羰基铁粉作为微波吸收材料的研究进展

2023-05-13覃仁驰孟凡彬

覃仁驰,孟凡彬

羰基铁粉作为微波吸收材料的研究进展

覃仁驰,孟凡彬

(西南交通大学 材料科学与工程学院,成都 610031)

介电损耗低、吸收带宽较窄、密度高等缺点制约着羰基铁粉(Carbonyl Iron Powder,CIP)在吸波领域中的应用。在CIP材料的基础上,使用不同的改性方法,开发“轻、宽、强、薄”的CIP微波吸收材料,实现对微波的高效吸收。综述近年来羰基铁粉作为吸波材料的研究现状,介绍和分析不同改性方法,如形貌改性、涂覆改性、复合改性等对羰基铁复合材料吸波性能的影响。CIP作为微波吸收材料,可以通过不同改性方法来改善缺点,制备的复合材料更符合当下社会对吸波材料的需求,与传统CIP材料相比,CIP复合材料作为微波吸收剂,具有更大的潜力。

微波干扰;羰基铁粉;微波吸收材料;改性

近年来,随着隐身技术、通信技术和电子电气设备等技术的高速发展,人们对这些技术带来的微波干扰和污染也越来越重视。微波干扰会造成严重的电磁危害,它不仅能干扰仪器的正常运行,中断仪器的信号接收,甚至导致仪器损坏,同时也会严重危害人体健康,比如微波辐射可能破坏人体神经系统,或者导致癌症[1-5]。微波干扰是人类目前迫切需要解决的问题,因此开发新型高效吸收电磁辐射的材料显得格外重要。

微波吸收材料,不仅可以有效解决微波干扰和污染问题,而且在军事装备的隐身技术领域有着重要地位。高效的吸波材料能够帮助军事设备摆脱雷达的探测,以达到军事设备隐身的效果。在众多微波吸收材料中,羰基铁粉是比较具有代表性的。羰基铁粉(CIP)凭借其高磁导率、低成本[6]以及洋葱头层状结构,一直是吸波领域重点研究的材料。作为软磁材料,CIP吸波能力强和较小的磁滞损耗也是它作为吸波材料的优势。但是CIP的劣势也很明显,低介电损耗和狭窄的吸收带宽不能满足日益增长的吸波性能需求,同时作为软磁材料,还具有密度高和阻抗不匹配等固有缺点[7-9],不能达到现代吸波材料“超薄,轻质,带宽,强吸收”的要求[10],故单一的羰基铁材料并不能满足当代隐身技术和日常发展中的应用需求。因此,需要对羰基铁粉进行改性以提升它的吸波性能。本文对吸波机理,羰基铁粉的改性研究工作展开系统综述,并对该领域以后的研究工作进行展望。

1 吸波机理

当电磁波到达吸波材料表面后,一部分会被反射,一部分进行透射,还有一部分会被损耗机制吸收并转化为其他形式的能量[11]。电磁波在吸波材料上的反射分为表面反射和多次反射,其中,多次反射能增加电磁波在材料内部反射的次数,使电磁波与材料的分子和电子产生更多的相互作用[12],使电磁波尽可能转换为热能,进而被吸波材料吸收,以达到设备隐身和电磁波能量损失的效果。因此,通过改变吸波材料的形貌结构实现更高频率的多次反射,是提升材料吸波能力的有效办法。在设计吸波材料时,研究人员更希望电磁波通过多次反射从而被材料吸收,为了达到这个目的,设计的吸波材料都需要满足阻抗匹配和能量损耗2个特性。

阻抗匹配指电磁波传输到材料表面后,因吸波材料的阻抗和自由空间的阻抗相等,所以几乎不会有电磁波反射回源点,电磁波在材料内部进行多次反射,进而转换为其他形式的能量被材料吸收。若两者阻抗不一致,将会有部分电磁波在材料表面进行反射,从而使材料吸波效率下降。

能量损耗主要包括介电损耗和磁损耗,指吸收损失减少电磁波的能量[13],通过特定方法,可以测量出相应电磁参数以评估材料的吸收性能,即复磁导率(=−j)和复介电常数(=−j),其中和分别为磁场能量和电场能量的存储量,和分别为能量耗散能力[14-15]。当和增大时,吸波材料对电磁波的吸收随之增大。介电损耗正切和磁损耗正切表示材料的介电损耗和磁损耗能力的大小,分别由tan()=″/′和tan()=″/′表示[16-17]。

综上所述,研制吸波能力强的材料需要综合考虑材料的形貌、阻抗匹配和能量损耗特性,以实现更好的电磁波吸收。

2 羰基铁粉基微波吸收材料研究进展

2.1 羰基铁粉的制备

羰基铁粉是广泛运用于微波吸收中的一种材料,尺寸在微米级到纳米级之间,目前羰基铁粉的制备方法有2种:高压气相合成法和中压气相合成法。高压气相合成法是目前最为成熟的羰基铁粉的合成方法。首先将富含铁原料的球磨成粉状,再在氢气气氛下进行还原,然后在高温高压下与一氧化碳进行反应,得到五羰基铁液体,纯化去除其中的杂质后,再对纯五羰基铁进行热分解,得到球形铁核,碳吸附在球形铁核表面,逐渐生长为洋葱头层状结构的羰基铁。中压气相合成法是目前生产羰基铁粉的重点研究的方法,其成本更低、生产条件更简单、更易规模化生产。羰基铁粉粒径小且均匀、分散性好、活性高,能够应用在粉末冶金、医药、微波吸收等领域。

2.2 羰基铁粉的形貌优化

材料的微观结构对材料的性能影响很大。大多数研究中使用的羰基铁粉颗粒都为球形,但是其趋肤深度一般只有1~2 μm,仅只有羰基铁粉平均粒径的四分之一[18-19],粒径大于其趋肤深度,交变电磁场很难穿透表面到达材料内部,不利于材料对于微波的吸收。在Yin等[18]的研究中也提到,材料颗粒的各向异性会导致自然共振的增加,提升材料的复磁导率。因此,通过调节材料的微观结构,如粒径、形貌结构、长径比、各向异性等都会明显影响材料的吸波性能[18]。

在高频区域,吸波材料磁导率的实部会发生突然下滑的现象,虚部出现共振,这便是snoek极限。常见的羰基铁粉有球形和片状2种形态,但球形羰基铁粉的snoek极限过低,难以满足“超薄、轻质、带宽、强吸收”的要求[10],而具有各向异性的片状结构的羰基铁粉,能够具有更高的snoek极限,能够具备更高的磁导率和共振频率,能够在更高频区域进行微波吸收[20],表现出更优异的吸波能力。因此,片形羰基铁粉趋肤效应小,能够在更高频区域进行微波吸收,更满足当代对微波吸收材料的需求。

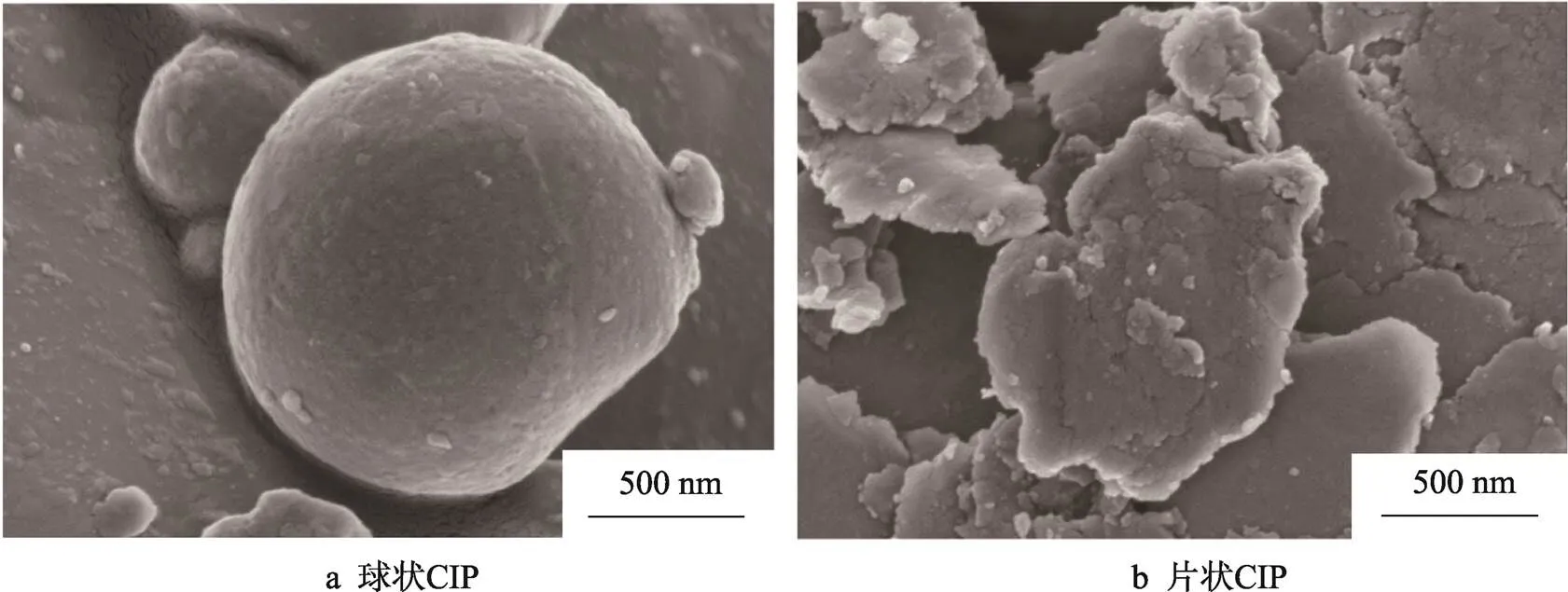

Yin等[21]通过简便的高能球磨法对球状羰基铁粉进行处理并检测。进行球磨后的羰基铁粉由球状结构转变为了片状结构,如图1所示。经研究发现,片状羰基铁粉的磁导率明显增加,这是因为片状的羰基铁粉具有外部平面各向异性,可以显著提高其吸波性能,并能够在更低频率区域表现出更好的吸波性能。

Wang等[22]通过对球形羰基铁粉的热处理和随后的湿磨,成功制得了片状羰基铁粉。热处理后的羰基铁粉初始粒径较大,能够提升随后湿磨中的晶粒取向度,从而形成长径比更大的片状羰基铁粉,提升材料的吸波能力,特别在低频区域,能够表现出更优秀的吸波性能。Wang等[23]研究得出,热处理会导致晶粒粒径增加,但应变减少,球磨反而导致粒径减小,但是会使应变增加。Wang等[23]通过对热处理温度和铣削时间的控制,成功在晶粒粒径和应变之间寻求到平衡,此方法不仅能够有效制备低频高性能吸波材料,也为诱导微粒颗粒的纹理提供了新的思路。

图1 不同结构的CIP的SEM形貌

2.3 羰基铁粉的涂层改性

一般而言,在材料基体表面上涂覆一层合适的材料能够改善其物化性能,如其抗氧化能力、热稳定性、磁性能等[24]。在此思路上,可通过对羰基铁粉进行涂层以提升其电磁波吸收能力,以及在特定环境下的稳定性和耐腐蚀性等。大多数涂层在羰基铁粉磁芯上会形成壳状结构[25],具有低密度、高比表面积、更大孔隙等优势。能够有效降低吸收密度、调节介电常数和提高阻抗匹配的效果[26],此结构能表现出较优异的吸波能力[27]。

涂层材料一般分为2种:金属涂层和电介质涂层。涂覆金属的复合材料能够表现出高性能的微波吸收,但是容易被氧化和腐蚀,涂覆电介质的复合材料表现出低密度和强介电损耗特性,还能够保护羰基铁粉磁芯免受污染和腐蚀[25]。

在众多涂层材料中,不得不提到的是二氧化硅,它凭借良好的隔离性、易于控制涂层工艺、保护性强、成本低等优点备受关注[28]。在Wang等[28]在对二氧化硅涂覆于羰基铁粉表面的研究工作中,他们成功合成了二氧化硅涂覆羰基铁粉的复合材料(CIP@SiO2),并用L–赖氨酸代替传统的NH3−H2O作为新的反应催化剂。L–赖氨酸是一种有效的催化剂,可以促进二氧化硅颗粒的形成、排列和均匀化[29-30]。如图2所示,涂覆了二氧化硅后,羰基铁粉表面上存在略微粗糙的壳,它们的形成是羰基铁粉表面张力存在的结果[31]。比较涂覆前后吸波能力可以发现,涂覆后羰基铁粉的吸波能力远强于涂覆前羰基铁粉的吸波能力,且有效吸收带宽也有明显提升,随着二氧化硅涂层厚度的提升,总体吸波能力趋势表现为先增强再减弱,涂覆层越厚,其在低频电磁波领域吸收能力加强。

图2 CIP和CIP@SiO2的SEM图和电磁吸收性能

Zhou等[32]对二氧化硅涂覆羰基铁粉的研究中表明,涂覆了二氧化硅后,可以使复合材料的复介电常数下降,能够达到合适的阻抗匹配。涂覆后的材料能够吸收较宽的带宽主要是因为二氧化硅改善了复合材料的阻抗匹配[24]。同时涂覆二氧化硅能够在一定程度上防止羰基铁粉氧化和被腐蚀,并能提升复合材料的耐高温性[33]。

除了二氧化硅,PVDF和氧化锌等介电材料也常被用作涂覆材料。Joseph等[34]研究表明,将PVDF涂覆在羰基铁粉上,能增强材料的介电和磁损耗机制,从而提升电磁波吸收能力[35]。Zhou等[36]研究了利用氧化锌涂覆羰基铁粉(CIP@ ZnO),指出氧化锌黏附羰基铁粉后,在其表面的极化电荷与界面极化效应形成了介电损耗。这些介电损耗与羰基铁粉的磁损耗构成了该复合材料的主要电磁损耗机制。

研究人员同时也对金属涂层进行了大量研究,以提升羰基铁粉的吸波性能。Chen等[37]通过化学镀的方法,将Co/C涂覆在羰基铁粉的表层以提升其耐腐蚀能力和吸波能力。结果表明,材料具有优秀的电磁波吸收能力和抗腐蚀性能,其主要原因是材料具有磁电协同效应的稳定核壳结构,能够有效增强材料的介电损耗和磁损耗。在Xie等[38]对镀银羰基铁粉的研究中,通过正交实验得出,在最佳实验条件下复合材料的总电磁屏蔽值超过了33 dB,意味着此复合材料具有十分优异的电磁波吸收性能,且因为银的存在,该复合材料也具有较好的耐热性能。

综上所述,涂层能够明显影响羰基铁粉的吸波性能,提升材料的吸波性能,同时也可以使材料具有耐热、抗腐蚀和抗氧化的性能。

2.4 羰基铁粉的复合改性

如前文所述,羰基铁粉是典型的磁损耗吸波材料,其磁损耗正切值高于介电材料的磁损耗正切值[39-40]。若羰基铁粉再与磁损耗吸波材料复合,则吸波性能将会降低,与当今社会对吸波材料的要求不符合[10]。为使磁损耗吸波材料表现出良好的微波吸收性能,可将羰基铁粉作为填充物,与介电损耗吸波材料进行混合,使其单一的损耗机制转变为双重损耗机制的复合材料,提升其微波吸收性能[41]。不同填充量的羰基铁粉对吸波材料的形貌结构、导磁率和磁化强度变化[42]等有很大的影响,从而表现出不同程度的吸波性能。Ye等[43]报告称,随着复合材料中羰基铁粉的比例增加,提高了复合材料的介电损耗能力,双重损耗机制下,复合材料的吸波能力远远优于单一的羰基铁粉或者石墨烯的吸波能力。随着羰基铁粉的填充比例上升,复合材料的微粒孔数明显增加,能促进2种损耗机制的协同作用。值得注意的是,随着羰基铁粉填充比例的增加,材料的吸波性能先减弱后提升。在Duan等[44]报告中可以看到,随着羰基铁粉的填充比例增加,吸波材料的反射损耗峰往低频方向移动,能够弥补吸波材料在低频区域的不足,从而提升其吸波性能。综上所述,若想得到高性能的复合吸波材料,需要对羰基铁粉的填充比例进行控制,以达到优异的吸波性能。

常用的与羰基铁粉混合的材料主要包括碳质介电材料,如石墨(Graphite,GR)、炭黑(Carbon Black,CB)、碳纤维(Carbon Fiber,CF)、石墨烯、碳纳米管(Carbon Nanotubes,CNT)等,以及非碳质介电材料,如氧化锌、氧化锰和钡铁氧体等。石墨的结构呈二维圆盘状,被广泛应用于开发轻质导电多功能材料。研究表明,当石墨厚度和直径减小时,能够具备良好的微波吸收性能[45-46]。Xu等[47]通过化学气相分解法将羰基铁粉涂覆在石墨上,得到的复合材料具备更高的介电常数和虚导磁率,从而增加复合材料的微波吸收性能。在此研究中也发现,将羰基铁粉涂覆在石墨上时,由于二者的电导率不相等,导电网络更易建立,并形成畴壁移动,导致磁损失。在Xu等[48]的另一项研究中,他们认为整齐排列的羰基铁粉和添加的石墨是提高复合材料许可率和电导率的关键因素。

石墨烯具有较大的比表面积和良好的导热性,可用于吸波材料的制备[49-50],Ye等[43]进行了石墨烯和羰基铁粉的复合微球研究。复合材料中,磁损耗和介电损耗实现了互补。前者主要由羰基铁粉的自然共振和涡流损耗提供,后者主要由石墨烯本身的缺陷和复合材料内部的不均匀界面引起的偶极极化和界面极化提供。此外,二者之间还能形成导电网络,从而加强微波吸收。随着羰基铁粉的添加比例增加,复合材料的吸波性能随之减少或增加。为了达到较高的性能,还需要对二者的比例进行调配。在另一项对石墨烯和羰基铁粉的复合材料研究中,Zuo等[51]指出,石墨烯和羰基铁粉的界面会产生界面极化,其引起的相关弛豫是减少入射电磁波能量的有效方法。

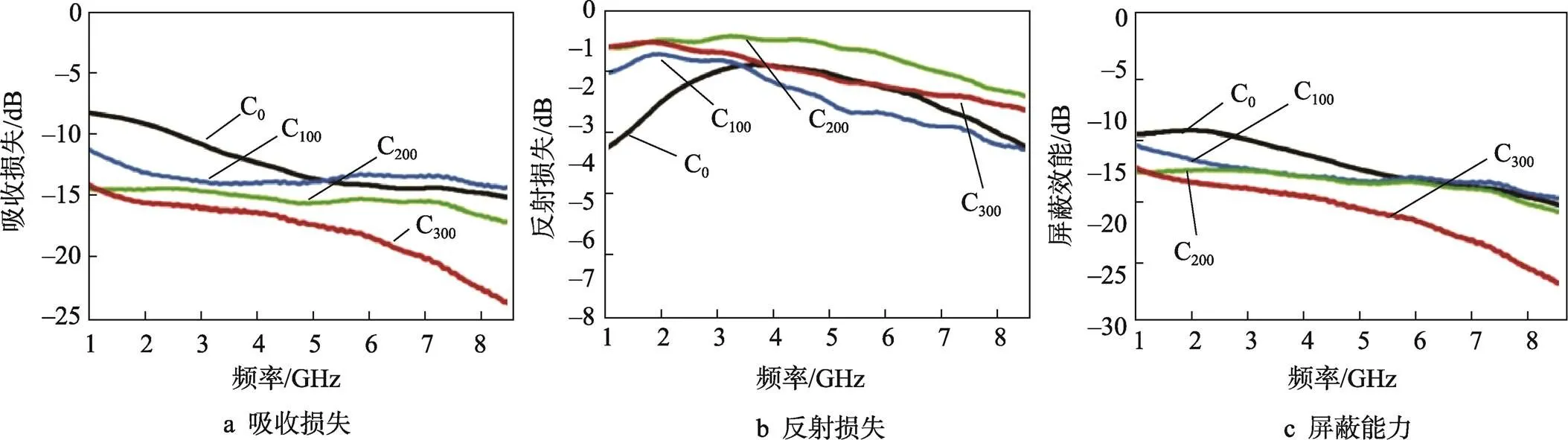

碳纤维吸波材料密度小,具有广泛的微波吸收特性。研究表明,添加碳纤维能增加复数介电常数,但不影响复数磁导率[52]。Jang等[53]的研究中,将羰基铁粉嵌入碳纤维聚合物中进行测试,结果如图3所示。复合材料的吸波能力随着羰基铁粉的比例上升而增加,羰基铁粉的增加改善了材料的电导率和磁化性能。吸收损耗是该材料进行微波吸收更主要的因素。

图3 CIP含量不同的样品的吸收、反射和总电磁屏蔽能力

碳纳米管凭借其高适应性,良好的电化学性能、热稳定性和磁性特征[54-55],被广泛应用于复合材料的填充材料中。在Jang等[56]成功研制了碳纳米管和羰基铁粉组成的纳米杂化颗粒。实验结果表明,随着纳米杂化颗粒含量的提升,电导率和吸波效率都会提高。研究人员认为电导率的变化是因为磁化固化过程中纳米杂化颗粒的排列不同导致的。基于羰基铁粉的复合材料响应磁场会形成基于羰基铁粉的链状结构,这些纳米杂化颗粒可以通过排列有效地在基质中形成致密的导电网络,从而使基于羰基铁粉的复合材料的导电性提高[57-59]。非碳质介电材料,如钡铁氧体,也可与羰基铁粉制备为复合材料。复合材料具有更宽的吸收带宽和更低的反射损耗,二者的复合材料在很宽的频率范围内不会表现出低反射[60]。

上述研究表明,通过羰基铁粉和不同介电材料的复合,能够有效改善材料的微波吸收性能。在羰基铁粉和其他材料的共混中,材料的形貌、尺寸、物化特性、填充比例和复合方式等都会明显影响材料微波吸收的性能。

3 结语

近年来,CIP作为典型的磁损耗吸收材料,在微波吸收领域取得了丰富的研究成果。然而,CIP仍然存在一些缺点,如,介电损耗低、吸收带宽较窄、密度高等,因此在实际应用时受到了一些限制。目前,众多学者已经可以通过形貌优化、涂层改性、复合改性等手段对基于CIP的吸波材料进行调控来获得更好的微波吸收效果,但仍然有很多方面需要克服,如吸波频带窄、复合材料比例的准确调控等。因此,需要聚焦于以下发展方向:

1)“轻、宽、强、薄”依然是羰基铁粉基微波吸收材料需要大力研究的目标。

2)具有更小趋肤效应和更高snoek极限的片状羰基铁粉将会是未来相关领域重点研究的对象。

3)在提升吸波材料的吸波效能的同时,还需要考虑环境对材料的影响,社会的发展需要材料具备如热稳定性、抗腐蚀性等诸多性能,以便在极端环境下正常工作,这便需要研制性能更全面的吸波材料。

[1] ZHAO Xiao-guang, DONG Shun, HONG Chang-qing, et al. Precursor Infiltration and Pyrolysis Cycle-Dependent Microwave Absorption and Mechanical Properties of Lightweight and Antioxidant Carbon Fiber Felts Reinforced Silicon Oxycarbide Composites[J]. Journal of Colloid and Interface Science, 2020, 568: 106-116.

[2] ZHANG Li-ying, LIU Ming, BI Shu-guang, et al. Polydopamine Decoration on 3D Graphene Foam and Its Electromagnetic Interference Shielding Properties[J]. Journal of Colloid and Interface Science, 2017, 493: 327-333.

[3] ROSU G, BALTAG O. EMI Shielding Disclosed through Virtual and Physical Experiments[M]. Amsterdam: Materials for Potential EMI Shielding Applications, Elsevier, 2020: 27-61.

[4] LIAO Zi-jian, MA Ming-liang, TONG Zhou-yu, et al. Fabrication of One-Dimensional ZnFe2O4@carbon@ MoS2/FeS2Composites as Electromagnetic Wave Absorber[J]. Journal of Colloid and Interface Science, 2021, 600: 90-98.

[5] FENG Shi-xuan, ZHAI Fu-tian, SU Hua-hua, et al. Progress of Metal Organic Frameworks-Based Composites in Electromagnetic Wave Absorption[J]. Materials Today Physics, 2023, 30: 100950.

[6] DUAN Yu-ping, LIU Yi, CUI Yu-long, et al. Graphene to Tune Microwave Absorption Frequencies and Enhance Absorption Properties of Carbonyl Iron/Polyurethane Coating[J]. Progress in Organic Coatings, 2018, 125: 89-98.

[7] ZHENG Si-nan, ZENG Zhi-hui, QIAO Jing, et al. Facile Preparation of C/MnO/Co Nanocomposite Fibers for High-Performance Microwave Absorption[J]. Composites Part A: Applied Science and Manufacturing, 2022, 155: 106814.

[8] CAO Xiao-long, JIA Zi-rui, HU Dong-qi, et al. Synergistic Construction of Three-Dimensional Conductive Network and Double Heterointerface Polarization via Magnetic FeNi for Broadband Microwave Absorption[J]. Advanced Composites and Hybrid Materials, 2022, 5(2): 1030-1043.

[9] JIANG Qian, QIAO Ye, XIANG Chun-jie, et al. Metacomposite Based on Three-Dimensional Ferromagnetic Microwire Architecture for Electromagnetic Response[J]. Advanced Composites and Hybrid Materials, 2022, 5(4): 3190-3200.

[10] WANG Xiao, PAN Fei, XIANG Zhen, et al. Magnetic Vortex Core-Shell Fe3O4@C Nanorings with Enhanced Microwave Absorption Performance[J]. Carbon, 2020, 157: 130-139.

[11] SHU Jin-cheng, YANG Xin-yu, ZHANG Xin-ran, et al. Tailoring MOF-Based Materials to Tune Electromagnetic Property for Great Microwave Absorbers and Devices[J]. Carbon, 2020, 162: 157-171.

[12] ELMAHAISHI M F, AZIS R S, ISMAIL I, et al. A Review on Electromagnetic Microwave Absorption Properties: Their Materials and Performance[J]. Journal of Materials Research and Technology, 2022, 20: 2188-2220.

[13] XIA Chao, PENG Yuan-dong, YI Xu-wu, et al. Improved Magnetic Properties of FeSiCr Amorphous Soft Magnetic Composites by Adding Carbonyl Iron Powder[J]. Journal of Non-Crystalline Solids, 2021, 559: 120673.

[14] WU Nan-nan, ZHAO Bei-bei, CHEN Xiao-yue, et al. Dielectric Properties and Electromagnetic Simulation of Molybdenum Disulfide and Ferric Oxide-Modified Ti3C2TXMXene Hetero-Structure for Potential Microwave Absorption[J]. Advanced Composites and Hybrid Materials, 2022, 5(2): 1548-1556.

[15] XIAO Jun-xiong, QI Xiao-si, GONG Xiu, et al. Defect and Interface Engineering in Core@shell Structure Hollow Carbon@MoS2Nanocomposites for Boosted Microwave Absorption Performance[J]. Nano Research, 2022, 15(9): 7778-7787.

[16] LI Chen, QI Xiao-si, GONG Xiu, et al. Magnetic-Dielectric Synergy and Interfacial Engineering to Design Yolk–Shell Structured CoNi@void@C and CoNi@void@C@MoS2Nanocomposites with Tunable and Strong Wideband Microwave Absorption[J]. Nano Research, 2022, 15(7): 6761-6771.

[17] WANG Rui, YANG Er-qi, QI Xiao-si, et al. Constructing and Optimizing Core@shell Structure CNTs@MoS2Nanocomposites as Outstanding Microwave Absorbers[J]. Applied Surface Science, 2020, 516: 146159.

[18] YIN Chun-lei, CAO Yue-bin, FAN Jun-mei, et al. Synthesis of Hollow Carbonyl Iron Microspheres via Pitting Corrosion Method and Their Microwave Absorption Properties[J]. Applied Surface Science, 2013, 270: 432-438.

[19] YANG R B, LIANG Wen-fan. Microwave Properties of High-Aspect-Ratio Carbonyl Iron/Epoxy Absorbers[J]. Journal of Applied Physics, 2011, 109(7): 07A311.

[20] 王轩, 朱冬梅, 向耿, 等. 羰基铁吸收剂的研究进展[J]. 材料导报, 2014, 28(23): 17-21.

WANG Xuan, ZHU Dong-mei, XIANG Geng, et al. Research Progress on Carbonyl Iron Absorber[J]. Materials Review, 2014, 28(23): 17-21

[21] YIN Peng-fei, ZHANG Li-min, WANG Jian, et al. Low Frequency Microwave Absorption Property of CIPs/ZnO/Graphene Ternary Hybrid Prepared Via Facile High-Energy Ball Milling[J]. Powder Technology, 2019, 356: 325-334.

[22] WANG Feng, LONG Chang, WU Tian-long, et al. Enhancement of Low-Frequency Magnetic Permeability and Absorption by Texturing Flaky Carbonyl Iron Particles[J]. Journal of Alloys and Compounds, 2020, 823: 153827.

[23] WANG Wei, GUO Jia-xiong, LONG Chang, et al. Flaky Carbonyl Iron Particles with both Small Grain Size and Low Internal Strain for Broadband Microwave Absorption[J]. Journal of Alloys and Compounds, 2015, 637: 106-111.

[24] QING Yu-chang, ZHOU Wan-cheng, JIA Shu, et al. Microwave Electromagnetic Property of SiO2-Coated Carbonyl Iron Particles with Higher Oxidation Resistance[J]. Physica B: Condensed Matter, 2011, 406(4): 777-780.

[25] DAI Wei-yong, CHEN Fu, LUO Hui, et al. Synthesis of Yolk-Shell Structured Carbonyl Iron@void@nitrogen Doped Carbon for Enhanced Microwave Absorption Performance[J]. Journal of Alloys and Compounds, 2020, 812: 152083.

[26] QIAO Ming-tao, LEI Xing-feng, MA Yong, et al. Application of Yolk–Shell Fe3O4@N-Doped Carbon Nanochains as Highly Effective Microwave-Absorption Material[J]. Nano Research, 2018, 11(3): 1500-1519.

[27] ZHAO Biao, GUO Xiao-qin, ZHAO Wan-yu, et al. Facile Synthesis of Yolk–Shell Ni@void@SnO2(Ni3Sn2) Ternary Composites via Galvanic Replacement/Kirkendall Effect and Their Enhanced Microwave Absorption Properties[J]. Nano Research, 2017, 10(1): 331-343.

[28] WANG Han-qun, WANG Meng, ZHANG Xiao-chen, et al. A New Type of Catalyst Allows Carbonyl Iron Powder to be Coated with SiO2for Tuned Microwave Absorption[J]. Surfaces and Interfaces, 2020, 21: 100755.

[29] YOKOI T, SAKAMOTO Y, TERASAKI O, et al. Periodic Arrangement of Silica Nanospheres Assisted by Amino Acids[J]. Journal of the American Chemical Society, 2006, 128(42): 13664-13665.

[30] CHEN Jian-wen, WANG Xiu-cai, YU Xin-mei, et al. Significantly Improved Dielectric Performances of Nanocomposites via Loading Two-Dimensional Core-Shell Structure Bi2Te3@SiO2Nanosheets[J]. Applied Surface Science, 2018, 447: 704-710.

[31] LI J, FENG W J, WANG J S, et al. Impact of Silica-Coating on the Microwave Absorption Properties of Carbonyl Iron Powder[J]. Journal of Magnetism and Magnetic Materials, 2015, 393: 82-87.

[32] ZHOU Ying-ying, XIE Hui, ZHOU Wan-cheng, et al. Enhanced Antioxidation and Microwave Absorbing Properties of SiO2-Coated Flaky Carbonyl Iron Particles[J]. Journal of Magnetism and Magnetic Materials, 2018, 446: 143-149.

[33] WANG Hong-yu, ZHU Dong-mei, ZHOU Wan-cheng, et al. Electromagnetic Property of SiO2-Coated Carbonyl Iron/Polyimide Composites as Heat Resistant Microwave Absorbing Materials[J]. Journal of Magnetism and Magnetic Materials, 2015, 375: 111-116.

[34] JOSEPH N, THOMAS SEBASTIAN M. Electromagnetic Interference Shielding Nature of PVDF-Carbonyl Iron Composites[J]. Materials Letters, 2013, 90: 64-67.

[35] LIU Li-dong, DUAN Yu-ping, LIU Shun-hua, et al. Microwave Absorption Properties of one Thin Sheet Employing Carbonyl–Iron Powder and Chlorinated Polyethylene[J]. Journal of Magnetism and Magnetic Materials, 2010, 322(13): 1736-1740.

[36] ZHOU Chang, FANG Qing-qing, YAN Fang-liang, et al. Enhanced Microwave Absorption in ZnO/Carbonyl Iron Nano-Composites by Coating Dielectric Material[J]. Journal of Magnetism and Magnetic Materials, 2012, 324(9): 1720-1725.

[37] CHEN Jin-chuan, LEI Wei-wei, HUANG Chi, et al. Magneto-Electric Adjustable Co/C Porous Layer Coated Flaky Carbonyl Iron Composites with Bifunctions of Anti-Corrosion and Microwave Absorption[J]. Journal of Alloys and Compounds, 2022, 927: 167104.

[38] XIE Hui, ZHOU Ying-ying, REN Zhao-wen, et al. Enhancement of Electromagnetic Interference Shielding and Heat-Resistance Properties of Silver-Coated Carbonyl Iron Powders Composite Material[J]. Journal of Magnetism and Magnetic Materials, 2020, 499: 166244.

[39] PINHO M S, GREGORI M L, NUNES R C R, et al. Performance of Radar Absorbing Materials by Waveguide Measurements for X- and Ku-Band Frequencies[J]. European Polymer Journal, 2002, 38(11): 2321-2327.

[40] LI Song-yan, TIAN Xiao-xia, WANG Jia-fu, et al. Ternary Heterogeneous Core-Shell Structure CIP@PPy/ MWCNTs Composites for Broadband Microwave Absorption, Diamond and Related Materials, 2022, 130: 109420

[41] LI Yong, CHEN Chang-xin, PAN Xiao-yan, et al. Multiband Microwave Absorption Films Based on Defective Multiwalled Carbon Nanotubes Added Carbonyl Iron/Acrylic Resin[J]. Physica B: Condensed Matter, 2009, 404(8/9/10/11): 1343-1346.

[42] NI J L, HU F, FENG S J, et al. Soft Magnetic Properties of FeSiAl/Carbonyl Iron Composites with High Magnetic Permeability and Low Magnetic Loss[J]. Journal of Alloys and Compounds, 2021, 887: 161337.

[43] YE Xi-cong, GAO Qi, HE En-yi, et al. Graphene/Carbonyl Iron Powder Composite Microspheres Enhance Electromagnetic Absorption of 3D Printing Composites[J]. Journal of Alloys and Compounds, 2023, 937: 168443.

[44] DUAN Yu-ping, WU Guang-li, GU Shu-chao, et al. Study on Microwave Absorbing Properties of Carbonyl-Iron Composite Coating Based on PVC and Al Sheet[J]. Applied Surface Science, 2012, 258(15): 5746-5752.

[45] MICHELI D, PASTORE R, GRADONI G, et al. Reduction of Satellite Electromagnetic Scattering by Carbon Nanostructured Multilayers[J]. Acta Astronautica, 2013, 88: 61-73.

[46] MICHELI D, VRICELLA A, PASTORE R, et al. Synthesis and Electromagnetic Characterization of Frequency Selective Radar Absorbing Materials Using Carbon Nanopowders[J]. Carbon, 2014, 77: 756-774.

[47] XU Yong-gang, YAN Zhen-qiang, ZHANG De-yuan. Microwave Absorbing Property of a Hybrid Absorbent with Carbonyl Irons Coating on the Graphite[J]. Applied Surface Science, 2015, 356: 1032-1038.

[48] XU Yong-gang, ZHANG De-yuan, CAI Jun, et al. Microwave Absorbing Property of Silicone Rubber Composites with Added Carbonyl Iron Particles and Graphite Platelet[J]. Journal of Magnetism and Magnetic Materials, 2013, 327: 82-86.

[49] XU Dong-wei, YANG Sen, CHEN Ping, et al. Synthesis of Magnetic Graphene Aerogels for Microwave Absorption by In-Situ Pyrolysis[J]. Carbon, 2019, 146: 301-312.

[50] ZHI Dan-dan, LI Tian, LI Jin-zhe, et al. A Review of Three-Dimensional Graphene-Based Aerogels: Synthesis, Structure and Application for Microwave Absorption[J]. Composites Part B: Engineering, 2021, 211: 108642.

[51] ZUO Yu-xin, SU Xin-ran, LI Xin-wei, et al. Multimaterial 3D-Printing of Graphene/Li0.35Zn0.3Fe2.35O4and Graphene/Carbonyl Iron Composites with Superior Microwave Absorption Properties and Adjustable Bandwidth[J]. Carbon, 2020, 167: 62-74.

[52] QING Y C, ZHOU W C, JIA S, et al. Electromagnetic and Microwave Absorption Properties of Carbonyl Iron and Carbon Fiber Filled Epoxy/Silicone Resin Coatings[J]. Applied Physics A, 2010, 100(4): 1177-1181.

[53] JANG D, CHOI B H, YOON H N, et al. Improved Electromagnetic Wave Shielding Capability of Carbonyl Iron Powder-Embedded Lightweight CFRP Composites[J]. Composite Structures, 2022, 286: 115326.

[54] LI W H, LYNAM C, CHEN J, et al. Magnetorheology of Single-Walled Nanotube Dispersions[J]. Materials Letters, 2007, 61(14/15): 3116-3118.

[55] SLOBODIAN P, PAVLÍNEK V, LENGÁLOVÁ A, et al. Polystyrene/Multi-Wall Carbon Nanotube Composites Prepared by Suspension Polymerization and Their Electrorheological Behavior[J]. Current Applied Physics, 2009, 9(1): 184-188.

[56] JANG D, YOON H N, SEO J, et al. Improved Electromagnetic Interference Shielding Performances of Carbon Nanotube and Carbonyl Iron Powder (CNT@CIP)- Embedded Polymeric Composites[J]. Journal of Materials Research and Technology, 2022, 18: 1256-1266.

[57] KIM S, KIM P, PARK C Y, et al. A New Tactile Device Using Magneto-Rheological Sponge Cells for Medical Applications: Experimental Investigation[J]. Sensors and Actuators A: Physical, 2016, 239: 61-69.

[58] YU Miao, YANG Pin-gan, FU Jie, et al. A Theoretical Model for the Field-Dependent Conductivity of Magneto-Rheological Gels and Experimental Verification[J]. Sensors and Actuators A: Physical, 2016, 245: 127-134.

[59] KIM Y K, KIM J, JANG D, et al. A Study on the Effects of Multiwall Carbon Nanotubes on Dynamic Stiffness of Hydrophilic-base Magnetorheological Gel, Current Nanoscience 2019, 15(3): 319-323.

[60] FENG Y B, QIU T, SHEN C Y. Absorbing Properties and Structural Design of Microwave Absorbers Based on Carbonyl Iron and Barium Ferrite[J]. Journal of Magnetism and Magnetic Materials, 2007, 318(1/2): 8-13.

Research Progress of Carbonyl Iron Powder as Microwave Absorbing Material

QIN Ren-chi, MENG Fan-bin

(School of Materials Science and engineering, Southwest Jiaotong University, Chengdu 610031, China)

The application of carbonyl iron powder (CIP) in wave absorption is restricted by its low dielectric loss, narrow absorption bandwidth, high density, and other shortcomings. The work aims to develop "light, wide, strong, thin" CIP microwave absorbing materials through different modification methods based on CIP materials, to effectively absorb microwaves. The research status of using carbonyl iron powder as wave absorbing materials in recent years was reviewed. The effects of different modification methods, such as morphology modification, coating modification and composite modification, on the wave absorbing properties of carbonyl iron composites were introduced and analyzed. As a microwave absorbing material, CIP can be improved by different modification methods to ameliorate the shortcomings. The prepared composites are more in line with the current demand for wave absorbing materials. Compared with traditional CIP materials, CIP composites have greater potential as microwave absorbers.

microwave interference; CIP; microwave absorbing materials; modification

TB34

A

1001-3563(2023)09-0129-08

10.19554/j.cnki.1001-3563.2023.09.016

2023−03−16

覃仁驰(2001—),男,本科生。

孟凡彬(1985—),男,博士。

责任编辑:曾钰婵