一锅法制备S型异质结光催化剂Fe2O3/Fe2TiO5及其高效降解有机污染物性能

2022-09-16赵英杰寿幼平王江南石婷婷

常 方 赵英杰 寿幼平 张 騄 王江南 石婷婷

(交通运输部天津水运工程科学研究院,天津 300000)

0 Introduction

Water is one of the important resources that human beings depend on for survival and development.However,nearly a third of the population worldwide is estimated to lack access to safely managed drinking water services[1-2].In the last years,water pollution is becoming a major concern due to novel and dangerous anthropogenic pollutants.Reducing the release of wastewater into the environment and degrading the contaminants from wastewater are important strategies for water environment purification[3-5].

Many water treatment ways have been employed to degrade organic pollutants,such as physical absorption,biological purification,advanced oxidation processes(AOPs),electrochemical processes,and photocatalytic degradation.Among them,photocatalytic degradation is a kind of AOPs.Compared to traditional AOPs,the active-oxidizing species HO· or·O2-isin-situproduced by semiconductor photocatalysis[6-14].Semiconductor photocatalysts can be excited by light with energy higher than their band gap values,and then generate electron-hole pairs.Hole-electron pairs separate and transfer to the photocatalyst surface,produce HO· or·O2-,and then lead to the oxidation of organic pollutions.To obtain high photocatalytic efficiency,a semiconductor should have a small band gap enabling the utilization of a wide range of solar light[15-20].Fe2O3with a narrow band gap ofca.2.0 eV,can absorb a large amount of visible sunlight.Besides,Fe2O3has many other advantages,such as being lowcost,and non-toxic,making it a promising photocatalyst material.However,Fe2O3exhibits low conductivity and over-positive conduction band position,which are adverse to its photocatalytic efficiency.

Many strategies were employed to overcome these problems and improve photocatalytic efficiency on Fe2O3.Nano-engineering,intentional n-type doping,and electrocatalyst loading have been often used to improve charge separation efficiency or the surface oxidation rate[21-24].Besides,constructing heterojunction with another semiconductor material is an effective way to improve the separation of electron-hole pairs by the built-in electric field.This strategy has been successfully applied to many semiconductors[21-26],including BiVO4,WO3,TiO2,and so on.

Constructing heterojunction between Fe2O3particles and another semiconductor with a suitable band position benefits the separation of photo-generated carriers.Fe2TiO5is such a semiconductor with a band gap ofca.2.0 eV and similar to Fe2O3while showing higher conduction and valence band levels,which can form staggered band positions with Fe2O3,therefore,effective step-scheme(S-scheme)heterojunction can be developed between Fe2O3and Fe2TiO5[27-29].Moreover,Fe2TiO5exhibits a high conduction band level located atca.-0.2 eV vs reversible hydrogen electrode,making the composite materials propose the capacity to reduce O2to·O2-and further improve the photocatalytic properties.In previous reports,Fe2O3/Fe2TiO5composites were commonly applied in oxygen evolution[30-32],and rarely seen in pollution degradation[33].The preparing Fe2O3/Fe2TiO5composite was mainly by an ion-exchange method,i.e.employing Fe2O3or TiO2as the substrate to inter-react with Ti or Fe precursors at high temperature[30,32-33].Yu and Waqas fabricated Fe2O3/Fe2TiO5composite utilizing sol-gel and calcination method[31,34].

In this work,for the first time,Fe2O3/Fe2TiO5composite materials were prepared by a one-pot solvothermal method.Compared to the pure Fe2O3and pure Fe2TiO5,the photocatalytic properties toward removing methylene blue(MB)were significantly improved,which is mainly due to the promoted charge separation efficiency and the preserved higher-energy electrons from Fe2TiO5caused by the S-scheme heterojunction.

1 Experimental

1.1 Preparation of Fe2O3/Fe2TiO5 heterojunction particles

Fe2O3/Fe2TiO5heterojunction particles were fabricated by a solvothermal method.Firstly,2.51 mmol Fe(NO3)3·9H2O was added to 50 mL isopropanol.Under stirring,0.625 mmol of titanium isopropoxide was immediately added to the above solution.The precursor solution,after further being stirred for another 1 h,was transferred into a 100 mL Teflon-line stainless steel autoclave.Then the autoclave was sealed and heated in an oven at 150℃for 12 h.After cooling down naturally,the prepared precipitates were washed with deionized water four times.As-prepared precipitates were dried at 80℃overnight,then dried precipitates were annealed in air at 550℃for 2 h and then 700℃for 10 min.Then the Fe2O3/Fe2TiO5heterojunc-tion particles were obtained.

Fe2O3was prepared by the same steps employed for Fe2O3/Fe2TiO5fabrication, except that only Fe(NO3)3·9H2O was added to the precursor solution without titanium isopropoxide.Fe2TiO5was also prepared by this solvothermal method[31].In the precursor solution,2.51 mmol Fe(NO3)3·9H2O and 1.25 mmol of titanium isopropoxide were added in sequence.Other steps were the same as that of Fe2O3/Fe2TiO5fabrication.The photoelectrodes based on the prepared Fe2O3,Fe2TiO5,and Fe2O3/Fe2TiO5were also fabricated with the same process.Firstly,10 mg of each sample was dispersed in 1 mL glycol.20 μL solution was spincoating on F-doped SnO2coated glass(FTO),then another 20 μL solution was immediately dropped on the above FTO.After drying at 150℃for 30 min,the film was calcined at 600℃for 1 h.

1.2 Characterization

The crystal structures of the prepared samples were probed by a powder X-ray diffraction(XRD)on a Bruker diffractometer system,using CuKαradiation(λ=0.154 18 nm)with a working voltage and current of 40 kV and 40 mA,respectively.The scan rate was 0.04(°)·s-1in a 2θrange of 5°-70°.The morphology test of the samples was carried out on a field emission scanning electron microscope(SEM;JEOL,JSM-6700F with an accelerating voltage of 5 kV).The working voltage for SEM-EDS(EDS=energy dispersive X-ray spectroscopy)mapping was 20 kV.Transmission electron microscope(TEM)images were recorded on a transmission electron microscope(HT7700).Highresolution TEM(HRTEM)was conducted at 200 kV.The optical absorption spectra of the samples were performed on a UV-visible(UV-Vis)spectrophotometer(Shimadzu,UV-Vis 2550).Electrochemical impedance spectra(EIS)of the three photoelectrodes were measured at 0.9 V(vs RHE)using an electrochemical workstation(Shanghai Chenhua,660E)with a 10 mV amplitude perturbation and frequencies between 0.1 Hz and 1 MHz.

1.3 Photocatalytic property measurements

20 mg Fe2O3/Fe2TiO5was added into a 100 mL water solution with an MB concentration of 10 mg·L-1.After 40 min absorption,3 mL solution was filtrated and taken for the test.Then the remained solution was stirred and irradiated under light with a power of 100 mW·cm-2.TThe area of the beaker exposed to the light wasca.20 cm2.The light source used in this work was a 100 W LED lamp.The reaction solution was cooled by running water during the whole irradiating process to exclude the thermal effect.3 mL solution was taken every 30 min.Current-potential curves were tested on an electrochemical workstation using a three-electrode system.

2 Results and discussion

2.1 Characterization of Fe2O3,Fe2TiO5,and Fe2O3/Fe2TiO5

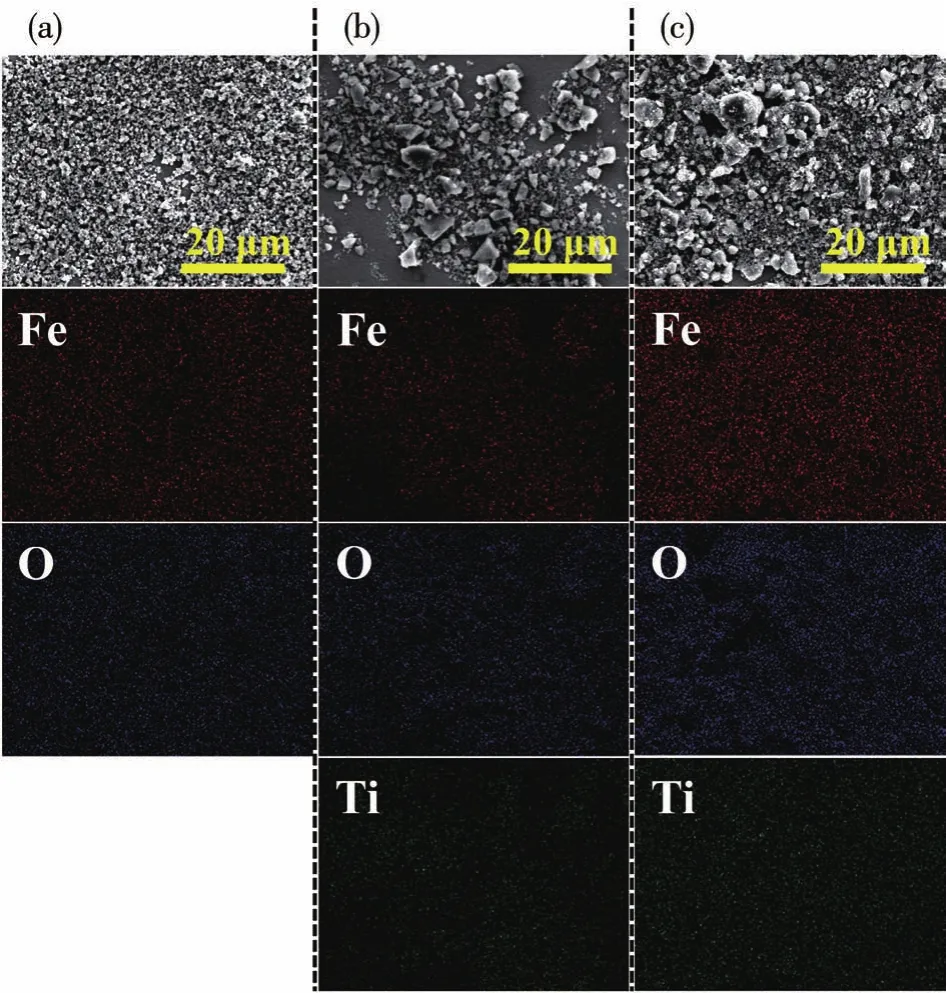

To investigate the crystallinity and phase of asprepared samples,XRD was carried out(Fig.1).All the peaks of the black curve at 24.2°,33.3°,35.7°,40.9°,49.5°,54.1°,57.6°,62.4°,and 64.1°can be assigned to Fe2O3(hematite,PDF No.33-0664),while all peaks of the red curve belong to the pseudobrookite Fe2TiO5(PDF No.41-1432).The results indicate that Fe2O3and Fe2TiO5have been successfully prepared.Both XRD peaks of Fe2O3and Fe2TiO5were observed in Fe2O3/Fe2TiO5,demonstrating that Fe2O3/Fe2TiO5was obtained by the one-pot solvothermal method.Moreover,the high peak intensity of the three samples indicates their well crystalline nature.Note that the prepared Fe2O3/Fe2TiO5composite showed only two relatively low peaks at 18.1°and 25.6°.To evaluate the contents of Fe2O3and Fe2TiO5in the composite,EDS has been per-formed.Elemental Ti was not observed in the pure Fe2O3,while in Fe2TiO5,both Fe and Ti were detected with an atomic ratio of 1.93 which is close to the Fe/Ti stoichiometric proportion in Fe2TiO5.In terms of Fe2O3/Fe2TiO5composite,the atomic ratio of Fe/Ti was 3.99,which is the same as the feed proportion,indicating the content of Fe2O3and Fe2TiO5was equal in molar quantity.EDS mapping on the three samples has also been tested and the results are shown in Fig.2.For Fe2O3/Fe2TiO5,Fe,O,and Ti were uniformly distributed in the sample,demonstrating that Fe2O3or Fe2TiO5can contact each other well.

Fig.1 XRD patterns of Fe2O3,Fe2TiO5,and Fe2O3/Fe2TiO5

Fig.2 SEM-EDS element mapping images of(a)Fe2O3,

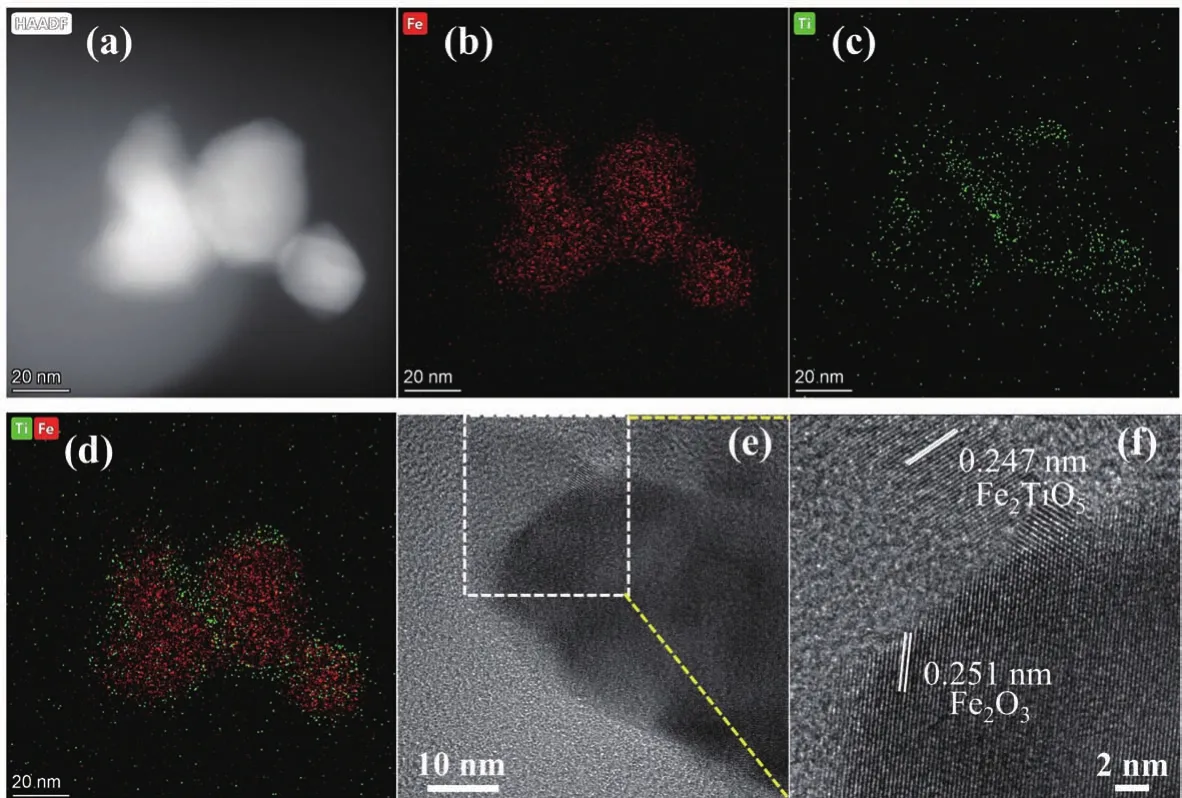

TEM was performed to further investigate the crystallinity and phase of the Fe2O3/Fe2TiO5composite.As shown in Fig.3b-3d,elemental Fe was evenly distributed in the particles,while elemental Ti is mainly distributed on the particle surface and interface.HRTEM has also been measured and the results are shown in Fig.3e and 3f.Fringe spacing of 0.251 and 0.247 nm can be indexed to the(110)plane of Fe2O3and(301)plane of Fe2TiO5,especially,demonstrating the formation of heterojunction between Fe2O3and Fe2TiO5.In addition,Fe2O3is well crystalline in the whole Fe2O3sample,while the crystalline region in Fe2TiO5is relatively small and enshrouded with an amorphous phase.This result indicates that Fe2TiO5spreads over the surface of Fe2O3,and the crystallinity of Fe2TiO5is restricted to some extent.Moreover,the TEM-EDS results suggest that the atomic ratio of Fe and Ti wasca.5.6,which is larger than the feed proportion and SEM-EDS values.It is understandable considering that part of small Fe2TiO5particles falls away from Fe2O3during the ultrasonic process.Overall,the results of XRD,SEM-EDS,and TEM demonstrate that Fe2O3/Fe2TiO5heterojunction composites have been successfully prepared.

Fig.3 TEM-EDS element mapping images(a-d),and HRTEM images(e,f)for Fe2O3/Fe2TiO5

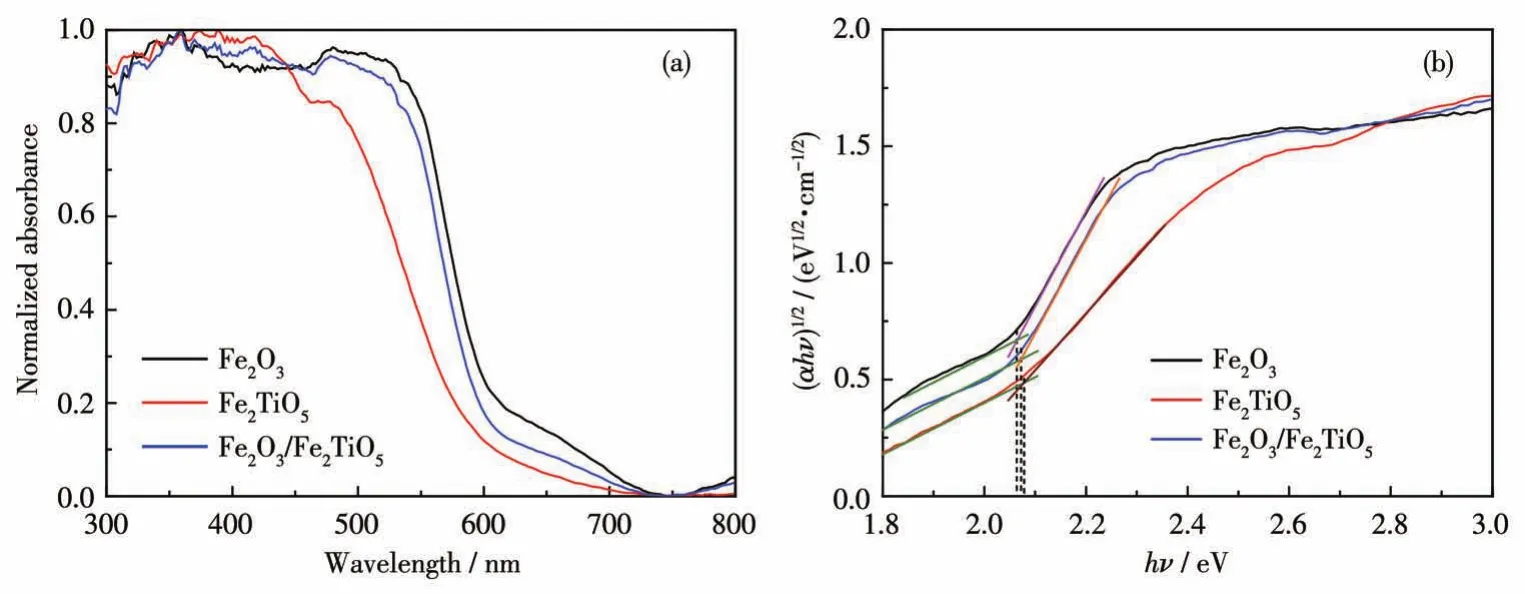

Light absorption properties show a great effect on the final photocatalytic degradation performance.Therefore,UV-Vis diffuse reflectance spectra(DRS)of the prepared samples were measured to evaluate their absorption properties.The UV-Vis DRS results have been converted to absorption form using the Kubelka-Munk function as shown in Fig.4a.Besides,the curves have been normalized.As shown in Fig.4a,all samples exhibited absorption regions from UV to visible wavelengths.Fe2O3exhibited the widest light absorption,while the absorption edge of Fe2TiO5blue shift compared to Fe2O3and proposed the narrowest light absorption region.While,from 500 to 600 nm,the absorption of Fe2O3/Fe2TiO5was higher than that of Fe2TiO5and smaller than the absorption of Fe2O3.The band gaps of Fe2O3,Fe2TiO5,and Fe2O3/Fe2TiO5were estimated by drawing Tauc plots,which are shown in Fig.4b.In the ordinate of the curves,n=2 represents the direct band gap,whilen=1/2 represents the indirect band gap[13,35].As Fe2O3and Fe2TiO5are indirect band gap semiconductors,n=1/2 was employed here to calculate their band gaps.The band gaps of the three samples were similar with the values of 2.05-2.08 eV,which match the previously reported values[31].

Fig.4 (a)Absorption spectra and(b)Tauc plots of Fe2O3,Fe2TiO5,and Fe2O3/Fe2TiO5

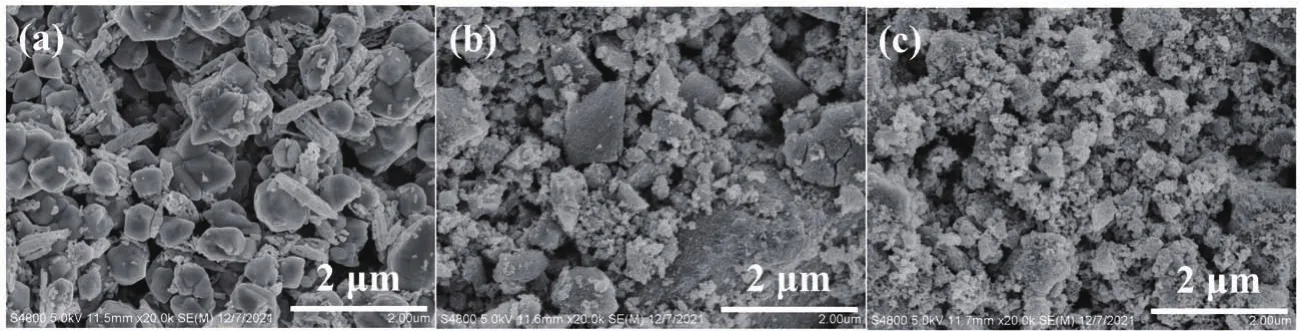

Morphologies of the prepared samples were analyzed by SEM.As shown in Fig.5,all the samples show an ellipsoidal shape with uniform distribution.The particle size of the nanoparticles was less than 50 nm.The small particle size enables a large semiconductor/solution interface,facilitating the injecting of photoexcited charges into the solution.In consideration of the similar shape and size of Fe2O3,Fe2TiO5,and Fe2O3/Fe2TiO5,their MB absorption amount should be a little different,which is following the MB absorption experiment.

Fig.5 SEM images of(a)Fe2O3,(b)Fe2TiO5,and(c)Fe2O3/Fe2TiO5

2.2 Photocatalytic performance

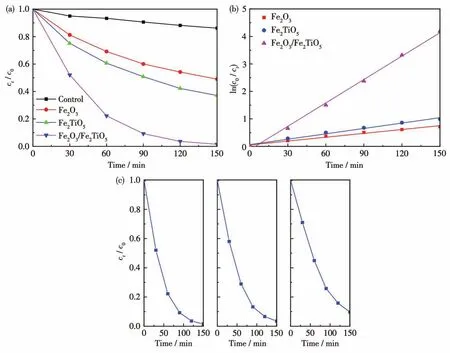

To evaluate the performance of Fe2O3,Fe2TiO5,and Fe2O3/Fe2TiO5,the photocatalytic degradation of MB organic pollutants experiments was performed.10 mg·L-1MB aqueous solution was employed in this experiment,the concentration of the three samples was 20 mg per 100 mL MB aqueous solution.The filter for filtering Fe2O3,Fe2TiO5,and Fe2O3/Fe2TiO5was saturated by MB first.After 40 min of adsorption-desorption equilibrium,the photocatalytic degradation experiment was carried out by exposing the illumination solution.2 mL solution was taken out from the MB solution every 30 min using a disposable syringe with the filter.The MB degradation rates on Fe2O3,Fe2TiO5,and Fe2O3/Fe2TiO5are shown in Fig.6a.Fe2O3/Fe2TiO5exhibited the highest degradation rate.The degradation efficiencies of the three samples were also calculated according to the formula of(c0-ct)/c0,wherec0is the initial concentration after adsorption-desorption equilibrium,ctis the concentration atttime.After 150 min irradiation,MB degradation efficiency of Fe2O3/Fe2TiO5reached 98.4%,while the efficiencies of Fe2O3and Fe2TiO5were just 50.9% and 62.9%,respectively.As discussed above,though the light absorption property of Fe2O3was better than that of Fe2TiO5,their photocatalytic activity was similar.This is because the conduction band minimum(CBM)of Fe2TiO5was higher and can reduce O2to·O2-,which provides another pathway for degradation,except for oxidizing MB by the hole in valence band maximum(VBM).Among the three samples,Fe2O3/Fe2TiO5presented the highest degradation rate and highest degradation efficiency.To further understand the photocatalytic degradation process,the data were fitted by a first-order kinetic equation,ln(c0/ct)=kt,which is commonly used as a mode to analyze organic pollutant degradation[35].The results are shown in Fig.6b,and the degradation rate constantkwas fitted from the slope of the line.Thekvalue of Fe2O3/Fe2TiO5was 2.787×10-2min-1,which is significantly higher than that of Fe2O3(5.06×10-3min-1)and Fe2TiO5(7.47×10-3min-1).

Fig.6 (a)Degradation performance of MB over the different samples;(b)Plots of ln(c0/ct)vs illuminated time;(c)Stability of Fe2O3/Fe2TiO5on MB degradation

To evaluate the stability of Fe2O3/Fe2TiO5,cycle tests for the photocatalytic degradation of MB were tested.The solid particles should be relatively evenly dispersed in the solution after ultrasonic dispersion before the reaction and agitation during the reaction.Moreover,the intermediate solution was taken each time.Therefore,after the first cycle,since the 10 mL solution has been taken out,ca.1/10 of Fe2O3/Fe2TiO5has also been taken out along with the solution.Therefore,we just added MB into the remained 90 mL solution to keep MB and the catalyst concentrations still at 10 and 0.2 mg·mL-1,respectively.As shown in Fig.6c,compared with the 1st cycle,although the degradation rates of the 2nd and 3rd cycles slightly decreased,degradation rates were still high.This result indicates the high stability of as-synthesized Fe2O3/Fe2TiO5composite material.

2.3 Mechanism for the improvement

Photocatalytic performance highly depends on light absorption of the semiconductor and charge separation in the bulk semiconductor.As discussed above,the light absorption property of Fe2O3/Fe2TiO5was not the best,the highest photocatalytic property of Fe2O3/Fe2TiO5must result from the significantly improved charge separation efficiency.Moreover,in Fe2O3/Fe2TiO5,besides the preserved higher-energy holes from Fe2O3which oxidize MB,the preserved higherenergy electrons from Fe2TiO5which provide another pathway for MB degradation.

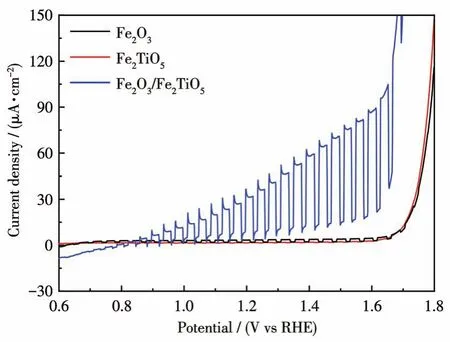

To verify the mechanism proposed above,photoelectrodes based on Fe2O3,Fe2TiO5,and Fe2O3/Fe2TiO5were prepared to evaluate their separation efficiency of the photogenerated charge carriers.The photoelectrodes were tested in a three-electrode system,where photoelectrode was used as a working electrode,Ag/AgCl was used as a reference electrode,and Pt was used as the counter electrode.The scan rate was 30 mV·s-1.The electrolyte was 1 mol·L-1NaOH.As shown in Fig.7,the Fe2O3/Fe2TiO5photoelectrode presented significantly higher photocurrents than that of Fe2O3and Fe2TiO5.The significantly increased photocurrent density of Fe2O3/Fe2TiO5can be attributed to the higher charge separation efficiency due to the formed heterojunction between Fe2O3and Fe2TiO5[27].

Fig.7 Chopped current vs potential curves on Fe2O3,Fe2TiO5,and Fe2O3/Fe2TiO5photoelectrodes

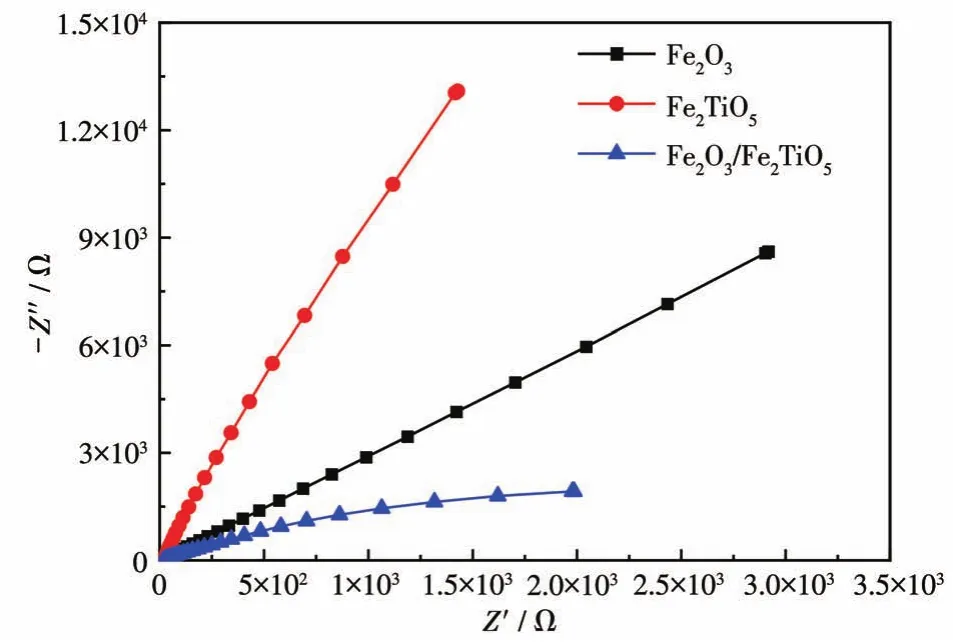

EIS was also conducted to confirm the charge transport properties of the three samples.As shown in Fig.8,the Fe2O3/Fe2TiO5photoelectrode exhibited the smallest diameter,indicating the faster charge transfer kinetics in the film.This phenomenon can be attributed to the build-in field induced by the heterojunction between Fe2O3and Fe2TiO5since the built-in field can facilitate the separation of electron-hole pairs.It should be pointed out that the charge transfer resistance of Fe2O3is smaller than that of Fe2TiO5,which is consistent with the reported result[36].

Fig.8 Nyquist plots of the Fe2O3,Fe2TiO5,and Fe2O3/Fe2TiO5photoelectrodes

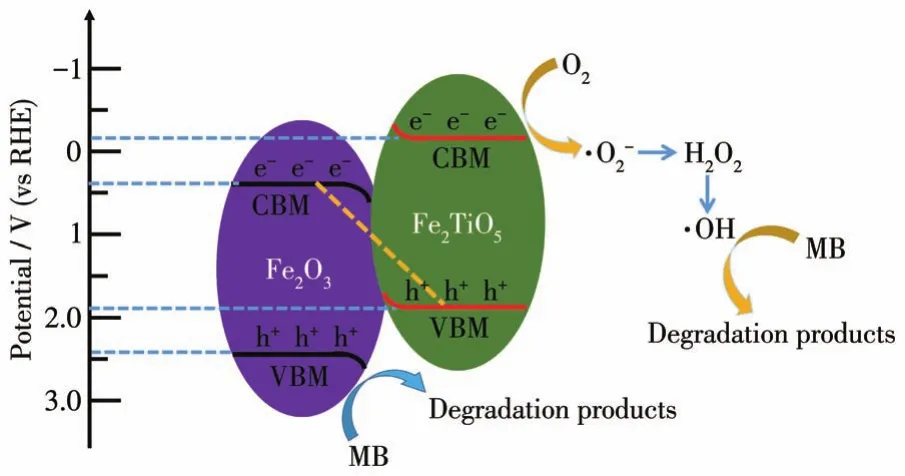

A possible mechanism for photocatalytic degradation of MB by Fe2O3/Fe2TiO5is illuminated in Fig.9.Fe2TiO5has higher CBM and VBM levels than that Fe2O3.Under irradiation,Fe2O3and Fe2TiO5absorb light and generate electron-hole pairs,respectively.An S-scheme heterojunction[37]is formed between Fe2O3and Fe2TiO5.In this S-scheme heterojunction,electrons in CBM of Fe2O3and holes in VBM of Fe2TiO5can recombination with each other,while holes in VB of Fe2O3and electrons in CBM of Fe2TiO5separate and transfer to Fe2O3/solution and Fe2TiO5/solution surface,respectively.Due to the recombination electrons presenting relatively lower energy,the preserved electrons with higher energy in FeTiOcan reduce Oto·O-,2522and then produce·OH,which can degrade MB effectively.While the reserved holes in Fe2O3can degrade MB directly.Therefore,the Fe2O3/Fe2TiO5heterojunction can remove MB more effectively.

Fig.9 Schematic diagram of charge carrier transfer process and possible photocatalytic mechanism of Fe2O3/Fe2TiO5

3 Conclusions

In summary,Fe2O3,Fe2TiO5,and Fe2O3/Fe2TiO5have been prepared by a facile one-pot solvothermal method.In Fe2O3/Fe2TiO5,Fe2O3and Fe2TiO5can form S-scheme heterojunction,and thus promotes the electrons in CB of Fe2TiO5and holes in VB of Fe2O3transfer to the surface.In this way,carriers with higher energy were preserved.Compared to Fe2O3and Fe2TiO5,the photocatalytic degradation rate and efficiency of Fe2O3/Fe2TiO5were significantly improved.This approach provides a facile way to achieve Fe2O3/Fe2TiO5S-scheme heterojunction materials and can offer a reference to construct heterojunction on other materials.

Acknowledgments:The National Nonprofit Institute Research Grants of TIWTE(Grant No.TKS190408),Science and Technology Development Fund of Tianjin Waterway Engineering Research Institute,Ministry of Transport(Grant No.KJFZJJ190201),and Scientific Research Program of Shanghai Science and Technology Commission(Grant No.19DZ1204303).