Effect of Polymer Network Morphology on the Performance of Polymer Dispersed Liquid Crystal (PDLC) Composite Films

2022-10-08SHENJiyuanLINHaonanRENYunxiaoSUNChangBAOJinyingXIAOJiumeiGAOYanzi

SHEN Jiyuan, LIN Haonan, REN Yunxiao, SUN Chang, BAO Jinying,XIAO Jiumei, GAO Yanzi

(1. Department of Applied Mechanics, University of Sciences and Technology Beijing, Beijing 100083, China; 2. Department of Applied Mechanics, University of Sciences and Technology Beijing, Beijing 100083, China; 3. Department of Materials Physics and Chemistry, School of Materials Science and Engineering, University of Sciences and Technology Beijing, Beijing 100083, China; 4. Department of Materials Physics and Chemistry, School of Materials Science and Engineering, University of Sciences and Technology Beijing, Beijing 100083, China;5. Department of Materials Science and Engineering, College of Engineering, Peking University, Beijing 100083, China; 6. Department of Applied Mechanics, University of Sciences and Technology Beijing, Beijing 100083, China; 7. Beijing Advanced Innovation Center for Materials Genome Engineering Institute of Advanced Materials and Technology, University of Sciences and Technology Beijing, Beijing100083,China)

Abstract: The effects of the morphologies of liquid crystal (LC) droplets left in polymer network on the performance of polymer dispersed liquid crystal composite films were investigated. By adjusting the relative content range of the crosslinking and diluents, the morphologies of polymer network can be changed. Therefore,the properties of PDLC composite films with imparity polymer morphologies were obtained by experiments and the finite element simulation. Results of the experimental and finite element simulation showed that the electrooptical properties of PDLC composite films were inversely proportional to the domain size of the polymer network and the mechanical properties were proportional to the domain size of the polymer network.

Key words: polymer dispersed liquid crystals; polymer network morphology; finite element simulation;mechanical properties; electro-optical properties

1 Introduction

Polymer dispersed liquid crystal (PDLC) was composite materials composed of liquid crystal (LC)droplets and dispersed within a continuous polymer matrix[1-3]. In recent years, PDLC films have been the subject of intensive studies due to their unique optical properties and electrically responsive/birefringent characteristic of liquid crystals (LCs). Also, PDLC films has the advantages of simple preparation method, easy to prepare in a large area, flexibility and good optical propertiesetc. Thus, it has potentially useful for a variety of applications including smart windows, optical shutters, anti-peeping films, flexible large-area display,and other devices[4-8]. PDLC composite films can be fabricated by three methods, polymerization induced phase separation (PIPS), thermally induced phase separation (TIPS) and solvent-induced phase separation(SIPS)[9-11]. The PIPS method has been widely used due to the advantages such as facile fabrication, environmental protection and energy-saving[12-14]. The PDLC films can be switched from light scattering states to transparent state in the electric field-on state. The working principle of PDLC films are shown in Fig.1. When the PDLC composite films are placed in the electric field-on state, the films become transparent because the LC molecules are reoriented along the electric field.Once the electric field is removed, the composite film returned to a light scattering state because of the refractive-index mismatch between the polymer matrix and LC molecules[15].

Acrylates and (meth)acrylates are common and cheap monomers for producing of UV-curable polymers with widespread uses in fabrication PDLC composite films. The research shows that (meth)acrylate has an active effect on the electro-optical properties of PDLC films[16]. This paper reported that the effects of monomer structure on the morphology of polymer networks and the electro-optical properties of the PDLC films. However, the effects of polymer morphology on the electro-optical properties and mechanical properties of PDLC films were rarely systematically investigated.In addition, the excellent mechanical properties have great significance for the practical application of PDLC composite films. Thus, it was worthwhile to research the relationship between the morphology of polymer network and the properties of PDLC composite films.

In this study, PDLC films were prepared by different proportions of cross-linking agents and diluents which lead to different polymer network morphologies. Subsequently, the mechanical and electro-optical properties were obtained by experimental test and the finite element. The relationship between morphology of polymer network and the properties of PDLC films were systematically investigated. Therefore, this paper has great significance for the design of the morphology of PDLC composite films.

2 Experimental

2.1 Materials and instrument

The nematic liquid crystals (NLC) used in our experiment were SLC1717 (TNI=365 K, Δn=0.201,no=1.519, Shijiazhuang Chengzhi Yonghua Display Materials Co. Ltd.). The monomers were benzyl methacrylate (BZMA, 98%, Shanghai Meryer Chemical Technology Co. Ltd.), polyethylene glycol diacrylate 600(PEGDA 600, Shin-Nakamura Chem. Co. Ltd.),and photo-initiator Irgacure651 (Haihang Industry Co.Ltd.). These materials were used without further purification.

2.2 Sample preparation

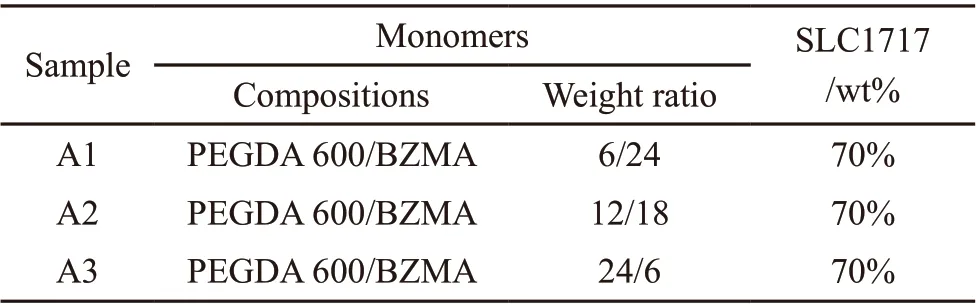

To prepare PDLC composite films with excellent mechanical properties and good electric properties, this study is based on a liquid crystal/methyl acrylate system. The PDLC films were prepared by different proportions of cross-linking agents and diluents to obtain different polymer network morphologies of PDLC composite films. The compositions of composites are shown in Table 1. The photo-initiator Irgacure 651 accounted for 2.0 wt%of the total mass of the system. Then, the composites were vigorously stirred until a homogeneous mixture had formed before they were filled into the indium tin oxide (ITO) coated films substrates by capillary action. And the thickness of the films was adjusted 20.0±1.0 μm by polyethylene terephthalate(PET) film spacing. The mixture was then exposed to ultraviolet (UV) irradiation under a 7.0 W/mm2high-pressure UV lamp for 5.0 min at room temperature. Thus, the PDLC composites films were prepared.

Table 1 Sample A1-A3 formula ratio

2.3 Measurements

2.3.1 LC device parameters tester (LCT)

The electro-optical properties of PDLC films were measured using an LC device parameters tester. The cured PDLC films in the sample card slot of LCT connect two sides with the electric field. A halogen laser beam was used as an incident light source (wavelengthλ=632.8 nm). When processing the sample data, all data are normalized with the transmittance of the empty liquid crystal box being 100%.

2.3.2 Scanning electron microscopy (SEM)

Before observation, the sample to be observed was cut into 7 mm2squares and soaked in a glass bottle containing cyclohexane for about a week.The solvent was replaced every two days to extract the liquid crystals from the films better. Finally, the samples soaked for a week were dried in a vacuum drying oven at 333.2 K for 24 hours, and the surface was sprayed with gold.

2.3.3 Electro-mechanical universal testing machines

The mechanical properties of PDLC composite films were studied by using electro-mechanical universal testing machines. The tested films were cut into 400 mm2squares and the thickness of the films was adjusted 20.0±1.0 μm by PET films spacing. The sample is fixed to the equipment and then used a tensile force at the rate of 5 mm/min-1.

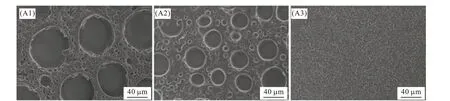

Fig.2 SEM image of A1-A3 polymer network of samples

3 Results and discussion

3.1 Polymer morphologies of PDLC films

The polymer network’s morphology and the size of liquid crystal droplets were observed as shown in Fig.2 and Table 2. The mass ratio of SLC1717 in A1-A3 samples accounts for 70%, and the cross-linking agent and diluent accounted for the remaining 30%.The ratio of cross-linking agent and diluent in sample A1-A3 was 1/4, 2/3, 4/1, respectively. It can be clearly seen that the pore size of the polymer networks decreases when the ratio of PEGDA 600 and BZMA increases. There were small meshes around large domains in the samples A1-A3 and the average diameter sizes of large domains were 65.9, 32.75, and 3.23 μm,respectively. There were many influencing factors for the different morphology of the polymer network[17].Herein, the main reason for this phenomenon is that with the increase of the cross-linking agent content,the content of the methacrylate of the dual-functional group in the polymerization system keeps increasing.Thus, the curing rate in the curing reaction process is accelerated due to the increasing amount of functional group in the polymer reaction. Therefore, due to the low content of cross-linking agent in sample A1, the content of functional groups in polymerization reaction is relatively low, which leads to the slow curing rate and the continuous agglomeration of liquid crystal microdroplets around the phase separation. Finally, the continuous accumulation of liquid crystal microdroplets formed large size microdroplets.

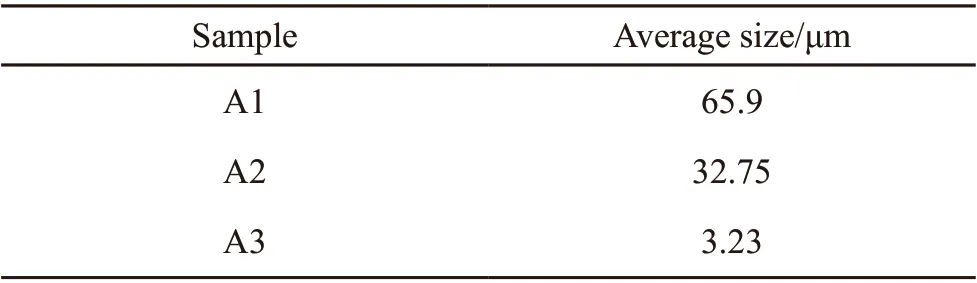

Table 2 The average size of liquid crystal microdroplets

3.2 Electro-optical properties of PDLC films

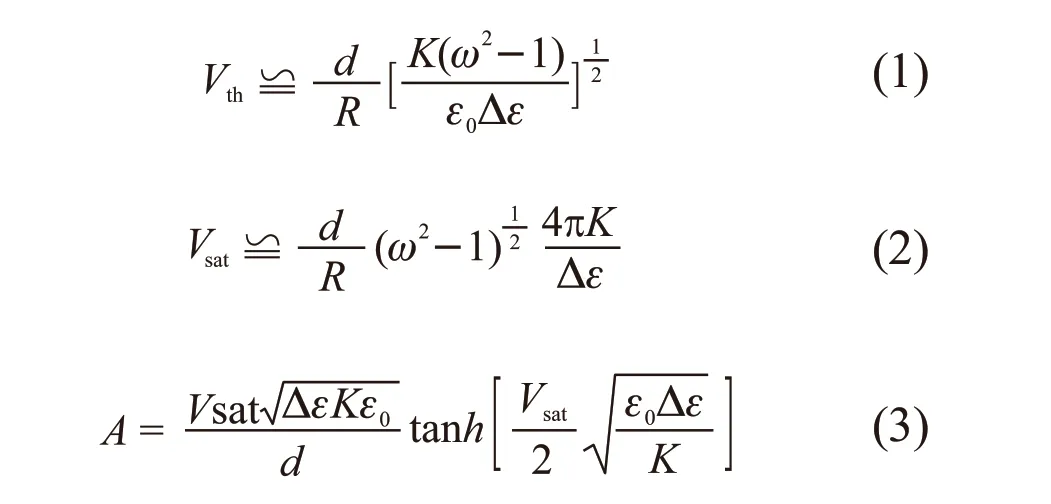

The electro-optical properties of PDLC composite films were mainly through the threshold voltage(Vth), saturation voltage (Vsat), contrast ratio (CR) and response time (tonandtoff). Fig.3(a) shows with the voltage increase, the transmittance of samples A1-A3 increased. As can be seen in Fig.3(b), with the decreasing average diameter sizes of polymer network, the threshold voltage (Vth) and the saturation voltage (Vsat) of samples A1-A3 increased. TheVthandVsatare inversely proportional to the average diameter sizes of the polymer network. Here, theVthandVsatcan be defined as the voltage when the saturation transmittance of PDLC film reaches 10% and 90%. The larger the domain size of the LC in PDLC composite films, the lower the polymer-LC interfaces anchoring energy. TheVthis a linear function of the reciprocal size of the domain size of the polymer network according to

where,Ais the anchoring energy of liquid crystal droplet,dis the film thickness,Ris the domain radius,Kis the effective elastic constant, Δεis the dielectric anisotropy,ωis the aspect ratio of an elongated droplet andε0is the vacuum dielectric constant[18,19].

As shown in Fig.3(c), CR is proportional to the average diameter sizes of the polymer network. CR is one of the parameters to describe the PDLC films’electro-optical performance, which can be defined asTon/Toff.CRof sample A1-A3 were 12.6, 10.5 and 7.4,respectively. The turn-on response time and turn-off response time are the switching times of the PDLC films.

Fig.3 Electro-optical performance curves of A1-A3 samples: (a) The voltage-transmittance curve; (b) Threshold voltage and saturation voltage; (c) Contrast; (d) On state response time and off state response time

As the content of cross-linking agent increases,the size of the liquid crystal microdroplets decreases gradually, and the density of the microdroplets increases. This increases the surface area of the liquid crystal microdroplets in the system that needs a greater voltage to drive all the liquid crystals along the electric field’s direction. As shown in Eq.(3), the anchoring energy of liquid crystal droplet increases with the increase of driving voltage, and Eq.(2) shows that the driving voltage is inversely proportional to the radius of the liquid crystal droplet. The orientation of liquid crystal droplet is difficult when the anchoring energy of liquid crystal increases. Thus, the size of the liquid crystal increases,more force is required for the orientation of the liquid crystal, and it is easier to restore the original state when the voltage is removed. So, the turn-on response time will gradually increase and the turn-off response time is inversely proportional to the turn-on response time.

3.3 Mechanical properties of PDLC films

In practical applications, the mechanical properties of PDLC films are as important as the electro-optical properties. Therefore, it is also necessary to explore the relationship between the mechanical properties and the morphology of the PDLC films.

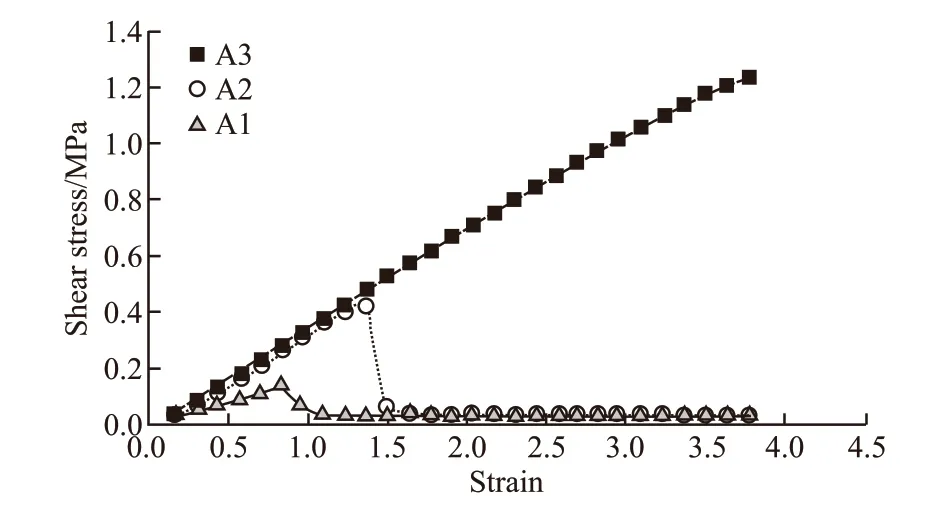

3.3.1 Experimental test

Fig.4 showed the shearing force-displacement curves of the PDLC films under the current system. It was obvious that the shearing force is inversely proportional to the size of the polymer network. The pore size of polymer network was decreased with the sharp increment of shearing force. The shearing force of sample A1-A3 were 0.14, 0.43 and 1.23 MPa, respectively.The sharp increment of shearing force was attributed to the density of polymer network increasing with the increase of crosslinking agent content. The area of contact between the polymer network of PDLC composite films and the PET substrate increases.

Fig.4 Shear force-displacement curves of sample A1-A3

3.3.2 Simulation and comparison

ANSYS is used to set up the finite element analysis simulation. Establishing a reasonable model can simplify the analysis time and the calculation amount of analysis can be reduced. The smallest polymer grid unit is taken here, and then ANSYS is used for modeling analysis and solution.

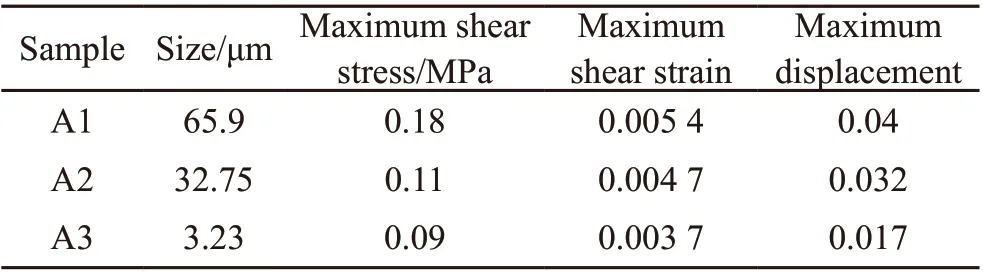

First, we need to obtain a series of mechanical property parameters by consulting, and plastic constitutive relation is adopted. Establish a 1/2 model for the minimum polymer grid cell to simplify the calculation.The Solid 185 and the Surf 154 were selected for this analysis. The shearing stress uniformly distributed on the upper and lower surfaces of the model are applied with the same resultant force and opposite direction.Then, the models fixed all degrees of freedom except the horizontal direction of upper and lower surfaces.Secondly, the small meshes around large domains need to considered. Simulation results show that these holes have little effect on the overall force and the rate of change was only 5.9%, which can be ignored. Finally,the simulation model and the simulation results are shown in Table 3. Under the same stress condition, the shear stress inside sample A1-A3 were 0.18, 0.11 and 0.09 MPa. It was observed that the shearing stress inside the polymer network was increased. Thus, the difficult of destroy sample A1-A3 grew in the sequence,and it can be a good agreement with the above experimental results.

Table 3 General post-proc of samples A1-A3

4 Conclusions

The effect of polymer network morphology on the electro-optical properties and the mechanical properties of the PDLC composite films were systematically investigated. As the ratio of cross-linking agent/diluent increases, the size of the liquid crystal microdroplets decreases gradually, and the microdroplets’ density increases. The increasing mesh size in this PDLC system decreased the films transmittance,CR,Vth,Vsatandton,while increasedtoffand the shear force. The electro-optical properties of PDLC composite films were inversely proportional to the domain size of the polymer network. The mechanical properties of PDLC composite films were proportional to the polymer network’s domain size. Thus, the domain sizes of the polymer network will have a certain influence on the performance of PDLC thin films.

杂志排行

Journal of Wuhan University of Technology(Materials Science Edition)的其它文章

- Preparation and Performance of Graphene Oxide Modified Polyurethane Thermal Conductive Insulating Adhesive

- Preparation of Controllable Cross-Linking Polyethylene Foaming Materials and Their Properties

- Enhanced Thermoelectric and Mechanical Properties of p-type Bi0.5Sb1.5Te3 Bulk Alloys by Composite Electroless Plating with Ni&Cu

- Fatigue Behavior of a Dissimilar Aluminum Alloy Welding Joint With and Without Natural Defect

- Characteristic of Near-surface Microstructure and Its Effects on the Torsion Performance of Cold Drawn Pearlitic Steel Wires for Bridge Cables

- Effects of Varying Copper Content on the Microstructure and Mechanical Properties of FeCoNiCux