Fabricating amide functional group modified hyper-cross-linked adsorption resin with enhanced adsorption and recognition performance for 5-hydroxymethylfurfural adsorption via simple one-step

2022-04-27LeiHuShunhuiTaoJuntingXianXiaodongZhangYaoLiuXiaojieZhengXiaoqingLin

Lei Hu,Shunhui Tao,Junting Xian,Xiaodong Zhang,Yao Liu,Xiaojie Zheng,Xiaoqing Lin,2,3,*

1 School of Chemical Engineering and Light Industry,Guangdong University of Technology,Guangzhou 510006,China

2 Guangdong Provincial Key Laboratory of Plant Resources Biorefinery,Guangdong University of Technology,Guangzhou 510006,China

3 Guangzhou Key Laboratory of Clean Transportation Energy Chemistry,Guangdong University of Technology,Guangzhou 510006,China

Keywords:Adsorption 5-Hydroxymethylfurfural Isotherm Thermodynamics Kinetics Mechanism

ABSTRACT In this study,three kinds of amide functional group modified hyper-cross-linked adsorption resin were synthesized by alternating radical copolymerization in simple one-step and applied for 5-hydroxymethylfurfural (5-HMF) adsorption.The successful synthesis and properties of adsorbents were evaluated with Fourier transform infrared spectroscopy,scanning electron microscopy,nitrogen adsorption–desorption isotherms,thermogravimetric analysis,and elemental analysis.Poly(N,N′-4,4′-diphenyl methane-bismaleimide-alt-divinylbenzene) (poly (BDM-alt-DVB)) resin exhibited highest adsorption capacity for 5-HMF (64.0 mg.g-1 wet resin) and excellent adsorption selectivity (α5-HMF/LA=2.71 ± 0.1 2,α5-HMF/FA=13.88 ± 0.15,α5-HMF/Glucose=11.91 ± 1.11) in the multi-component solution at 25 °C.Langmuir isotherm model well fitted the equilibrium adsorption data within the initial 5-HMF concentration range of 0.5–10.0 g.L-1 with highest correlation coefficient.Furthermore,the thermodynamic parameters demonstrated that the adsorption of 5-HMF onto poly(BDM-alt-DVB)resin was spontaneous and exothermic.Kinetic study revealed that the adsorption process was fast,reaching equilibrium within 12 min.Importantly,the poly(BDM-alt-DVB)resin also demonstrated excellent reusability.In summary,the poly (BDM-alt-DVB) resin will be useful in 5-HMF hydrolysate separation applications.

1.Introduction

Nowadays,the available sustainable pathway for biofuels,and platform chemicals production urgently needs to be developed along with the limited fossil resources and increasing environmental concerns related to CO2emissions[1,2].Among various renewable resources,lignocellulose biomass is a globally available and renewable carbon–neutral resource,which can be used to produce biofuels and chemicals [3,4],reduce the dependence on fossil resources,decrease CO2emission,and shows great potential for the realization of sustainable development [5].

5-Hydroxymethylfurfural (5-HMF) is an important and widely studied bio-based platform chemical [6,7],which is regarded as a bridge between biomass raw materials and petroleum refining industry [8,9],because 5-HMF contains a furan ring,an aldehyde group,and a hydroxymethyl group,which can be further converted into levulinic acid [10],2,5-furandlicarboxylic acid [11],2,5-dihydroxymethylfuran [12],2,5-dimethylfuran [13],5-ethoxymethylfurfural [14] via different chemical reactions.However,it is still a great challenge to effectively separate 5-HMF from low concentration and multicomponent hydrolysate [15].For instance,5-HMF can be easily re-hydrated to levulinic acid and formic acid under the conditions of excessive water molecule [16].Moreover,condensation reactions of 5-HMF resulted in formation of humin (soluble or insoluble polymerized carbonaceous species)and polycondensates at high reaction temperature [2].For this issue,researchers put forward several methods such as vacuum distillation [17],extraction [18,19],membrane filtration [20,21],adsorption [22–25] to separate and recover 5-HMF from reaction mixtures.Compared with other methods,adsorption is used more versatility for 5-HMF separation because of low cost,simple operation,and large industrial processing capacity.Therefore,the design,synthesis,and application of various novel adsorbents have become one of the most active research directions in the field of adsorption and separation materials all around the world.

Currently,activated carbons [26,27],zeolite [25,28,29],ionexchange resins [23,24],and hyper-cross-linked adsorption resins(HCLARs) [30] are used to separate and recover 5-HMF.Among them,hyper-cross-linked adsorption resins have attracted great attention because of their high specific surface area,controllable pore structure,abundant surface functional groups,and excellent adsorption/desorption performance.Since hyper-cross-linked resin first synthesized by Davankov in 1969[31],it has attracted extensive attention of researchers.Nevertheless,the traditional Davankov post crosslinked method usually uses strong carcinogenic chloromethyl ether and the improved Davankov post crosslinked method uses the expensive vinyl benzyl chloride monomer.

In our previous work,an amide modified post-cross-linked poly(divinylbenzene-co-ethyleneglycoldimethacrylate) resin was synthesized and used to adsorb 5-HMF from aqueous solution,providing a new idea for the efficient separation of furaldehyde compounds containing hydrogen bond acceptor/donor [32].This method avoids the use of monochlorodimethyl ether,and evinylbenzyl chloride.However,there are still some problems,such as complex synthesis steps,low atom utilization rate,and excessive consumption of halogen-containing catalyst.In recent years,the simple one-step method of alternating radical copolymerization has been used to prepare functional group modified (HCLARs).The polar structure of different monomers can be used for alternating copolymerization,so that the HCLARs possess adjustable pore structure and surface polarity.Gao et al.[33]developed a new type of hyper-cross-linked organic microporous polymers(HOMP)based on the radical copolymerization of bismaleimides and divinylbenzene,which has a good application prospect in gas adsorption.

In this work,three amide functional group modified hyper-crosslinked poly(hydrophilic network monomer A-alt-hydrophobic network monomer B)(poly(A-alt-B))resins were prepared by one-step to simplify the synthetic route of resin and improve the atom utilization.Additionally,the adsorption isotherms,thermodynamics,kinetics,and desorption behavior towards 5-HMF on poly (BDMalt-DVB) resin were investigated systematically.Meanwhile,the adsorption mechanism was proposed for the adsorption behavior.On the basis of above,this work may provide a methodological reference for the application of new adsorption and separation materials in the field of lignocellulosic biomass resources pretreatment,and have a wide range of universality.

2.Materials and Methods

2.1.Materials

N,N′-4,4′-diphenylmethane-bismaleimide (4,4’-bismaleimidodi phenylmethane,BDM,98%),N,N′-1,3-phenylene-dimaleimide(mPDM,97%),2,2-azobis(2-methyl-propionitrile) (AIBN,98%),tetrahydrofuran (THF,A.R.grade,99.0%),glucose (Glu,A.R.grade,99.0%),formic acid (FA,A.R.grade,99.0%) and levulinic acid (LA,A.R.grade,99.0%) were obtained from Macklin (Shanghai,China).Divinylbenzene (DVB,80%),styrene (St,99%) and N,Ndimethylformamide(DMF,A.R.grade,99.5%)were purchased from Aladdin.5-HMF (A.R.grade,≥98%) was purchased from Nanjing Spring &Autumn Biological Engineering Co.,Ltd.(Nanjing,China).All chemicals were directly used without further purification.

2.2.Methods

2.2.1.Preparation of poly (BDM-alt-DVB) resin

The poly (A-alt-B) resins were prepared via simple one-step of alternating copolymerization of hydrophilic network monomer A(BDM/mPDM) and hydrophobic network monomer B (DVB/St)(Fig.1).In this reaction,hydrophilic network monomer A and hydrophobic network monomer B with a total molar ratio of 40 mmol and 0.2 mmol AIBN were dissolved in 100 ml DMF.The mixture was stirred at room temperature and deoxygenated by nitrogen bubble for 0.5 h.Then,the reaction temperature was raised to 80°C and copolymerize for 24 h.Afterwards,the obtained resins were washed using hot water for several times and extracted by THF in Soxhlet for 24 h.The obtained resins were dried under vacuum at 50 °C for 48 h.

2.2.2.Characterization of poly (BDM-alt-DVB) resin

Fourier transform infrared(FT-IR)spectroscopy of poly(A-alt-B)resins was carried on a Nicolet 6700 (Thermo-Fisher,USA) instrument (4000–500 cm-1) using KBr disks [34].The morphology of poly (A-alt-B) resins were analyzed by TESCAN MIRA4 scanning electron microscope (TESCAN,Czech) operated at 10 keV and 10 pA.The pore structure and pore size distribution (PSD) of poly(A-alt-B) resins were measured via the nitrogen adsorption–desorption isotherms at-196°C using a QUADRASORB SI surface area and porosity analyzer (Quanta Chrome,USA).ANETZSCH STA 449 F5 thermal analyzer(NETZSCH,Germany)was applied for thermogravimetric analysis (TGA) of poly (A-alt-B) resins at temperature between 25 to 900 °C (heating rate 10 °C.min-1).The elemental analysis of poly (A-alt-B) resins were measured via UNICUBE Elemental Analyzer (Elementar,Germany).

2.2.3.Selective adsorption experiments

The selective adsorption experiments of 5-HMF,LA,FA,and glucose from multi-components mixture solution onto poly (A-alt-B)resins were carried out by a ZQZY-80BS shaker (dosage was 10.0 g.L-1,25°C,agitation speed 120 r∙min-1,4 h).The initial concentrations of 5-HMF,LA,FA,and glucose were 5.0,2.5,1.0,and 1.0 g.L-1,respectively.After reaching equilibrium,the poly (Aalt-B) resins were filtered with 0.45 μm membrane filter and the concentrations of adsorbate were measured via high performance liquid chromatography (HPLC,1260 Infinity II,Agilent,USA).The capacity and selectivity of 5-HMF to LA,FA,and glucose were calculated according to the following equations [35]:

2.2.4.Adsorption experiments

The detailed experimental operation of the 5-HMF singlecomponent adsorption equilibrium is the same as in Section 2.2.3.For isotherm adsorption study,the poly (BDM-alt-DVB) resin(dosage was 10.0 g.L-1) was added into 5-HMF aqueous solution with various initial concentrations (0.5–10.0 g.L-1).After shaking at 120 r∙min-1for 4 h by varying temperature between 15 and 45°C,the poly(BDM-alt-DVB)resin was separated and the residual concentration of 5-HMF were determined by HPLC.The adsorption capacity of poly (BDM-alt-DVB) resin can be calculated using Eq.(1).Similarly,the kinetic adsorption experiments were performed at different 5-HMF initial concentration (1.0,2.5,5.0,and 10.0 g.L-1)at different temperatures(15,25,35,and 45°C)by controlling adsorption time from 0 to 30 min at specific time intervals(preliminary experiments show that 30 min is enough to reach equilibrium).The dosage of poly (BDM-alt-DVB) resin was fixed at 10.0 g.L-1.The adsorption amount of 5-HMF at any contact time,t,was calculated by Eq.(3) [36]:

Fig.1.Synthesis of the poly (A-alt-B) resins.

2.2.5.Desorption and recycle

After the adsorption experiment,1.0 g of 5-HMF loaded poly(BDM-alt-DVB) resin was eluted by 60 ml of 70% (v/v) ethanol in a shaking incubator (25 °C,120 r∙min-1).After desorption for 4 h,the poly (BDM-alt-DVB) resin was filtered and washed with deionized water for the next adsorption process.Each experiment was repeated three times and the number of cycles of adsorption and desorption was ten times.

2.2.6.Analytical methods

The concentrations of the components in aqueous solution were determined by HPLC analysis using an Aminex HPX-87H anion exchange column (300 mm × 7.8 mm,Bio-Rad Corp.,USA) on an Agilent 1260 Infinity II equipped with a refractive index (RI) and UV detector [37].The column temperature was set at 55 °C.The mobile phase was 5 mmol∙L-1H2SO4and the flow rate was maintained at 0.5 ml.min-1.

3.Results and Discussion

3.1.Characterization

3.1.1.FT-IR analysis

The FT-IR spectrum displayed in Fig.S1 (see Supplementary Material) was used to confirm successful synthesis of poly (A-alt-B) resins.The characteristic peak at 3087–3105 cm-1(C-H stretching vibrations of=C-H) is weakened significantly,indicating that the successful cross-linking of hydrophilic network monomer A (BDM/mPDM) and hydrophobic network monomer B (DVB/St) by alternating radical polymerization.The vibrational peak at 2926 cm-1,which appears in the spectra of the resin is attributed to the C-H group stretching in-CH2-group,originating from the DVB/St [38].The series absorption peaks at 1708 and 1384 cm-1are related to C=O group and C-N-C group of BDM/mPDM [39],confirming successfully copolymerization of the hydrophilic network monomer A (BDM/mPDM) and hydrophobic network monomer B (DVB/St).

3.1.2.BET analysis

The parameters of poly (A-alt-B) resins calculated from N2adsorption–desorption isotherms are listed in Table 1.As demonstrated in Figs.S2 to S4,at the low relative pressure (P/P0<0.05),N2uptake of the poly (BDM-alt-DVB) resin and poly (mPDM-alt-DVB) resin increased rapidly with the increment of relative pressure (P/P0<0.05),suggesting that these two resins have micropores [32].However,this phenomenon did not occur in the poly(BDM-alt-St) resin,showing that it does not possess micropores.At the medium relative pressure (0.05

0.95) also reflected that the resins contain macropores structure.It is emphasized that the hysteresis loop was unclosed.Similar phenomena have been observed for other microporous/mesoporous materials,and may be attributed either to the polymer has a complex structure containing throats and cavities,or to the swelling effect of the polymer skeleton in liquid nitrogen [40,41].All of the above analyses were consistent with the results of the pore size distribution of the poly (A-alt-B) resins in Figs.S5 to S7.As shown in Figs.S5 to S7,the peaks in the micropore region (dp≤2 nm) and mesopores region(2 nm<dp<50 nm)were clearly observed in the pore size distribution(PSD)curves of the poly(BDM-alt-DVB)resin and poly (mPDM-alt-DVB) resin,implying that the existence of micropores and mesopores in the two resins.It is interesting to find that poly (BDM-alt-DVB) resin has fewer micropores and more mesopores than poly (mPDM-alt-DVB) resin.

3.1.3.SEM analysis

The morphology and surface texture of the poly(A-alt-B)resins observed by SEM are presented in Fig.S8.As shown in Fig.S8,the poly(A-alt-B)resins were in heterogeneous granular form.The surface of the poly (A-alt-B) resins were rough,with many holes and some collapses.This phenomenon may be due to the fact that the amide group in hydrophilic network monomer A(BDM/mPDM)makes the pores collapse,resulting in rough resin surface and irregular pore shape.Among them,the poly (BDM-alt-DVB) resin contained the most holes,which was consistent with the results of BET analysis.

3.1.4.TG analysis

The thermogravimetric and derivative thermos-gravimetric curve for the poly (A-alt-B) resins are presented in Figs.S9 to S11.With the increase of temperature,the resins began to lose mass slowly.The poly (A-alt-B) resin first lost about 2.2% of its mass when the temperature is lower than 100 °C,which was due to water lost from the pores in poly(A-alt-B)resin.As the temperature exceeds 405.0 °C,the mass loss rate of the poly (BDM-alt-DVB),poly (BDM-alt-St) and poly (mPDM-alt-DVB) resin began to increase obviously,and the maximum thermal mass loss rate occurs at 486.0,458.5,and 480.4 °C,respectively.This is because the chemical bonds such as C=O bond and C=C bond in the resin were broken,and the molecular backbone chains and most organic components were degraded [42].When the temperature reaches 700 °C,the mass loss rate of the resin decreases gradually.Furthermore,the resin did not show any appreciable mass loss above the 800 °C and the final resin mass is about 40.30%,31.53%,and 41.20% of the original resin mass,respectively,indicating that the resins have high thermal stability.And the plausible explanation for this observation is the poly(A-alt-B)resins possess inert chemical structure and high cross-linking network [43].

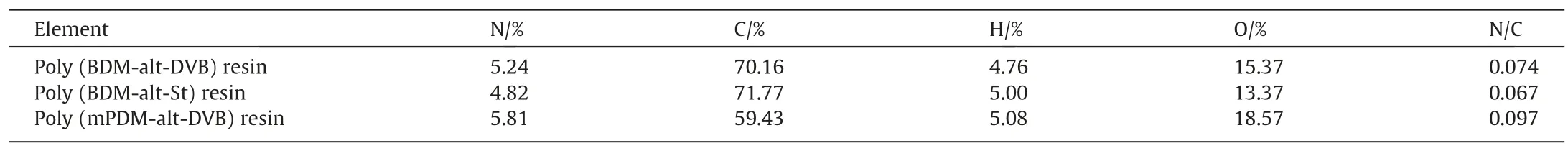

3.1.5.Elemental analysis

Elemental compositions of the poly(A-alt-B)resins are listed in Table 2.The results show that the poly(A-alt-B)resins contained C,H,N,and O.Among them,elements C and H arises from hydrophilic network monomer A (BDM/mPDM) and hydrophobic network monomer B(DVB/St),and elements N and O raised from the amide groups in hydrophilic network monomer A (BDM/mPDM),confirming the alternating structure of the resin.However,the content of element C in the poly (mPDM-alt-DVB) resin was less than that of the other two resins.This may be because mPDM has one benzene ring less than BDM and the content of element C in mPDM is less than that of BDM.

Table 1 Structural parameters of the poly (A-alt-B) resins

Table 2 Elementary mass analysis of the poly (A-alt-B) resins

3.2.Adsorption equilibrium selectivity

Fig.2 shows the experimental results of competitive adsorption of 5-HMF,LA,FA,and glucose from multicomponent solution.Clearly,all poly(A-alt-B)resins exhibited poor adsorption capacity for FA and glucose.However,poly (BDM-alt-DVB) resin possesses highest adsorption capacity for 5-HMF (64.0 mg.g-1wet resin)than poly (BDM-alt-St) and poly (mPDM-alt-DVB) resins in the multi-component solution at 25 °C.Moreover,the selectivity factors α5-HMF/LA,α5-HMF/FA,and α5-HMF/glucoseonto the poly (BDM-alt-DVB) resin reached up to 2.71 ± 0.12,13.88 ± 0.15 and 11.19 ± 1.11,respectively,which were much higher than the other two resins,indicating the poly (BDM-alt-DVB) resin possesses higherrecognition specificity to 5-HMF,and the 5-HMF molecule is easy to specifically bind to the active adsorption site on the poly(BDM-alt-DVB) resin.This can be explained by the fact that the poly (BDM-DVB) resin has amide groups which increases the surface polarity and rich pore structures.5-HMF is adsorbed on the poly (BDM-alt-DVB) resin through π–π stacking and hydrogen bonding interaction between 5-HMF molecular and amide groups[34].In addition,poly(BDM-alt-DVB)resin contains more benzene rings,enhancing the hydrophobic interaction between the benzene ring of the poly (BDM-alt-DVB) resin and the furan ring of 5-HMF[35].Therefore,compared with the poly (BDM-alt-St) and poly(mPDM-alt-DVB) resins,5-HMF in the multicomponent solution is more easily adsorbed by the poly (BDM-alt-DVB) resin which is selected for the next experiment.

3.3.Adsorption isotherm

Fig.3 displays the isotherm adsorption of poly (BDM-alt-DVB)resin for 5-HMF at different temperatures.At the same temperature,the adsorption capacity of 5-HMF onto poly (BDM-alt-DVB)resin gradually increase with the increase of 5-HMF concentration.Furthermore,the equilibrium adsorption capacity gradually decreased with the increase of temperature,suggesting that the adsorption process was exothermic.

The isotherm adsorption data of poly (BDM-alt-DVB) resin for 5-HMF are analyzed by Langmuir [44] and Freundlich [45] isotherm model.The Langmuir isotherm model assumes that adsorption take place on homogeneous surface by monomolecular layer without any interaction between the absorbed materials [46].It can be mathematically described as follows:

Langmuir isotherm can be characterized by RL,which in terms of a dimensionless separation factor or equilibrium parameter[47].RLis calculated by the following equation:

Fig.2.Adsorption capacity(a)and selectivity(b)of 5-HMF(5.0 g.L-1),LA(2.5 g.L-1),FA(1.0 g.L-1)and glucose(1.0 g.L-1)onto the poly(A-alt-B)resins in multicomponent system at 25 °C.

Fig.3.Adsorption isotherms of 5-HMF on poly (BDM-alt-DVB) resin from aqueous solution at 15,25,35,and 45 °C,respectively.

where C0is the initial concentration of 5-HMF(g.L-1).RLrepresents the type of isotherm and the magnitude of RLdetermines the feasibility of the adsorption process:RL=0,the adsorption is irreversible;0<RL<1,the adsorption is favorable;RL=1,the adsorption is linear;RL>1,the adsorption is unfavorable.

Freundlich isotherm model can be applied to multilayer adsorption procession,with the sites of adsorption which located on surface are not uniform [48].It can be represented as follows:

It can be seen from the detailed information in Table 3 that adsorption of poly (BDM-alt-DVB) resin fits Langmuir isotherm model well with the higher R2.The results indicate that the adsorption of 5-HMF on the surface of poly (BDM-alt-DVB) resin within the studied 5-HMF concentration range is monolayer.The maximum adsorption capacity qmaxdecreased with the increase of temperature,which was consistent with the results of adsorption isotherms.The highest uptake of 5-HMF was 159 mg.g-1wet resin in the experimental concentration range at 15°C.Furthermore,the values of RLfor adsorption of 5-HMF onto poly (BDM-alt-DVB)resin at initial concentration are greater than zero and less than unity suggests the favorable adsorption.Additionally,compared with other adsorbents for 5-HMF adsorption (Table 4),the poly(BDM-alt-DVB) resin has the highest adsorption capacity for 5-HMF.

Table 3 Langmuir and Freundlich isotherm parameters for the adsorption of 5-HMF onto poly (BDM-alt-DVB) resin at 25–45 °C

Table 4 Comparison of the maximum sorption capacity for adsorption of 5-HMF by various adsorbents at 25 °C

3.4.Thermodynamics study

The thermodynamic parameters used to evaluate the spontaneous nature of the adsorption process are important.In this study,Van’t Hoff equation was used to calculate the thermodynamic parameters [50]:

From Table 5,the values of ΔG were negative,indicating the adsorption for 5-HMF on the ploy (BDM-alt-DVB) resin is spontaneous.Additionally,the absolute values of ΔG were less than 20 kJ.mol-1,suggesting physical adsorption [51,52].At the same initial concentration,the absolute values of ΔG decreased with the increase of temperature,which further confirms that the poly(BDM-alt-DVB) resin has better adsorption capacity for 5-HMF at low temperature.The negative ΔH values reflect the adsorption of 5-HMF onto the poly(BDM-alt-DVB)resin is an exothermic reaction,which is consistent with the results of adsorption isotherm.Meanwhile,the positive values of ΔS suggest the good affinity of 5-HMF toward the poly(BDM-alt-DVB)resin and increase randomness at solid/liquid interface during the adsorption process and enhancement in the degree of freedom of adsorbed species which occurs due to the desorption of the water molecules previously adsorbed on the surface of poly (BDM-alt-DVB) resin [53–57].

Table 5 Thermodynamic parameters for the adsorption of 5-HMF onto poly(BDM-alt-DVB)at various temperatures

3.5.Adsorption kinetics

The effect of temperature on the adsorption rate of 5-HMF onto poly(BDM-alt-DVB)resin is shown in Fig.4.Clearly,the adsorption capacity of 5-HMF on the resin increases obviously during the initial stage of different adsorption temperatures due to the sufficient adsorption sites on the resin surface for 5-HMF adsorption.With the extension of adsorption time,the available vacancies on the resin surface gradually decrease,and 5-HMF molecules diffuse from the resin surface to the particle along the pore direction,resulting in the adsorption rate decreased slowly until the adsorption reached equilibrium,and the adsorption capacity of 5-HMF remained unchanged for a certain time (<12 min) [58].With the temperature increasing from 15 to 45 °C,the equilibrium adsorption capacity of the resin for 5-HMF decreased from 67.2 to 48.8 mg.g-1wet resin,indicating that the equilibrium adsorptioncapacity of the resin for 5-HMF had a negative effect on the temperature,and the increase of temperature was not conducive to the adsorption of 5-HMF.

Fig.4.Kinetic adsorption experimental data of 5-HMF onto poly (BDM-alt-DVB)resin at various temperatures.

Fig.5.Kinetic adsorption experimental data of 5-HMF onto poly (BDM-alt-DVB)resin at various initial 5-HMF concentrations.

Fig.6.Adsorption/desorption cycles on the recoveries of poly(BDM-alt-DVB)resin.

Fig.5 displays the effect of different initial concentration (1.0–10.0 g.L-1) on the adsorption rate of 5-HMF onto poly (BDM-alt-DVB) resin at 25 °C.As shown in Fig.5,the adsorption kinetics of 5-HMF on resin at different initial concentrations was studied at 25°C.The results showed that the equilibrium adsorption capacity of the resin for 5-HMF increased from 23.5 to 82.7 mg.g-1wet resin when the initial concentration increased from 1.0 to 10.0 g.L-1,which indicated that the resin had good adsorption performance for high concentration of 5-HMF.This may be because the higher 5-HMF initial concentration results in greater mass transfer driving force to overcome the mass transfer resistance of the resin in the 5-HMF adsorption process,enhancing the adsorption capacity [59].

In this study,the pseudo-first-order (Eq.(10)) [60] and the pseudo-second-order kinetic model (Eq.(11)) [61] were utilized to understand the mechanism and the adsorption kinetics of 5-HMF onto poly (BDM-alt-DVB) resin under different experimental temperatures and concentrations.As shown in Tables 6–7,the values of R2from the pseudo-second-order model were higher than the values of R2from the pseudo-first-order model.And the values of qcalcalculated from the pseudo-second-order model were also found to be very close to experimental values qexp,indicating that the pseudo-second-order model well-fitted the adsorption of 5-HMF onto poly (BDM-alt-DVB) resin at different temperatures and different initial 5-HMF concentrations.

Table 6 Kinetic parameters for the adsorption of 5-HMF onto poly (BDM-alt-DVB) resin at various temperatures (C0=5.0 g.L-1)

Table 7 Kinetic parameters for the adsorption of 5-HMF onto poly (BDM-alt-DVB) resin at various initial 5-HMF concentration (T=25 °C)

Fig.7.Proposed adsorption mechanisms of 5-HMF molecules on the poly (BDM-alt-DVB) resin.

3.6.Desorption and recycle

The regeneration and reuse of resin is an important parameter to evaluate the potential of the adsorption resin.According to Fig.6,the static adsorption capacity and desorption efficiency of the poly (BDM-alt-DVB) resin have been similar after ten adsorption–desorption–regeneration–reabsorption cycles,indicating that the performance of the poly(BDM-alt-DVB)resin has basically no changed after 10 times of use.It can be concluded that the resin exhibited excellent adsorption and desorption performance,suggesting that the poly (BDM-alt-DVB) resin is a promising and valuable absorbent to separate 5-HMF from aqueous solution or biomass hydrolysate.

3.7.Adsorption and desorption mechanism

The exploration of the adsorption mechanism helps to deeply understand the interaction between the adsorbent modified by the specific functional groups and the adsorbate,so as to provide more possibilities for the design of new high-performance adsorbents [62].The possible interactions between the 5-HMF molecules and the poly (BDM-alt-DVB) resin are illustrated in Fig.7.

It is noteworthy that the adsorption mechanism of the poly(BDM-alt-DVB) resin toward 5-HMF molecules involved hydrogen bonds and hydrophobic–hydrophobic interaction.The amide functional group and carbonyl group of the poly (BDM-alt-DVB) resin skeleton and the methylol group in the 5-HMF molecule could form hydrogen bonds (O...H-N,O...H-O).In addition,there are π-π hydrophobic interactions between the benzene rings in the resin and the furan ring of 5-HMF.Similar interactions have been reported in previous studies for adsorption of 5-HMF using hyper-cross-linked adsorption resins [49].Hydrogen bond and hydrophobic–hydrophobic force synergistically increases the adsorption capacity of 5-HMF.Moreover,the short-range and directivity of hydrogen bonds give the poly (BDM-alt-DVB) better adsorption recognition.More importantly,during the desorption process,the lower hydrogen bond energy would ensure the reversibility of the adsorption of 5-HMF on the poly (BDM-alt-DVB) resin.

4.Conclusions

In this work,three novel types of hyper-cross-linked resin based on alternating radical copolymerization of hydrophilic network monomer A and hydrophobic network monomer B were synthesized by simple one-step.Compared with the traditional strategy,this method has the following advantages:(I) the synthetic route of hyper-cross-linked resin is simple,(II) the atom utilization is improved,(III)no halogen containing catalyst is needed.The static adsorption results showed that the poly (BDM-alt-DVB) resin exhibited higher adsorption capacity and selectivity for 5-HMF in multicomponent solution than other two resins.Furthermore,the adsorption of 5-HMF onto poly (BDM-alt-DVB) resin was physical,spontaneous,and exothermic.Importantly,the kinetic results showed that the adsorption of 5-HMF onto poly (BDM-alt-DVB)resin reached adsorption saturation within 12 min.In desorption process,the adsorption capacity and recovery efficiency of 5-HMF from poly(BDM-alt-DVB)resin has basically unchanged after repeated use.In summary,the poly (BDM-alt-DVB) resin is a promising adsorbent material to remove 5-HMF from aqueous solution or biomass hydrolysate for its excellent adsorption and desorption performance.

CRediT Authorship Contribution Statement

Lei Hu:Conceptualization,Methodology,Writing– original draft.Shunhui Tao:Data curation,Formal analysis.Junting Xian:Data curation,Formal analysis.Xiaodong Zhang:Visualization,Investigation.Yao Liu:Visualization,Investigation.Xiaojie Zheng:Visualization,Investigation.Xiaoqing Lin:Supervision,Project administration,Methodology,Writing– review &editing.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

This work was supported by National Natural Science Foundation of China (21978053,51508547),the Key Area Research and Development Program of Guangdong Province(2020B0101070001),and the ‘‘One-Hundred Young Talents”Program of Guangdong University of Technology (220413185).

Supplementary Material

Supplementary data to this article can be found online at https://doi.org/10.1016/j.cjche.2021.11.006.

Nomenclature

Ceequilibrium concentration,g.L-1

Ctconcentration at contact time,g.L-1

C0initial concentration,g.L-1

ΔG Gibbs free energy change,kJ.mol-1

ΔH enthalpy change,kJ.mol-1

Kdthermodynamic equilibrium constant

KFFreundlich adsorption isotherm constant,mg.g-1-1/nF.L1/nF

k1pseudo-first-order rate constant,min-1

KLLangmuir adsorption isotherm constant,L.g-1

k2pseudo-second-order rate constant,mg.g-1.min-1

m mass of the wet resin,g

nFFreundlich adsorption isotherm constant

qcalcalculate adsorption capacity,mg.g-1

qeequilibrium adsorption capacity,mg.g-1

qexpexperimental adsorption capacity,mg.g-1

qmaxmaximum saturated adsorption capacity,mg.g-1

qtadsorption capacity at contact time,mg.g-1

R gas constant,8.314 J.mol-1.K-1

RLseparation factor

ΔS entropy change,J.mol-1.K-1

T solution temperature,°C

t contact time,min

V volume of solution,ml

α selectivity factor

ρ the density of the solution,g.L-1

杂志排行

Chinese Journal of Chemical Engineering的其它文章

- Green hydrogen:A promising way to the carbon-free society

- Electrochemical CO2 mineralization for red mud treatment driven by hydrogen-cycled membrane electrolysis

- Fabrication of azobenzene-functionalized porous polymers for selective CO2 capture

- Significantly enhanced charge transfer efficiency and surface reaction on NiP2/g-C3N4 heterojunction for photocatalytic hydrogen evolution

- CO2 capture by double metal modified CaO-based sorbents from pyrolysis gases

- Methane hydrate crystal growth on shell substrate