Progress of vanadium phosphorous oxide catalyst for n-butane selective oxidation

2022-04-27MuhammadFaizanYingweiLiRuiruiZhangXingshengWangPiaoSongRuixiaLiu

Muhammad Faizan,Yingwei Li,Ruirui Zhang,Xingsheng Wang,Piao Song,2,Ruixia Liu,2,*

1 Beijing Key Laboratory of Ionic Liquids Clean Process,State Key Laboratory of Multiphase Complex System,Institute of Process Engineering Chinese Academy of Sciences,Beijing 100190,China

2 University of Chinese Academy of Sciences,Beijing 100049,China

Keywords:N-butane selective oxidation Oxidation of light alkanes Vanadium phosphorus oxide (VPO)Maleic anhydride

ABSTRACT The utilization of lighter alkanes into useful chemical products is essential for modern chemistry and reducing the CO2 emission.Particularly,n-butane has gained special attention across the globe due to the abundant production of maleic anhydride (MA).Vanadium phosphorous oxide (VPO) is the most effective catalyst for selective oxidation of n-butane to MA so far.Interestingly,the VPO complex exists in more or less fifteen different structures,each one having distinct phase composition and exclusive surface morphology and physiochemical properties such as valence state,lattice oxygen,acidity etc.,which relies on precursor preparation method and the activation conditions of catalysts.The catalytic performance of VPO catalyst is improved by adding different promoters or co-catalyst such as various metals dopants,or either introducing template or structural-directing agents.Meanwhile,new preparation strategies such as electrospinning,ball milling,hydrothermal,barothermal,ultrasound,microwave irradiation,calcination,sol–gel method and solvothermal synthesis are also employed for introducing improvement in catalytic performance.Research in above-mentioned different aspects will be ascribed in current review in addition to summarizing overall catalysis activity and final yield.To analyze the performance of the catalytic precursor,the reaction mechanism and reaction kinetics both are discussed in this review to help clarify the key issues such as strong exothermic reaction,phosphorus supplement,water supplement,deactivation,and air/n-butane pretreatment etc.related to the various industrial applications of VPO.

1.Introduction

The oxidation of light alkanes are durable for producing various valuable chemicals and be recruited in many industrial applications.In this scope,n-butane catalytic selective oxidation to maleic anhydride(MA)is the first and so far most effective industrial process.Vanadium phosphorus oxide catalysts (VPO) exhibits the peculiar competency to activate C-H bond and selectively oxidize n-butane to MA [1,2],is commercially well-established industrial catalyst since 1980s,before that merely benzene synthesis was available for MA production.The production capacity of MA around the world in 2023 is expected approximately 3.43 million metric tons;more or less 70 percent MA production obtained from n-butane oxidation,remaining capacity is still achieved from benzene synthesis[3].The trend has shifted from benzene to n-butane oxidation due to the formation of more by products that causes the high budget-value and pollution concerning environmental issues because of its higher toxicity.Further,its moderately lower feed concentrations(<2%(mol))exploited the process stream flammability [4].Because of its industrial significance and scientifically integrating prospects,noteworthy research papers and patents (a few hundreds) have been accounted for selective oxidation of nbutane to MA from VPO catalysts.

The exploration of VPO catalyst is beginning since 1960s,researchers initially used the support of vanadium catalysts for benzene oxidation,was the only option for the manufacturing of MA as an industrial process.After that,the addition of phosphors ligand into vanadium substrate termed as V-P-O complex brought an excellent catalytic performance for producing MA as compared to previously reported methods.The different metal dopants are contributing the unique physiochemical properties of VPO catalysis.For example,doped with 1% Co has positive attitude for phtalic anhydride productivity,meanwhile MA selectivity is mitigated [5].On the other hand,doped with 1% Fe generates least selectivity towards phtalic anhydride and enriched in CO and CO2stream [6].The o-xylene selective oxidation of phthalic anhydride produced the maleic anhydride along with CO and persistent oxidation products.However,available literature inaugurates the intimate aspects affiliated with different molecular-level sagacity,are still a hot issue [7,8].The performance of VPO catalyst is based on active phase,which is crucial for reaction kinetics and mechanism.In such condition,vanadium oxidation state is closes to +4.Meanwhile,the presence of phosphorous at the VPO surface is directly engaged in the catalysis reactivity.The purpose of n-butane activation is to proceed the hydrogen abstraction mechanism and thus considered as rate-determining step.

The VPO catalyst has quite complex structures with the existence of nearly fifteen different phases[9],its surface morphology,phase composition,P/V ratio,and acidity are highly dependent on synthesis,and has a considerable effect on VPO catalysis performance.The main active phase component of VPO catalyst is vanadyl pyrophosphate (VO)2P2O7,which commences from the main precursor i.e.VOHPO4.0.5H2O (HVP),through topotactic transformation under the activation conditions (Fig.1) [10].This catalytic conversion is somewhat convoluted by considering the reaction which consists of 14 electrons transfer and three oxygen insertions that bring about the presence of consecutive reactions as well as parallel reactions [11].Different research groups found that the different phases existed simultaneously and presented the various models of selective and active VPO surface sites and phases for nbutane oxidation[12–14].The VPO catalyst experience many challenges such as small specific surface area(~20 m2.g-1)and low MA selectivity (60%–65% (mol)) [15,16].Consequently,it is remonstrance to attain higher MA selectivity yield with maximum n-butane conversion and engage the tremendous attention [17].

Fig.1.The evolution scheme proposed for the VPO catalyst with respect to time[18].

The evolution of catalyst performance is based on active phase.To enhance the activity of active phase,various preparation methods such as electrospinning,ball-milling,hydrothermal/solvothermal,barothermal,ultrasound,microwave irradiation,calcination,sol–gel method were employed to synthesize the better precursor and improved the physicochemical properties such as surface area and acidity,content of lattice/surface oxygen,crystal phases,P/V ratio,and redox V+4/V+5ratio.In current review,we described the above mentioned factors in the views of overall catalytic performance.In addition to this discussion,we also elaborate the industrial issues such as strong exothermic reaction,phosphorus supplement,water supplement,deactivation,and air/n-butane pretreatment,which are closely related to that catalytic yield.

2.Strategies for the Preparation of VPO

It has far widely recognized that the preparation approach of VPO catalyst can promptly affect the oxidation state,the Lewis acid density,the structure morphology,and the location of the vanadium species.The catalytic behavior of VPO catalyst is observed from the conversion rate and yield of selective product.The method of preparing the VPO precursor is the curial step for the activation of final VPO and then affects its catalytic performance.

2.1.Common methods

As mentioned before the main precursor HVP is the catalytic precursor of active phase (VO)2P2O7.Generally,it involves the reacting substrate of vanadium (V2O5) and phosphorus (H3PO4)with the assistance of reducing agent in the presence of solvents.

2.1.1.Aqueous phase method

Initially,aqueous media used for preparing catalyst precursor,generally utilizing hydrochloric acid as reducing agent and generally alluded as the VPA course (Fig.2):

Fig.2.VPO precursor is prepared from aqueous phase method.

In the beginning,aqueous media is used to prepare the precursor [7].HCl is replaced by different reducing agents such as phosphorous acid,lactic acid and oxalic acid.Extensive efforts have been devoting to explore the alternative sources of vanadium,for example,NH4VO3and VCl3/V2O5introduced as vanadium source instead of vanadium pentoxide for main precursor phase of precursor.The reduction of vanadium pentoxide can be achieved in the presence of cetyltrimethylammonium chloride and phosphoric acid at higher temperature,this strategy has been introducing for the exploration of the ideal precursor.Similarly,in direct reaction of H3PO4and V2O5are followed the same strategy.

2.1.2.Organic phase method

Aqueous medium is replaced with alcohol for achieving large surface area (the VPO route),additionally;alcohol is providing the reducing agent characteristics,such as aliphatic alcohol could be utilized for producing the precursor phase that leads the lamellar morphology,whose basal plan configuration is identical with precursor phase and carbon length of starting alcohol effects the d(001) values.In one-pot alcoholic route,the most common alcohol is isobutanol,further available common synthesis solvents are benzyl alcohol and/or isobutanol for VPO catalyst [2,19–22].Alternatively,either ketones or aldehydes functional groups are applied then reactant product would be VO(H2PO4)2by means of interaction between V2O5and H3PO4(Fig.3) [23,24].

Fig.3.Organic phase method is used to prepare the VPO precursor.

The reduction of VOPO4.2H2O precursor occurred in the presence of both aqueous and alcohol medium named as VPD route.Both long/short chain alcohols are helpful for the preparation the VPO catalyst.HVP is prepared from the VOPO4.2H2O precursor.The whole process is initiated by the reaction of H3PO4and V2O5,and then reduced it with alcohol for better yield (Fig.4).

Fig.4.Two-stage organic phase method is used to prepare the VPO precursor.

Various glycols such as 1,4-butandiol,1,3-propandiol and 1,2-etandiol have the capacity to change the morphology.The organic content of the precursor is related with the ‘aspect ratio’’ of the crystal.Crystallographic stacking is disturbed when large content of organic compounds is retaining.In aqueous and organic phase methods,the role of solvent and reducing agent is very crucial to proceed the reaction.

2.1.3.Role of solvent and reducing agent

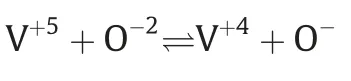

Water and hydrochloric acid are abundantly used as solvent and reducing agent in the preparation of VPO precursor.VPO precursor contains the mixture of vanadium ions,which represent the V+3,V+4,and V+5oxidation state.Average oxidation state is an important characteristic of VPO precursor that can be presented with the help of this equation.

It can be assumed that reducing agent played a decisive role in average oxidation state of vanadium while isolate the VPO precursor.Other reported reducing agents are:isobutanol,allyl alcohol,glycerol,crotyl alcohol,allyl alcohol+t-butyl alcohol,HC1+H2C2O4and N2H .2HC1.Large specific area has also been alleged in the presence of benzyl alcohol and isobutanol being a solvent and reducing agent.The average oxidation state of the precursor arbitrated from the strength of the reducing agent.Moreover,reducing agent is also helpful in the determination of reaction temperature at which activated catalyst perform their catalytic actions.

The active catalyst,mainly its preparation method includes the hydrochloric acid digestion of phosphoric acid (H3PO4) and vanadium pentoxide (V2O5) in the presence of non-aqueous solvent or aqueous solvent,such as isobutanol,tetrahydrofuran (THF) or methanol followed by removing the solvents then final catalyst precursor are ready for selective oxidation of n-butane.In ballmilling process,cyclohexane is used as solvent in the absence or presence of organic comb graft copolymers as dispersants for increasing the BET surface areas up to 55 m2.g-1or even more.Different pore modifying agent for instance methylcellulose,glycol,and citric acid,which increases the pore volume from 0.8 to 1 pm are utilized[7].Final VPO catalyst is retained via evaporation of the solvent.In literature reported solvents are:water,ethanol,isobutanol,allyl alcohol,crotyl alcohol and allyl alcohol with tbutyl alcohol.The utilization of organic solvent supports the large surface area,apart from large surface area utility its catalytic performance does not always improve simultaneously.The reaction condition at which final precursor is retained and isolated via filtration and nature of the solvent probably influence the morphology and phase composition of the catalyst.

To date,enormous endeavors have been devoted to acquiring the knowledge about the nature of the active phase of the catalyst.This knowledge is ascribed in physiochemical properties of active phase.Phase properties are predicted from the presence of valance state of vanadium (V+3,V+4and V+5),adsorbed and lattice oxygen,acidity,P/V ratio,redox V+4/V+5ratio,etc.Additionally,surface area and structural configuration such as morphology always have impact on the performance of developed precursor.The effective catalyst needs intensive investigation and proper consideration during synthesis because it will affect the physicochemical properties of VPO precursor and eventually it will have influenced on final yield.

2.1.4.Effect of the starting vanadium species

The VPO precursor has been used for developing the active phase,which have more vanadium species.The precursor is usually utilized the V2O5substrate,however,other vanadium substrate such as NH4VO3could be used during the preparation of precursor[25].The VPO precursor can be prepared in the presence of N2,O2or air(via calcination process)and developed the so many precursors such as NH4HVPO6,(NH4)2[(VO2)2C2O4(HPO4)2∙5H2O]and NH4(VO2)2PO4[26].These precursors especially have following phases i.e.VO(PO3)3,VO(PO3)2or (VO)2P2O7.In addition to that VOSO4,VO[OCH(CH3)2]3and VO(acac)2have been used as vanadium source to develop the mesostructured VPO phases[27],they were totally relying on their activation conditions and conditioning procedure [26].

Researchers found that prepared VPO precursor exist in fifteen different phases such as α1-,α2-,β-,δ-,γ-and X1-VOPO4etc.,which have specific metal oxides.For instance,VOPO4.2H2O precursor is prepared from POCl3and VOCl3in the presence of aqueous and nitrogen stream inside furnace and then powder form of VOPO4-.2H2O was retained [28].Afterwards,it will transform into α-VOPO4and β-VOPO4phases in the presence of nitrogen environment (via calcination process).Finally,active phase of catalyst is produced being initiating the in-situ activation [28].This process is helpful for those reagents,which are more convenient in gasphase reactions.

2.1.5.Modification of VPO via promoters

More efficient and reliable catalysts should be synthesized in selective oxidation of n-butane for producing the higher yield of MA at optimized reaction conditions.Many researchers continuously keep investigating novel preparation methods for the exploration of ideal VPO precursor.These methods include the combination of co-catalyst and mixed metal promoters as a metal dopant.Various structure-directing agents and templates are utilizing to reform the bulk VPO catalyst characteristics.Generally,inorganic metal and organic chemicals are usually introduced as electronic and structural promoters during the synthesis of VPO to improve its catalytic performance.