Design on Online Fault Diagnosis System of Stealmaking Gas Dedust Fan

2022-06-27WEIXieben

WEI Xieben

(Shantou Polytechnic, Shantou 515000, Guangdong, China)

Abstract:The study introduces the meanings of the technology on dedust fan′s online detection and fault diagnosis, the ways of fault diagnosis, the common fault analysis and the design of stealmaking gas dedust fan′s online fault diagnosis. It shows the whole system′s design, establishment and functional test. XM series modules have been used to realize the online fault diagnosis. The system′s functional requirements are proved by experiment.

Keywords: dedust fan; online detection; fault diagnosis; entek XM

1 Online detection and fault diagnosis technology of dedust fan

In the past, dedust fan equipment′s detection was separated from the fault diagnosis system, which is a stand-alone fault diagnosis system for a particular detected fan. Moreover, it′s a close system. The interaction and procession of information are limited to the system. As the development of computer and the Internet, remote fault diagnosis has been realized. In recent years, due to its rapid development and promising prospect, Internet has become the carrier of all kinds of information. It′s the trend of using open soft hardware to develop systems[1-2]. Offline detection and fault diagnosis collect the equipment′s operating information by detective sensors, then the information is input into the computer by data collection devices, analyzed and diagnosed by the computer, which is economical and convenient. But such method can only be applied to regular detection. Stand-alone detection and fault diagnosis technology is to equip a detection and fault diagnosis system for a particular device. This way is timely and reliable, but it′s poorly economical and the information of all detective diagnosis system can′t be shared. While such problems can be solved by remote detection diagnosis. It relates the monitoring scene to the diagnosis center. The monitoring scene sends service requests to the diagnosis center and the diagnosis center responses to different requests.

2 Dedust fan′s fault diagnosis methods

Currently, dedust fan′s fault diagnosis technology is various. Detection fault diagnosis system can timely estimate if the device malfunctions, find out the fault causes, fault locations and foresee fault influences, which can repair the devices pointedly[3]. The fault locations can be repaired pointedly. The repair cycle has been extended, repair time shorted, repair quality enhanced, spare parts reduced and device management improved.

1) Based on the Internet data, the system can monitor bearing blocks′ vibration and the signal of axial displacement. Then it compares the data with the standard and estimates the situation of the devices so as to make an exceed-limit alarm. The system can monitor many kinds of faults and estimates how serious the problems are in real time, such as the axial movement, axial faults, loose connection, asymmetric axis, structural resonance and dynamic unbalance. The system also shows the amplitude and makes an alarm. RS-485 bus monitors DCS communication in the detection diagnosis system and fan control rooms, and sends the data to PLC. If the data is higher than the risk value, the device will be locked down[4-5]. Microsoft Sql Server 2 000 sets up real time database and the data is used mainly for status analysis and accident cause analysis.

2) In short, remote monitor and diagnosis is monitoring and diagnosing different places by modern communication technology, which to be specific, is to combine fault diagnosis and computer network technology. On the one hand, companies set up status monitoring servers and monitoring points at key positions and send the data to the servers. On the other hand, fault diagnosis centers and servers are set up in research organizations with advanced technology, which can provides companies with remote technology and service. In this way, companies and research institutes establish a connective diagnosis network which is not limited to room and place. Data collecting subsystem is collecting data all the time and storing the data in the database servers. The data shows the situation of fans and tells us if it′s higher than the standard. If so, alarms will rise and subsystem stops collecting the data. Sample data will be stored in the database and query status is shown again. By the monitoring scene, device managers or fault diagnosis experts click to check the database and post disturbance review, diagnose the faults generally or intelligently and input diagnosis results and suggestions into the database[6].

3 Fans′ common diagnosis analysis

Because of dust and corrosion, rotors have been worn down. Impellers will have the problems like scaling, chip shell, endurance cracks or uneven abrasion, which will lead to intense vibration. Fans will face common problems like unbalanced rotors, asymmetry, bent rotors, oil film whirl and vibration, friction between dynamic and static equipment, rotor cracks and loose rotor bearing parts.

1) Unbalanced rotors

Unbalanced rotors include the mass eccentricity of the rotor system and the defect of rotors. Mass eccentricity is caused by reasons like the rotors′ bad quality, assembling errors and uneven texture, which is also called initial unbalance. Rotor defect means the unbalance of new rotors. Parts(impellers, vanes, etc) are broken, fallen and thrown away because of corrosion, abrasion, media scaling and fatigue as rotors rotates.

2) Rotor asymmetry

Rotor asymmetry is the main fault of the fan equipment. The axes of rotors are made of couplers. Assembling errors, crushed rotors and equipment sedimentation will cause symmetry errors like axial displacement, axes′s angle displacement and comprehensive displacement. This is called rotor asymmetry.

3) Oil film whirl and vibration

Oil film whirl and vibration are the self-oscillation because of the characteristics of nonlinear oil film dynamics. Big fans usually use sliding bearings. Under certain bearing conditions, when the rotating speed is not high, even affected by an outside disturbing force by accident, the shaft neck can go back to the balanced positions[7]. When the speed is higher than a certain number, the shaft neck can′t go back to the initial positions, but whirls along a elliptical and closed track (oil film whirl) or vibrates along irregular curves (oil film vibration). This makes the axes unstable.

4) Friction between dynamic and static equipment

In big fans, in order to improve the machine′s efficiency, the sealing clearance and axial clearance are small to reduce the leakage of gas and oil. But if the clearance is too small, friction between rotors and static parts will occur. Vibration will happen because of axis bending, unbalanced rotors, inconsistent thermal expansion between rotors and static parts, gas dynamic effects, sealed stimulating dynamic effects and rotor asymmetry. Sealed parts will be worn down if the problem is not serious. Otherwise, rotors and static parts will crash and more serious accidents will happen.

5) Loose rotor bearing parts

Loose rotor bearing parts mean the errors of the bearing system′s coordination, insufficient magnitude of interference or abnormal vibration because of the loose bolts. In the rotor bearing system, when the clearance between the bearing cover and shell is big or the magnitude of interference is insufficient, the bearing cover will be deformed cyclically under the effects of rotors′s centrifugal force, which changes the axes′ geometrical parameters and thus affect the stability of the oil film. When the bolts are loose, the system will have irregular displacement because of the clearance of the junction surface.

6) Axes cracks

Rotating machine like fans usually has higher speed and heavier load. When the axes are running for a long time, fatigue cracks maybe occur, which will result in serious accidents. Currently, diagnosing the axes′ cracks is to monitor the amplitude changes from working speed to critical speed when the fan is started or halted, or to monitor the rotors′ amplitude and the phase position′s changes. The horizontal fatigue cracks are arcuate like shells. Because of different stress, cracks will be open, closed or half open and half closed. If the stress is over than the self-weight load, the cracks will be open under the effects of pulling stress. If deflection is higher than it when there are cracks, the amplitude and phase position will change under a certain running speed. When the cracks are pressed, the cracks will be closed, which won′t affect rotors′ vibration characteristics. But if the pressure is the cracks′ weight or other radial load, the cracks will open or close from time to time, which will result in complicated vibration.

7) Bending of rotors

The bending of rotors includes arcuate bending and temporary bending. Arcuate bending is that the axes are arcuate. It′s deformed and curved permanently because of unreasonable axial structure, serious manufacturing errors, uneven texture and improper storage. There are also other reasons such as not timely barring after hot shutdown, bad heat stability and bigger curves after a long time use. Temporary bending is caused by heavier preload, insufficient warming when the machine starts, higher rising speed, heavier loading and uneven heat. Arcuate bending and temporary bending are different faults, but the principles are similar.

4 Online fault diagnosis system of stealmaking gas dedust fan

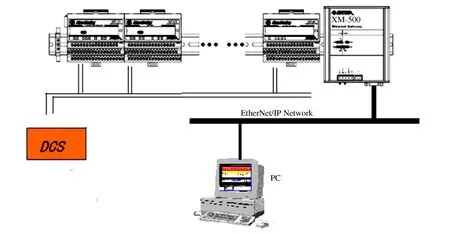

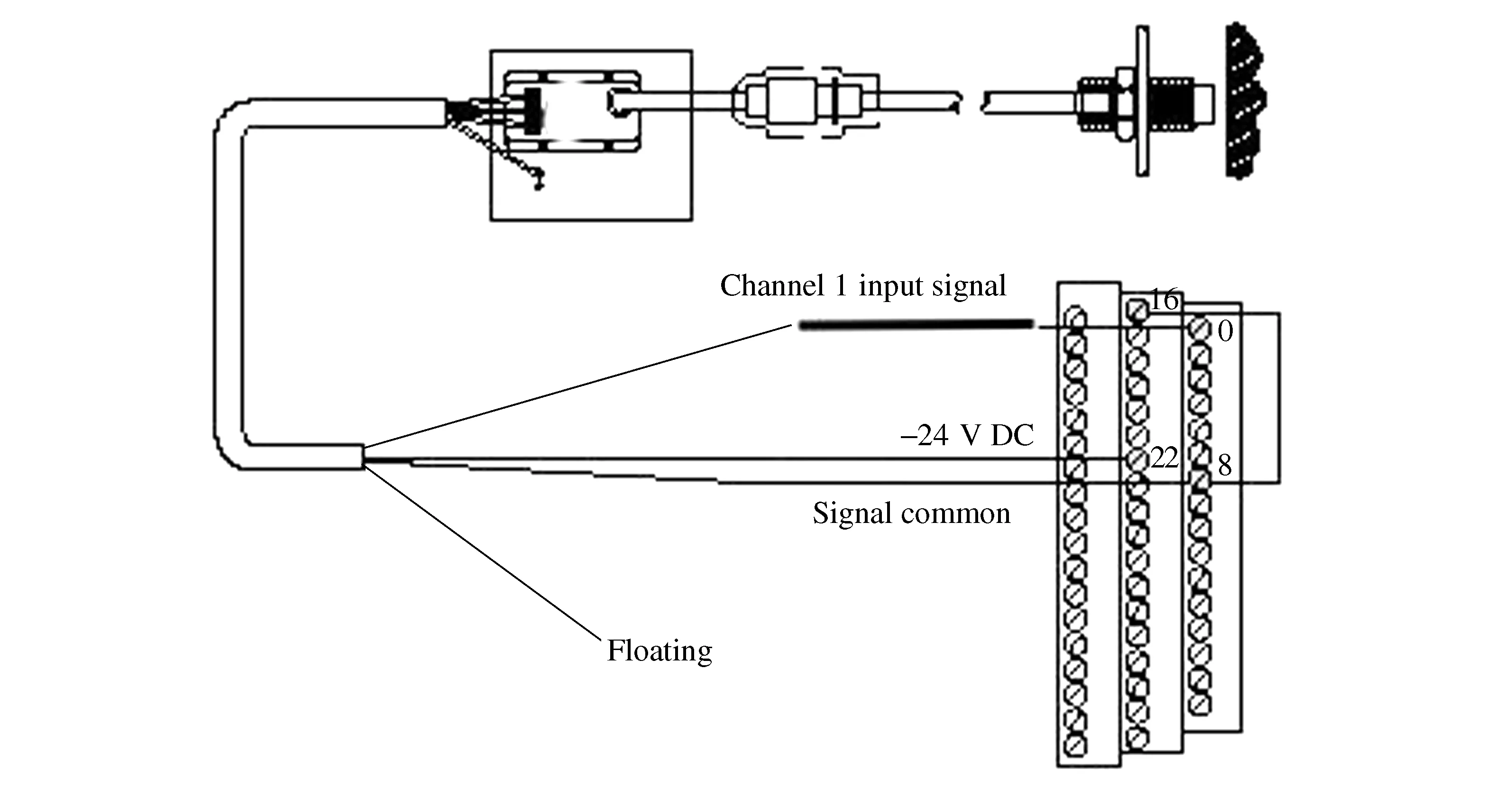

Entek series modules are designed according to Din guide rail. Modules are connected with each other by serial ports, which is easily assembled. As shown in Figure 1 and Figure 2, modules are XM-120, XM-120, XM-120, XM-120, XM-362, XM-320 and XM-500 from left to right. DIN guide rail needs to be connected to the ground by framework or ground electrode. Bolts are equipped to the ground connection terminals or DIN guide rail. If DIN guide rail is covered by non-conducting material (anodic oxidation, oil paint, etc.), it′s necessary to scratch the surface near the mounting hole to be non-conductive. XM system needs to be connected to the framework or ground electrode in the way of single point, which means that all ground electrodes are connected to a single position to avoid ground loop. Besides, battery input needs to be connected to the ground in a single point. Converted RTN signal is connected to the framework or ground electrodes in XM system, change-over switch or other connected equipment.

Figure 1 Module combination

Figure 2 The installation of XM-320

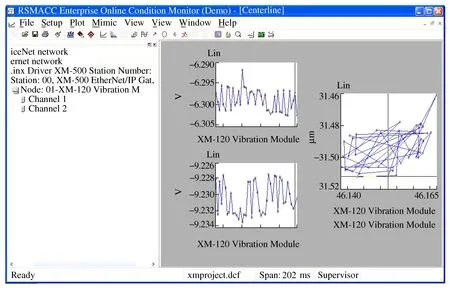

As shown in Figure 3, XM-500 ethernet modules are connected to devicenet and information or ethernet/IP network, which has the function of protocol conversion between different network layers. As DeviceNet′s master station, XM-500 can build connection with other XM modules, which can collect XM modules′ measurement data and alarming data. XM-500 modules can connect 63 subsidiary XM modules, provide a ethernet TCP/IP connector and support IT protocols SMTP, FTP, HTTP and control protocols ethernet/IP. XM-500 modules′ nominal voltage is 24 V DC and the power plugs are two-pin plugs. Sockets are on the modules. XM-500 modules will start immediately when the sockets are put into the two-pin slots. XM-500 modules use a inline 5-pin plug so as to be linked to DeviceNet. Slots are on XM-500 modules. When XM-500 modules are connected, node address and baud rate can be set and EDS files can be input.

Figure 3 DeviceNet cable′s tails of XM-500 modules

5 Simulation experiment and analysis

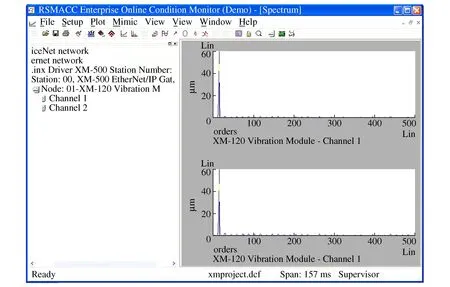

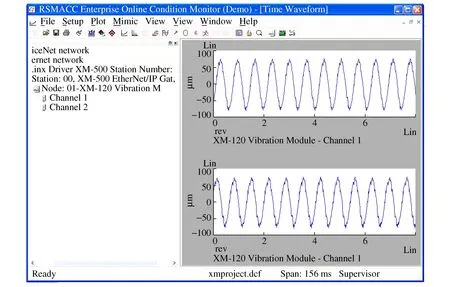

Add unbalanced blocks to the rotor and the rotating speed is same (880 r/min). Figure 4 to Figure 7 show the experiment data. The vibration waveform is the dynamic image showing the changes of vibration amplitude′s moment value. Waveform analysis is to analyze and observe the wave′s shape, the amplitude and the speed of changes and build a relationship with the rotors′s running status, which can help us to find out the abnormal situations and diagnose the fault types. Waveform analysis is observing the wave to infer rotors′ vibration, master the vibration rules and know all kinds of characteristics of the rotors′ status and faults. In the rumble spectrum, different frequency indicates different vibration reasons. If we know the frequency component in the vibration signal, it′s easy to find out the reasons. For example, rotor unbalance will cause the frequency component of sigle and double frequency and asymmetry will cause triple frequency response. According to the waveforms, the wave is in sine wave. Through simple calculation, we can know that frequency of the experiment vibration frequency is about 15 Hz and the frequency is 15 Hz on the frequency spectrum. In the experiment, the rotating speed is 880 r/min (about 15 Hz) and the vibration is also 15 Hz. From the trajectory Figure of the axis, we can know that the vibration is caused by unbalanced rotors, which is in accordance with the theory prediction. The experiment proves that online monitoring can grasp the axis′s status and the detection system is feasible. This system can transform vibration signal into electric signal and send it to the computer for further analysis and diagnosis.

Figure 4 Frequency spectrum

Figure 5 Waveform

Figure 6 Orbit of shaft center

Figure 7 Polar coordinates

6 Conclusion

According to stealmaking gas dedust fan′s structure and the production characteristic of continuous operating, this study designs a online monitoring and fault diagnosing system. By Entek series hardware, the system monitors the dedust fan′s running status, collects and analyzes data, adjusts the operating interface, sets parameters and builds a database at the same time[8]. XM-500 modules are used to monitor the dedust fan, which is very complicate but practical to develop remote online monitoring and diagnosing systems for rotating machine like dedust fans. It′s necessary to improve, upgrade and expand the system as its subjects and monitoring methods change.