by the method of DNA Clean Beads and Qubit was used to quantify after purification. Fluorescence was used to quantify the recovered PCR amplification products in accordance with the preliminary quantitative electrophoresis results. The results were analyzed, and the qualified libraries were sequenced by high-throughput sequencing.

3 Results and Discussion

3.1 Effects of Pretreatment Conditions on the Release of Organic Matter from Sludge

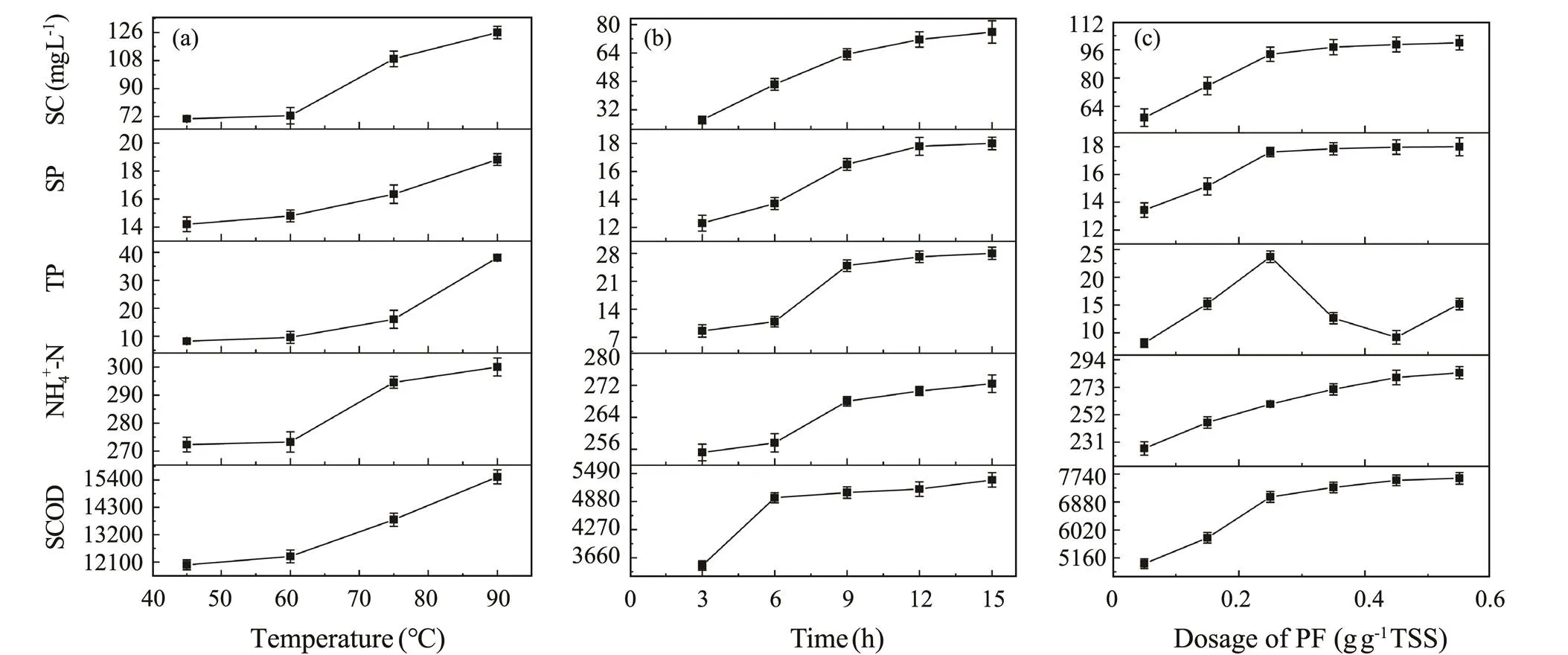

Sludge hydrolysis is the rate-limiting stage of the pro- cess of anaerobic digestion. The leaching of organic matter from sludge can be efficiently enhanced under a pro- per pretreatment condition, increasing the substrate for anaerobic digestion. The temperature and time of pretreatment, as well as the dosage of PF, have a significant impact on the sludge hydrolysis process. The trends of SCOD, NH4+-N, TP, SP, and SC under different temperatures, times, and dosages of PF were shown in Fig.1.

Fig.1 Changes of SCOD, NH4+-N, TP, SP, and SC in sludge under different temperatures (a), time (b), and dosages of PF (c).

As can be seen from Fig.1a, the SCOD, SP, and SC grew as the treatment temperature rises, showing the dissolution of organic matter in sludge can be effectively promoted by raising the temperature. Moreover, the higher the temperature, the more cell dissociation took place, while the cell membrane rupture, and phospholipid bilayer decomposition by sludge microorganisms, resulted in a significant increase in TP content. The TP content of sludge treated at 45, 60, 75, and 90℃ was 1.58, 1.85, 3.08, and 7.33 times that of raw sludge, respectively, and the growth rate was dramatically accelerated. With the destruction of protein structure by high temperature, the content of NH4+-N increased substantially, reaching 294.6mgL−1after 75℃ pretreatment. However, a temperature of 90℃ seemed not a more effective choice for the release of NH4+-N, since, after a treatment temperature of 90℃, the growth rate of NH4+-N release was very limited.

Several studies suggested that for thermal hydrolysis treatment at lower temperatures, the processing time is a critical factor (Appels., 2010; Choi., 2018; Liu., 2021). Fig.1b showed that the level of SCOD grew from 3489.28 to 4961.64mgL−1with the extension of treatment time from 3h to 6h. However, there was almost no increase in its content after the pretreatment time longer than 6h. SC and SP concentrations raised from 36.3 to 75.8mgL−1and 12.3 to 18mgL−1, respectively, as the processing time extended from 3 to 12h. The reason for the divergent trends in SCOD and the two organic substances mentioned above may be that, even after 6h of low-temperature pretreatment, the organic matter in the sludge were still aggregated in large molecules and needed a longer pretreatment period could provide enou- gh energy to release the SP and SC constantly. The primary source of NH4+-N was the decomposition of proteins so the growth trends of SP and NH4+-N were identical, which was similar to the conclusion reached by Bougrier. (2007). The release of NH4+-N increased from 257.6 to 269.5mgL−1in the range of 6 to 9h. In addition, within this time frame, TP grew from 10.90 to 24.92mgL−1, which is a growth rate of 128.6%.

In Fig.1c, the release of SCOD, NH4+-N, TP, SC, and SP at different dosages of PF was illustrated. Growth trends in SCOD, SC, and SP can verify that PF addition broke down the sludge floc structures, perhaps resulting in more biodegradable materials for subsequent SCFAs synthesis. The efficiency of organic solubilization did not noticeably improve whenever the addition of PF above 0.25gg−1TSS, which would result in significant reagent waste and be detrimental to cost management. It could be seen that NH4+-N levels have been rising rapidly, along with a dosage of PF, which may be due to a large number of various molecular weight proteins being oxidized into small molecules by the remaining PF. The TP content was largely affected by the amount of PF applied. Only 8.16 mgL−1of TP was presented as PF was supplied in a concentration of 0.05gg−1TSS. When the addition of PF was increased to 0.25gg−1TSS, the level of TP rose to 23.7 mgL−1due to the destruction of microbial cell membrane by the intense oxidation effect of PF. However, the amount of TP showed a clear decrease trend as the concentration of PF was raised to 0.35gg−1TSS or more. TP is mainly removed during sewage sludge treatment by excessive absorption of phosphorus through phosphorus accumulating organisms (PAOs) or by the addition of metal ions such as Mg2+, Ca2+, Fe3+, and Al3+, thus forming chemical precipitation (He, 2018). Biological phosphorus removal usually requires the enrichment of a large number of PAOs, and external environmental conditions such as pH and temperature can have a significant impact on the effect of PAOs (Zou and Wang, 2016), and their phosphorus removal effect was very limited under the short-term pretreatment conditions. The addition of Fe3+to sludge is an effective way to remove phosphorus from sludge (Rittmann., 2011). When the concentration of Fe3+in the sludge exceeds a certain amount, it combines with phosphate to form a precipitate that is transferred to the solid phase, thus decreasing the phosphorus content in the sludge supernatant.

The results mentioned above showed that EPS can be effectively destroyed by both PF and low-temperature thermal hydrolysis pretreatment, and the contents of dissolved organic matter in the liquid phase of sludge varied with treatment temperature, reaction time, and addition of PF. The effective temperature and time of pretreatment and PF dosage were selected by monitoring the trend of organic matter in order to enhance pretreatment efficiency and avoid wasting energy and reagents. The rapid change of organic substances including SP and SC was faster at a thermal hydrolysis temperature of 60–90℃. The dosage selection range to prevent wasting PF was 0.05–0.25gg−1TSS in an investigation of the impact of PF addition on dissolved organic matter in sludge. The effect of thermal hydrolysis time on the solubilization of organic matter was also significant, the changes of SP and SC in the liquid phase were more rapid during 6–12h of treatment, according to the experimental results.

3.2 Effects of Co-Pretreatment on the Release of Organic Matter from Sludge

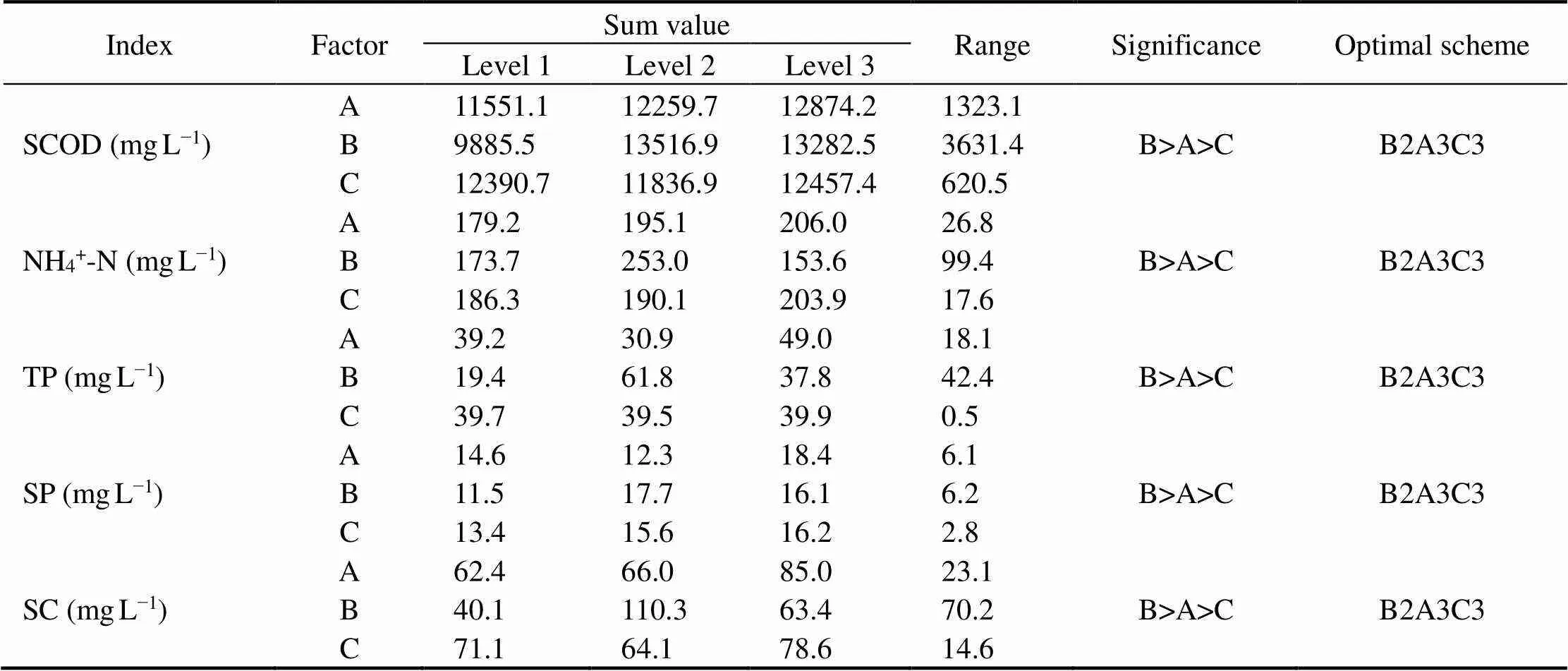

The optimal ranges of pretreatment temperature, time, and dosage of PF were determined from the previous experimental results. After that, orthogonal experiments were used to identify the ideal pretreatment conditions for the PF and low-temperature thermal hydrolysis co-pre- treatment,.., the optimal combination of dosage of PF, temperature, and treatment time. The results of orthogonal experiments with three factors and three levels were listed in Table 2.

Thermal hydrolysis and chemical pretreatment were both simple and effective pretreatment procedures (Kor-Bicakci and Eskicioglu, 2019; Nguyen., 2021). The results of the orthogonal experiments can be found that the optimum pretreatment condition was B2A3C3, which involved administering 0.25gg−1TSS PF while treating the sludge at 75℃ for 12h. The temperature of thermal hydrolysis was the main factor affecting the release of organic matter in sludge. It was entirely feasible that raising the temperature can improve the energy of molecular motion, destroy the sludge floc structure, and make release of organic matter, rapidly increasing the contents of organic matter. The dosage of PF was another crucial determining factor since the variation of SCOD, SP, and SC revealed that the appropriate concentration of PF had a significant contribution to the dissolution of substances. The least impact of hydrothermal time on sludge hydrolysis can be attributed to the fact that its rate and degree of sludge hydrolysis were less remarkable than direct physical and chemical factors.

Table 2 Experimental arrangements and results of the orthogonal experiments

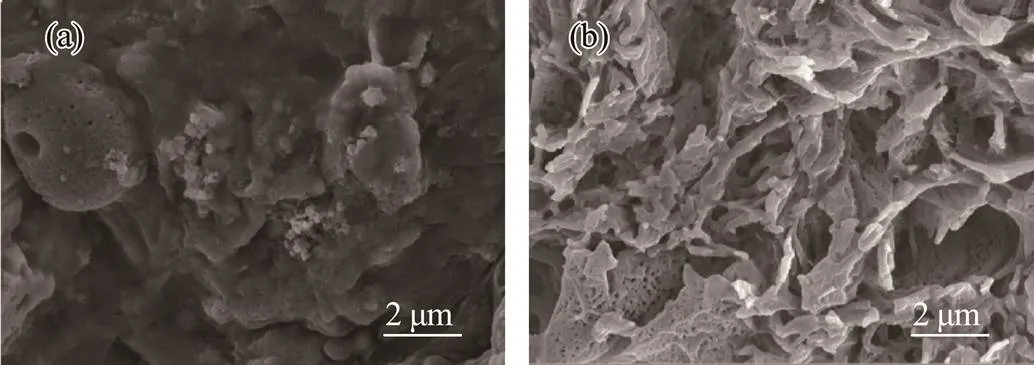

Due to the dense floc structure, the organic matter lea- ching rate of WAS is generally quite low. The rise in tem- perature during pretreatment and the strong oxidizing property of PF may have an effect on the structure of the sludge, and the surface morphology is part of the sludge structure, thus the change in surface morphology may be one of the important reasons for the variation in the leaching of organic matter from the sludge. The SEM images on the surface morphology of raw sludge and combined pretreated sludge were presented in Fig.2. As can be seen in Fig.2a, the raw sludge showed a dense blocky structure, while the sludge with pretreatment, as depicted in Fig.2b, had a loose flocculent structure with the originally more complete sludge floc surface broken down. The change in surface morphology may be an important explanation for the increase in sludge organic matter leaching.

Fig.2 SEM images of the raw sludge (a) and the sludge under co-pretreatment (b).

3.3 Effect of Co-Pretreatment on the Products of Anaerobic Digestion

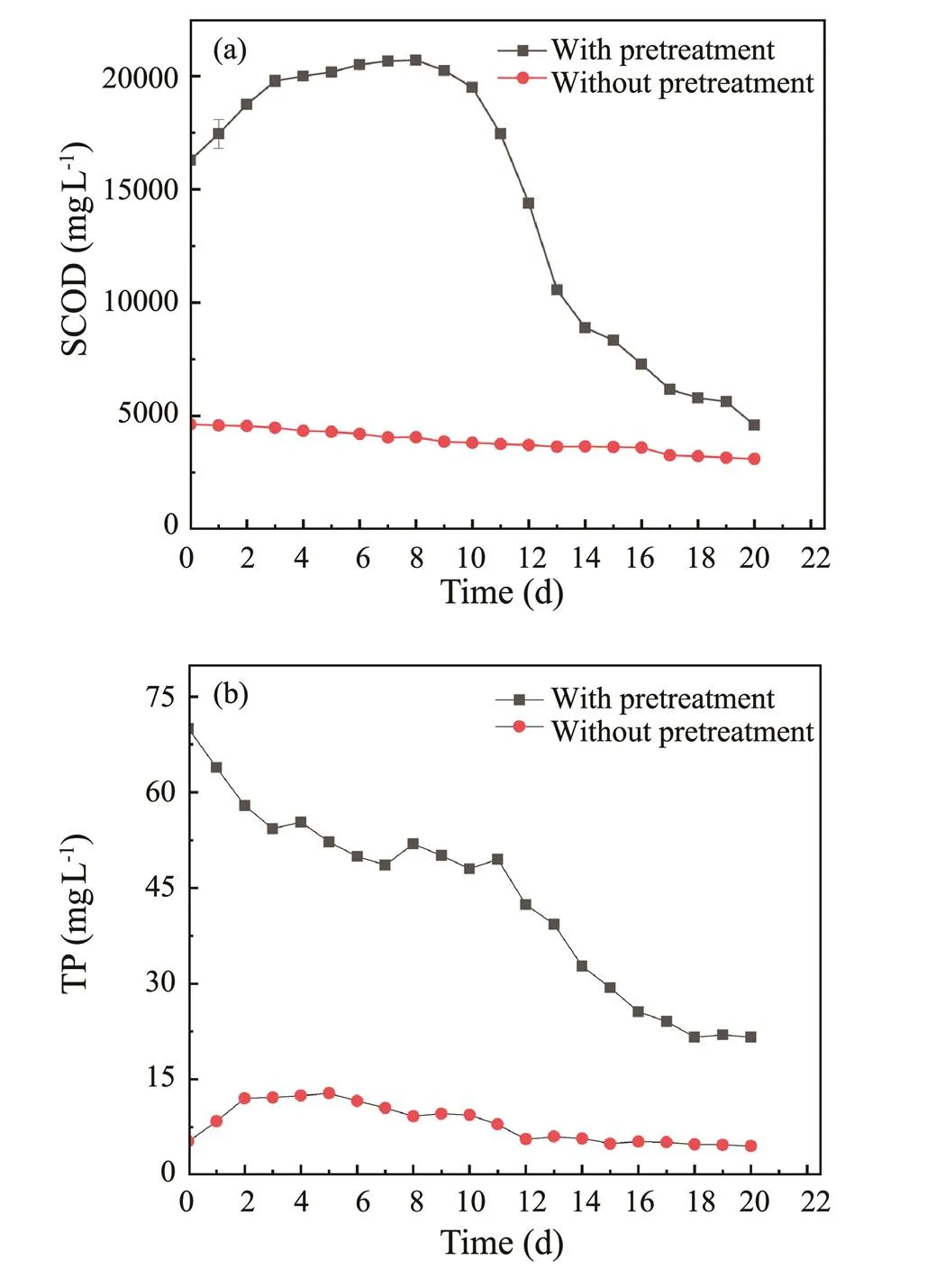

To further understand the action pattern of acid production in sludge during anaerobic digestion, changes of SCOD and TP concentrations in the 20d of anaerobic digestion experiment were determined. The SCOD of the co-pretreatment sludge was much higher than that of the untreated sludge before the initiation of anaerobic digestion, as shown in Fig.3a, demonstrating that the co-pre- treatment efficiently accelerated sludge hydrolysis. On the eighth day of digestion, the SCOD of the co-pre- treated sludge reached its highest level of 20711.91mgL−1. Afterwards, more organic materials were consumed by anaerobic digestion than were daily leached from the sludge. Hence, the SCOD value in sludge began to fall on the ninth day (Randall and Liu, 2002). Most of the organic contents in unpretreated sludge cannot be released because of the tight EPS structure. Meanwhile, the origi- nal organic matter in unpretreated sludge were converted into other compounds by microbes, which caused the SCOD value to decrease during anaerobic digestion. The SCOD removal rate of un-pretreated sludge after anaerobic digestion was only 32.8%, whereas the rate of co-pre- treatment was 71.8%. A huge amount of substrate was generated in the pretreatment process, which enhanced the activity of specific microorganisms greatly and contributed to the development and reproduction of related bacteria. The organics initially present in the sludge were changed into various kinds of compounds by some microbes, greatly lowering the SCOD value.

Fig.3 Changes of SCOD (a) and TP (b) concentrations during anaerobic digestion with time for 20d.

The variation of TP during anaerobic digestion was represented in Fig.3b. Disruption of the phospholipid bilayer on the microbial cell membrane caused a significant increase in TP in the sludge so the extent of sludge structure disruption can thus be roughly predicted by the TP content. Before anaerobic digestion, similar to SCOD, the TP content of co-pretreated sludge was significantly higher than that of un-prepared sludge, revealing that the co-pretreatment disrupted the cell membrane, causing a remarkable increase in the TP content of the sludge. During the process of anaerobic digestion, the content of TP continuously decreasing. The phosphorus in the sludge solids was bound by the Fe3+created by the PF, preventing it from being released into the supernatant. In addition, PAOs have been found to consume a portion of the phosphorus in the external environment during their growth and metabolism, resulting in a decrease in the amount of TP (He, 2018).

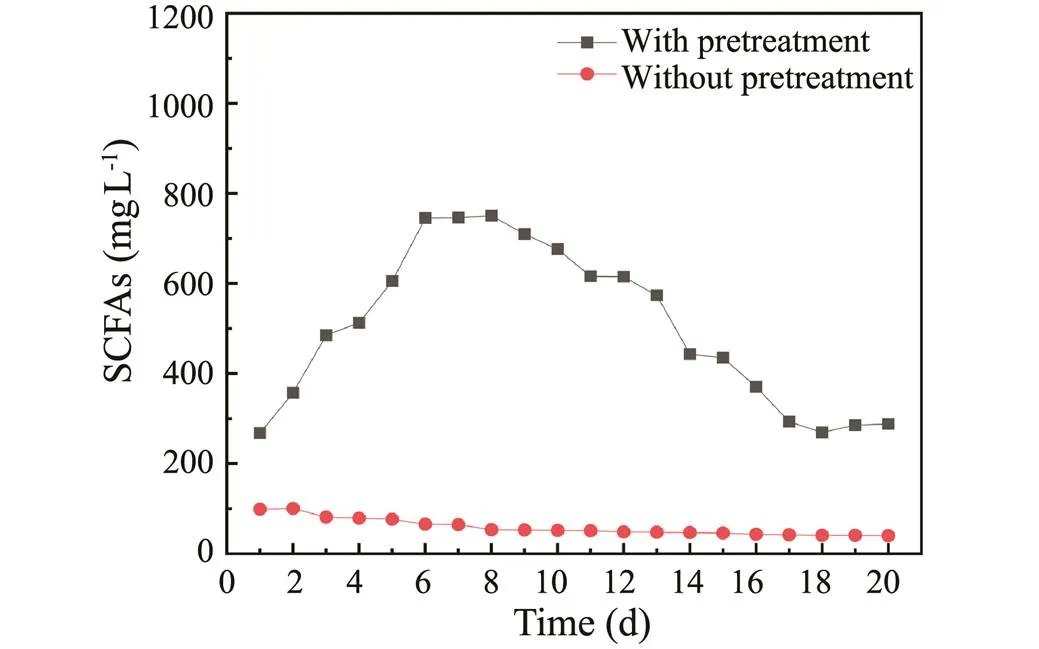

The yields of SCFAs from anaerobic digestion of sludge in the reactor under different pretreatment strategies were shown in Fig.4. In comparison to un-treated sludge, more SCFAs were produced in co-pretreated sludge during anaerobic digestion, and the huge rise in the creation of SCFAs was caused by the enormous amounts of organic matter leaching, which provided the bacteria involved in the acid production process with enough substrates for their life activities. The SCFAs output of co-pretreatment sludge reached the maximum value of 750.3mgL−1on the eighth day of anaerobic fermentation, which revealed the potential of the co-pre- treated sludge to produce SCFAs by anaerobic digestion has been substantially enhanced. The acids were extensi- vely utilized by methanogens during subsequent anaerobic digestion to make methane. As a result, more SCFAs were devoured daily than were synthesized, which caused a drop in SCFAs concentration (Weiland, 2010).

Fig.4 Changes of total SCFAs concentrations during anaerobic digestion with time for 20d.

3.4 Effects of Co-Pretreatment on Microbial Community Variations

The anaerobic digestion was actually a complex pro- cess of numerous microorganisms using various substrates in the sludge for their life activities. The mechanism of action of functional flora during anaerobic digestion can be discovered by comprehending the composition and quantitative changes of the relevant bacteria. Chao1 and Ace levels were proportional to the richness of the bacterial population and the more uniform the distribution of species and the higher the community richness, the larger the Shannon index. As shown in Table 3, the decrease of Chao1, Ace, and Shannon indicated that the richness and diversity of microbial communities in co-pretreated sludge reduced, which was due to the fact that the living conditions of microorganisms in the original sludge were altered since the addition of strong oxidizing PF and the change of temperature. Thus, some bacterial groups that were not adapted to the new environment were destroyed, and this conclusion was confirmed in the TP analysis. The high amounts of organic materials that were leaching from the sludge were exploited by some bacteria involved in the creation of SCFAs to grow and reproduce as a result of their ability to adapt to the changing environment, thus increasing acid production.

Table 3 Sequencing results of Chao1, Ace, and Shannon index of bacteria communities in digesters with pretreatment and without pretreatment

The relative number of microorganisms in sludge by phylum and class was shown in Fig.5. As seen in Fig.5a, Bacteroidota, Proteobacteria, Chloroflexi, and Firmicutes were the primary strains in the anaerobic digesting process at the phylum level,with a total proportion of 62.9% for co-pretreatment and 62.7% for blank. In sludge, Bacteroidota was a vital microbe that can create a huge number of hydrolases to break down carbohydrates and proteins (Yin and Wang, 2016). The relative abundance of Bacteroidota increased from 17.5% to 18.7% after pretreatment, which may be due to the large amount of carbohydrates and proteins released by the pretreatment process providing sufficient substrate for the growth and reproduction of Bacteroidota. In the meantime, Chloroflexi abundance grew from 7.0% to 10.0%. Chloroflexi usually appeared in the anaerobic digestion process of sewage and the process of nitrogen and phosphorus removal, which can degrade carbohydrates into organic acids (Björnsson., 2002). The presence of acid-producing bacteria was unquestionably favorable to the synthesis of SCFAs.On the other hand, Proteobacteria was the main consumer of SCFAs during anaerobic digestion (Luo., 2015), accounting for 24.9% of all microorganisms in the blank group, while its proportion in the co-pretreatment group was reduced to 17.6% after anaerobic digestion. The main causes of the rise in acid production at the phylum level are an increase in the abundance of hydrolyzing and acid-producing bacteria and a decline in acid consumers.

Fig.5 Comparison of microbial communities on phylum (a) and genus (b) levels under pretreatment group and without pretreatment group.

The microbial community changes during anaerobic digestion of sludge were further assessed at the genus level, as depicted in Fig.5b. Bacteroidetes_vadinHA17, Bacteroides, Prevotella, and Lentimicrobium, belonging to the Bacteroidota phylum, all increased their proportion in the anaerobic digestion system. The enrichment of the genuswas obvious, and its abundance was 1.75% and 0.19% in the with-pretreatment and without-pretreatment groups, respectively. Bacteroidetes_va- dinHA17 is a genus that can enhance the activity of enzymes involved in the production of lactic acid and propionic acid and its abundance increases from 1.59% in the without-pretreatment group to 1.96% in the pretreatment group, which corresponds well with the law of increase in sludge hydrolysis efficiency and the microbial change on the phylum level mentioned above (Wang., 2021). Microorganisms of the Chloroflexi are reported to be better tolerant to extreme environments (Sun., 2014). The low-temperature pretreatment was not as harsh as the high-temperature, which caused a minor but not significant increase in the abundance of two microbial genera belonging to the Chloroflexi: Anaerolinea and RBG-13-54-9. The increase in their abundance contributes to both the phosphorus removal process and the acid production process of sludge. It has been shown that Proteobacteria are mainly involved in the degradation of acetate, propionate, and butyrate during anaerobic digestion (Wong., 2013). The trends were not identical for the different genera of microorganisms in the Proteobacteria phylum, with three of the five genera showing a decrease in abundance while only two groups showed an increase, and the overall abundance was 3.53% in the without-pretreatment system and 3.33% in the pretreatment system. This suggests that pretreatment may have played a suppressive role on the microorganisms consuming SCFAs, which is consistent with the conclusion of microbial changes at the phylum level.

4 Implication

Existing studies have demonstrated that the utilization of PF for sludge cracking and anaerobic digestion to generate SCFAs is an economically significant and environmentally friendly strategy (Tong and Chen, 2007). However, several studies have shown that high PF dosages, such as 0.9gg−1VSS, 0.5gg−1VSS and 0.4gg−1TSS, are required to achieve better sludge lysis and anaerobic digestion (Liu., 2017; Li., 2018a, 2018b), which is not conducive to cost management in wastewater treatment plants. Research has been conducted to improve anaerobic digestion and reduce treatment costs by combining PF with alkaline conditions or some chemicals such as free nitrite (He., 2018; Wang., 2020). In this research, we investigated the optimal combined pretreatment conditions by PF in combination with low-tem- perature thermal hydrolysis,.., adding 0.25gg−1TSS of PF to the sludge and treating it at 75℃ for 12h. The SCOD of the sludge under this condition reached 13516.9 mgL−1and achieved a favorable organic matter leaching rate. Subsequent anaerobic digestion experiments indicated that the sludge treated by the combination of PF and low-temperature thermal hydrolysis exhibited higher production efficiency of SCFAs. The pretreatment temperature in this experiment was more moderate than in the traditional high temperature, and the dosage of PF was significantly reduced, which lowered energy waste and chemical consumption as well as decreased the requirement for experimental apparatus and equipment. Moreover, the anaerobic digestion experiments in this study were conducted at 25℃, which can save more energy compared with the traditional 35℃. In summary, the treatment of sludge by PF and low-temperature thermal hydrolysis pretreatment methods contributes to the improvement of anaerobic digestion efficiency as well as product improvement, which may be economically feasible. In the future, the treatment method should be further optimized to improve the digestion efficiency, such as changing the sequence of PF addition and low-tempera- ture thermal hydrolysis treatment, and changing the inoculation method to improve the utilization of organic matter. This experiment was conducted on a laboratory scale without further pilot scale up, and further pilot experiments should follow to investigate its more precise economic benefits.

5 Conclusions

The feasibility of PF and low-temperature thermal hydrolysis co-pretreatment to improve sludge hydrolysis as well as to increase the yield of SCFAs was assessed in this work. The optimal experimental setup for co-pre- treatment consisted of a 75℃ temperature, a 12h pretreatment period, and a PF dosage of 0.25gg−1TSS. The degree of hydrolysis of the co-pretreated sludge was significantly greater, and the organic matter leaching rate was higher, indicating that the co-pretreatment caused damage to the sludge floc. The removal rate of SCOD and TP was successfully enhanced through co-pretreatment and anaerobic digestion, which facilitated the final disposal of the sludge. The output of SCFAs was improved due to the growth of acid-producing bacteria and the reduction of methanogenic bacteria. The findings obtained herein are helpful for recovering materials from WAS and alleviating environmental concerns.

Acknowledgements

This research was supported by the National Natural Science Foundation of China (No. 41276067), and the Air Liquide (China) R & D Co., Ltd. (No. 20200216).

APHA, 2005. Standard methods for the examination of water and waste water. American Public Health Association, Wash- ington D. C., USA.

Appels, L., Degreve, J., Bruggen, B. V., Impe, J. V., and Dewil, R., 2010. Influence of low temperature thermal pre-treatment on sludge solubilisation, heavy metal release and anaerobic digestion., 101 (15): 5743-5748.

Björnsson, L., Hugenholtz, P., Tyson, G. W., and Blackall, L. L., 2002. Filamentous Chloroflexi (green non-sulfur bacteria) are abundant in wastewater treatment processes with biological nutrient removal., 148 (8): 2309-2318.

Bougrier, C., Delgenes, J. P., and Carrere, H., 2007. Impacts of thermal pre-treatments on the semi-continuous anaerobic digestion of waste activated sludge., 34 (1): 20-27.

Carrere, H., Bougrier, C., Castets, D., and Delgenes, J. P., 2008. Impact of initial biodegradability on sludge anaerobic digestion enhancement by thermal pretreatment., 43 (13): 1551-1555.

Choi, J. M., Han, S. K., and Lee, C. Y., 2018. Enhancement of methane production in anaerobic digestion of sewage sludge by thermal hydrolysis pretreatment., 259: 207-213.

Fang, W., Zhang, X. D., Spanjers, H., and Zhang, T., 2021. Enhancing volatile fatty acid production during anaerobic fermentation of waste activated sludge with persulfates: Peroxy- monosulfateperoxydisulfate., 9 (30): 10073-10082.

Guo, B., Hu, J. W., Zhang, J. S., Wu, Z. G., and Li, Z., 2021. Enhanced methane production from waste activated sludge by potassium ferrate combined with ultrasound pretreatment., 341: 125841.

He, H. Y., Liu, Y. L., Wang, X. S., Huang, Z. S., Xu, C. B., Yang, T.,., 2018. Effects of newly prepared alkaline ferrate on sludge disintegration and methane production: Reaction me- chanism and model simulation., 343: 520-529.

He, Z. W., 2018. Study on influence factors and mechanisms of short chain fatty acids production and phosphorus release during waste activated sludge anaerobic fermentation process. PhD thesis. Harbin Institute of Technology.

He, Z. W., Tang, C. C., Liu, W. Z., Ren, Y. X., Guo, Z. C., Zhou, A. J.,., 2019. Enhanced short-chain fatty acids production from waste activated sludge with alkaline followed by potassium ferrate treatment., 289: 121642.

Huang, W. L., Cai, W., Huang, H., Lei, Z. F., Zhang, Z. Y., Tay, J. H.,., 2015. Identification of inorganic and organic species of phosphorus and its bio-availability in nitrifying aerobic granular sludge., 68: 423-431.

Kor-Bicakci, G., and Eskicioglu, C., 2019. Recent developments on thermal municipal sludge pretreatment technologies for enhanced anaerobic digestion., 110: 423-443.

Li, L., He, J. G., Wang, M. F., Xin, X. D., Xu, J., and Zhang, J., 2018a. Efficient volatile fatty acids production from waste activated sludge after ferrate pretreatment with alkaline environment and the responding microbial community shift., 6 (12): 16819-16827.

Li, L., He, J. G., Xin, X. D., Wang, M. F., Xu, J., and Zhang, J., 2018b. Enhanced bioproduction of short-chain fatty acids from waste activated sludge by potassium ferrate pretreatment., 332: 456-463.

Liu, H., Han, P., Liu, H. B., Zhou, G. J., Fu, B., and Zheng, Z. Y., 2018a. Full-scale production of VFAs from sewage sludge by anaerobic alkaline fermentation to improve biological nutrients removal in domestic wastewater., 260: 105-114.

Liu, T. J., Wu, C. S., Wang, Y. L., Xue, G. Y., Zhang, M. L., Liu, C. Q.,., 2021. Enhanced deep utilization of low-organic content sludge by processing time-extended low-temperature thermal pretreatment., 6 (43): 28946-28954.

Liu, Y. L., Kang, X. R., Li, X., Wang, Z., and Jing, Z. Q., 2017. Performance and mechanism of sludge dewaterability enhanced by potassium ferrate pretreatment and calcium chloride addition., 7 (2): 136-141.

Liu, Y., Zhao, J. W., Li, X. M., Wang, D. B., Yang, Q., and Zeng, G. M., 2018b. Synergistic effect of free nitrite acid integrated with biosurfactant alkyl polyglucose on sludge anaerobic fermentation., 78: 310-317.

Lowry, O. H., Rosebrough, N. J., Farr, A. L., and Randall, R. J., 1951. Protein measurement with the Folin phenol reagent., 193 (1): 265-275.

Lu, J. Q., Gavala, H. N., Skiadas, I. V., Mladenovska, Z., and Ahring, B. K., 2008. Improving anaerobic sewage sludge digestion by implementation of a hyper-thermophilic prehydrolysis step., 88 (4): 881-889.

Luo, J. Y., Feng, L. Y., Chen, Y. G., Sun, H., Shen, Q. T., Li, X.,., 2015. Alkyl polyglucose enhancing propionic acid enriched short-chain fatty acids production during anaerobic treatment of waste activated sludge and mechanisms., 73: 332-341.

Nguyen, V. K., Chaudhary, D. K., Dahal, R. H., Trinh, N. H., Kim, J., Chang, S. W.,., 2021. Review on pretreatment techniques to improve anaerobic digestion of sewage sludge., 285: 119105.

Pilli, S., Yan, S., Tyagi, R. D., and Surampalli, R. Y., 2015. Thermal pretreatment of sewage sludge to enhance anaerobic digestion: A review., 45 (6): 669-702.

Randall, A. A., and Liu, Y. H., 2002. Polyhydroxyalkanoates form potentially a key aspect of aerobic phosphorus uptake in enhanced biological phosphorus removal., 36 (14): 3473-3478.

Rittmann, B. E., Mayer, B., Westerhoff, P., and Edwards, M., 2011. Capturing the lost phosphorus., 84 (6): 846-853.

Sun, R., Xing, D. F., Jia, J. N., Zhou, A. J., Zhang, L., and Ren, N. Q., 2014. Methane production and microbial community structure for alkaline pretreated waste activated sludge., 169: 496-501.

Tong, J., and Chen, Y. G., 2007. Enhanced biological phosphorus removal driven by short-chain fatty acids produced from waste activated sludge alkaline fermentation., 41 (20): 7126-7130.

Wang, J. S., Zhang, Z. J., Ye, X., Pan, X. F., Lv, N., Fang, H. D.,., 2020. Enhanced solubilization and biochemical methane potential of waste activated sludge by combined free nitrous acid and potassium ferrate pretreatment., 297: 122376.

Wang, R. M., Li, C. X., Lv, N., Pan, X. F., Cai, G. J., Ning, J.,., 2021. Deeper insights into effect of activated carbon and nano-zero-valent iron addition on acidogenesis and whole anaerobic digestion., 324: 124671.

Weiland, P., 2010. Biogas production: Current state and perspectives., 85 (4): 849-860.

Wong, M. T., Zhang, D., Li, J., Hui, R. K. H., Tun, H. M., Brar, M. S.,., 2013. Towards a metagenomic understanding on enhanced biomethane production from waste activated sludge after pH 10 pretreatment., 6 (1): 1- 14.

Wu, C., Jin, L. Y., Zhang, P. Y., and Zhang, G. M., 2015. Effects of potassium ferrate oxidation on sludge disintegration, dewaterability and anaerobic biodegradation., 102: 137-142.

Wu, Q. L., Zheng, H. S., Chen, Y., Liu, M., Bao, X., and Guo, W. Q., 2021. Alkylethoxyglucoside-enhanced volatile fatty acids production from waste activated sludge: Performance and mechanisms., 289: 125765.

Xiao, B. Y., Tang, X. Y., Yi, H., Dong, L. X., Han, Y. P., and Liu, J. X., 2020. Comparison of two advanced anaerobic digestions of sewage sludge with high-temperature thermal pretreatment and low-temperature thermal-alkaline pretreatment., 304: 122979.

Xu, Q. X., Fu, Q. Z., Liu, X. R., Wang, D. B., Wu, Y. X., Li, Y. F.,., 2021. Mechanisms of potassium permanganate pretreatment improving anaerobic fermentation performance of waste activated sludge., 406: 126797.

Yang, G., Zhang, G. M., and Wang, H. C., 2015. Current state of sludge production, management, treatment and disposal in China., 78: 60-73.

Yin, Y. N., and Wang, J. L., 2016. Changes in microbial community during biohydrogen production using gamma irradiated sludge as inoculum., 200: 217- 222.

Zhang, L. H., Liu, H., Zheng, Z. Y., Ma, H. J., Yang, M., and Liu, H. B., 2018. Continuous liquid fermentation of pretreated waste activated sludge for high rate volatile fatty acids production and online nutrients recovery., 249: 962-968.

Zhang, L. H., Xu, C. B., Champagne, P., and Mabee, W., 2014. Overview of current biological and thermo-chemical treatment technologies for sustainable sludge management., 32 (7): 586-600.

Zhao, J. W., Wang, D. B., Liu, Y. W., Ngo, H. H., Guo, W. S., Yang, Q.,., 2018. Novel stepwise pH control strategy to improve short chain fatty acid production from sludge anaerobic fermentation., 249: 431-438.

Zhao, P. H., Liu, Y. L., Dou, C. C., and Wan, P. L., 2020. Study on dissolution characteristics of excess sludge by low-tem- perature thermal hydrolysis and acid production by fermentation., 5 (40): 26101-26109.

Zhao, P. H., Liu, Y. L., Dou, C. C., Zhu, N. P., Wan, P. L., and Wang, X. L., 2021. Study on the characteristics of dissolution and acid production in waste activated sludge: Focusing on the pretreatment of thermal-alkali with rhamnolipid., 327: 124796.

Zou, H. M., and Wang, Y., 2016. Phosphorus removal and recovery from domestic wastewater in a novel process of enhanced biological phosphorus removal coupled with crystallization., 211: 87-92.

(August 11, 2022;

November 7, 2022;

December 23, 2022)

© Ocean University of China, Science Press and Springer-Verlag GmbH Germany 2023

. E-mail: fenglj@ouc.edu.cn

(Edited by Ji Dechun)

杂志排行

Journal of Ocean University of China的其它文章

- Effects of 5-Azacytidine (AZA) on the Growth, Antioxidant Activities and Germination of Pellicle Cystsof Scrippsiella acuminata (Diophyceae)

- Improving Yolo5 for Real-Time Detection of Small Targets in Side Scan Sonar Images

- Wave Radiation by a Floating Body in Water of Finite Depth Using an Exact DtN Boundary Condition

- Underwater Acoustic Signal Noise Reduction Based on a Fully Convolutional Encoder-Decoder Neural Network

- Revisiting the Seasonal Evolution of the Indian Ocean Dipole from the Perspective of Process-Based Decomposition

- Assessment of Storm Surge and Flood Inundation in Chittagong City of Bangladesh Based on ADCIRC and GIS