Optimization of thermoelectric properties in elemental tellurium via high pressure

2023-11-02DongyaoZhao赵东尧ManmanYang杨曼曼HairuiSun孙海瑞XinChen陈欣YongshengZhang张永胜andXiaobingLiu刘晓兵

Dongyao Zhao(赵东尧), Manman Yang(杨曼曼), Hairui Sun(孙海瑞),Xin Chen(陈欣), Yongsheng Zhang(张永胜), and Xiaobing Liu(刘晓兵),§

1Laboratory of High-Pressure Physics and Materials Science(HPPMS),School of Physics and Physical Engineering,Qufu Normal University,Qufu 273165,China

2Advanced Research Institute of Multidisciplinary Sciences,Qufu Normal University,Qufu 273165,China

Keywords: high pressure,thermoelectric,thermal conductivity,power factor

With the advent of the electronic information age, it has become the strategic focus of sustainable development to build a new energy system,develop green and recyclable renewable resources and improve energy conversion efficiency.[1,2]Thermoelectric materials with the most potential candidate for environmental energy are mainly determined by the dimensionless coefficientzT=S2T/ρ(κe+κph+κbip),whereSis Seebeck coefficient,ρis resistivity,Tis Kelvin temperature,κe,κph, andκbipare electron, phonon, and bipolar thermal conductivities, respectively.[3-5]However, due to the strong coupling between carriers and phonons, it is a great challenge to optimize the related parameters together.Over the past few decades, classical, high-performance, multicomponent compounds such as Bi2Te3and SnSe have produced encouraging results.[6-10]However, the diversity of elements leading to the segregation and complex structure increases the difficulty to get clear about the mechanism of the improvement.Hence, many research have been focused on single-element semiconductors.[11,12]

Elemental semiconductor thermoelectric materials, such as black phosphorus (BP) and tellurium (Te), provide a better basis for interpreting the relationship between the internal physical parameters of the material due to the unicity of the elements.Theoretical predictions demonstrate that BP and its derivatives show great potential for novel ecofriendly thermoelectric applications because of the unique inplane anisotropic electronic structure.[10,13-19]Element Te, a narrow band gap semiconductor, has been considered as a potential candidate for thermoelectric materials because of its high degeneracy, large effective mass and high Seebeck coefficient.[20]Many attempts have been made to further improve the efficiency of thermoelectric conversion.[21,22]Linet al.realized doping by hot pressing, and finally optimize the carrier concentration to 2.65×1019cm-3, thus improving the electrical properties of Te.[23]Anet al.used the spark plasma sintering(SPS)method combined with the intrinsic quasi-onedimensional(1D)structure of the sample,which contributed to form the chain texture along the crystallographicc-axial direction,to optimize the carrier and phonon scattering to a certain extent.[24]Suet al.effectively replaced the alloying of samples by using the high pressure and high temperature(HPHT)method, and the phonon thermal conductivity of the material decreased from 0.65 W·m-1·K-1to 0.45 W·m-1·K-1,which optimized the phonon transport and ultimately improved the thermoelectric performance.[25]Therefore,it is not hard to see that an effective synthesis method is vital to obtain high quality thermoelectrics.Among them, HPHT technology is playing an important role in synthesizing specimens because of the advantages,such as time-saving,high efficiency,manufacturing defects and controllable reaction conditions.[25-29]In our previous work, we constructed a BP-Te heterogeneous structure to optimize the thermoelectric performance of Te through HPHT method.[16]Hence, it is essential to investigate the effect of pressure on Te.

In this work,we successfully synthesized Te samples with doping BP under different pressures to explore the impact of pressure on electrical and thermal properties.Our results demonstrate thatzTvlues of Te-based materials are greatly improved under high pressure.The maximumzTvalue(zTmax)and the averagezTvalue(zTave)of Te+0.25 wt%GeP5samples synthesized at 5.5 GPa are significantly enhanced by 55%(68%) compared to 3.0 GPa.Moreover, with the content of GeP5increasing,the performance is further optimized.Thus,high pressure is proved to be an effective means for seeking high performance thermoelectrics.

Using high purity germanium (Ge, 99.999%) and phosphorus(P,99.999%)ingot as raw material,single crystal GeP5was prepared by HPHT method.The high purity Te ingot(99.999%) and GeP5were weighed by mass ratio.The raw materials were then packaged in a mortar and ground for an hour.Then the target polycrystalline samples were prepared at 1000 K and 3.0 GPa-5.5 GPa for 30 minutes through HPHT method.

The crystal structures of powder samples had been characterized by Cu-Kαradiation x-ray diffraction(XRD)(PANalytical X’pert3, Holland).Raman spectroscopy (HR Evolution, JY Horiba) was carried on a spectrometer with excitation wavelength of 633 nm.The surface morphology and element distribution of the samples were tested by scanning electron microscope (SEM, Carl Zeiss Sigma 500 VP).TEM images were obtained on a Thermo Fisher Talos F200S G2(United States).The carrier-dependent parameters were measured at room temperature on the Hall device (Lake Shore 8404, USA) using van der Pauw geometry.Resistivity (ρ)and Seebeck coefficient(S)were measured simultaneously in CTA-3s (Cryoall China).Thermal conductivity (κ) is calculated byκ=D×Cp×dwhereDis the thermal diffusion coefficient measured on a laser heat-conducting instrument (Netzsch LFA457,Germany).The heat capacity(Cp)values were estimated by Dulong-Petit law.The density (d) was determined by Archimedean principle.

Figure 1(a)shows powder x-ray diffraction(XRD)data of Te and GeP5-composited Te samples synthesized under different pressures.The collected XRD patterns can be well characterized as hexagonal structure ofP3121 group.[30]As shown in the figure,no other second phase was observed.Figure 1(b)shows the typical Raman spectra of all sample prepared under various pressures.It can be observed that the peaks located at 91 cm-1,119 cm-1,138 cm-1are correspond to the three characteristic peaks of elemental Te phase, representing the three vibration modes E1,A1,and E2,respectively.[31]Meanwhile, three obvious characteristic peaks at 358 cm-1,434 cm-1,and 462 cm-1,can be attributed to BP phase,representing A1g, B2g, and A2gvibration modes, respectively.[32]The results show that GeP5decomposed into BP and Ge via HPHT conditions.

Fig.1.Phase characterization of produced GeP5-composited Te samples under different synthetic pressures:(a)XRD patterns and(b)Raman spectrum.

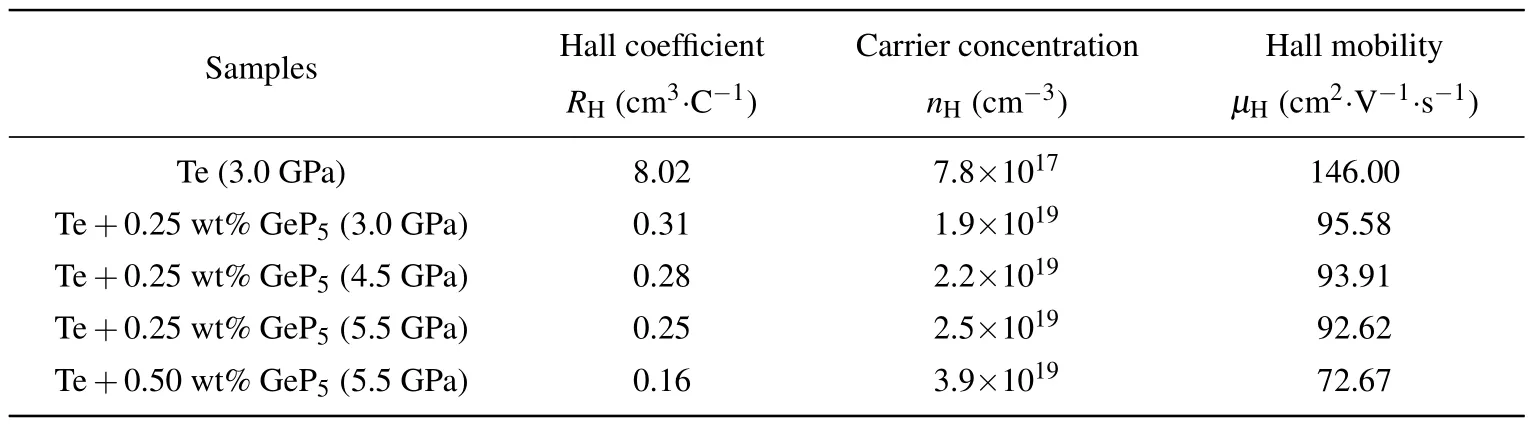

Hall effect test of the prepared samples was carried out at room temperature,listed in Table 1.The positive Hall coefficient reveal that all samples are p-type semiconductor.It can be seen that the introduction of GeP5significantly increased the carrier concentration(nH)of Te.The decomposed Ge has two less electron than Te,and when it replaces Te as an acceptor impurity,it can introduce holes,meaning that the electrons in the valence band are transferred to the acceptor level,which leads to a significant increase in hole concentration.More importantly, with the synthetic pressure increasing, we find that thenHare improved up to 2.5×1019cm-3, which is two orders of magnitude higher than the pure Te sample, while the fluctuation of mobility (µH) is in a small range.The result leads to substantial optimization of electrical properties.

Table 1.The Hall effect test for the samples synthesized under different pressures.

Fig.2.Temperature-dependent electronic transport properties of Te, GeP5-composited Te samples synthesized under different pressures.(a)Resistivity.(b)Seebeck coefficient.(c)Relationship between the carrier concentration and Seebeck coefficient.(d)Power factor(PF).

The electrical transport performance depending on temperature was measured in the range of 300 K-610 K.Figure 2(a) shows the lower resistivity of the GeP5-composited Te samples.In addition, as plotted in Fig.2(b),GeP5-introduced samples exhibit higher Seebeck coefficient comparing with pristine Te when the test temperature is above 450 K.Both the parameters are optimized in higher temperature range, and the values increase continuously with the temperature increasing.When the temperature exceeds 550 K, theSgradually decreases due to the appearance of intrinsic excitation, resulting in an increase in minority carriers,[33]which restrains theSof the sample.Comparing with pure Te, the introduction of GeP5makes the bipolar effect move to high temperature region.Figure 2(c) shows the relationship betweenSandnHbased on the single parabolic band model.We can find that the carrier effective mass (m∗,black line) of pure Te is smaller than the GeP5-composited Te samples, which can partly eliminate the reduction ofSby the increasing ofnH.Combined with the changes in theρandS,we noted that the PF values of the sample were significantly enhanced with the synthetic pressure rising,reaching a maximum value of 10.18 µW·cm-1·K-2at 490 K of Te+0.50 wt% GeP5sample synthesized at 5.5 GPa, as shown in Fig.2(d).Higher fabricating pressure improves the decomposition efficiency of GeP5, thus leading to the increase ofnH, ultimately optimizing the electrical transport property.

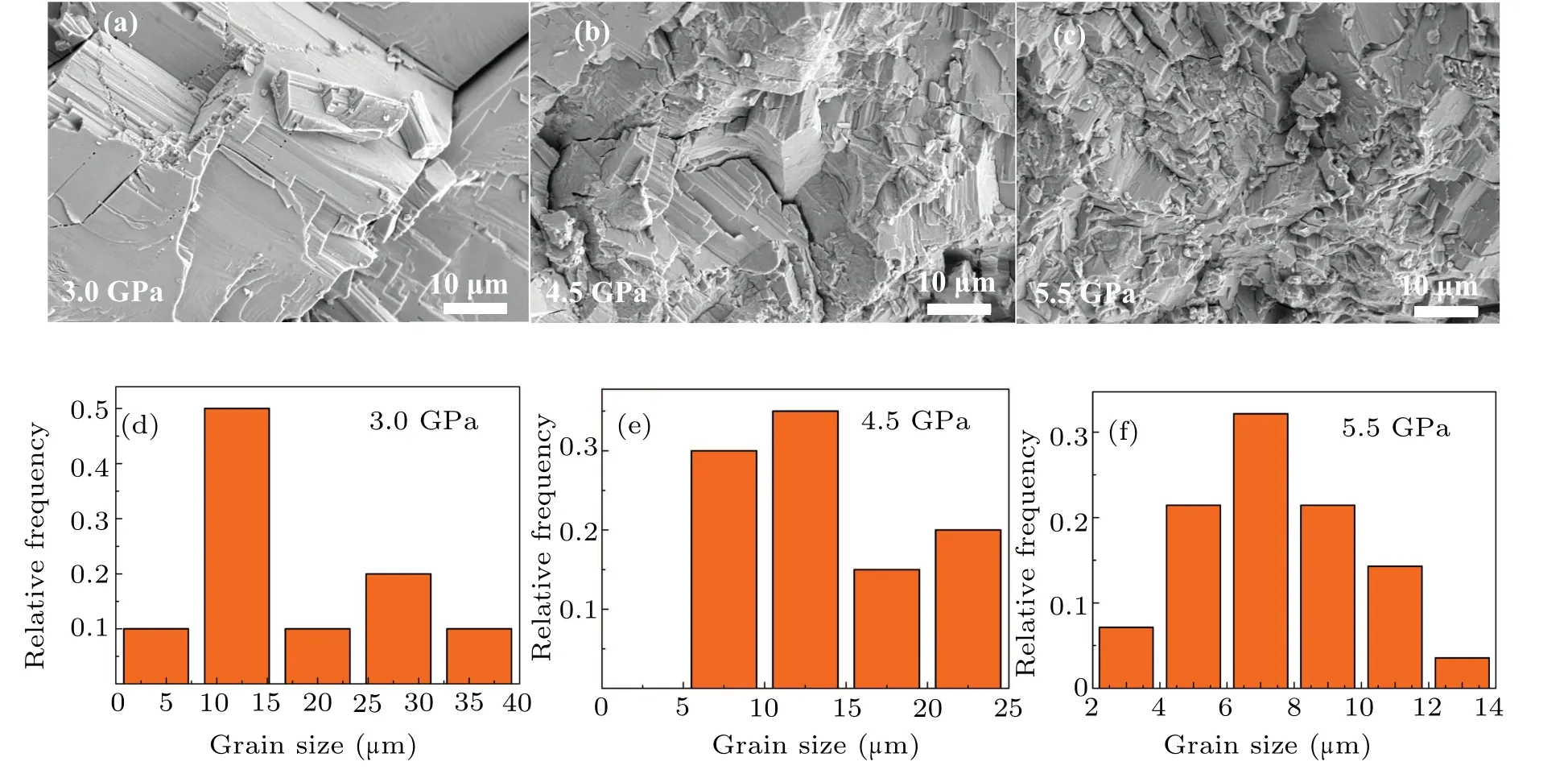

Figures 3(a)-3(c) is the scanning electron microscope(SEM)images of the GeP5-composited Te sample synthesized at 3.0 GPa, 4.5 GPa, and 5.5 GPa, respectively.The images show that with the increase of synthetic pressure, the grain boundaries become more abundant (as shown in Figs.3(d)-3(e)), indicating that high pressure has an inhibitory effect on grain growth.The affluent boundaries in the sample can enhance the phonons scattering, and then reduce the phonon conductivity.[34]

Figures 4(a)-4(e) show the SEM images and the corresponding energy dispersive spectrometer (EDS) mapping of the sample synthesized at 5.5 GPa.It can be clearly observed that the BP embedded in the matrix,indicating that GeP5have decomposed into Ge and P,and the elemental P has been converted into BP phase basing on the Raman results in Fig.1(b),randomly distributing around the grain boundaries.In addition, the element Ge uniformly disperses in the basis materials,which has positive influence on the diminution of thermal conductivity.

Fig.3.(a)-(c)SEM images for the produced GeP5-composited Te samples synthesized under different pressures,(d)-(f)grain size distribution corresponding to panels(a)-(c).

Fig.4.(a)SEM image of Te+0.5 wt%GeP5,(b)-(e)the corresponding EDS elemental mappings.

The detailed microstructure of Te+0.50 wt% GeP5synthesized at 5.5 GPa was characterized by high-resolution transmission electron microscopy (HRTEM) and inverse fast Fourier transform (IFFT) as shown in Fig.5.We can observe the clear lattice fringes of the sample, and then select the yellow and red regions for IFFT in Fig.5(a).As shown in Figs.5(b)and 5(c),the Te can be observed in the sample,evidenced by the gauged interplanar distances of 0.323 nm,corresponding to the(101)planes.Meanwhile,(041)planes of BP is also observed,proved by the measured interplanar distances is 0.223 nm.It indicates that BP acts as the second phase in Te matrix, which is benefit for enhancing the scattering of intermediate frequency phonon.Moreover,the lattice deformation and dislocation can also be found in the domains within our samples, which can effectively disperse the transportation of phonons, reducing the lattice thermal conductivity, thus optimizing the thermoelectric properties.

Fig.5.Microstructure of produced GeP5-composited Te sample:(a)HRTEM image,and(b),(c)the IFFT images.

Figure 6(a)shows the temperature dependence of the total thermal conductivity(κ)in the range of 300 K-610 K.Theκof all samples prepared under high pressure markedly decreases comparing with the pristine Te.With the increase of temperature,theκgradually decreases in the range of 300 K-550 K, and then shows an upward trend due to the emergence of intrinsic excitation.The minimum thermal conductivity is achieved 0.61 W·m-1·K-1at 550 K for the sample of Te+0.25 wt%GeP5synthesized at 4.5 GPa.We further calculated the phonon and bipolar thermal conductivity according to Wiedemann-Franz law:κph+bip=κ-κe,(κe=LσT,Lis the Lorenz number, which is estimated by the equationL=1.5+exp(-|S|/116),[35,36]as shown in Fig.6(b), about 36%decrease for the sample synthesized at high pressure.The reduction ofκph+bipcan be attributed to the combining effect of the existence of BP,lattice defects,and more grain boundary density introduced by high pressure.

Benefitting from the superiority of high pressure and the introduction of BP, the figure of merit,zT, of GeP5-composited Te sample is significantly improved, as shown in Fig.7(a) and Fig.S1(f).ThezTmaxof Te+0.50 wt% GeP5sample synthesized at 5.5 GPa is obtained of 0.76 at 524 K,which is~11 times that of the pure Te.In Fig.7(b),thezTavepresents a progressive increase with the synthetic pressures rising.The peak and averagezTvalues of Te+0.25 wt%GeP5at the temperatures range of 300 K-610 K are increased by 55%and 68%compared with the sample synthesized at 3.0 GPa.

In short, we demonstrated that, under HPHT conditions,the dynamic regulation of carrier behavior and grain boundary density can achieve the double optimization of the electrical property and thermal transport for element Te.The results show that the peakzTof Te+0.25 wt%GeP5synthesized at 5.5 GPa reaches 0.65 at 524 K, which is 55% improvement compared with the lower preparation pressure.Importantly,this work clearly confirms the advantages of pressure that can dramatically modulating the thermoelectric transport properties, being an effective way for searching high performance thermoelectric materials.

Acknowledgements

Project supported by the National Natural Science Foundation of China (Grant Nos.11804185, 11974208,52172212, 52102335, and 52002217) and the Natural Science Foundation of Shandong Province, China(Grant Nos.ZR2020YQ05, ZR2019MA054, 2019KJJ020,ZR2021YQ03,and 2022KJA043).

猜你喜欢

杂志排行

Chinese Physics B的其它文章

- Single-qubit quantum classifier based on gradient-free optimization algorithm

- Mode dynamics of Bose-Einstein condensates in a single-well potential

- A quantum algorithm for Toeplitz matrix-vector multiplication

- Non-Gaussian approach: Withstanding loss and noise of multi-scattering underwater channel for continuous-variable quantum teleportation

- Trajectory equation of a lump before and after collision with other waves for generalized Hirota-Satsuma-Ito equation

- Detection of healthy and pathological heartbeat dynamics in ECG signals using multivariate recurrence networks with multiple scale factors