钛催渗低温离子渗氮对304不锈钢组织性能的影响

2023-11-06李润涛孙斐汪丹丹魏坤霞杨卫民胡静

李润涛,孙斐,汪丹丹,魏坤霞,杨卫民,胡静,2*

钛催渗低温离子渗氮对304不锈钢组织性能的影响

李润涛1a,b,孙斐1a,3,汪丹丹1a,b,魏坤霞1a,2,杨卫民1a,c,胡静1a,b,2*

(1.常州大学 a.江苏省材料表面科学与技术重点实验室 b.材料科学与工程国家级实验教学示范中心,江苏 常州 213164;2.常州大学 怀德学院,江苏 靖江 214500;3.常州工业职业技术学院 现代装备制造学院,江苏 常州 213164)

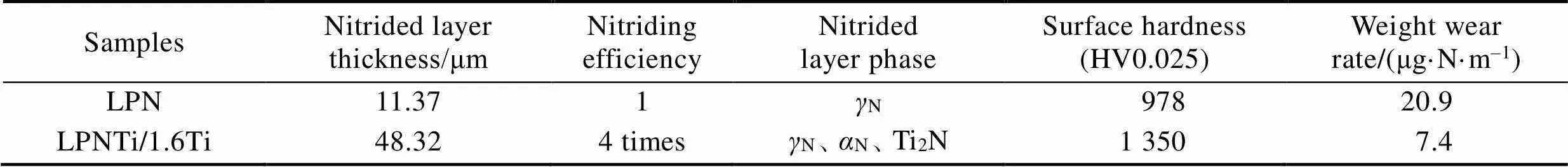

在保障304奥氏体不锈钢良好耐蚀性前提下,研发显著改善表层硬度及耐磨性的低温高效离子渗氮技术。低温离子渗氮时,在试样周围均匀放置微量海绵钛,研发304奥氏体不锈钢创新钛催渗低温离子渗氮技术。采用光学显微镜、扫描电子显微镜、能谱分析仪、X射线粉末衍射仪、显微维氏硬度计、摩擦磨损测试仪,以及电化学工作站等设备分别对试样截面显微组织、物相及成分、截面显微硬度、渗层耐磨性能、耐蚀性能等渗层组织性能进行测试与分析。304奥氏体不锈钢在420 ℃/4 h钛催渗离子渗氮处理后,不仅保持了良好耐蚀性,且渗层耐蚀性比常规低温离子渗氮略有提升,同时,表面硬度与耐磨性大幅提高,表面硬度由常规离子渗氮的978HV0.025提升至1350HV0.025。磨损率由20.9 μg/(N·m)降低至7.4 μg/(N·m),下降了约2/3。特别有价值的是,钛催渗低温离子渗氮效率比传统离子渗氮显著提升,渗氮层厚度由常规离子渗氮的11.37 μm增厚到48.32 μm,即渗氮效率提高到常规离子渗氮的4倍以上。本研究研发的钛催渗低温离子渗氮技术在保障304奥氏体不锈钢优良耐蚀性的同时,能够大幅度提升不锈钢表面硬度及耐磨性能,且具有显著的催渗效果。

钛催渗;离子渗氮;304奥氏体不锈钢;耐蚀性;硬度;耐磨性

奥氏体不锈钢因具有优异的耐蚀性能与良好的塑性及韧性,在深海、化工、医疗、食品等工业领域有广泛的应用[1-2]。但奥氏体不锈钢由于表面硬度低、耐磨性差的原因,导致无法满足同时兼顾耐蚀性与耐磨性的服役要求,使用范围受到很大限制[3-4]。因此必须对其表面改性才可能同时满足耐蚀性与耐磨性的综合要求。

目前,工业上对奥氏体不锈钢表面改性技术主要有气体渗氮、盐浴氮碳复合渗(QPQ)、氮碳共渗等,其中离子渗氮技术具有清洁高效、工件变形量小的优势,已逐步取得了一定效果。根据已有的研究发现,离子渗氮(PN)在温度高于450 ℃时会导致奥氏体不锈钢中析出铬氮化物,使基体耐蚀性下降[5-6];而低温离子渗氮(LPN)在450 ℃以下,虽然可形成高耐磨性、高耐蚀性氮膨胀奥氏体相(N相或相),从而避免铬氮化物析出[7-10],但低温离子渗氮存在的不足是:渗氮效率极低,获得需求厚度的N相渗层需要几十 h甚至更长的渗氮时间。基于此,探索一种既能保障不锈钢的高耐蚀性、高耐磨性要求,又具有高效率的表面改性技术具有重要的研究价值。

基于Ti为强氮化物形成元素,离子渗氮过程中可优先与N结合形成氮化物,抑制铬氮化物的形成,从而保障不锈钢的耐蚀性。同时,钛氮化物TiN/Ti2N具有极高的硬度,能够显著改善不锈钢表面耐磨性[11-15]。同时,Ti作为促进相(铁素体)的形成元素,有利于促进离子渗氮过程中形成N相,基于N相比N相具有更好的强化效果,从而达到进一步提高渗层硬度的效果[16-17]。为此,本研究首次探索在离子渗氮时添加微量Ti,从而实现奥氏体不锈钢钛催渗低温离子渗氮(LPNTi),旨在保障304奥氏体不锈钢耐蚀性前提下,研发低温高效高耐磨性创新表面改性技术。

1 实验材料与方法

选用固溶态304奥氏体不锈钢为实验材料,其化学成分如表1所示。将工件加工成尺寸为10 mm× 10 mm×5 mm的试样,使用240 目~2 000目的SiC砂纸依次进行打磨,再将试样放于无水乙醇中,使用超声波清洗10 min,取出后吹干待用。

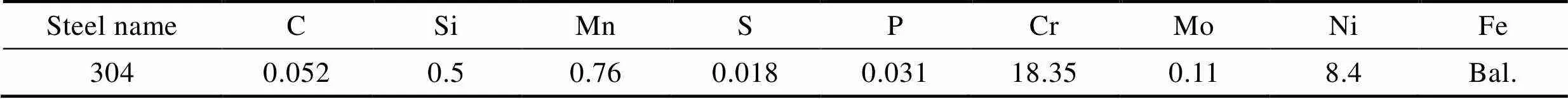

表1 304奥氏体不锈钢化学成分(质量分数,%)

Tab.1 Chemical composition of 304 austenitic stainless steel (mass fraction, %)

将304奥氏体不锈钢试样放入离子渗氮炉中,每炉放置5个相同尺寸试样,并在试样周围均匀摆放形状尺寸及质量基本相同的海绵钛(纯度为99.1%~ 99.7%)颗粒进行钛催渗离子渗氮,海绵钛添加量为每个试样周围摆放0.8 g~2.0 g。在渗氮之前先通入氢气进行溅射30 min,之后通入氮气与氢气(N2∶H2=1∶3)进行钛催渗离子渗氮,设定炉压为420 Pa,温度为420 ℃,达到指定温度后保温4 h。实验结束后,待炉内温度冷却至室温,取出试样进行组织与性能分析。

使用光学显微镜观察不同工艺条件下的试样截面显微组织并分析渗层厚度变化。使用X射线衍射仪(XRD)测试物相组成。使用扫描电子显微镜(SEM)观察最佳添加量条件下的试样表面形貌并进行EDS能谱分析。使用维氏显微硬度计测量表面显微硬度,载荷与保荷时间分别为:25 g、15 s,每个试样测量5次确定平均硬度值及误差带。使用摩擦磨损试验机测量耐磨性,对磨材料为直径约为5 mm的GCr15钢球,加载载荷为2.5 N,对磨时间为15 min,总滑动距离为40 m,重复3次试验,以平均摩擦系数值作为最终摩擦系数值。使用精度为0.1 mg的电子分析天平在磨损试验前后称量试样重量,计算质量磨损率,为进一步对比磨损率,使用景深数字显微镜观察最佳添加量条件下的试样磨痕表面形貌,记录磨痕最大深度、宽度及面积数据,综合分析渗层的耐磨性能。使用电化学工作站测试耐蚀性,腐蚀液为浓度为3.5%的NaCl溶液,参比电极为标准饱和甘汞电极,辅助电极为铂电极,实验温度为室温,动电位扫描速率为2 mV/s。

以上数据均使用Origin软件作图,通过对比,分析钛催渗离子渗氮对304奥氏体不锈钢组织及性能的影响。

2 实验结果与讨论

2.1 截面金相组织及渗氮层厚度分析

依据离子渗氮国家标准GB/T 11354-2005[18],离子渗氮工艺设计的原则是在不改变基体组织的前提下,在零部件表层形成高性能渗氮层。观察离子渗氮试样截面金相组织最主要目的是为了测试渗氮层厚度,渗氮层厚度即为沿截面金相组织垂直方向测量从试样表面至与基体组织有明显分界处的距离。同时,通过对比相同渗氮时间条件下形成的渗氮层厚度可以判断渗氮效率,即相同渗氮时间形成的渗氮层越厚,渗氮效率越高。图1为低温常规离子渗氮和钛催渗离子渗氮试样的截面金相组织。由图1可知,在420 ℃/4 h工艺条件下所有试样表层都形成了渗氮层。同时,对比常规离子渗氮和钛催渗离子渗氮试样截面金相组织可看出,钛催渗离子渗氮处理的渗氮层厚度明显厚于常规离子渗氮,且随钛含量增加而不断增加。当钛添加量达到1.6 g时,渗氮层厚度达到极大值48.32 μm,是常规离子渗氮的4倍以上。再进一步增加钛添加量到2.0 g时,渗层厚度不再提升,反而略有减薄。由此可得出结论:钛催渗离子渗氮工艺效率明显高于常规离子渗氮,且工艺效率与钛添加量密切相关,在钛添加量为1.6 g时,工艺效率最高,达到常规离子渗氮工艺效率的4倍以上。

图1 低温常规离子渗氮和钛催渗离子渗氮(420 ℃/4 h)试样截面金相组织

2.2 渗层物相分析

图2为低温常规离子渗氮和钛催渗离子渗氮试样X射线衍射谱。由图2可知,304奥氏体不锈钢基体主要由相与微量相组成。经低温离子渗氮处理后,相衍射峰强度减小,并形成了N衍射峰,同时相衍射峰消失,说明表层形成了一定量过饱和含氮奥氏体,即N或相。经钛催渗低温离子渗氮处理后,相衍射峰强度随钛含量增加而逐渐减小,在钛添加量为1.6 g以上时完全消失,同时,N衍射峰强度增加,并形成一定量N,由此说明微量钛不仅加速N相形成,还有助于促进相向相转变,从而形成过饱和含氮铁素体型固溶体,即N相。N相类似于马氏体,具有比N更高的硬度[19-20]。同时,钛催渗离子渗氮处理后,还新增了Ti2N相,Ti2N是一种硬度高、摩擦系数低的化合物。Ti2N与N的共同强化作用,将显著提升钛催渗离子渗氮渗层硬度,该推测与图4显示的表面硬度结果吻合。

图2 低温常规离子渗氮和钛催渗离子渗氮(420 ℃/4 h)试样XRD图谱

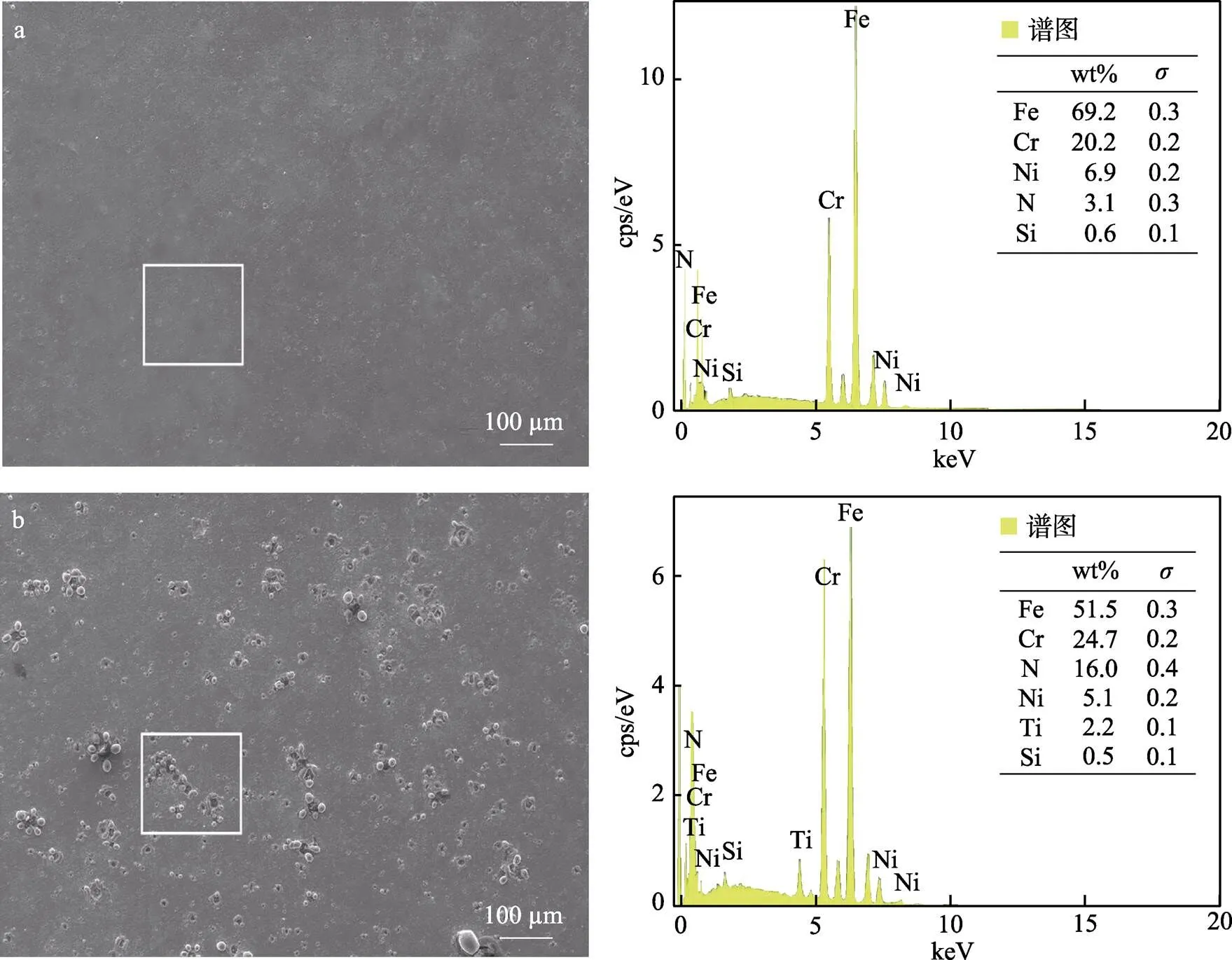

2.3 表面形貌及微区成分分析

图3为低温常规离子渗氮和钛催渗离子渗氮试样表面形貌及微区能谱分析。通过表面形貌对比可知,钛催渗离子渗氮处理后,表面新增了大量弥散分布的颗粒,同时通过对比所选微区的EDS分析可发现,钛催渗离子渗氮处理试样表面含有2.2 % Ti元素,且N含量显著提升到16%,由此说明表面新增的钛能大幅促进活性N在表面吸附,提升试样表面N浓度,从而显著提升渗氮效率,该分析与图1显示的渗氮层厚度显著提升结果吻合。

图3 低温钛催渗离子渗氮(420 ℃/4 h)试样表面SEM形貌(500x)及扫描区域能谱分析图

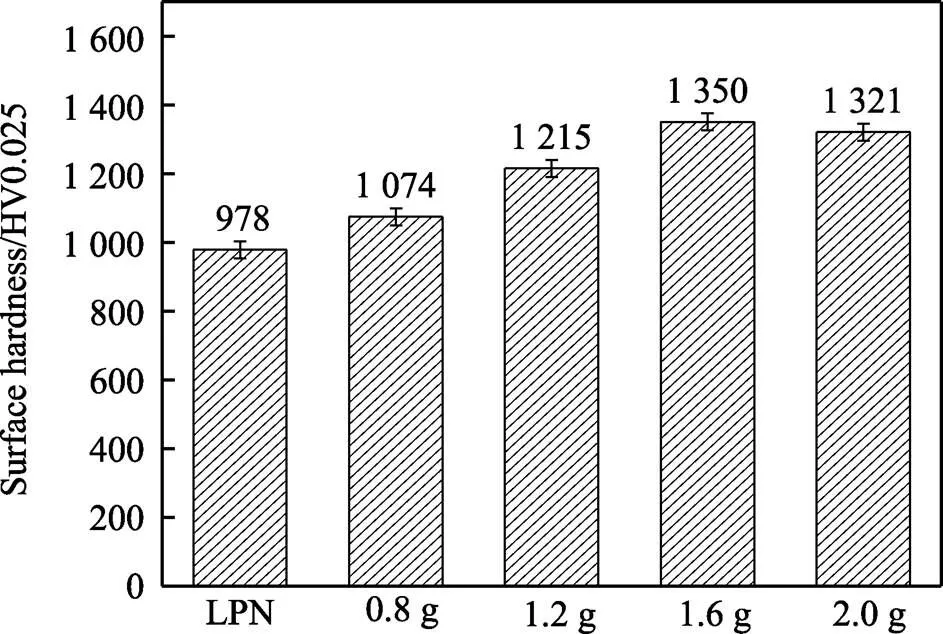

2.4 表面硬度分析

图4为低温常规离子渗氮和钛催渗离子渗氮试样表面硬度。由图4可知,钛催渗离子渗氮处理的表面硬度随钛含量增加而不断提高,当钛添加量达到1.6 g时,表面硬度由978HV0.025提高到极大值的1 350HV0.025,比常规离子渗氮提升了372HV0.025。再进一步增加钛添加量到2.0 g时,表面硬度不再提高,反而略有下降。结合图1可得出结论:钛催渗离子渗氮不仅工艺效率显著提高、且表面硬度显著提升。基于XRD(如图2所示)及能谱(如图3所示)分析结果,可以推断钛催渗离子渗氮处理表面硬度显著提升的主要原因是渗氮层形成了大量弥散分布的高硬Ti2N相及少量高硬度N相。

图4 低温常规离子渗氮和钛催渗离子渗氮(420 ℃/4 h)试样表面硬度

2.5 耐磨性分析

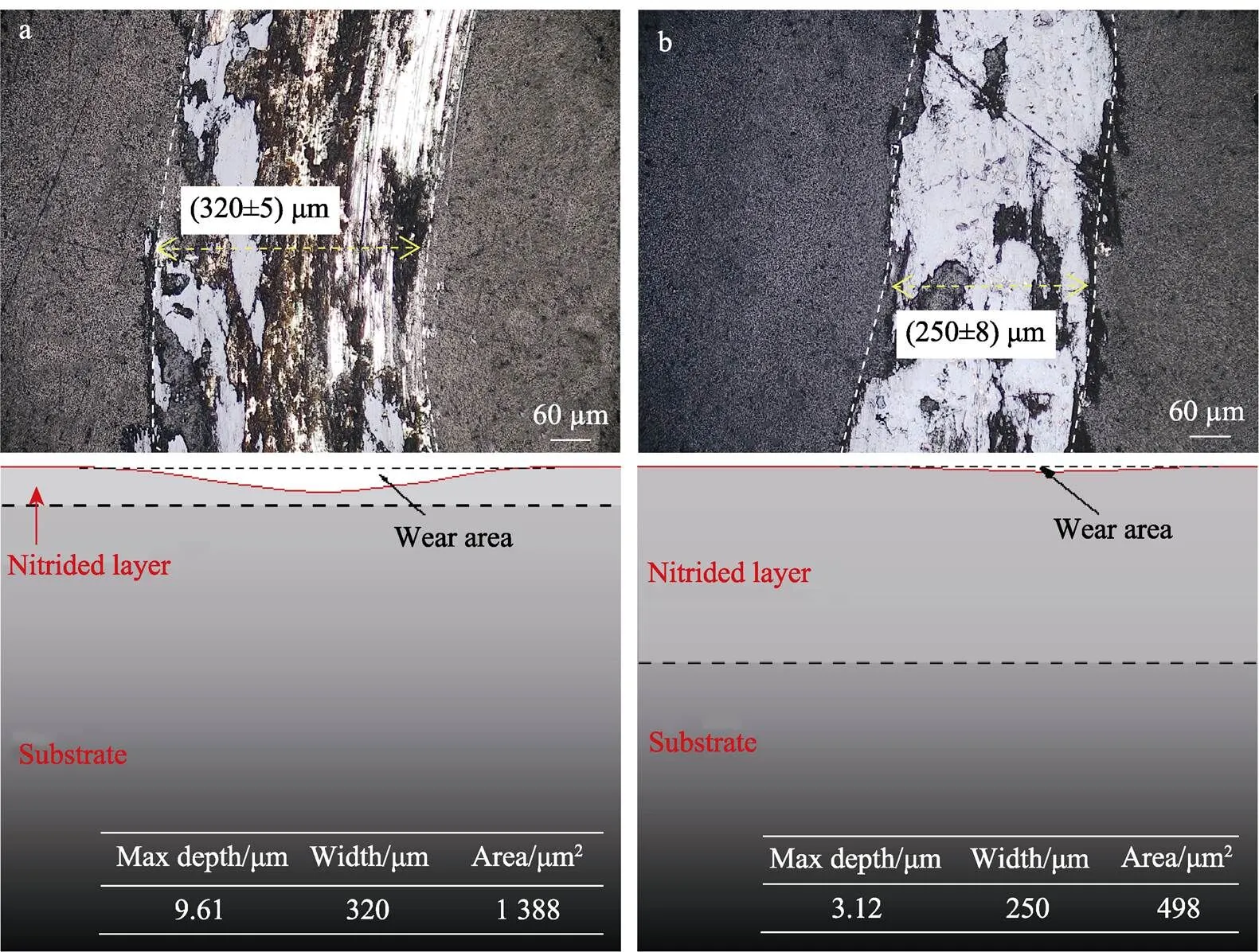

图5为低温常规离子渗氮和钛催渗离子渗氮试样摩擦系数曲线。由图5可知,常规低温离子渗氮摩擦因数约为0.96,摩擦因数随着Ti添加量的增加而逐渐减小,在添加量达到1.6 g时,试样摩擦因数最低,约为0.42。图6为低温常规离子渗氮和钛催渗离子渗氮试样磨痕形貌及磨损截面扫描图。对比可知,钛催渗离子渗氮试样的最大深度、磨痕宽度和磨损面积都显著小于常规离子渗氮试样,钛催渗离子渗氮磨痕的最大深度、宽度和磨损面积分别为3.12 μm、250 μm、498 μm2;常规离子渗氮则分别为9.61 μm、320 μm、1 388 μm2。

图5 低温常规离子渗氮和钛催渗离子渗氮(420 ℃/4 h)试样摩擦系数对比

图6 低温离子渗氮和钛催渗离子渗氮(420 ℃/4 h)试样磨痕形貌、截面磨痕及磨痕尺度对比

同时,磨损试验前后采用天平测量了试样质量,磨损率的计算,见式(1)。

δ = (0)/×(1)

式中:为磨损率;0为试样磨损前质量;为磨损后质量;为摩擦副重量;为摩擦副移动距离。

通过上述计算,得出常规低温离子渗氮磨损率为20.9 μg/(N·m),钛催渗低温离子渗氮试样磨损率显著降低到7.4 μg/(N·m)。结合图5与图6的结果,可以获得结论:与常规离子渗氮相比,钛催渗离子渗氮处理可以显著提高304不锈钢的耐磨性。

2.6 耐蚀性分析

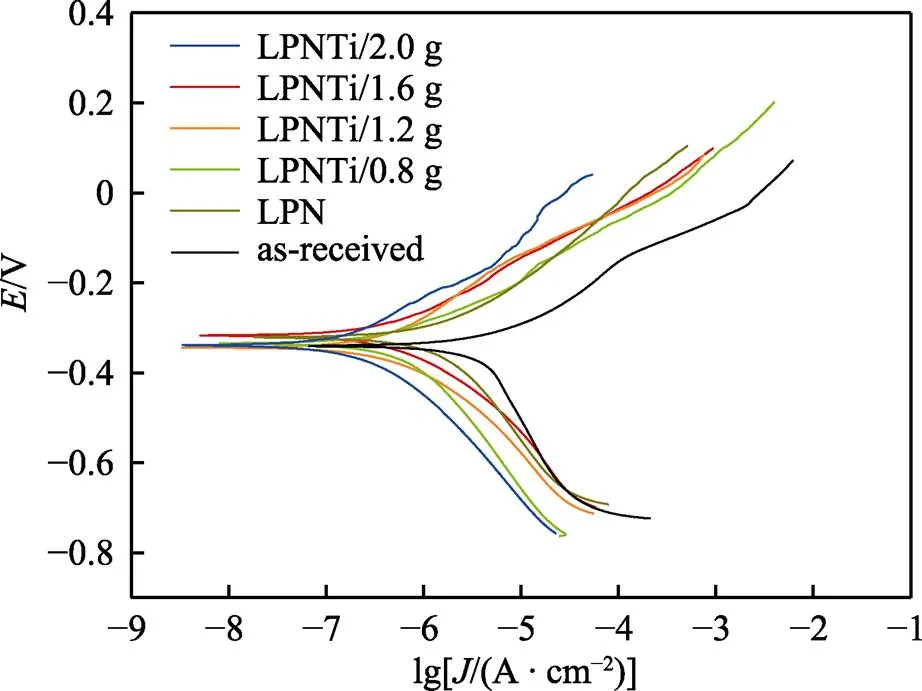

图7为低温常规离子渗氮和钛催渗离子渗氮试样极化曲线,表2为不同工艺条件下的极化曲线拟合的电化学参数。结合表2和图7可知,常规低温离子渗氮试样腐蚀电位比基体略有提升,即耐蚀性略有改善。而钛催渗离子渗氮试样与常规低温离子渗氮相比,耐蚀性进一步改善,当添加量达到1.6 g时,耐蚀性最佳,腐蚀电位由–320.77 mV增加至–316.68 mV,腐蚀电流密度由0.404 μA/cm2降低至0.133 μA/cm2,腐蚀速率由6.73 μm/a降低至3.68 μm/a。

以上结果表明,低温高效钛催渗离子渗氮不仅没有降低304奥氏体不锈钢耐蚀性,反而使其耐蚀性略有改善,其可能原因是:钛催渗离子渗氮后,氮化层更厚,且耐蚀性极佳的N相含量增加。

图7 低温常规离子渗氮和钛催渗离子渗氮(420 ℃/4 h)试样极化曲线

表2 图7极化曲线拟合的电化学参数

3 机理分析讨论

钛催渗低温离子渗氮与常规离子渗氮综合效果对比见表3。由表3可知,在420 ℃/4 h工艺条件下,当Ti添加量为1.6 g时,渗氮层厚度较常规低温离子渗氮提升了4倍以上,即工艺效率提高4倍以上。同时,在保障耐蚀性的前提下,显著提升了试样表面硬度和耐磨性。

基于轰击溅射理论,在钛催渗离子渗氮过程中,海绵钛被轰击出Ti+,从而增强了高能离子对试样表面的轰击溅射作用,使表层产生更多缺陷(空位、位错及亚晶界等)[21],为氮原子的扩散提供更有利的条件;另一方面,Ti作为一种强氮化物元素,与N的亲和力很强[22],活性Ti原子周围吸附聚集大量活性N原子,使表面N浓度大幅提高,浓度梯度的提升有利于加速其向内部扩散。因此,Ti对离子渗氮具有显著催渗作用,达到显著提升渗氮层厚度的效果。

同时,相较于常规离子渗氮,钛催渗离子渗氮试样表面硬度与耐磨性大幅提升,原因是由于活性Ti原子与活性N原子易结合形成高硬度氮钛化合物,从而大幅提升表面硬度及耐磨性[23-25];此外,Ti为促进相(铁素体)形成元素,从而促进过饱和固溶体N形成,基于过饱和固溶体N比N强化效果更好,有利于进一步提高表层硬度[26]。因此,低温钛催渗离子渗氮能大幅提升表面硬度与耐磨性是多种强化相因素共同作用的结果。

表3 钛催渗低温离子渗氮与常规离子渗氮综合效果对比

Tab.3 Comparison of the comprehensive effects of conventional plasma nitriding and low temperature plasma Ti-nitriding

4 结论

在420 ℃/4 h工艺条件下,对304奥氏体不锈钢进行钛催渗低温离子渗氮处理,与常规低温离子渗氮对比,得出如下结论。

1)钛催渗低温离子渗氮处理时,渗氮层厚度随Ti添加量的增加而增加,当Ti添加量达到1.6 g时,钛催渗低温离子渗氮催渗效果最为显著,渗氮层厚度由常规低温离子渗氮处理的11.37 μm增加到48.32 μm,即渗氮层工艺效率提升4倍以上。

2)钛催渗低温离子渗氮渗层主要由S相和αN及表面弥散分布的Ti2N组成,与常规低温离子渗氮相比,新增了Ti2N和αN。

3)钛催渗低温离子渗氮处理后,表面硬度随Ti添加量增加而提升,当Ti添加量达到1.6 g时,由常规低温离子渗氮的978HV0.025提升至1 350HV0.025。

4)钛催渗低温离子渗氮后,相较于常规不锈钢低温离子渗氮,耐蚀性进一步改善。

5)钛催渗低温离子渗氮试样耐磨性随Ti添加量增加而提高,当Ti添加量达到1.6 g时,耐磨性能最佳,磨痕变窄变浅、磨痕面积减少。摩擦因数由常规低温离子渗氮的0.96降低至0.42。磨损率由20.9 μg/(N·m)降低至7.4 μg/(N·m),下降约2/3。

[1] UNAL O, MALEKI E, VAROL R. Comprehensive Analysis of Pulsed Plasma Nitriding Preconditions on the Fatigue Behavior of AISI 304 Austenitic Stainless Steel[J]. International Journal of Minerals Metallurgy and Materials, 2021, 28(4): 657-664.

[2] LI Y XU H Z, ZHU F, et al. Low Temperature Anodic Nitriding of AISI304 Austenitic Stainless Steel[J]. Materials Letters, 2014, 128: 231-234.

[3] LU Y Y, WU J Q, WEI K X, et al. Dynamic Equilibrium of the Surface Oxide Film During Plasma Oxynitrocarburising and Its effect on Performances[J]. Journal of Materials Research and Technology, 2022, 20: 2271-2276.

[4] 孙斐, 胡佳佳, 王树凯, 等. 气压对304奥氏体不锈钢低温离子渗氮组织与性能影响[J]. 材料热处理学报, 2014, 35(S2): 221-225.SUN Fei, HU Jia-jia, WANG Shu-kai, et al. Effect of Gas Pressure in Low Temperature Plasma Nitriding on the Microstructure and Properties for 304 Austenitic Stainless Steel[J]. Transactions of Materials and Heat Treatment, 2014, 35(S2): 221-225.

[5] BORGIOLI F, GALVANETTO E, BACCI T. Low Temperature Nitriding of AISI300 and 200 Series Austenitic Stainless Steels[J]. Vacuum, 2016, 127: 51-60.

[6] 吴梦泽, 李烈军, 彭继华. 氢氮比对奥氏体不锈钢低温离子渗氮性能的影响[J]. 材料热处理学报, 2018, 39(9): 105-112.WU Meng-ze, LI Lie-jun, PENG Ji-hua. Effect of Hydrogen to Nitrogen Ratio on Low Temperatureion Nitriding of Austenitic Stainless Steel[J]. Transactions of Materials and Heat Treatment, 2018, 39(9): 105-112.

[7] 王引真, 冯雅, 孙永兴, 等. 表面纳米化与离子渗氮对304不锈钢的影响[J]. 材料科学与工艺, 2019, 27(1): 59-64. WANG Yin-zheng, FENG Ya, SUN Yong-xing, et, al. Effect of Surface Nanocrystallization and Plasma Nitriding Parameters on 304 Stainless Steel[J]. Materials Science and Technology, 2019, 27(1): 59-64.

[8] LI D, WU J Q, MIAO B, et al. Enhancement of Wear Resistance by Sand Blasting-assisted Rapid Plasma Nitriding for 304 Austenitic Stainless Steel[J]. Surface Engineering, 2020, 36, 5: 524-530

[9] WANG L. Surface Modification of AISI304 Austenitic Stainless Steel by Plasma Nitriding[J]. Applied Surface Science, 2003, 211: 308-314.

[10] DONG H. S-phase Surface Engineering of Fe-Cr, Co-Cr and Ni-Cr alloys[J]. International Materials Reviews, 2010, 55(2): 65-98.

[11] WANG S K, CAI W, LI J C, et al. A Novel Rapid D.C. Plasma Nitriding at Low Gas Pressure for 304 Austenitic Stainless Steel[J]. Materials Letters, 2013, 105: 47-49.

[12] 张乘玮, 付天琳, 陈涵悦, 等. 钛合金缝隙腐蚀、离子渗氮与表面纳米化的研究进展[J]. 表面技术, 2019, 48(11): 114-123.ZHANG Cheng-wei, FU Tian-lin, CHEN Han-yue, et al. Research Progress on Crevice Corrosion, Plasma Nitriding and Surface Nanocrystallization of Titanium Alloys[J]. Surface Technology, 2019, 48(11): 114-123.

[13] 钟厉, 王帅峰, 门昕皓, 等. 38CrMoAl钢钛催渗等离子氮化工艺研究[J]. 表面技术, 2021, 50(12): 159-166.ZHONG Li, WANG Shuai-feng, MEN Xin-hao, et al. Research on Plasma Nitriding Process of 38CrMoAl Steel with Ti Catalyst[J]. Surface Technology, 2021, 50(12): 159-166.

[14] 麻恒, 赵晓兵, 魏坤霞, 等. 42CrMo4钢硼氮离子复合渗与离子渗氮对比研究[J]. 表面技术, 2022, 51(4): 121-126. MA Heng, ZHAO Xiao-bing, WEI Kun-xia, et al. Comparative Study of Plasma Boron-nitriding and Plasma Nitriding for 42CrMo4 Steel. Surface Technology, 2022, 51(4): 121-126.

[15] 毛长军, 魏坤霞, 刘细良, 等. 微量钛对离子渗氮渗层特性及性能的影响[J]. 中国表面工程, 2020, 33(1): 34- 38. MAO Chang-jun, WEI Kun-xia, LIU Xi-liang, et al. Effects of Trace Titanium on Characteristics and Properties of Plasma Nitriding Layer[J]. China Surface Engineering, 2020, 33(1): 34-38.

[16] LI G J, WANG J, LI C, et al. Microstructure and Dry- sliding Wear Properties of DC Plasma Nitrided 17-4 PH Stainless Steel[J]. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms, 2008, 266(8): 1964-1970.

[17] 李小英, 田林海, 窦文博, 等.经济型双相不锈钢的离子氮化及其组织结构和腐蚀磨损性能[J]. 中国表面工程, 2015, 28(3): 1-9. LI Xiao-ying, TIAN Lin-hai, DOU Wen-bo, et al. Microstructure and Corrosion Wear Resistance of Plasma Nitrided LDX2101 Lean Duplex Stainless Steel[J]. China Surface Engineering, 2015, 28(3): 1-9.

[18] GB/T 11354-2005, 钢铁零件渗氮层深度测定和金相组织检验[S]. GB/T 11354-2005, Determination of Nitrided Case Depth and Metallographic Microstructure Examination for Steel and Iron Parts[S].

[19] SHEN L, WANG L, WANG Y, et al. Plasma Nitriding of AISI304 Austenitic Stainless Steel with Pre-shot Peening[J]. Surface and Coatings Technology, 2010, 204(20): 3222- 3227.

[20] AMUTH S, SASIDHAR K N, MEKA S R. High Nitrogen Alloying of AISI316L Stainless Steel Powder by Nitriding[J]. Powder Technology, 2021, 390(693): 456-463.

[21] LI R T, WEI K X, ZHAO X B, et al. Excellent Behavior of Coatings on 304 Stainless Steel by Efficient Low Temperature Plasma Titanium-nitriding[J]. Materials Letters, 2022, 324: 132795.

[22] KHIDIROV I. Revision of the Ti-N Phase Diagram as Probed by Neutron Diffraction[J]. Russian Journal of Inorganic Chemistry, 2011, 56(2): 298-303.

[23] LIU L, SHEN H H, LIU X Z, et al. Wear Resistance of TiN(Ti2N)/Ti Composite Layer Formed on C17200 Alloy by Plasma Surface Ti-alloying and Nitriding[J]. Applied Surface Science, 2016, 388: 1-6.

[24] PERUMAL P, RAMANATHAN K, GANESAN L, et al. Investigation of TiN Coating Uniformity and Its Corrosion Behaviour Using Image Process[J]. Materials Research Express, 2019, 6(4): 1-21.

[25] BATORY D, SZYMANSKI W, PANJAN M, et al. Plasma Nitriding of Ti6Al4V Alloy for Improved Water Erosion Resistance[J]. Wear, 2017, 374: 120-127.

[26] WANG X G, YAN M F, LIU R L, et, al. Effect of Rare Earth Addition on Microstructure and Corrosion Behavior of Plasma Nitrocarburized M50NiL Steel[J]. Journal of Rare Earths, 2016, 34(11): 1148-1155.

Effect of Low Temperature Plasma Nitriding with Ti Catalyst on the Microstructure and Properties of 304 Stainless Steel

1a,b,1a,31a,b,1a,2,1a,c,1a,b,2*

(1. a. Jiangsu Key Laboratory of Materials Surface Science and Technology, b. National Experimental Demonstration Center for Materials Science and Engineering, Changzhou University, Jiangsu Changzhou 213164, China; 2. Huaide College, Changzhou University, Jiangsu Jingjiang 214500, China; 3. Institute of Modern Equipment Manufacturing, Changzhou Institute of Industry Technology, Jiangsu Changzhou 213164, China)

304 austenitic stainless steel has excellent corrosion resistance, but its poor hardness and wear resistance make it hard to meet the requirements in some applications, and thus surface modification is required to promote its practical applications. Plasma nitriding (PN) is a widely used surface modification technology, while higher temperature plasma nitriding results in a decrease of the corrosion resistance and lower temperature plasma nitriding (LPN) brings about quite low efficiency. In order to overcome the problems in the traditional plasma nitriding, low temperature plasma nitriding with Ti catalyst is primarily proposed in this study, and the research aims to effectively enhance the hardness and wear resistance without reduction of corrosion resistance and with high efficiency. To reach this research goal, low temperature plasma nitriding with Ti catalyst (LPNTi) was conducted at 420 ℃ for 4 h by putting some amount of sponge titanium around the samples during plasma nitriding, and the effect of plasma nitriding with Ti catalyst on the microstructure and properties of 304 austenitic stainless steel was systematically investigated by optical microscope, SEM, EDS, X-ray diffractometer (XRD), microhardness tester, friction and wear tester, electrochemical workstation, etc. The results indicated that excellent corrosion resistance of 304 austenitic stainless steel was kept and even turned to be better after plasma nitriding with Ti catalyst compared with that under traditional plasma nitriding, with the corrosion potential increasing from –320.77 mV to –316.68 mV. SEM, XRD and EDS analysis showed that LPNTi layer was mainly composed of S phase, αNand a little Ti2N with high hardness, which meant that Ti was helpful for the phase transformation of γ to α, and αNwas formed due to this phase transformation. The surface hardness could be significantly enhanced from 978HV0.025 by plasma nitriding to 1350HV0.025 by plasma nitriding with Ti catalyst due to the double strengthening effect from αNand Ti2N, which was more than 6 times of 208HV of the matrix. Meanwhile, the wear resistance was dramatically enhanced, the friction coefficient decreased from 0.96 to 0.42, the weight wear rate decreased from 20.9 μg/(N·m) to 7.4 μg/(N·m), decreasing by about 2/3, and the wear marks became much narrower and shallower and the wear area was reduced greatly. More importantly, the nitriding efficiency was remarkably improved as well, with the thickness of nitrided layer increasing from 11.37 um by PN to 48.32 um by LPNTi under the same nitriding condition of 420 ℃/4 h, more than 4 times thicker than that by PN. In all, the excellent corrosion resistance of 304 austenitic stainless steel can be held and even becomes better after low temperature plasma nitriding with Ti catalyst (LPNTi) treatment. The surface hardness and wear resistance can be dramatically enhanced due to the formation of S phase strengthened by αNand a little Ti2N. More importantly, the treatment efficiency of plasma can be remarkably improved, which is more than 4 times of that by plasma nitriding.

Ti catalyst; plasma nitriding; 304 austenitic stainless steel; corrosion resistance; hardness; wear resistance

2022-08-03;

2023-02-16

TG178

A

1001-3660(2023)10-0422-08

10.16490/j.cnki.issn.1001-3660.2023.10.038

2022-08-03;

2023-02-16

国家自然科学基金(21978025, 51774052);江苏省第三期优势学科建设项目(PAPD-3);江苏高校品牌专业建设工程资助项目(TAPP);材料表面科学与技术重点实验室开放课题;江苏省研究生创新基金项目(CX10292)

The "National Natural Science Foundation of China (21978025; 51774052); Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD-3); Top-notch Academic Program Projects of Jiangsu Higher Education Institutions (TAPP); Open Project of Jiangsu Key Laboratory of Materials Surface Science and Technology and Postgraduate Research & Practice Innovation Program of Jiangsu Province(CX10292)

李润涛, 孙斐, 汪丹丹, 等. 钛催渗低温离子渗氮对304不锈钢组织性能的影响[J]. 表面技术, 2023, 52(10): 422-429.

LI Run-tao, SUN Fei, WANG Dan-dan, et al. Effect of Low Temperature Plasma Nitriding with Ti Catalyst on the Microstructure and Properties of 304 Stainless Steel[J]. Surface Technology, 2023, 52(10): 422-429.

通信作者(Corresponding author)

责任编辑:蓝英侨