Enhanced thermal conductivity and microwave dielectric properties by mesostructural design of multiphase nanocomposite

2022-07-26LipingZhouPengXuFaxiangQin

Liping Zhou,Peng Xu,Faxiang Qin

Institute for Composites Science Innovation (InCSI),School of Materials Science and Engineering,Zhejiang University,38 Zheda Road,Hangzhou,310027,PR China

Keywords:Immiscible blends Nanocomposite Microwave dielectric properties Thermal conductivity

ABSTRACT Next-generation packaging materials are expected to have higher thermal conductivity,because the heat accumulated in high-performance electronic equipment should be removed to increase the service life of the equipment.At the same time,the dielectric loss of the material needs to be reduced to lessen signal delay and attenuation,especially for the applications under high frequency.In this work,we introduce nano-silicon carbide(SiC) and carbon nanotubes (CNTs) into the polystyrene (PS) and poly(methyl methacrylate) (PMMA) blends system.The design of two-way migration at the interface of CNTs and SiC nanoparticles is realized through the masterbatch method and processing technology control.As a result,the thermal conductivity is successfully increased up to 75%.Meanwhile,compared to the CNTs single-phase migration system,it effectively reduces the dielectric loss of the nanocomposite and optimizes the electrical insulation.This work has significant practical application value in the design of electronic device substrates and packaging materials,and provides an innovative methodology for the mesostructure design of multiphase nanocomposites.

1.Introduction

Recently,high integration and high power in modern electronic device fields lead to sharp reduction in products size and increasing power density [1–3].Therefore,the demand for high thermal conductivity of electronic packaging or substrate materials is gaining momentum to improve the stabilities and service life of the products [4,5].Moreover,with the advent of the era of 5G and higher frequency communications,there are also new requirements for the high-frequency dielectric properties of materials[6].Due to the excellent processability and mechanical properties,polymer matrix composites modified with thermally conductive nanofillers have attracted extensive attention [7–9].Adding carbon nanomaterials with extremely excellent thermal conductivity(such as carbon nanotubes and graphene,etc.) [10,11] can effectively reduce the filler loading.However,at the same time they will form conductive networks in the composite which will result in higher dielectric loss,signal delay and attenuation [12,13].Therefore,it is necessary to research and develop polymer nanocomposites that can coordinate and optimize the microwave dielectric loss,electrical insulation,and thermal conductivity.

The construction of double percolation structure in co-continuous immiscible blends is considered to be an effective way to reduce the loading of fillers while retaining high electrical conductivity [14,15] or thermal conductivity [16,17].Chao et al.[18] built up PC/PA66/AlN/MWCNT quaternary nanocomposites to achieve a stable thermal conductive network via a sequential melt mixing technique where hybrid fillers are both selectively located in the PA66 phase.Owing to the intrinsic continuous structures,three-dimensional interconnected heat-conductive networks can increase the thermal conductivity of composites more effectively [1,19,20].In particular,in the co-continuous structure of immiscible polymer blends,a three-dimensional interface can be formed spontaneously[21,22].In our previous research,the localization of CNTs at the interface in PS/PMMA immiscible system has been achieved by controlling the processing technology and masterbatch method,which can significantly increase the dielectric constant of the composites [23].However,the dielectric loss increases at the same time.On this basis,we introduce another thermally conductive nanofiller (SiC) into the system.Based on the migration characteristics of nanoparticles in the immiscible polymer blends [24,25],we design a bridging structure of the two hybrid nanofillers at the interface.Through the synergistic effect of CNTs and SiC,the leakage conduction loss caused by CNTs is reduced.Meanwhile,the thermal conductivity of composites can be improved effectively.As such,this structure is very innovative in the design of multi-phase nanocomposites and it provides a new design idea for the optimization of multi-functional nanocomposites performance.

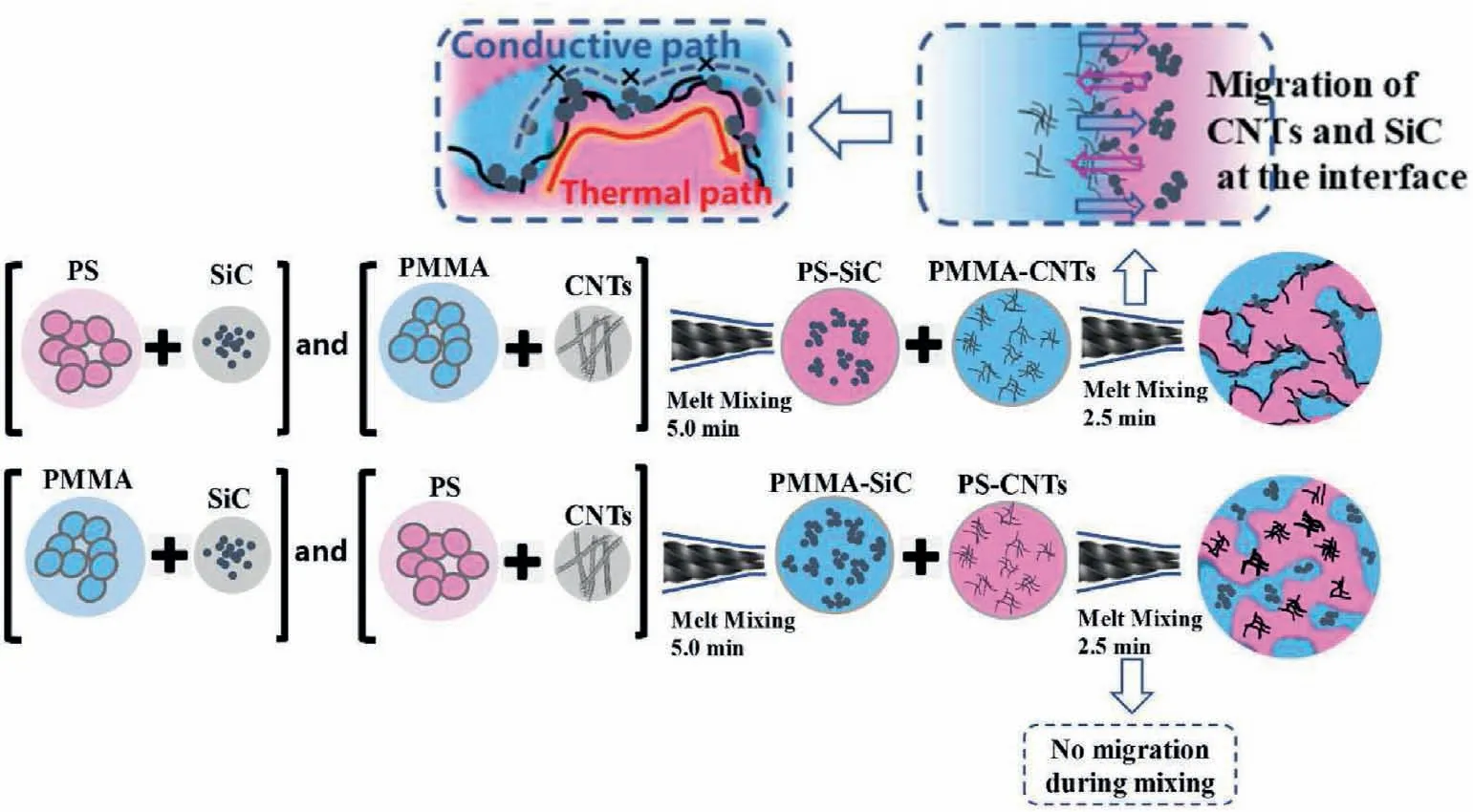

Fig.1.Schematic diagram of the processing technology and the blocking of the conductive path and the promotion of the thermal path caused by the migration of nanofillers.

2.Experimental

2.1.Materials

Polystyrene (PS) resin pellets with General-purpose type I and Polymethyl methacrylate(PMMA)pellets with high flow injection stage were received from Aladdin Shanghai (China).Pristine CNTs (purity:95%,outer diameter:<8 nm,inner diameter:2–5 nm,length:10–30 μm)were obtained from Chengdu Organic Chemicals Co.Ltd.,Chinese Academy of Sciences.

2.2.Nanocomposites preparation

The polymers were dried at 60°C for 24 h to remove moisture before use.For no migration system,the nanocomposites were prepared in a two-step process.Firstly,CNTs and PS or SiC and PMMA were mixed on Miniature High-performance Composite Material Mixing Molding System(HAAKE MiniLab II)at 200°C and 60 rpm for 5 min to obtain SCNTs and M-SiC masterbatches(here M stands for PMMA phase,S for PS phase).Secondly,the S-CNTs masterbatch was blended with PMMA or M -SiC at 200°C and 60 rpm for 2.5 min to obtain nanocomposites without migration of CNTs and SiC named as M/S-CNTs and M-SiC/SCNTs,respectively.The same processing technology was also applied to the migration system,here the masterbatches were M-CNTs and S–SiC.Then the M-CNTs masterbatch was blended with PS or S–SiC to prepare M-CNTs/S and M-CNTs/S–SiC which will avail nanofillers migration at the polymer-polymer interface.The concentration of CNTs in the nanocomposites is 1 vol%(CNTs1)or 2 vol%(CNTs2),and the loading of SiC is 1 vol%(SiC1)or 2 vol%(SiC2).The volume ratios of masterbatch were set at 50/50 to obtain co-continuous morphology of blends.

2.3.Morphology characterization

The cold field-emission scanning electron microscopy (FE-SEM,Hitachi S-4800) with accelerating voltage of 3 kV was employed to analyze the morphology of the samples.The samples were first fractured with liquid nitrogen treatment and then use formic acid solvent to dissolve PMMA phase to clearly distinguish the two-phase.

TEM measurements were performed on a HT-7700 transmission electron microscopy operated at an acceleration voltage of 100 kV to analyze the localization and migration of the CNTs and SiC.The specimens were cut into films with a thickness of 50 nm by Ultra-thin frozen slicer(EMUC7)equipped with a glass knife.

2.4.Dielectric measurements

Dielectric measurements in the frequency range of 8.2–12.4 GHz were performed by vector network analyzer (R&S,ZNB20) and the complex permittivities were extracted from the S-parameters by Nicolson-Ross-Weir method.The cuboid shaped specimens(22.86×10.16×2 mm)compressed at 200°C were used.

2.5.Electrical conductivity measurements

Compression molded samples (20 mm×20 mm×1 mm) at 200°C were prepared for electrical conductivity measurements.DC electrical conductivities at room temperature were recorded using a CHI 660E electrochemical analyzer from CH Instruments by linear sweep voltammetry(LSV).

2.6.Thermal conductivity measurements

The thermal conductivity of the nanocomposites was measured on TPS 2500 S(Hot Disk Company,Sweden)The test method is the transient planar heat source method,which is suitable for measuring most materials.The sample (diameter 40 mm,thickness 4 mm) required for the measurement is obtained through the hot pressing process consistent with the above measurements.

3.Results and discussions

3.1.The morphologies of nanocomposites with different nanofillers localization

In this work,we choose masterbatch method to realize the distribution control of nanofillers.The wetting coefficient has been calculated in our previous work[23].As is shown in Fig.1,the CNTs premix with PS phase to obtain masterbatch I (M -SiC),the SiC nanoparticles premix with PMMA phase to prepare masterbatch II (S-CNTs),and then masterbatch I and II simultaneously mix at a volume ratio of 50/50 to obtain M-SiC/S-CNTs(50/50)nanocomposite.

Fig.2(a and b) are the TEM images of M-SiC1/S-CNTs1 (50/50) in which the relatively darker phase is the PS phase and the brighter phase is the PMMA phase,the black spherical particles are SiC nanoparticles and the round tubular ones are CNTs.It can be seen from Fig.2(a) that the nanocomposite forms a relatively complete co-continuous structure.Upon zooming in,one can observe that the SiC nanoparticles are largely distributed in the PMMA phase,while the CNTs are still located in the PS phase (Fig.2(b)).The results show that if the nanofillers are predistributed in the affinity phase through the masterbatch method,there will be no migration phenomenon.On the other hand,from the SEM images (Fig.2(c and d)),it can be seen that the interface after PMMA phase extraction is relatively smooth,and there are no protrusions of CNTs or SiC nanoparticles.It proves once again that they have not migrated to the interface.

On the basis of no migration system,we further adjust the composition of the masterbatch,aiming to construct a two-way migration of CNTs and SiC at the polymer-polymer interface.We prepare masterbatch I for M-CNTs composite,and masterbatch II for S-CNTs composite.The two masterbatches blend again at a volume ratio of 50/50 to obtain MCNTs1/S–SiC1 (50/50) nanocomposite.Here,the nanofillers preferentially mix with the unfavorable phase respectively to induce their migration.From thermodynamic incentive,the nanofillers in the thermodynamic unfavorable phase tend to migrate to the equilibrium phase so as to achieve a relatively stable state with lower surface energy.Normally,the relative viscosity of the polymer melts also plays an important role in the location of nanofillers.However,this work selects polymer blend (PMMA/PS) with little difference in melt viscosity at mixing condition [23],so that the localization of nanofillers can be controlled from the thermodynamics perspective.It can be clearly observed from the TEM images(Fig.3(a and b))that through the control of the processing time,with this masterbatch component one can realize the design of CNTs and SiC located at the interface during the two-way migration process to a certain extent.Because the two nanofillers have a tendency to migrate,the flexible CNTs with a large aspect ratio will be bolted to the SiC nanoparticles and form bridges during the migration through the limited interface area.However,it cannot be ensured that all the CNTs and SiC can form such a structure at the interface.

Fig.2.(a–b)TEM images of M-SiC1/S-CNTs1(50/50)nanocomposite with 1 vol%CNTs and 1 vol%SiC;the darker phase is the PS phase and the brighter phase is the PMMA phase;(c–d)SEM images of the M-SiC1/S-CNTs1(50/50)nanocomposite,where the PMMA phase is extracted with formic acid(the black holes in the images).

Fig.3.(a–b) TEM images of M-CNTs1/S–SiC1(50/50)nanocomposite with 1 vol% CNTs and 1 vol% SiC;(c–d) SEM images of the M-CNTs1/S–SiC1(50/50) nanocomposite,the arrows in the figure indicate the CNTs and SiC distributed at the interface.

Meanwhile,the SEM images also verify this structure.Fig.3(c)shows that the nanocomposite maintains co-continuous structure well.Examing the interface of M-SiC1/S-CNTs1(50/50)(Fig.2(d)),here,we can clearly observe that the interface is not smooth.There are SiC nanoparticles and CNTs protrusions on the interface after PMMA phase extraction (the circle marked in the Fig.3(d)).Some of the nanofillers distributed at the interface still partially adhere to the PS phase,so they will not fall off with the dissolution of PMMA phase,which is consistent with the results of TEM observation.It shows that the processing technology designed in this work can achieve the two-way migration effect and interface location of the two fillers.More characterization images are shown in Fig.S3.

3.2.The effect of nano fillers distribution on electrical properties

In our previous research,we found that CNTs located at the interface of the co-continuous morphology blend can enhance the micro-capacitor effect,which greatly increases the high frequency dielectric constant(ε′)of M-CNTs1/S composite.However,in order to meet the application requirements of electronic device substrate materials,it is still necessary to optimize the problem of high dielectric loss (ε′′).Therefore,we introduce SiC into the system and regulate the distribution of SiC and CNTs to research the effect on microwave dielectric properties.

The complex dielectric frequency spectra of the nanocomposites with different nanofillers distribution in the frequency range of 8.2–12.4 GHz is shown in Fig.4(a and b).First of all,for no migration system (M/SCNTs1 and M-SiC1/S-CNTs1),it can be seen in Fig.2 and Fig.S1 that there is no migration of the added nanofillers.The CNTs are all located in the PS phase and the SiC nanoparticles still distribute in the PMMA phase.Compared with M/S-CNTs,the ε′value of M-SiC1/S-CNTs increases slightly,and the value of ε"has almost no change.They are located in different phase,so the effect of SiC is limited.For the migration system (M-CNTs1/S),the CNTs in M-CNTs1/S nanocomposite mainly concentrate at the interface (see Fig.S2) and a three-dimensional network of CNTs can be formed at the continuous polymer-polymer interface.On this basis,SiC is introduced and a two-way migration system is built.The bridges between CNTs and SiC nanoparticles appear at the interface where SiC nanoparticles will interrupt the conductive network of CNTs(Fig.1).As a result,the dielectric loss factor(tanδ)of MCNTs1/S–SiC1 drops sharply.The dielectric loss comes from the leakage conduction loss of CNTs.Compared with(M-CNTs)/PS,the dielectric loss has been reduced by more than 60%.At the same time,it can be seen in Fig.4(c)that the value ε′is also reduced because of the damage of microcapacitor structure but it is still higher than M-SiC1/S-CNTs1 (no migration).When we increase the content of SiC in the two-way migration system to 2 vol%(M-CNTs1/S–SiC2),as shown in Fig.4(d),the value of ε′increases obviously while the dielectric loss remains low.Therefore,the construction of two-way migration at the interface of CNTs and SiC can reduce the dielectric loss effectively.

Fig.4.The complex dielectric spectra (8.2–12.4 GHz) of no migration and CNTs and SiC two-way migration nanocomposite:(a) real part;(b) imaginary part;(c–d)comparison of loss tangent (tanδ) and dielectric constant of nanocomposites with different content of nanofillers.

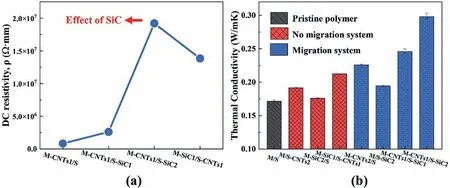

Fig.5.(a) DC resistivity of the nanocomposites with two-way migration;(b) thermal conductivity of no migration/migration nanocomposite system relative to pristine polymer.

3.3.The electrical resistivity and thermal conductivity of nanocomposites

Fig.5(a)shows the DC resistivity of nanocomposites with migration.When the content of CNTs is 1 vol%,the DC resistivity of(M-CNTs1)/S is low(8.3×105Ω mm)due to the formation of the conductive network at the interface.In contrast,in the two-way migration system,the DC resistivity of M-CNTs/S–SiC1 can increase to 2.6 × 106Ω mm at a low loading of SiC(1 vol%).Moreover,when the content of SiC reaches 2 vol%,the resistivity of M-CNTs1/S–SiC2 is increased by two orders of magnitude(1.9×107Ω mm)compared to(M-CNTs1)/S.Hence,one can see that the electrical resistivity has been significantly improved.The schematic diagram in Fig.1 can offer more intuitive understanding of the effect of adding SiC nanoparticles on increasing electrical resistivity.Through the control of the processing technology,the CNTs and SiC are located at the interface and cross-linked with each other.Herein,the SiC nanoparticles act as an open circuit of the conductive path formed by the connected CNTs.Thus,the electrical insulation performance of the system can be effectively improved.

Fig.5(b)shows the thermal conductivity of nanocomposites with no migration and two-way mutual migration of CNTs and SiC.It can be seen from the overall trend that the thermal conductivity of no migration system is lower than two-way migration system.From the above analyses,it is known that the migration process causes linking of the CNTs and SiC nanoparticles at the PS-PMMA interface.Unlike the electrical conductivity,the heat conduction in the composites mainly comes from phonon conduction,which requires the thermally conductive fillers to make effective contact and reduce the interface thermal resistance with the matrix.Therefore,building a three-dimensional network of the thermally conductive fillers in the composites is a better design approach.CNTs and SiC nanoparticles distributed at the continuous polymerpolymer interface synergistically increase thermal conductivity.Here,the CNTs serve as a thermal bridge between SiC nanoparticles(as shown in Fig.1)[26].Meanwhile,according to the volume exclusion effect(the interface phase occupies a small volume)[18],the thermal conductivity of the composite can be effectively improved at a lower filler loading.The thermal conductivity of the M-CNT1/S–SiC2 nanocomposites (in which the content of CNTs is 1 vol% and the content of SiC is 2 vol%) is 0.298 W/mK.Compared with the M/S (0.171 W/mK) it has been improved by 75%.

Here we provide a method capitalizing on the difference in affinity to control the migration of two different nanofillers in immiscible systems with the following three conditions to be met:1)two kinds of nanofillers have different affinity for the two polymers in the blend.2)the viscosity of the polymer is not much different with each other:Viscosity affects the migration of nanoparticles from dynamics which dominate over thermodynamics in selective localization of nanofiller in polymer blends.If the viscosity ratio of the polymer phases is close to 1,then thermodynamics determines the final location of the nanofillers.3)the adjustment of processing technology and migration time makes the nanofillers distribute at the interface.With this approach,improvement of thermal conductivity as well as the optimization of electrical performance for nanocomposite can be realized.It should be noted that the contents of nanofillers (CNTs 1 vol%,SiC 1 or 2 vol%) are very low in the nanocomposites,so it has not reached a high thermal conductivity.However,the improvement rate of thermal conductivity under such low loading of nanofillers is very considerable.Our goal is to achieve coordinated optimization of multiple performance in immiscible system while maintaining the processability of the nanocomposite.Indeed,the thermal conductivity is not very high,but it certainly can be further optimized towards practical applications.

4.Conclusions

This work is based on the application requirements of electronic device substrates and packaging materials to improve the thermal conductivity,reduce dielectric loss and optimize electrical insulation of nanocomposites.In order to maintain the excellent processability of composite materials and reduce the content of fillers,CNTs are used as thermally conductive fillers.At the same time,SiC nanoparticles are introduced into the system to reduce the dielectric loss caused by CNTs.From the TEM images it can be observed that SiC nanoparticles have better affinity with PMMA phase,while CNTs tend to be preferentially distributed in the PS phase.Based on this characteristic,a system of twoway migration of two nanofillers at the interface has been successfully achieved.During the migration,part of the CNTs and SiC nanoparticles are cross-linked and bound at the interface.As a result,the SiC nanoparticles block the conductive path of CNTs which can greatly reduce the leakage conduction loss of the system and realize the structural design of high dielectric constant and low loss.At the same time,the electrical insulation of the nanocomposite is improved.In addition,The CNTs act as the heat transfer bridge of SiC nanoparticles to improve the phonon transmission efficiency,so that the thermal conductivity of nanocomposites can be increased by 75%.In summary,the system of two-way migration at the two-phase interface can successfully reduce dielectric loss and improve thermal conductivity which provides an innovative method for the mesostructural design of multiphase composite materials.Also,the low filling level retains the excellent processability of the composite material with uncomplicated processing technique.

Declaration of competing interest

The authors have no conflict of interest to declare.

Acknowledgements

This work is supported by ZJNSF No.LR20E010001 and National Key Research and Development Program of China No.2021YFE0100500 and Zhejiang Provincial Key Research and Development Program(2021C01004) and Chao Kuang Piu High Tech Development Fund 2020ZL012 and Aeronautical Science Foundation 2019ZF076002.

Appendix A.Supplementary data

Supplementary data to this article can be found online at https://doi.org/10.1016/j.nanoms.2021.08.002.

杂志排行

Namo Materials Science的其它文章

- Preface of “Trends in Nanomaterials and Nanocomposites:Fundamentals,Modelling and Applications”

--Festschrift in honor of Prof Yiu-Wing Mai's 75th birthday - A comparative study of 85 hyperelastic constitutive models for both unfilled rubber and highly filled rubber nanocomposite material

- On mechanical properties of nanocomposite hydrogels:Searching for superior properties

- Ultra-transparent nanostructured coatings via flow-induced one-step coassembly

- VN nanoparticle-assembled hollow microspheres/N-doped carbon nanofibers:An anode material for superior potassium storage

- Molecular dynamics study on mechanical behaviors of Ti/Ni nanolaminate with a pre-existing void