Hybridization of activated carbon fiber cloth with electrospun nanofibers for particle filtration

2022-08-14YANGYunlongLIMingzheHOUShiyuLURuitaoKANGFeiyuHUANGZhenghong

YANG Yun-long, LI Ming-zhe, HOU Shi-yu, LU Rui-tao, KANG Fei-yu, HUANG Zheng-hong,*

(1. Key Laboratory of Advanced Materials (MOE), School of Materials Science and Engineering, Tsinghua University, Beijing 100084, China;2. School of Chemical and Environmental Engineering, China University of Mining and Technology (Beijing), Beijing 100083, China)

Abstract:Activated carbon fibers (ACFs) have high adsorption capacities and can be used in the treatment of benzene, while electrospun nanofibers are expected to be used as a filtration material. In this work, two hybrids of electrospun nanofibers and ACF cloth were prepared by electrospinning polyvinyl alcohol and polyacrylonitrile nanofibers into a phenolic resin-based ACF cloth. The filtration performance of the two hybrids was evaluated. Results indicate that there is a positive correlation between the filtration efficiency and the amount of electrospun nanofibers in the hybrid. The filtration efficiency increases with increasing air velocity, which is attributed to a piezoelectric effect introduced by the electrospun nanofibers. The hybrids have a good adsorption capacity for benzene, which suggests that the materials are promising for treating air pollution.

Key words: Electrospun nanofibers;Activated carbon cloths;Air particles filtration;Benzene;Adsorption

1 Introduction

Nowadays, haze and inhalable particulate matters have become severe air problems which further result in huge air pollution and a great threat to the public health. As the cause of haze and inhalable particulate matters, the air particles have been one of the major air pollutants, which leads to the increased risk of respiratory disease, cardiopulmonary disease and lung cancer[1-3]. Thus the removal of air particles is regarded as a necessary protection technique to human health up to now. Meanwhile, as the emission of volatile organic compounds (VOCs) increased with the developing of industry[4], benzene, one of major VOCs, leads to indoor air pollution and great cancer risk to human health. Therefore the removal technique for benzene is necessary to public health as well.

In order to remove the air particles, several physical techniques for air particles removal have been researched and applied so far, such as filtration, electrostatic precipitator. The filtration by fibrous filter is considered as a common and effective method to remove the air particles because of the low cost and the low-pressure drop[5-8]. Early in 1936, the enhancement of materials’ filtration performance by using electrospun nanofiber has been paid attention[9]. Up to date, various studies show that it is effective to load electrospinning nanofibers onto the glass fiber[10], organic and cellulose substrates base filter materials to enhance filtration performance[11]. Several factors influenced the filtration performance of electrospun nanofibers have been reported as well[12,13]. Currently,the electrospun nanofibers are considered as promising filtration materials[14], even towards the fine air particles removal[15,16]. Furthermore, as electret filter materials[17,18], electrospun nanofibers have flexible piezoelectric, which could improve the filtration efficiency of filters[19]. Thus, the electrospun nanofibers could be widely used for face mask, medical filter and protective clothing[20-22].

On the other hands, for benzene removal, different methods have been researched, such as adsorption,thermal oxidation, catalytic oxidation[23]. The adsorption by using porous carbon materials as the adsorbent, such as activated carbon (AC), activated carbon fiber (ACF), is seen as an effective method to remove the benzene, because of the high benzene adsorption velocity and large benzene adsorption capacity[24-28].

However, there are few studies focused on the materials which both have a high air particle filtration performance and an excellent benzene adsorption abil-ity. In this work, two hybrids of electrospun nanofibers and activated carbon cloths were prepared by electrospinning polyvinyl alcohol (PVA) and polyacrylonitrile (PAN) nanofibers on phenolic resin based activated carbon fiber (PRACFC). The filtration efficiency of two series of hybrids was evaluated through the filtration test under various air velocities. Benzene dynamic adsorption was also performed to evaluate adsorption performance. The hybrids of electrospun nanofibers and activated carbon cloth were proved to both have a high filtration performance and an excellent adsorption capacity, which is promising in the field of air pollution treatment.

2 Experimental

2.1 Raw materials

The raw materials include d phenolic resin based activated carbon fiber clothes (PR-ACFC, kynol Inc,Japan), polyvinyl alcohol (PVA, Sigma-Aldrich, molecular weight of 13 000-23 000), polyacrylonitrile(PAN, Sigma-Aldrich, average molecular weight of 150 000), dimethyl formamide (DMF, Sigma-Aldrich,anhydrous, 99.8%), hexadecyl trimethyl ammonium bromide (CTAB, Sigma-Aldrich, BioXtra, ≥99%),polypropylene melt-blown nonwoven filter (TM-F9 ,average diameter of 0.5 μm, Jinhai group, Zhuji,China), and glass fiber nonwoven filter (FR90N-H13,average diameter of 0.35 μm, Jinhai group, zhuji, and China). The PR-ACFC (PR20) has a specific surface of 2 179 m2·g−1, pore volume of 0.862 cm3·g−1, pore width of 1.07 nm.

2.2 Preparation of hybrid materials

The PVA precursor solution for electrospinning was prepared by dissolving 8% PVA in water with 0.05 g of CTAB, and stirred until complete dissolution under water bath of 80 °C. The precursor solution of PAN was prepared by dissolving 10% PAN in DMF, and stirred until complete dissolution under water bath of 80 °C.The PAN and PVA are consider as two stable precursors and easy to be electrospun. The average diameter of PAN and PVA electrospun nanofibers are about hundreds of nanometers. In this scale, nanofibers cannot cover the microporous structure of ACFC, which give ACFC a good adsorption performance. At the same time, the PAN and PVA electrospun nanofiber will offer a filtration performance. The hybrid samples were prepared by electrospinning the PVA or PAN nanofibers onto the square ACFC (8×8 cm2, 0.552 g), with the electrospinningc voltage of 20 kV, the distance between the nozzle and the ACFC of 20 cm, the speed of precursor solution injection of 1 mL·h−1under room temperature. 0.002-0.015 g nanofibers were electrospun onto ACFC. The two hybrid species, prepared by PVA and PAN precursor solutions, were named PRPVA and PRPAN,respectively.

2.3 Filtration efficiency tests

To verify the atmospheric particles filtration performance of the hybrid fiber samples, a test system was set up (Fig. 1). The system consists of an airflow generation system, an airtight metal filtration tube and an atmospheric particles detection system. The airflow generation system consists of an air velocity controller and a vacuum pump to generate stable air flow.The air velocity was detected by anemograph (KANOMAX 6006) and manometer (Shanghai Linsheng DP1000-1F). Sample was mounted in the middle of filtration tube. The atmospheric particles detection system consists of two CSJ-EⅡ laser particle counters, which could detect atmospheric particles amounts before and after filtration.

To compare the filtration efficiency of PRPAN,PRPVA and PR20, a filtration efficiency experiment under the same air velocity of 0.1 m·s−1was carried out. Two kinds of commercial filtration materials(TM-F9, with the filtration efficiency between 90%and 99% and particle size larger than 1.0 μm; FR90NH13) the filtration efficiency higher than 99.99% for particle size larger than 0.5 μm, were also tested for comparison. Filtration tests were carried out under different air velocity in the range of 0.1-2 m·s−1. The sampling period was 1 min, and the sampling volume was 2.83 L·min−1, which means that the sampling air volume was 2.83 L.

2.4 Benzene dynamic adsorption tests

The benzene dynamic adsorption of the composites was measured by using a dynamic adsorption system in Fig. 2. Dynamic adsorption system consists of a controller, a thermostat (SPX-150AB), a rectangle reactor (2×2×4 cm3) coupled to a gas chromatography(SHIMADZU, GC-14c) and controlling computer.The hybrid fiber cloth was cut into square samples(2×2 cm2), which was supported by two square honeycomb ceramics (2×2×2 cm3). The benzene dynamic adsorption tests were carried out under 298 K. The concentration of mixture gas was controlled by adjusting the flow rates of nitrogen and benzene, and the flow rate of mixture gas was 200 mL·min−1. The mixture gas with 30×10−6benzene fed in the adsorption test system continuously until the benzene concentration of exhaust stream reached the set breakthrough concentration. The adsorption capacity of samples could be calculated through the following equations

Mprepresents the total benzene adsorption amount (mol),tprepresents breakthrough time (min),c0represents the initial benzene concentration,c(t)represents the benzene concentration of exhaust stream (×10−6),vrepresents the flow rate of mixture gas (200 mL·min−1),Qprepresents the adsorption capacity of sample (mg·g−1),Mbenrepresents the molar mass of benzene (78.11 g·mol−1),mprepresents the m ass of sample (g).

3 Results and discussion

3.1 Morphologies of hybrid materials

Fig. 3 shows the scanning electron microscopy(SEM) images of PRPVA and PRPAN. Both in PRPVA and PRPAN, a thin layer of smooth, continuous and dispersive electrospun nanofibers were formed on the surface of ACFC. It is difficult to find cross-linking between PVA nanofibers (Fig. 3a),however, it is easy to find some tubercle structure in PAN nanofibers layer (Fig. 3b).

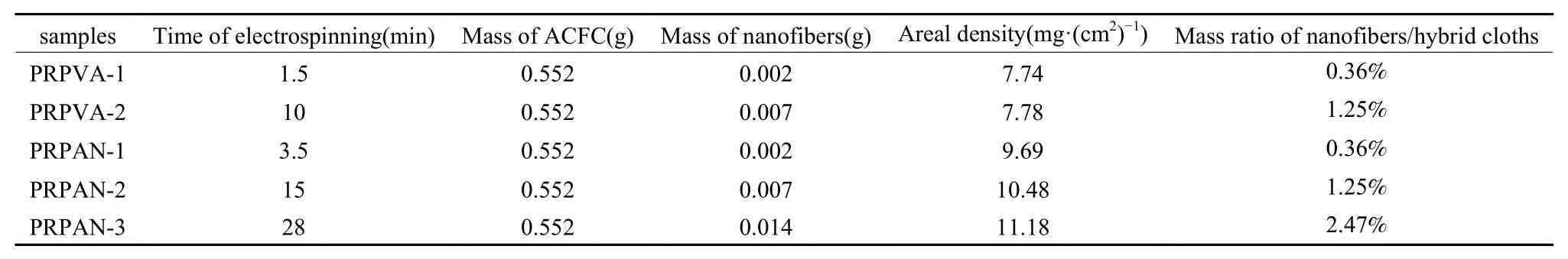

The SEM with high magnification in Fig. 3 shows that both the PAN nanofibers and PVA nanofibers have smooth surface, and the nanofibers of PAN and PVA are well dispersive. The average diameter of PVA electrospun nanofiber is about 500 nm(Fig. 3 (c)), while the average diameter of PAN electrospun nanofiber is about 300 nm (Fig. 3 (d)). The PAN nanofibers are thiner than the PVA nanofibers,which means PRPAN may have more electrospun nanofibers than PRPVA when the electrospinning nanofibers have the same mass. The difference between the PAN nanofibers and PVA nanofibers may affect the filtration and adsorption of materials.In order to discuss two series of electrospun nanofibers/ACFC hybrid, different amounts of nanofibers were electrospun on the ACFC, as listed in Table 1.

Table 1 Features of electrospun nanofibers/phenolic resin based carbon fibers hybrid cloths.

3.2 Filtration efficiency

All filtration efficiencies of hybrid materials towards airborne particles were tested, as shown in Fig. 4. PR20 has the lowest filtration efficiency.However, PRPVA and PRPAN have high filtration performances. It indicates that the substrate material PR20 has little filtration against airborne particles,while the electrospun nanofibers endow the substrate material PR20 with air particle filtration ability. The filtration efficiency of PRPAN nanofiber is higher than PRPVA nanofibers when the electrospun nanofibers with the same mass are loaded, which may be due to the diameter difference between PAN nanofibers and PVA nanofibers, according to the Table 1.The PRPAN-1 and PRPVA-1 have loaded the same mass of electrospun nanofibers, as shown in Fig. 4.The PRPAN-1 has a higher filtration efficiency than PRPVA-1, and the PRPAN-2 and PRPVA-2 show the same trend. From Fig. 3(c, d), the average diameter of PAN and PVA nanofibers were obtained, and the PAN electrospun nanofibers is thinner than PVA electrospun nanofibers obviously. This difference makes the PRPAN have more nanofibers than PRPVA when the same mass nanofibers are loaded, leading to an advantage of PRPAN. The curves also illustrate a positive correlation between the filtration efficiency and electrospun nanofibers amount. The filtration efficiency of PRPAN-3 is close to the commercial filtration materials.

The presented curves were obtained under a low air flow velocity of 0.1 m·s−1. The filtration experiments under different air velocities in the range of 0.1-2 m·s−1were carried out to obtain the filtration efficiency of PRPVA, PRPAN and commercial filter materials. The filtration efficiency increased with the increasing of electrospun nanofibers mass of hybrids(Fig. 4). Therefore, PRPVA-2 and PRPAN-3 were selected as typical samples for comparison with the commercial filtration material (FN90-H13). The filtration efficiency of three samples under different air flow velocity are shown in Fig. 5. The different color curves stand for different particle diameters (0.3, 0.5,1, 3 μm).

Generally, the filtration efficiency of commercial filtration materials decreased with the increasing of air flow velocity[29]. Fig. 5 shows that the filtration efficiencies of PRPVA (Fig. 5a) and PRPAN (Fig. 5b)increased with the increasing of air velocity, which is contrary to the commercial high efficiency particulate air filter materials of FN90-H13 (Fig. 5c). It suggests that the PRPVA and PRPAN have an excellent filtration performance under a high air velocity. The electrostatic force between filter and particle could significantly improve the filtration performances of filter[22,30,31]. As the substrate of hybrid materials, the distance among activated carbon fibers is much lager than the particles diameter, indicating that the ACFC substrate will not affect the filtration. Therefore, the difference of hybrids with the commercial filter material could be attributed to the piezoelectric effect of electrospun nanofibers[32,33]. During the preparation of hybrid, a high voltage applied to the nanofibers makes electrospun nanofiber catch a lot of electrostatic charges, which play an important promoting role in the air particle filtration of electrospun nanofiber. In the process of filtration, a high air velocity will result in the deformation of hybrid, and the piezoelectric effect will become much stronger than that under low air velocity. Consequently, the generated charges will enhance the Coulombic force between the filter and air particles[7,30]. Therefore, the filtration efficiencies of PRPVA and PRPAN are positively correlated with air velocity, compared with the commercial filter media relied on mechanical filtration. The PRPVA and PRPAN prepared by electrospinning PVA and PAN nanofibers on ACFC cloths possess excellent filtration performance especially under high air velocity. It is promising for the hybrid materials to be used for air particles filtration under high air velocity.

3.3 Dynamic adsorption

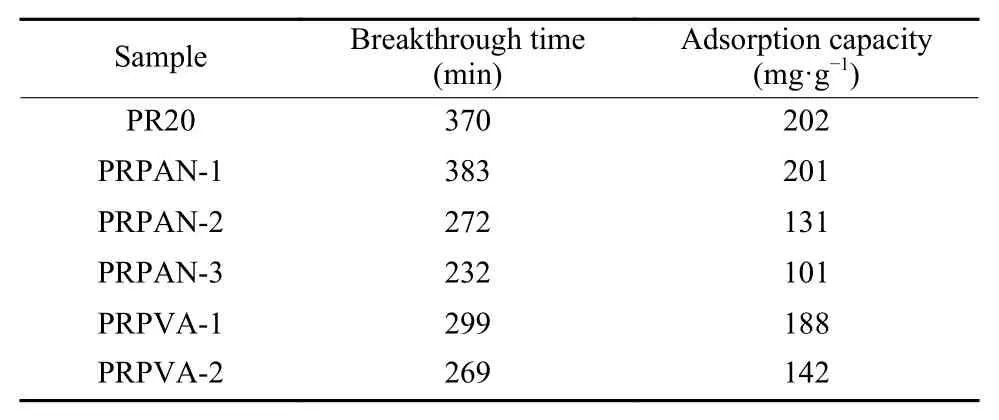

Benzene dynamic adsorption experiment was carried out to verify benzene adsorption performance.The benzene breakthrough curves of PRPAN and PRPVA are shown in Fig. 6. For the same series of samples, the adsorption capacities of hybrid decreased with the increasing of electrospun nanofibers.Comparing two series of PRPVA and PRPAN samples, PRPAN series have better adsorption performances than PRPVA for the same electrospun nanofibers amount. The breakthrough adsorption capacities of the PRPAN and PRPVA samples were obtained by integration, as listed in Table 2. The benzene dynamic adsorption of PR20 was carried out to determine the adsorption capacity of the substrate material as 202 mg·g−1.

Hybridizing with electrospun nanofibers, ACFC cloths are endowed with filtration ability against particles. However, their adsorption capacities towards VOC decreased. It can be seen from Table 2 that PRPAN-1 has a similar adsorption capacity to PR20, and the adsorption capacity of PRPVA-1 is 188.00 mg·g−1, which is lower than PR20. Thus, the adsorption performances were slightly affected by hybridizing tiny amount of electrospun nanofibers(0.36%). However, the adsorption capacity of hybrid materials decreased with the increasing of electrospun nanofibers. SEM image shows that the nanofibers are dense and spread randomly on the ACFC surface. Obvious pore coverage did not appear on sample surface, and the spreading of benzene molecule on the activated carbon cloth was somewhat blocked by the loaded electrospun nanofibers, leading to the decrease of adsorption capacity. When the nanofibers mass ratios reached at 2.47% (PRPAN-3) the adsorption capacity decreased by half (101 mg·g−1).The porous structure of activated carbon fiber plays an important role in the adsorption of VOC, and the surface coverage of nanofibers inevitably affected the porous structures of ACFC[26,34,35]. Because PAN nanofibers have thinner diameter, the PRPAN-series have less surface coverage and lower resistance to benzene molecular diffusion in comparison with PRPVAseries. Thus, the adsorption performances of PRPANseries are better than PRPVA-series. For the PRPAN-1 and PRPVA-1, tiny amount of electrospun nanofibers have little influence on the adsorption performances. The hybrid materials have a promising application in the simultaneous treatment of air particles and VOC.

Table 2 Calculate adsorption capacity of samples.

4 Conclusion

In this work, 2 series of hybrids of electrospun nanofibers and activated carbon hybrid materials cloths (PRPVA and PRPAN) were prepared by electrospinning PVA and PAN nanofibers onto phenolic resin based ACFC. The air particles filtration efficiency of hybrid cloths increases with the increasing of air velocity, which are different from the commercial filter materials. This unique performance of hybrids of electrospun nanofibers and activated carbon cloths could be attributed to the piezoelectric effect introduced by electrospun nanofibers. Moreover, distinct from the traditional commercial filter materials,the hybridization of activated carbon cloths with electrospun nanofibers gives a high air particle filtration efficiency. In addition, the hybrids also have an excellent benzene adsorption performance. The advantages allow such hybrids of electrospun nanofibers and activated carbon cloths have a promising application in urban air purification, industrial waste gas treatment,and air pollution prevention and control.

杂志排行

新型炭材料的其它文章

- Guide for Authors

- A correlation of the hydrogen evolution reaction activity to the number of defects formed by the decomposition of doped phosphorus species in carbon nanotubes

- Electrochemical sensing of phenacetin on electrochemically reduced graphene oxide modified glassy carbon electrode

- A sustainable strategy to prepare porous carbons with tailored pores from shrimp shell for use as supercapacitor electrode materials

- The synthesis of porous carbons from a lignin-rich residue for high-performance supercapacitors

- 《新型炭材料》征稿简则