Radiographic examination of Western bronze and stone sculptures: history of studies, methodologies and data interpretation

2023-01-13MICHELIMario

MICHELI Mario

(Department of Humanities, Roma Tre University, Rome 00154, Italy)

Abstract: Over the past fifty years, various complex interdisciplinary diagnostic plans have been implemented in Italy during the execution of conservation projects on stone sculptures and on large bronze sculptures.

Key words: Ancient metallurgy; Linear accelerator; Casting defect; Radiographic examination

0 Introduction

The radiographic investigation of a bronze statue can clarify all the issues related to the ancient techniques and to the conservation history only when this particular investigation is part of a multidisciplinary program.

In order to obtain a complete knowledge of the artefact, the radiographic examination must be provided within a well-articulated diagnostic program consisting of multidisciplinary chemical and physical examinations.

This approach has developed over the last fifty years through the contributions of important conservation scientists and facing more complex case studies.

Radiography was considered relevant to the study of ancient metals as early as the 1950s in Great Britain by researchers such as A.E.A.Werner (1911—1973), keeper of the British Museum Research Laboratory and co-author with H. J. Plenderleith in the second edition of the famous handbookTheConservationofAntiquitiesandWorksofArt(Oxford, 1971)[1].

A significant contribution, through the parallel radiographic and microstructural examination of metals, was offered in France by Albert France-Lanord (1915—1993), curator of the Musée Lorrain in Nancy (1941—1990) and of the Jarville-Nancy Iron Museum (from 1966)[2], director of the Laboratory of the Research Center on the History of Steel Industry (1955—1990) and founder of the Laboratory of Metal Archaeology (LAM) in Nancy, France.

1 Main case studies that contributed to the methodological development of radiographic diagnostics in the case of bronze sculptures

In Italy, the contribution of Massimo Leoni (1926—2000), deputy director of the Istituto Sperimentale dei Metalli Leggeri in Novara, is decisive. Leoni studied the process of corrosion of ancient metals, and was among the first, in the wake of Albert France-Lanord, to deal with the reconstruction of the casting processes used in antiquity through radiography and metallography[3]analysis.

In 1967, M. Leoni was commissioned by the Istituto Centrale del Restauro to examine the so-calledZeusofUgento, a bronze sculpture discovered in 1961 in southern Italy (Fig.1).

Fig.1 Zeus from Ugento circa 530 B.C., Puglia,southern Italy

The purpose of the investigation was to determine the state of preservation of the metal and the nature of the corrosion phenomena as well as the presence of any internal cracks in the casting, which were undetectable on the surface. Starting from the metallographic examination, Leoni hypothesized that the sculpture had undergone “a prolonged heating that had produced the homogenization of the solid solution and the destruction of the dendritic structure of the casting”[4].

Radiographic analysis of the entire sculpture (73 cm in height) was carried out using a gamma source of Cesium-137 (activity of 5 Curie) and revealed the presence of a clay core with residual traces of iron pins inside it (Fig.2)[5].

Fig.2 Gammagraphy of Zeus from Ugento in 1967 (Gamma source: Cesium-137)

Maurizio Marabelli (1934—2017), director of the Chemistry Laboratory of the Istituto Centrale del Restauro and scientific coordinator of the main studies and conservation interventions that would be carried out in the following decades, was one of the most notable figures from the early 1970s[6-7].

From 1972 until 1979, the Istituto Centrale del Restauro addressed the problem of conserving the Horses of San Marco. For the first time, a multidisciplinary program of investigations and chemical-physical analysis was developed.

Particularly important was the preliminary phase of the program, which was aimed at the shape detection using photogrammetry to create the graphic basis for the documentation of the entire project. The photogrammetric basis was used for the creation of thematic maps on which all the data obtained from the various examinations would be recorded.

Between 1975 and 1979, another case study played a fundamental role, namely, that of the Ephebe from Selinunte, a small bronze sculpture found in Sicily in 1882. After an initial restoration carried out in 1928, it was entrusted to the Istituto Centrale del Restauro from 1975 to 1979. This sculpture showed disproportions between different sections of the body, anomalies that had not been correctly interpreted by scholars. The conservator-restorer Alberto Di Maio (1939—1980), led by art historian Giovanni Urbani (1925—1994), director of the Istituto Centrale del Restauro at that time, proposed, as the result of a combined use of radiographic and endoscopic investigations, a convincing interpretation of the formal anomalies of the sculpture. The radiographic examination had revealed in the lower part of the thorax and in the upper part of the legs, three sections characterized by a radiographic high density that represented evident discontinuities.

To obtain the correct interpretation of the radiographic information, A. Di Maio explored the internal cavities of the sculpture using a rigid optical boroscope, with which he photographed the internal surfaces.

In this way, the nature and function of the anomalous areas could be understood: the sculpture, probably due to imperfect casting or for the repair of subsequent damage, had been “stretched” by cutting it in correspondence with the chest and upper part of the legs, and inserting, by welding, three elongation bands.

The case of the Ephebe of Selinunte stimulated scholars of ancient metallurgy to pay attention to the internal cavities of sculptures. An important consequence was the development of the laparoscopic restoration method, first used on the Riace Bronzes between 1992 and 1995.

At the end of the 1970s, as part of research conducted in cooperation with Maurizio Marabelli, the method for investigating ancient metal structures using ultrasound—in combination with radiographic techniques —was developed.

In addition to allowing the measurement of thickness and the identification of structural defects, ultrasound methods have also been used for the study of casting techniques[8].

The case study of Dionysus with a thyrsus from the National Roman Museum is exemplary (Fig.3). Radiographic investigation revealed an extensive ancient repair in the upper part of the thorax (Fig.4), which compensated for a large lack of filling during metal pouring, probably due to a displacement of the casting core.

Fig.3 Statue of Dionysus from the National Roman Museum, Rome

Fig.4 Thorax radiography of the statue of Dionysus from the National Roman Museum, Rome

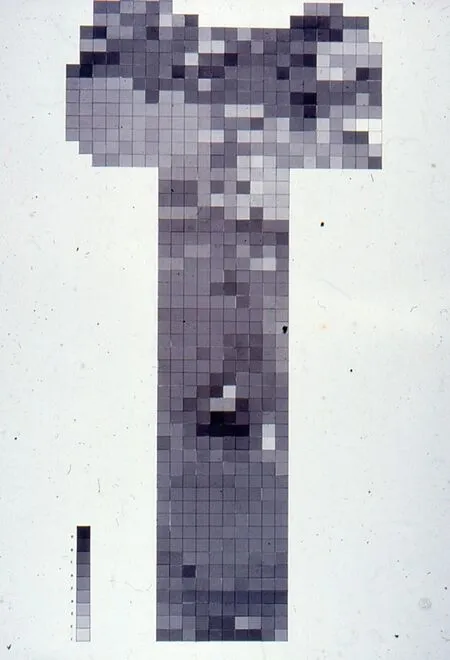

Thickness distribution was ascertained via 421 measurement with ultrasound made all over the body. Furthermore, to investigate the area affected by anomalies, detected through radiography, 636 measurements taken across the thorax were performed and processed. A graphic map made accordingly shows differences in thicknesses using grey tones of increasing darkness, which are linked to the thickness values (Fig.5 and Fig.6).

Fig.5 Thickness measurements (white spots) of the statue of Dionysus from the National Roman Museum, Rome

Fig.6 Thickness map of thorax with grey tones proportional to thickness measured of the statue of Dionysus from the National Roman Museum, Rome

At the beginning of the 1980s, there was an ever-increasing development of so-called “non-destructive tests”, and in the case of ancient metals, collaborations with the world of industrial metallurgical research were strengthened. The more precise interpretation of the indicators of metallurgical processes has made radiographic investigation indispensable for the correct reconstruction of techniques used in ancient times[9].

In recent decades the “integral” radiographic investigation of a work of art has been increasingly preferred to a so-called “spot” methodology, especially in the case of artifacts in which the presence of numerous and complex structural data is suspected[10].

2 Investigations conducted on the equestrian monument of Marcus Aurelius

2.1 Methodological approach

In the case of the equestrian monument of Marcus Aurelius (Fig.7), radiographic investigation is at the center of a complex diagnostic program[11].

Fig.7 Equestrian monument of Marcus Aurelius in Rome

A photogrammetric survey of the shape of the two elements that make up the group (rider and horse) was carried out.

Subsequently, non-destructive examinations were performed: radiography, measurements of the thickness of the metal core with ultrasound and Eddy-current testing. They were done in order to fully map the heterogeneities present in the metal which could be attributed to the execution processes, deriving from deterioration phenomena of mechanical origin or caused by previous restoration interventions.

In the case of bronze statuary, it must be kept in mind that irradiation with ionizing radiation can alter the results of thermoluminescence dating measurements to be carried out on the casting core, which in some cases is preserved.

Therefore, it is essential to collect samples of casting core before radiographic examination and to place dosimeters inside the statues to accurately measure the amount of energy that reaches the inner parts.

In many cases, orthogonal radiographic projections must be performed in order to correctly understand the progress of the internal structures.

2.2 Radiographic investigation performed on the equestrian monument of Marcus Aurelius

2.2.1Method employed

In the case of the equestrian statue of Marcus Aurelius, much of the internal cavity of the horse and rider was easily accessible and could be observed directly. This allowed the execution of the radiographic investigation of the single metal wall and the positioning of the X-ray films inside the sculpture. It also facilitated the subsequent interpretation of the radiograms considering that the direct viewing of the external and internal surfaces of the structure was possible[12].

This radiographic investigation was carried out in 1982. Its aims were:

1) to reconstruct the “technological history” of the bronze equestrian group, separating the data referring to the original structure from those relating to subsequent repairs;

2) to evaluate the discontinuities from a conservative point of view in order to contribute, with other investigation methodologies, to build a model of the mechanical behaviour of the structure.

In our case, the surface on which the survey was carried out had an extension of about 20 m2, in which 258 modules of the X-ray film of the size 30 cm × 40 cm were identified.

A grid characterized by a smaller module was created in order to produce overlapping areas in the sequence of the radiograms themselves.

The radiograms, except for the legs and tail of the horse, were obtained by investigating a single metal wall with the film positioned in the internal cavity and the X-ray equipment outside.

The alignment and centering of the X-ray source in relation to the film proved to be particularly complex. In this phase, a coinciding internal and external grid was used.

Considering that the thickness of the metal wall was between 4 mm and 20 mm, the X-ray equipment MONOGIL MT 350/6 GILARDONI was used.

Industrial X-ray films D4 and D7 STRUCTURIX AGFA GEVAERT were used.

2.2.2Criteria for study and interpretation

The study of the radiological data was carried out on the original films. In order to analyse the distribution of information over large areas, the radiograms were reproduced by contact on photographic paper, with the Logetronic printer, obtaining a balancing of the density differences.

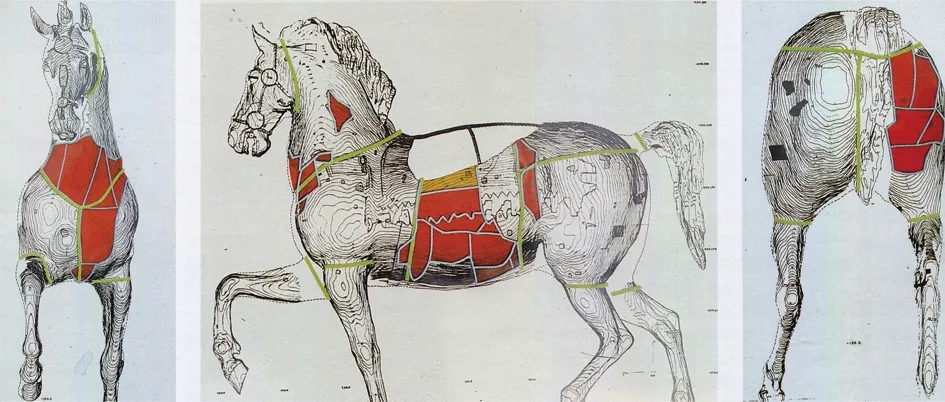

The reproductions were subsequently assembled. The “mosaic” reconstruction obtained, due to the complex shape of the sculptures and the inevitable geometric aberrations, sometimes resulted in a lack of coincidence of some details of the configuration (Fig.8).

Fig.8 Detail of the radiographic photomosaic: left side of the horse of the equestrian monument of Marcus Aurelius

For this reason, radiograms do not in themselves constitute a correct topographical representation of structural inhomogeneities, and the radiographic information must be reported on a topographical map obtained through references that can be acquired by observing the sculptures (Fig.9).

Fig.9 Thematic map of casting defects: left side of the horse of the equestrian monument of Marcus Aurelius

2.2.3Contribution of radiography to the reconstruction of executing techniques and subsequent restoration interventions

2.2.3.1Procedures for casting the different parts of the monument

The production history of the monument begins with the creation of a “prototype” of the work. Unfortunately, for this phase, material clues in the metal are no longer evident.

On the contrary, traces of the processes used in the various operating phases remain trapped in the metallic core.

In the case of the equestrian monument of Marcus Aurelius, the so-called “indirect lost wax” technique was used, with sections cast separately and then welded.

In the case of the knight, the original sculpture was probably divided into 17 parts by exploiting suitable intermediate boundary lines that would have allowed the execution of hardly perceptible welded joints[13].

The head, arms and legs are inserted into the draped thorax formed in nine elements, to which is added the rear part of the cloak made up of three parts.

Careful dosage of the thickness of the wax is extremely important because it is equivalent to the thickness of the metal in the final work.

The spreading of the foundry wax in the different parts of the rider had to be carried out with different methods selected appropriately for the different plastic characteristics of the parts.

In fact, the head, arms and legs, which could have been replicated from the original model by valve molding, were built in wax applied with “sciacquo” technique (by rinsing) and not with plates, a solution adopted for the draped sections of the figure.

The bare parts of the rider are characterized by uniform thickness, by an extremely flat internal surface and are devoid of the junction lines of the wax sheets corresponding to the valves, characteristic clearly connected with the “a lastre” (sheets) procedure.

On the contrary, in the draped parts the dosage of the thickness of the foundry wax (and therefore of the final bronze) is strictly connected to the complex articulation of the shape. Therefore there are considerable thickenings in correspondence with the internal and external cusps of the drapery and clear signs of treatment “with spatula” of the surface when the wax was applied.

Finally, considering that the total weight of the rider is equal to 620 kg, the hypothesized division into parts made the weight of each part extremely low, ranging from 30 kg to 80 kg.

The division into parts of the horse reflects a different logic, specific to the type of subject represented. In this case, the model was probably divided into 15 parts and the reconstruction of the junction lines of these is made particularly complex, due to the subsequent repairs.

The original parts were the head, including the neck, in three sections, the legs each a single element, the tail originally a single element, and finally the thorax, originally endowed with the extensive dorsal lack, concealed by the rider, in eight sections.

Subsequent to the drying of the casting core, the waxes were fitted withmetalpinsor chaplets, inserted through the wax into the core, to keep it in position inside the mold after the investment mold was baked and the wax was burnt out.

Themetalpinsused in the equestrian group had a square section with a side of 5 mm and after casting, during the finishing phase the metal parts were extracted and the cavities they occupied were concealed on the outer surface with smallbronzepatchesof copper alloy.

The process was completed withcastingsprueandairvents. The application of theinvestmentmoldof refractory material thatsurroundsthe wax model and the consequent incorporation of thecastingsprueandairventssystemand of the external portion of themetalpinscompleted the preparation for the casting.

2.2.3.2Metal pouring and casting defects

A ternary alloy composed of copper, tin and lead was used for the equestrian group with variable tin content between 4.4% and 9.7% and a lead content between 8.4% and 16.2%.

The wide variations in the alloy composition are linked on the one hand to the process of fusion in separate parts, and on the other hand to the conspicuous phenomena of lead segregation. The phase of pouring the metal into the mold and the subsequent cooling are the main steps of the entire production cycle.

During this phase, damages and casting defects can arise and compromise the perfection of the result.

Smallgasbubblesare homogeneously diffused in the monument; on the contrary,sponginessdue to an incomplete drying of the core is absent. It is possible to hypothesize that good care was taken in the preparation for the casting; otherwise, the casting clay could have been characterized by insufficient porosity, to insure a total absorption of the gases contained in the alloy.

The cooling process could have been particularly long and gradual, so as to allow the formation of extensivesegregationphenomenaof slag, oxides and non-solute lead which could be arranged in ordered bands corresponding to the advancement of the solidification front. This important phenomenon has allowed the localization of some areas where thecastingspruewas connected.

2.2.3.3Original welds

The separately cast original parts, freed from the casting clay and the contact areas ofcastingsprueand themetalpins, could then be assembled. An extremely relevant contribution to the reconstruction of the ancient procedures of welding was offered by an American archaeologist Arthur Steinberg (1937—2022)[14-15].In the original welds, the gap between the two edges of the contiguous sections was filled with molten metal alloy which forms aninternalweldbead(regular accretions of weld metal along the joint).

Radiographic investigation of the joining lines shows the typical defects of the swaged welded joints, such as an evident concentration ofpinholesand slag.

In most of the welds of the monument can be found a solution of continuity between theweldbeadand the edges of the parts to be welded, verified by ultrasound examination[16].

For this reason, the junction of the horse sections can be defined asmetalgluingand not realmetallurgicaljoints-soldering.

These solutions of continuity at the edges may have undergone a worsening as a result of mechanical stresses which, together with congenital stress, may have determined the numerous “transverse cracks” in the joints.

Thepinholesand theblow-holesconcentrated in clusters are not present in excessive quantities; in some areas, for example in the head, these casting defects are exceptionally large.

Macro segregation phenomena are widespread in the original parts of the monument.

Cracksmostly caused by fatigue are located in areas where the mechanical stresses of the structure are concentrated; one of these areas is located between the iliac and left femoral regions.

2.2.3.4Ancient repairs of casting defects

After the assembly of the parts, the ancient founders faced finishing of the external surface, freeing it from the roughness and the characteristic growths of the casting blank by cutting with chisels and by beating with hammers.

It is in that phase that all casting defects appearing on the surface, such asblow-holes, casting faults,shrinkagecracksandjointimperfections, were concealed with the application ofbronzepatches.

In the case of the equestrian group, small, rectangular and squarepatcheswere used for closing cavities caused by defects and the holes caused by themetalpins; in addition, large, polygonalpatcheswere used to compensate for large deficiencies and incomplete joints such as the median weld line of the belly.

The repair of the extensivecastingfault, done by pouring molten metal in the lacuna, directly on the internal surface, may have already been done by the time of finishing the monument.

The mechanical stresses and the cyclic phenomena of thermal expansion and contraction in the long life of the statue have constantly undermined the solidity of these metal inserts, to such an extent that during the last structural restoration carried out in 1912, a large number ofsecondarycastingrepairswere consolidated by placing threaded holes at the perimeter and subsequently inserting threadedmetalpins.

2.2.3.5Restoration of the horse (15th century)

The most complex repair work undergone by the monument was on the horse. Probably due to a mechanical event of considerable magnitude, heavy damage occurred in the left costal region, in the neck and in the right buttock. One could hypothesize a primary trauma in the left side caused by a fall associated with anterior and posterior failures (Fig.10).

Fig.10 Front, left and rear side graphic representations with the 15th-century repairs

In any case, it is likely that the damage suffered by the horse was concentrated along one side of the ancient welded joints.

As a plastic correction of the damaged parts was not possible, they were isolated with cut of the metal wall.

The largecastingfaultthat had been created was compensated for by the insertion of new bronze panels, although in some areas there was reuse of small portions of the original metal.

The new parts show completely different metallurgical characteristics, compared with the original horse sections. In the case of one of the panels, it seems that thewaxmodelwas modelled on a wooden board which still retains traces of chisel work.

All the panels of subsequent manufacture are characterized by a poor metallurgical quality and are shown to be full ofsponginess, probably caused by imperfect drying of the casting clay and a poor fluidity of the alloy. Furthermore, all these parts contain a rare form of macroscopic segregation of lead, completely absent in the original sections of the monument.

The lead appears concentrated in spherules that settle in the gas bubbles before solidification. Finally, therepairpatchesare totally absent in these panels, despite the large number of defects appearing on the surface that could justify their use. The individual panels were connected to the horse by welding using a remarkably complex methodology.

During the preparation of the assembly, near the edges of the parts to be joined, equidistant pairs of holes were made, so that they, during formation of the weld bead, could fill up. The purpose of this particular expedient is to produce an effective mechanical bond.

Another distinctive feature of this particular bonding technique is the large gap between the edges left on the outside, which gives it the typicalribbonappearance. The reason for this technical peculiarity is to increase the welding surface as much as possible, so as to further improve its efficiency.

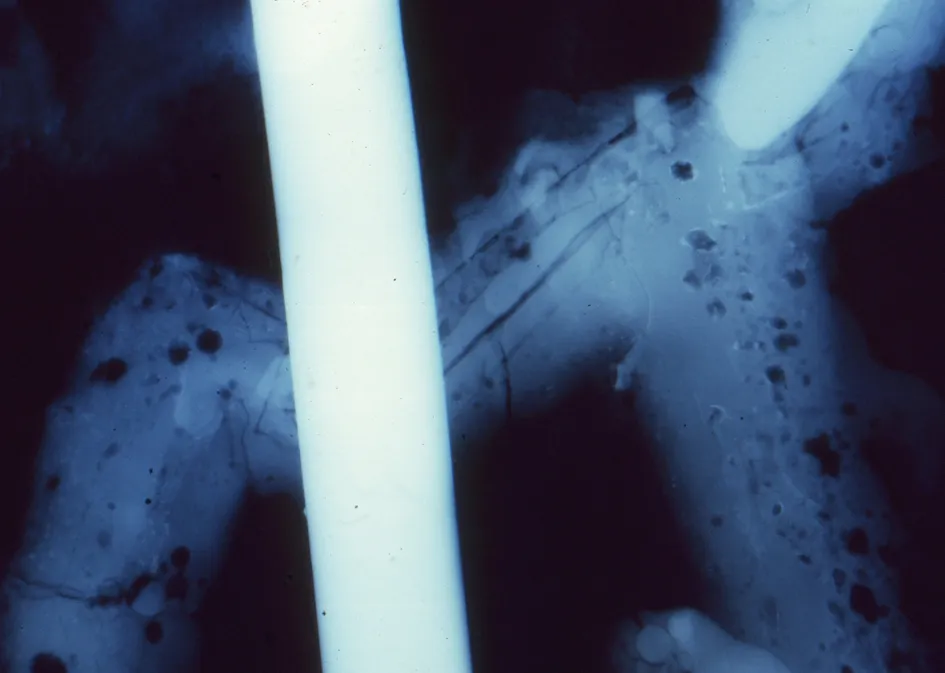

The pouring of the welding metal took place inside the horse, by feeding with small crucibles limited sections of the bead through thecastingsprue, of which all the attachments have remained perfectly preserved (Fig.11 and Fig.12).

Fig.11 Detail of 15th-century welds of the equestrian monument of Marcus Aurelius

Fig.12 Image of the joining line, inner wall of the horse: repair welding of the 15th century

This stratagem made it possible to slide the weld metal by operating with the horse in a natural standing position. An example of a joint with characteristics completely identical to those described here is in the “Lion” of Braunschweig, a bronze sculpture (12th century) probably produced by Saxon founders. At the present state of knowledge, still incomplete regarding metallurgical methodologies from the Middle Ages onwards, it is not possible to verify how widespread this welding technique was and how long it was used.

The methodological approach developed in the case of the radiographic investigation of the equestrian group of Marcus Aurelius was later used in other important case studies.

Among these, one of the most interesting is the X-ray investigation performed between 1984 and 1992, of the horses of the equestrian monuments of Alessandro and Ranuccio Farnese, made for the city of Piacenza by Francesco Mochi between 1612 and 1625 (Fig.13 and Fig.14).

Fig.13 Equestrian monument of Ranuccio Farnese,Piacenza (by Francesco Mochi,1612—1620)

Fig.14 Localization of the X-rays in the 6 graphic representations of the horse and thematic maps of discontinuities

Scientific interest in the reconstruction of ancient metallurgical techniques has increased.

As for Renaissance bronze sculptures, one of the major contributions of the last decades was offered by an art historian Richard Stone (1939—2021), conservator emeritus, the Metropolitan Museum of Art[17].

3 Use of high-energy X-rays

In 1983, in the course of X-ray investigation of theGroupoftheMajestyof the Cathedral of Orvieto, the use of a linear accelerator as an X-ray source was tested. The sculptural group consists of the Madonna and the Child in stone, with two groups on the sides each made up of three bronze angels and a large bronze canopy.

Construction of the various elements that make up this extraordinary group began in the early 14th century and installation on the facade of the church took place in 1329.

The conformations with extremely variable thickness and high maximum values made the radiographic examination complex.

The use of a gamma source was excluded and the medium energies produced by industrial X-ray tubes were not sufficient. Therefore, it was decided to use the high-energy X-rays produced by linear accelerators that produce emissions of several million electron volts (MeV) with a very high dose rate.

With these sources it was possible to use very fine grain radiographic films, thus increasing the radiological contrast; furthermore, considerable distances could be used between the focus of the instrument and the film, thus obtaining a high geometric and dimensional correctness of information. In addition, the high energy emitted was able to produce radiograms characterized by considerable latitude of thickness.

The structural features that had to be detected through radiographic examination in the case of the Madonna and the Child were constraint systems and structural lesions. In the case of the two groups of angels and the canopy, the intention was to reconstruct the metallurgical process used and highlight any structural damage.

The sculptures of the Orvieto Cathedral group were dismantled and transferred to the bunker of the Società Acciai Speciali Terni. A Varian Linatron 1 500 R/min type linear accelerator with a power of 7.5 MeV was used. For the thinner sections, a medium-energy X-ray tube, Gilardoni 350 kV, 6~12 mA, was used. Kodak Industrex M and R radiographic films were employed (Fig.15).

Fig.15 Group of the Majesty of the Cathedral of Orvieto transported to the bunker of the Department Caldarerie and Forced Pipelines of the Società Acciai Speciali Terni; linear accelerator Varian and medium-energy radiological equipment Gilardoni used

In the examined areas, the presence of constraints (upper and lower limbs of the Child and left hand of the Madonna) was assumed. In some situations where different materials were present (stone, lead, iron), both sources of energy were used to collect maximum information (Fig.16 and Fig.17).

Fig.16 Detail of the Madonna’s right arm

Fig.17 Radiography of the right arm of the Madonna performed with medium energies: processing of the X-ray image showed the iron pin embedded by molten lead

The structural state of the pins, the degree of filling and the shape of the holes were checked.

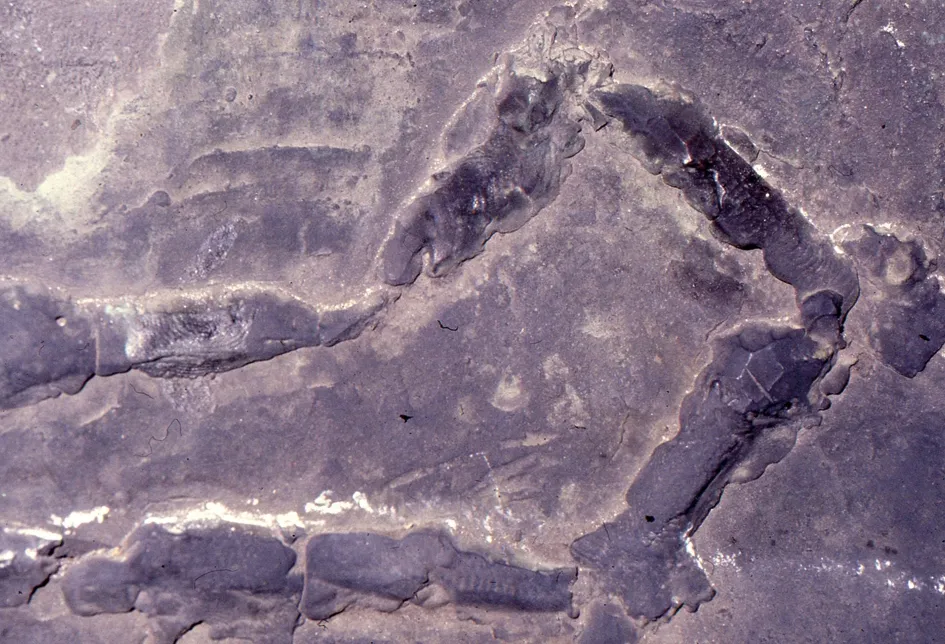

In the region of the Madonna’s abdomen, numerous subtle multiple-beam lesions were detected by high-energy irradiation. Numerous lesions were identified in the left hand of the Madonna through the use of medium-energy X-rays[18]. As for the groups of angels, completely new complex systems of support of the casting core were identified. They consisted of iron pins placed inside the thin clay core of the arms, surrounded by metal elements in the shape of a spiral (Fig.18 and Fig.19).

Fig.18 Angels of the left group

Fig.19 Detail of the right arm of the middle angel of the right group: we observed the inner pin surrounded by the spiral element that has the function of better supporting the casting core before the wax coating; image obtained with the linear accelerator and then subjected to elaboration in pseudo-relief

4 Conclusions

This paper aims to summarize the methodological development that has widely embraced the scientific approach to the study of large bronze sculptures in the last fifty years.

Radiographic investigation, among the first new methods to be used forartisticdiagnosticssince the early 20th century, continues to play a central role in the study of ancient technical procedures and in the evaluation of static-structural criticalities of bronze sculptures.

The correlations between the radiographic investigation, othernon-destructivetestingand methods, have been highlighted.

The case study that occupies a central role in this paper is the great project of investigation and conservation that was carried out in the 1980s on the equestrian group of the Marcus Aurelius of Rome. In this paper are illustrated in detail the results of the radiographic examination of that important masterpiece.

Also presented is another important case study, namely the application of the high-energy X-rays for the examination of a sculptural group in stone and bronze on the facade of the Cathedral of Orvieto. This is a rare example of an investigation using a linear accelerator as a source of ionizing radiation.

Finally, methodological issues have been presented and related to the study and interpretation of radiological data in the case of bronze sculptures.

Over the last twenty years, X-rays applied to the study of works of art have undergone many innovations: from X-ray films to digital X-ray sensors, new sophisticated image processing. However, the fundamental principles that govern the correct use of X-rays on works of art remain unchanged.