Study on Low-Temperature Properties of the Asphalt Modified by Carbon Nanotubes (CNTs) and Crumb Rubber (CR)

2022-04-14LiuYumeiZhengMulianLiuXiaWangChongtaoChengYongWangKe

Liu Yumei; Zheng Mulian; Liu Xia, Wang Chongtao; Cheng Yong; Wang Ke

(1. Key Laboratory for Special Area Highway Engineering of Ministry of Education,Chang’an University, Middle Section of South Erhuan, Xi’an 710064;2. Jining Hongxiang Highway Survey, Design and Research Institute Co., Ltd., Jining 272000;3. First Highway Consultants Co., Ltd., Xi’an 710075)

Abstract: The effect of adding crumb rubber (CR) and carbon nanotubes (CNTs) on the low-temperature properties of virgin asphalt was studied. Using the force-ductility test and the bending beam rheometer (BBR) test, the deformation resistance and rheological properties of asphalt samples at low temperatures were evaluated, respectively. Based on the result of BBR test, the creep functions of the Burgers model and the Zener model were used to fit the low-temperature creep characteristics of the asphalt samples. Furthermore, the differential scanning calorimetry (DSC) test and the attenuated total reflection-Fourier transform infrared spectroscopy (ATR-FTIR) test were utilized to appraise the low-temperature stability and chemical properties of asphalt samples, respectively. The results showed that CR significantly improved the lowtemperature properties of virgin asphalt, while CNTs had little effect. Moreover, during the degradation of CR, aromatic and aliphatic components were released. In particular, the aliphatic components of CR-modified asphalt were much higher than those of virgin asphalt, which had a significant effect on improving the low-temperature properties of the asphalt. The DSC test results showed that CR enhanced the low-temperature stability of the asphalt, while the addition of CNTs presented a slightly negative effect.

Key words: low-temperature properties; crumb rubber (CR); carbon nanotubes (CNTs); creep characteristic;asphalt components

1 Introduction

Crumb rubber (CR) produced by grinding scrap tires,which represent a recycled material, is used to modify asphalts and can provide an effective way to solve the premature failure of asphalt pavement along with consuming a large number of scrap tires[1-3]. However, the CR-modified asphalt is deficient in its high-temperature rutting resistance[2-4]. The combined modification with other materials has been proved to be an effective method to enhance the high-temperature performance of CRmodified asphalt[4-6].

In recent years, the use of nano-materials to modify asphalt has become an important research direction in the field of road engineering. Numerous studies have showed that nano-materials are helpful to ameliorating the high-temperature performance, fatigue resistance and aging resistance of asphalt thanks to their unique size effect, quantum tunneling effect, volume effect and surface effect[7-11]. For instance, the study performed by Van de Ven, et al.[9]showed that the addition of nanoclay significantly improved the long-term and shortterm aging properties of asphalt. Hong, et al.[10]used multi-dimensional nano-materials composed of organic expanded vermiculite (OEVMT) and surface modified nanoparticles (nano-ZnO, nano-SiO2or nano-TiO2)to modify asphalt. The result showed that the multidimensional nanomaterials could effectively prevent asphalt aging. Karahancer, et al.[11]found that the nano-Al2O3particles improved the rutting resistance and anti-fatigue properties of asphalt and the moisture susceptibility of hot mix asphalt (HMA). Among existing nano-materials used to modify asphalt, carbon nanotubes (CNTs) have obtained an increasing attention for its outstanding electrical, thermal and mechanical properties[12-17]. Many studies have indicated that CNTs have a remarkable amelioration on high-temperature properties, fatigue resistance and anti-aging properties of asphalt[13-15]. For instance, the research of Latifi, et al.[13]showed that when the dosage of CNTs was in the range of between 0.5% to 1.0%, the modification with CNTs could significantly improve the rutting resistance and fatigue resistance of asphalt. Gong, et al.[14]found that CNTs had a significant effect on the high-temperature properties and aging resistance of asphalt. The study of Ashish, et al.[15]showed that the addition of CNTs increased the creep recovery rate of asphalt and changed the viscoelastic zone of asphalt from linear to nonlinear during the lower creep cycle. There were some studies about asphalts modified by CR and CNTs alone, and these studies have shown that the two modifiers are advantageous for improving the performance of asphalt[13-17]. However, there are few studies using a combination of CNTs and CR to modify asphalt and improve the performance of asphalt. Besides,the current researches predominantly focused on the preparation process, high-temperature properties, fatigue resistance and anti-aging properties of asphalt modified by either CNTs or CR, there are no more details relating to the study on the modification of low-temperature properties.

To study the low-temperature properties of the asphalt modified by CNTs and CR, the CNTs-modified asphalt,the CR-modified asphalt and the CNTs/CR compositemodified asphalt were prepared. The virgin asphalt as the control group was used in this study. The forceductility test and the bending beam rheometer (BBR) test were applied to evaluate the low-temperature properties of the asphalt samples. In addition, the Burgers model and the Zener model were utilized to simulate the creep characteristics of the asphalts at low temperatures. The attenuated total reflection-Fourier transform infrared spectroscopy (ATR-FTIR) test was performed to analyze the change in chemical composition of the asphalts.Besides, the differential scanning calorimetry (DSC)test was used to study the low-temperature stability and temperature susceptibility of the asphalt samples by analyzing the changes in the glass state that occurs during heating.

2 Materials and Methods

2.1 Materials

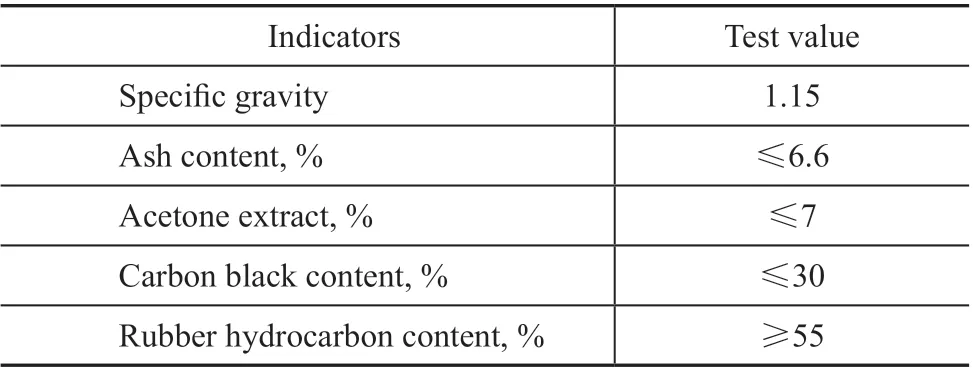

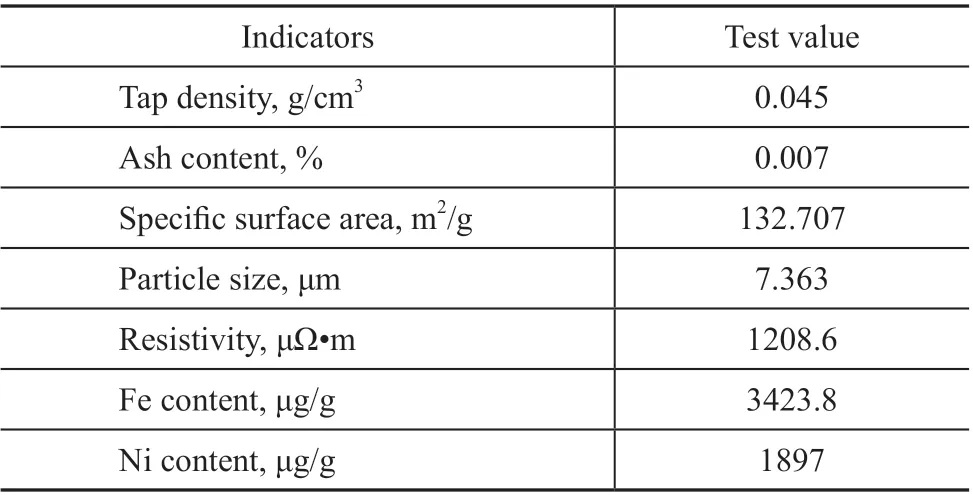

A #90 virgin asphalt was used to prepare the modified asphalt samples. The 40-mesh crumb rubber powder was produced by the ambient grinding technique, with its physical and chemical properties listed in Table 1.The CNTs used in this paper were the multi-wall carbon

nanotubes, with their property indexes shown in Table 2.

Table 1 Property indexes of CR

Table 2 Property indexes of CNTs

2.2 Preparation of samples

The modified asphalt samples were prepared by adding CR and CNTs to virgin asphalt. The proportion of CNTs and CR was specified as 1% and 10% by the weight of the virgin asphalt, respectively. The modified asphalt samples were prepared by means of a high-speed shearing machine equipped with an enclosed electric heater in this study. The preparation details were showed as follows.

Firstly, the virgin asphalt was heated in an enclosed electric heater at 140 - 150 °C. Secondly, a given weight of CNTs was added to the heated asphalt for 4 - 5 times,and this mixture was manually stirred at the same time.Then, a high-speed shearing machine was used to shear the heated asphalt containing CNTs at a rate of 3000 r/min for 40 minutes. After that, the temperature of this mixture containing CNTs was raised to 170 - 180 °C. A given weight of CR was added to this mixture and was stirred manually in the course of adding CR. When the CR was fully mixed with the asphalt, the mixture was sheared by the high-speed shearing machine at a rate of 3000 r/min for 60 minutes. Therefore the preparation of CNTs/CR composite-modified asphalt was completed.

In the procedure used to prepare the CR-modified asphalt and the CNTs-modified asphalt, the step of adding CNTs and CR was omitted, respectively.

2.3 Method

2.3.1 Force-ductility test

Based on JTG E20-2011[18], the Force-Ductility test at 10 °C was applied to appraise the low-temperature properties of the asphalts. A typical curve of Force-Ductility test for asphalt is shown in Figure 1. The point A means the peak force (Fmax), at which asphalt presents the maximum internal force; the area of OABDE is called the work of fracture (W), which can reflect the viscosity toughness of asphalt; the areas of OABC (WV) and BDCE(WT) are applied to characterize the viscoelasticity and the toughness of asphalt, respectively. Besides, the tensile flexibility (f), the yield strain energy (E) and the toughness ratio (RT/V) are also used to appraise the lowtemperature performance of asphalt, and the calculation formulas are shown as follows:

whereDmaxis the ductility at peak force (mm).

Figure 1 A typical curve of Force-Ductility test for asphalt

2.3.2 BBR test

The BBR test is considered as one of the most common and efficient methods to study the performance of asphalt at low temperatures[6,19], and it can comprehensively evaluate the low-temperature properties of asphalt by combining with the Force-Ductility test. The test temperature was determined as -12 °C, -18 °C and-24 °C. TheSandm-value were used to characterize the deformation resistance and the stress relaxation ability of asphalt at low temperatures, respectively.

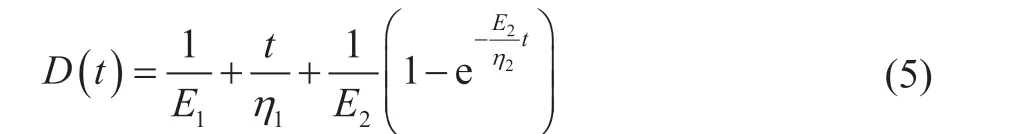

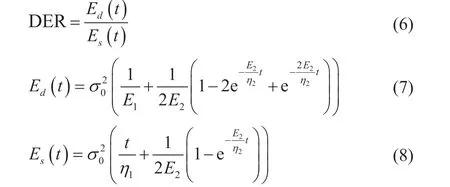

Based on the data of BBR test, the creep stiffness modulus of the asphalts can be calculated by Eq. (4). Additionally,the creep compliance in the Burgers model can be characterized by Eq. (5). For obtaining the parameters of the Burgers model, the Origin software is used to fit the creep characteristics of the asphalt samples.

whereE(t) is the creep stiffness modulus at timet(MPa);bis the beam width (mm);his the beam thickness (mm);ɛ(t)is the strain of specimen at timet(mm);Pis the applied constant load (mN);Lis the beam span (mm).

whereD(t) is the creep compliance at timet(MPa-1);E1andE2are the elastic indicators;η1andη2are the viscous indicators.The dissipated energy ratio (DER) can be calculated by using the model parameters (see Eqs. (6), (7) and (8)).

whereEd(t) andEs(t) are the dissipated energy and the stored energy per unit volume, respectively (MPa), andσ0is the stress of specimen (MPa).

The Zener model is also called the solid model with three parameters, which can represent the instantaneous elasticity and steady-state stress with solid characteristics.To further explore the creep characteristics of the asphalt samples at low temperatures, the Zener model was used to simulate the low-temperature creep behaviors of the asphalts. The expression is shown in Eq. (9), and the delay time (τ) is calculated by Eq. (10).

wherep1,q0andq1are the model parameters. Also,p1is called the relaxation time.

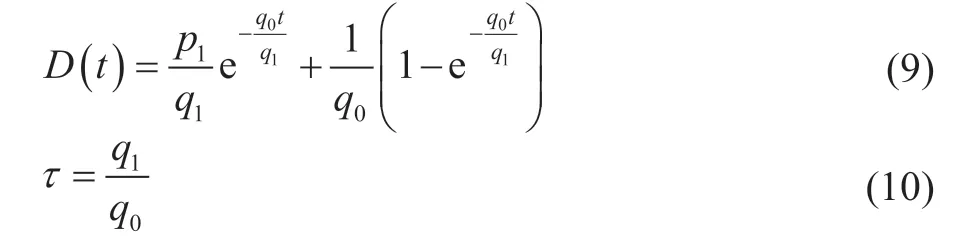

2.3.3 ATR-FTIR test

FTIR is one of the important methods to explore the chemical composition of asphalt materials. Thus, the infrared spectra of the asphalt samples were measured using a Bruker FTIR spectrometer equipped with a diamond ATR accessory in this study. Each sample was scanned 24 times on average within the wavenumber range of between 4 000 cm-1to 400 cm-1at a resolution of 4 cm-1. Additionally, the default OPUS 6.5 software was applied to perform the atmospheric/water compensation and baseline correction. For characterizing the chemical compositions of the asphalt samples before and after modification, the aromaticity index (IAR), the aliphatic index (IAL), and the long chains index (ILC) were calculated from the band areas measured from valley to valley[20-21], and the calculation formula is as follows.

2.3.4 DSC test

Glass transition is the inherent property of amorphous polymer materials, which is the transition between high elastic state and glass state[22]. The DSC test was conducted using a differential scanning calorimeter DSC 204 with the temperature increasing from -50 °C to 100 °C to measure the glass transition temperature (Tg) of the asphalt samples. The protective gas was nitrogen and the temperature increase rate was 10 °C/min.

3 Results and Discussion

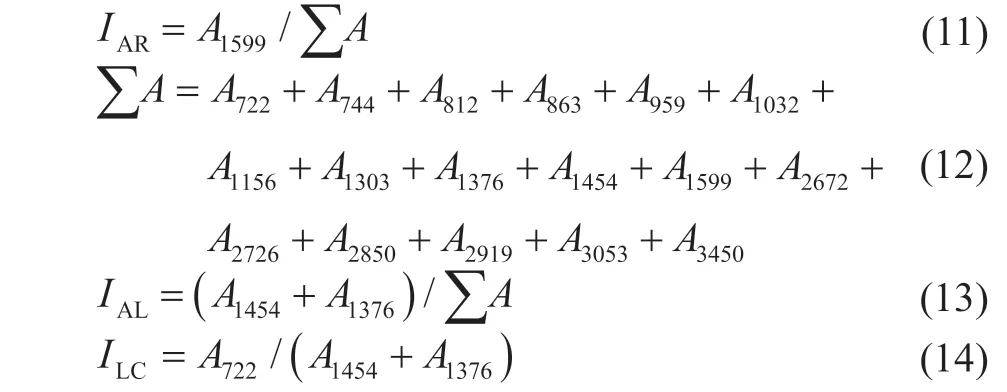

3.1 Analysis of Force-Ductility test results

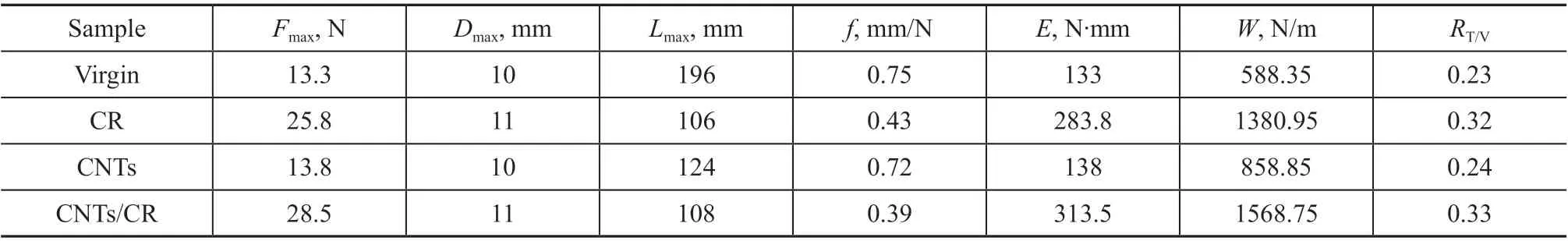

The Force-Ductility test results are shown in Figure 2 and Table 3. It can be seen from Figure 2 that the tensile force first increased and then decreased with the increase of ductility. In addition, all the asphalt samples had a similar gradient before reaching the peak force, which was only related to the asphalt matrix. It can be found from Table 3 that theLmaxvalue of the asphalt samples decreased after CR and CNTs were added, indicating that the two modifiers decreased the ductility of the asphalt at low temperatures. This result might be due to the fact that the addition of CNTs and CR led to the stress concentration at the interface between the modifiers and the asphalt.Besides, the addition of CR and CNTs increased the values ofFmax,RT/V,EandWof the asphalt and reduced thefvalue, which could occur, because CNTs and CR increased the bond angle of asphalt molecule to resist shear stress, so that a greater tensile force or a greater work was required to cause low-temperature deformation of the asphalt. That is to say, the performance of petroleum resin blended with the modifiers can be reflected by the internal force and deformation of the modified asphalts.

The data in Table 3 and Figure 2 suggest that CR possessed a significant effect on improving the lowtemperature properties, while CNTs had little effect. This was true, because the physical swelling and chemical degradation of CR particles occurred simultaneously,and the released components of CR particles during the chemical degradation formed a cross-linking network with the double bonds and aromatic rings of the asphalt.The agglomeration of CNTs in the asphalt led to the mutual sliding between CNTs that were not bound to the asphalt matrix, which resulted in the insignificant effect of CNTs on the low-temperature properties of asphalt.

Figure 2 The relationship curve between force and ductility

Table 3 Property indexes of the asphalt samples in Force-Ductility test

3.2 Analysis of low-temperature rheological properties

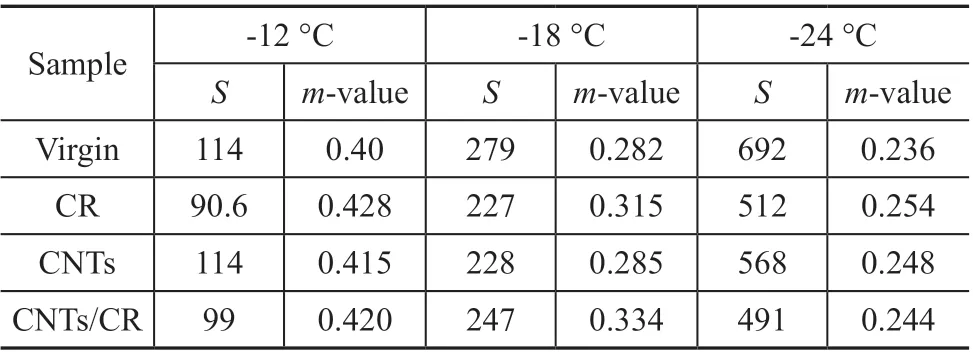

3.2.1Sandm-value

Generally speaking, the result of BBR test can be directly described bySandm-value at 60 s. According to the SHRP PG standard,Sshould be ≤ 300 MPa andmshould be ≥ 0.3 at the test temperature, indicating that the low-temperature performance of asphalt is qualified at this temperature[19]. TheSandm-value can reflect the time sensitivity and the stress relaxation capacity of asphalt.As a rule, a greaterm-value usually signifies outstanding low-temperature stress relaxation capacity of asphalt. In addition, a greaterSvalue means that the asphalt is brittle and is more prone to cracking at low temperatures.

TheSandm-value of the asphalt samples are presented in Table 4. It can be seen from Table 4 that theSvalue of the asphalt samples increased with the decrease of temperature,which revealed that low temperature can increase stiffness of the asphalts. TheSvalue of the modified asphalts was higher than that of the virgin asphalt, indicating that CNTs and CR enhanced the flexibility of the asphalt at low temperatures. Additionally, theSvalue of all the asphalt samples was lower than 300 MPa at -12 °C. It seems that CR had a more obvious enhancement effect on the flexibility of asphalt at low temperatures than CNTs.Evidence of this result is shown in Table 4; theSvalues of the composite-modified asphalt and the CR-modified asphalt were less than those of the virgin asphalt and the CNT-modified asphalt at the three test temperatures.

Them-value of the asphalt samples decreased with the decrease in temperature. Them-values of all the asphalt samples were greater than 0.3 at -12 °C, indicating that all the asphalt samples had good stress relaxation ability at -12 °C. At -18 °C, them-values of the CR-modified asphalt and the composite-modified asphalt met the requirements of SHRP PG standard, while those of the virgin asphalt and the CNTs-modified asphalt were less than 0.3. When the temperature was reduced to -24 °C,them-values of all the asphalt samples were lower than 0.3. Furthermore, them-values of the modified asphalts were greater than those of the virgin asphalt at all the test temperatures, indicating that the presence of CNTs and CR ameliorated the stress relaxation ability and time sensitivity of the asphalt at low temperatures.

Table 4 The S and m-value at 60 s

3.2.2 Low-temperature creep characteristics based on Burgers model

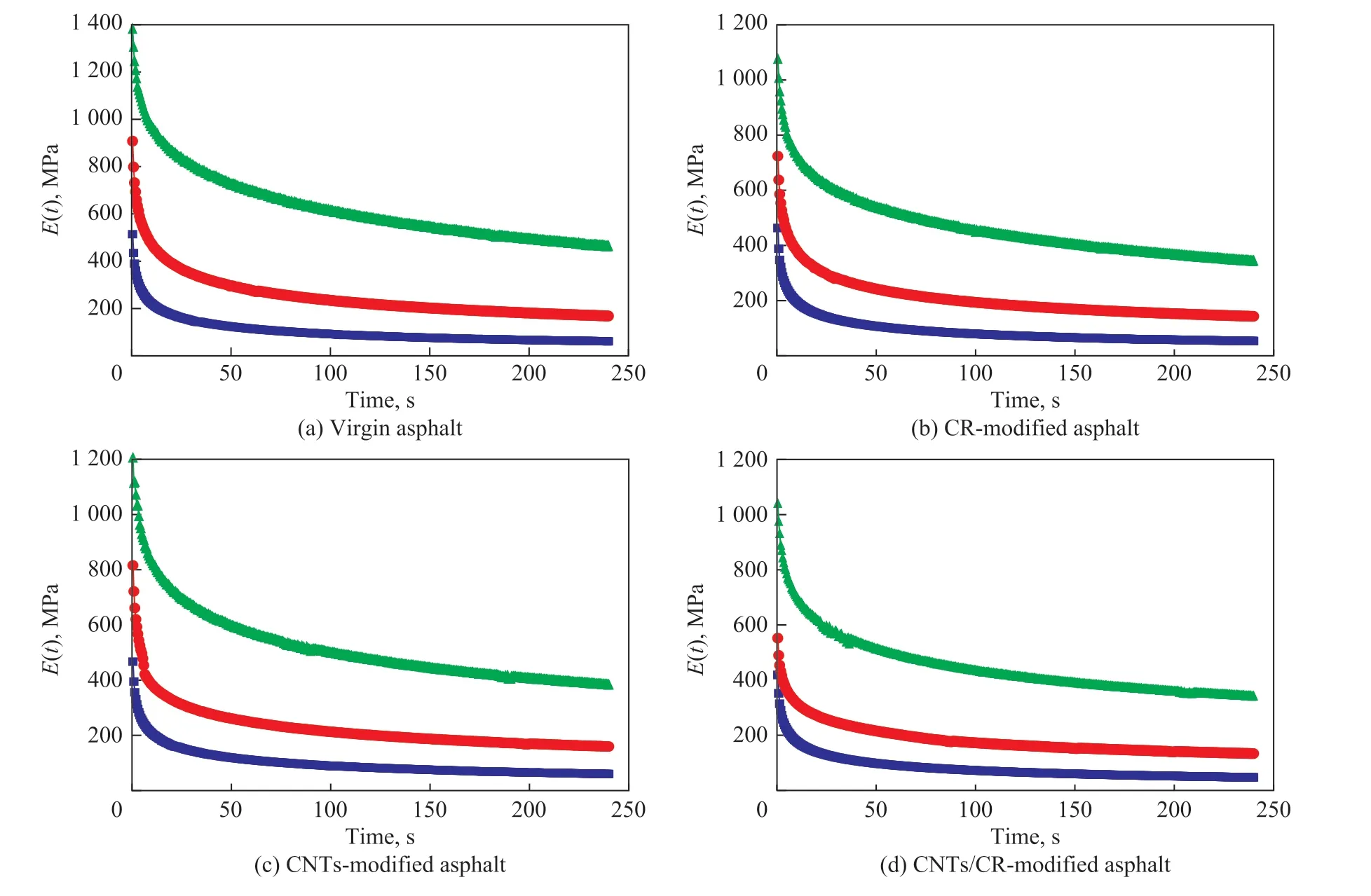

The creep stiffness modulus of the asphalt samples at different temperatures is shown in Figure 3. It can be seen from Figure 3 that the stiffness modulus of the asphalt samples decreased with the increase in loading time at the beginning of loading, and then tended to be stable.It can be seen from Figure 3 that the decrease rate of creep stiffness modulus of the asphalt samples at -12 °C was greater than that at -18 °C and -24 °C. This can be explained by an increased movement rate of the asphalt molecules at higher temperatures.

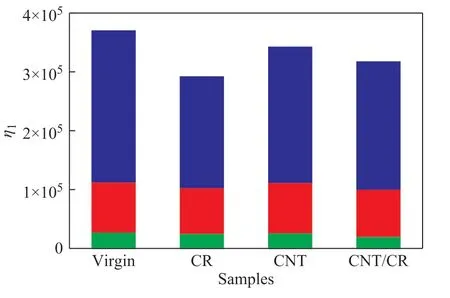

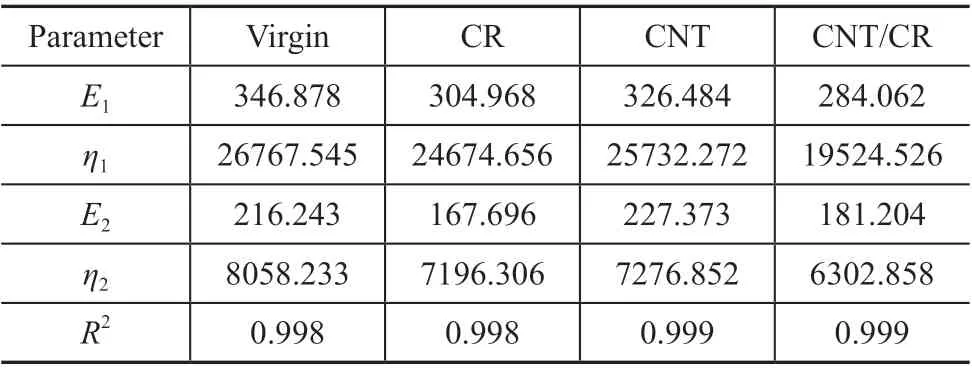

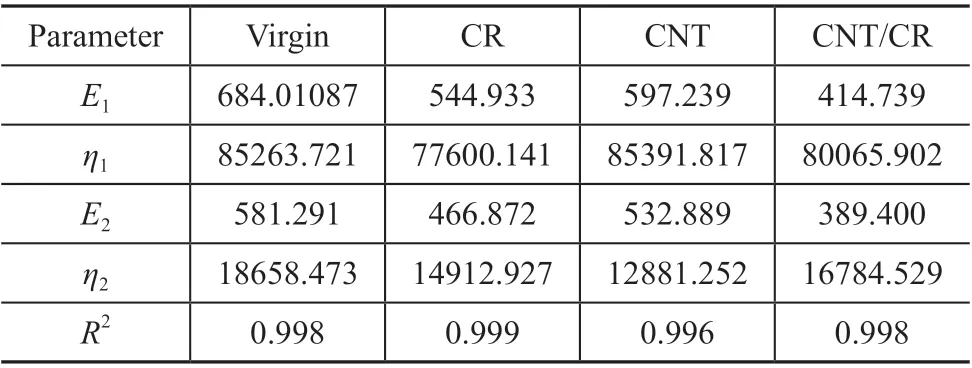

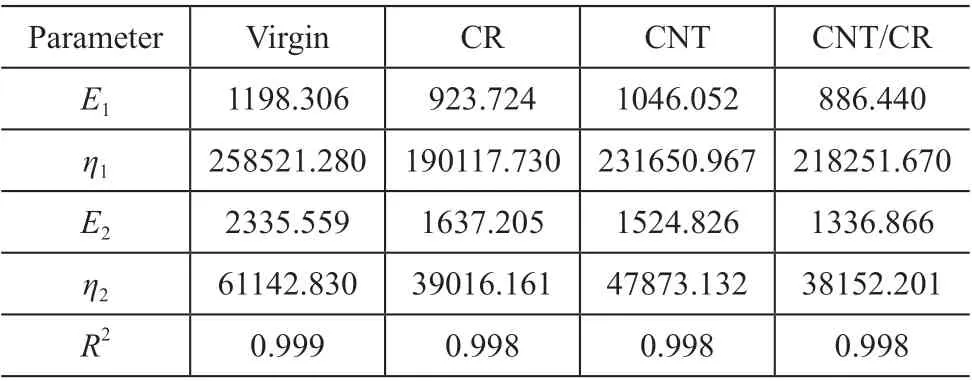

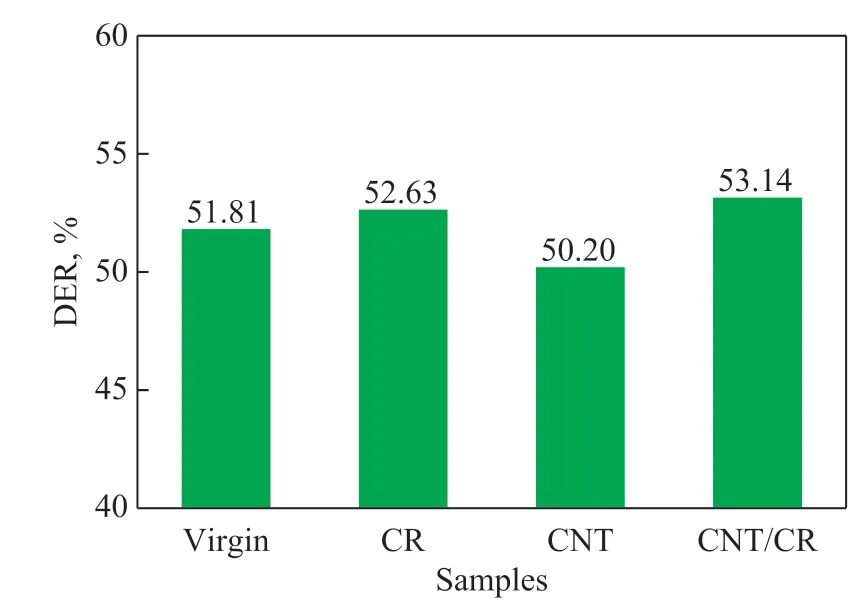

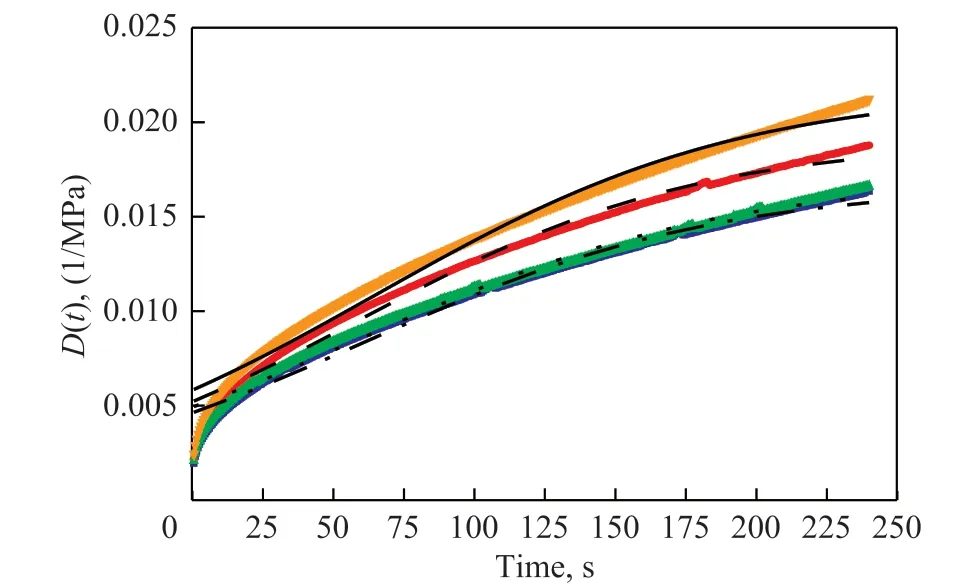

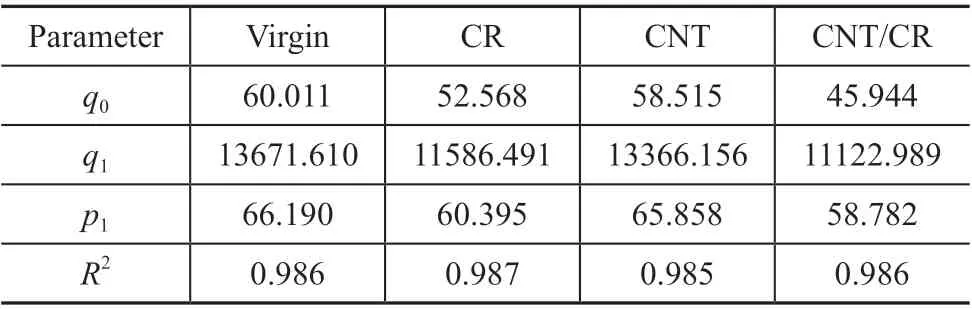

The software Origin 8.0 was used to perform the fitting program, and the creep data of BBR test at different temperatures were fitted by the Burgers model. A fitting example using the Burgers model is presented in Figure 4. The fitting results are listed in Tables 5, 6, and 7. The correlation coefficients (R2) of creep curves for all the asphalt samples were above 0.99, which indicated that the Burgers model can well fit the creep characteristics of the asphalt samples. According to the physical meaning represented by the Burgers model, the deformation resistance of asphalt can be characterized byη1in the four model parameters.As a rule, a smallerη1usually signifies outstanding antideformation ability of asphalt. As shown in Figure 5, theη1of asphalt samplesat the three test temperatures decreased in the following order: virgin asphalt > CNTs-modified asphalt> CR-modified asphalt > CNTs/CR-modified asphalt. This result indicated that the low-temperature properties of CNTs/CR composite-modified asphalt were the best, and the improvement effect of CR on low-temperature properties of asphalt was better than that of CNTs. DERcan be used to characterize the capacity of asphalt binder for absorbing the impact energy. In general, a higherDERvalue means that the asphalt possesses excellent ability to absorb the impact load and anti-cracking at low temperatures. As shown in Figure 6, the DER of the CR-modified asphalt and the CNT/CR composite-modified asphalt was higher than that of virgin asphalt, while that of the CNTs-modified asphalt was slightly smaller than that of virgin asphalt. This result demonstrated that CR improved the relaxation ability of the asphalt, while CNTs had little effect.

Figure 3 The stiffness modulus of the asphalt samples

Figure 4 A fitting example using the Burgers model at -12 °C

Figure 5 η1 of Burgers model for the asphalt samples

Table 5 The fitting parameters of Burgers model at -12 °C

Table 6 The fitting parameters of Burgers model at -18 °C

Table 7 The fitting parameters of Burgers model at -24 °C

Figure 6 DER of the asphalt samples

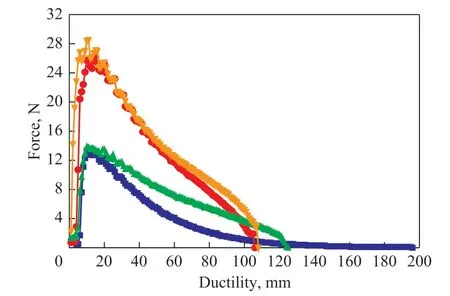

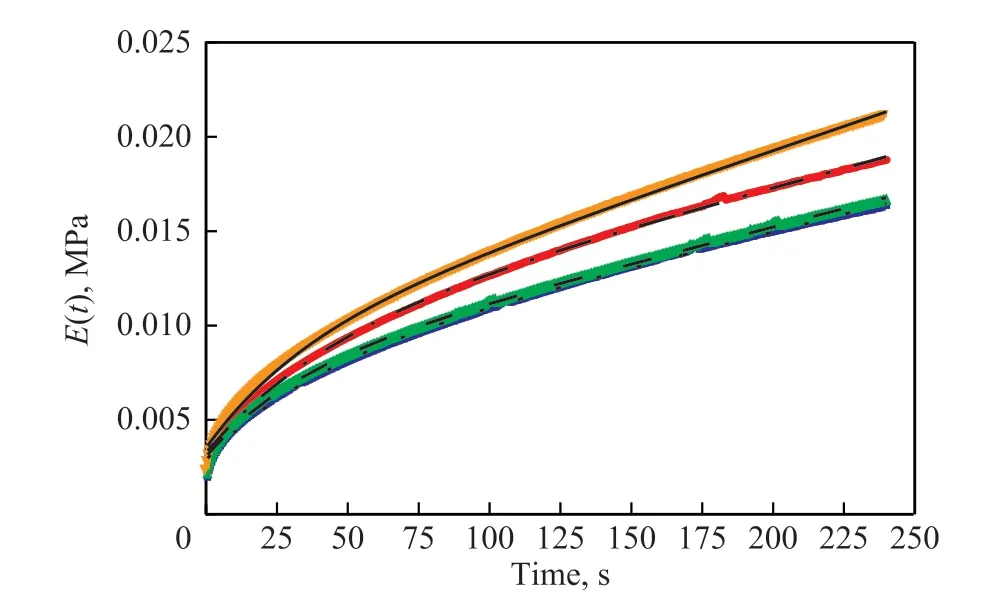

3.2.3 Low-temperature creep characteristics based on Zener model

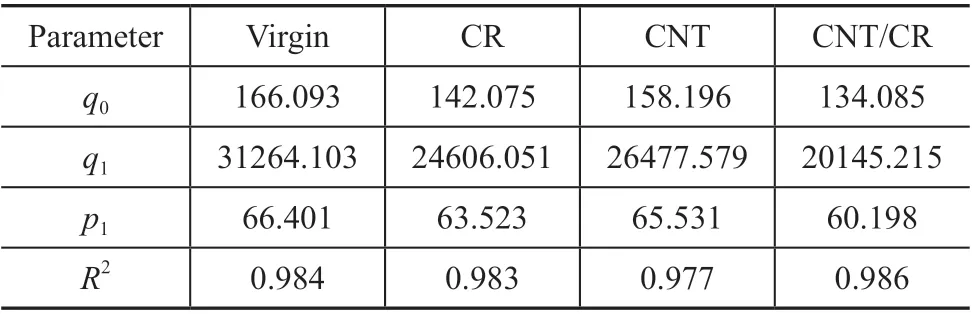

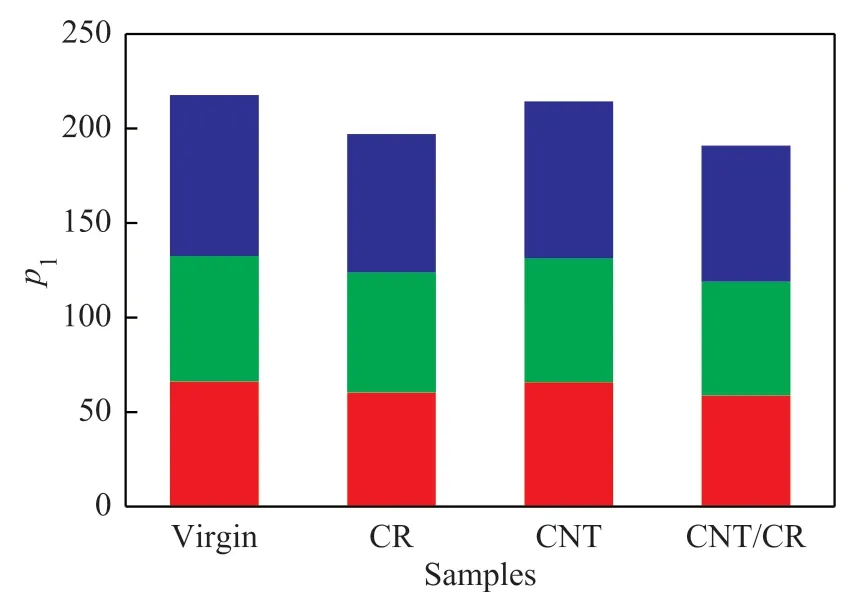

To verify the effectiveness of solid model for lowtemperature creep data, the creep curves of the asphalt samples were fitted by the Zener model. It can be seen from the correlation coefficients (R2) that the viscoelastic solid model could successfully simulate the lowtemperature creep behaviors of the asphalts.As shown in Figure 7, the creep compliance of the asphalt samples decreased in the following order: CNT/CR composite-modified asphalt > CR-modified asphalt> CNTs-modified asphalt > virgin asphalt, indicating that the influence of CNTs on creep compliance of the asphalt was less significant than that of CR. This result might be due to the fact that the elasticity of the compositemodified asphalt mainly came from rubber powder with coarse particles and good elasticity. Thus, the addition of CR remarkably improved the elasticity of virgin asphalt,and increased the creep compliance. Nevertheless, the added CNTs may mainly affect the phase structure of CR-asphalt blend system from the microscopic point of view. It can be seen from Tables 8, 9, and 10 that the temperature had a significant effect on the fitting parameters of the Zener model. As the temperature went down, the values of all the model parameters increased. Among these parameters,p1is usually used to characterize the relaxation time, and a higherp1value expresses the lower stress relaxation rate. It can be seen from Figure 8 that thep1vlue of the compositemodified asphalt was the lowest, followed by the CRmodified asphalt. This result might be due to the fact that the addition of CR reduced the relaxation time by increasing the viscosity and elasticity of asphalt, thus improving the lowtemperature elasticity and cracking resistance of the virgin asphalt. Besides, thep1value of the CNTs-modified asphalt was slightly lower than that of virgin asphalt, indicating that the improvement effect of CNTs on the stress relaxation characteristics of asphalt might be insignificant.

Figure 7 A fitting example using the Zener model at -12 °C

3.3 Analysis of ATR-FTIR infrared spectra

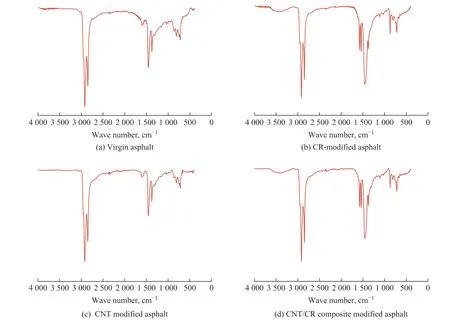

Infrared spectra of the modified asphalt samples arepresented in Figure 9. All the asphalt samples showed the strong absorption peaks at near 2 918 cm-1and 2 850 cm-1, which were the result of unsaturated C-H bond vibrations. Within this range, the absorption peak intensity of the CR-modified asphalt and the CNTs/CR compositemodified asphalt was higher than that of the virgin asphalt and the CNTs-modified asphalt. Moreover, the absorption peak shape and position of the composite-modified asphalt were very similar to those of the CR-modified asphalt, which may indicate that the influence of CNTs on the surface functional groups of asphalt was insignificant.The absorption peak intensity of the CR-modified asphalt and the CNTs/CR composite-modified asphalt at about 1 599 cm-1was significantly stronger than that of the virgin asphalt, which might be caused by the conjugation of C = C bonds and benzene rings in the rubber powder.Additionally, the absorption peak at near 1 538 cm-1may be caused by the stretching vibration of C = O of hydroxyl compound. The absorption peak intensity at near 1 454 cm-1of the CR-modified asphalt and the composite-modified asphalt was significant stronger than that of the virgin asphalt, which might be due to the bending vibration of C-H bond. The addition of CR enhanced the absorption peak intensity at near 860 cm-1and 721 cm-1, which manifested that CR increased the out of plane rocking vibration of C-H on the benzene ring. It can be observed from Figure 9 that the absorption peak intensity at near 1 599 cm-1for the CNTs-modified asphalt was greater than that of the virgin asphalt, which might be caused by the C = C stretching vibration of the benzene ring. It seems that the absorption peak intensity of the modified asphalts at 1 454 cm-1, 1 376 cm-1and 722 cm-1had little change as compared with the virgin asphalt.

Table 8 The fitting parameters of Zener model at -12 °C

Table 9 The fitting parameters of Zener model at -18 °C

Table 10 The fitting parameters of Zener model at -24 °C

Figure 8 The p1 of Zener model for the asphalt samples

According to the difference in molecular size, molecular polarity and molecular configuration, the chemical compositions of asphalt can be divided into four components by adsorption and chromatography. Numerous studies had shown that the content of aromatics and saturates has a significant impact on the low-temperature performance of asphalt[6,23-25]. Saturates are composed of straight chain and branched chain aliphatic hydrocarbons,alkyl cyclic hydrocarbons and alkyl aromatic hydrocarbons.Based on the literature review, the aromatic and aliphatic components are the most abundant light components released from CR under the condition of high-temperature and high-speed shear. Thus, FTIR is a suitable method to characterize the content of aromatic and aliphatic components in asphalt by measuring the concentration of oxygen-containing functional groups. In general,IARis used to describe the aromatic structure and represent the content of aromaticity.IALandILCare applied to characterize the aliphatic structures, whereIALsignifies the aliphatic content andILCrepresents the average length of aliphatic chains.

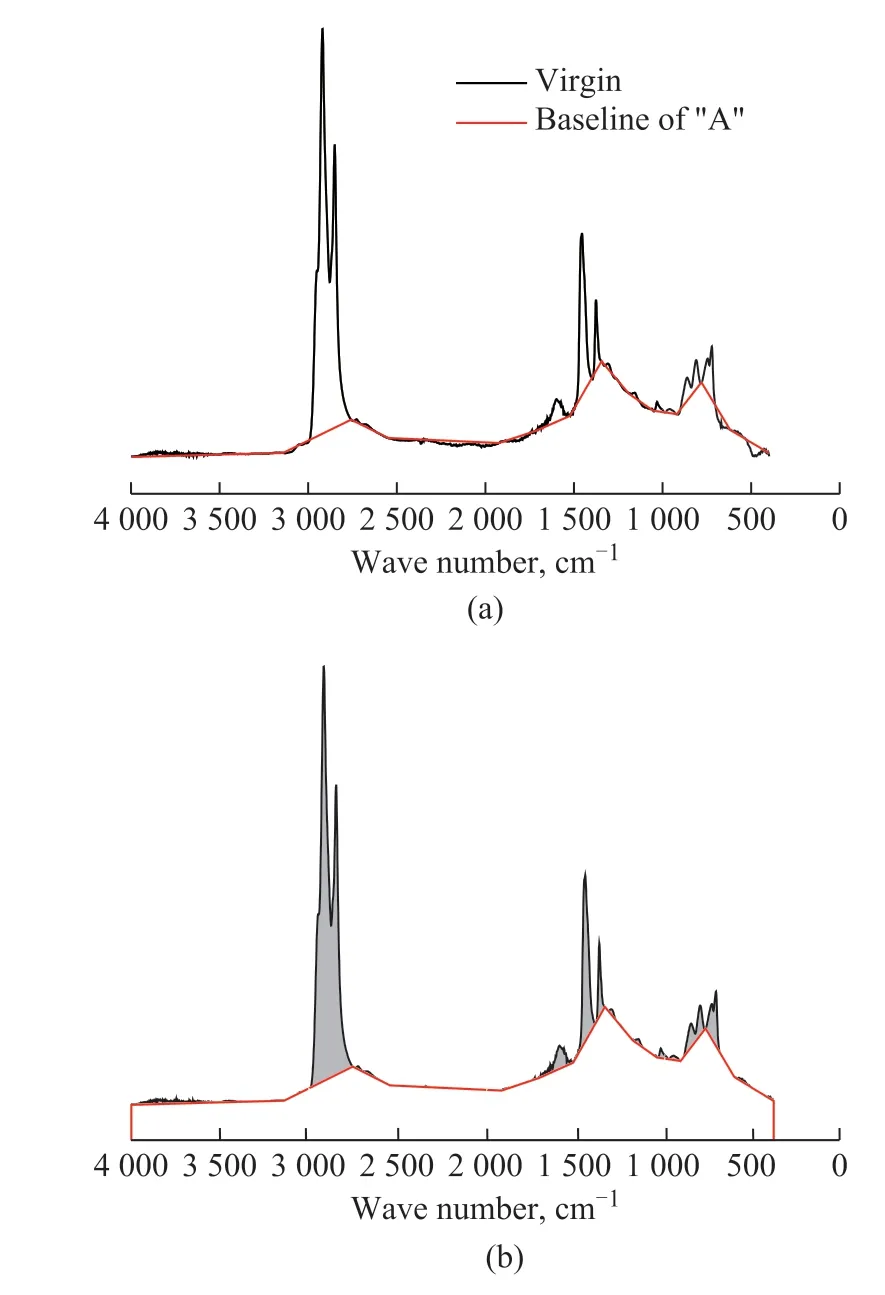

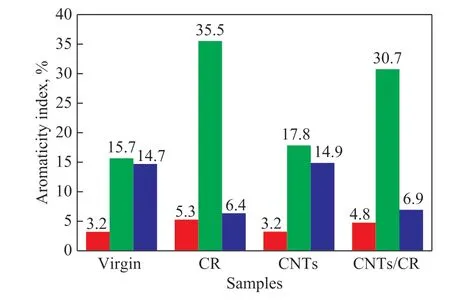

To quantify functional groups in the infrared spectrograms of asphalt, the band areas were used to calculate the values ofIAR,IALandILCfor the asphalt samples. The band areas were computed by the following procedure: Firstly,the spectra as absorbance versus wave number were collect. Secondly, the Bruker OPUS 6.5 software was used to compensate for the atmosphere and calibrate the baseline. Thirdly, the absorption peaks were extracted by the second-derivative method. Lastly, the band areas were calculated using valley-to-valley integration (see Figure 10). The calculated results ofIAR,IALandILCare shown in Figure 11. It can be seen from Figure 11 thatIARandIALof the CR-modified asphalt and the composite-modified asphalt were much higher than those of the virgin asphalt and the CNTs-modified asphalt. However,IARof the CNTs-modified asphalt was approximately equal to that of virgin asphalt. The results implied that the addition of CR significantly increased the content of aromatic and aliphatic components of the asphalt, while CNTs had little effect on the content of these components. Furthermore,the volatilization of light components in asphalt under the high-strength shear process and adsorption of the light components of asphalt by CNTs might be the reason why theIARvalue of the composite-modified asphalt was lower than that of the CR-modified asphalt. It can be seen from Figure 11 that CR decreased theILCof virgin asphalt,while CNTs had little effect. This outcome was true,because the chain length of aliphatic components released by the rubber powder under high-strength shearing process was shorter than that of aliphatic components of the asphalt, while CNTs could not chemically react with the asphalt components.

3.4 Analysis of glass transition temperature

Generally speaking, the glass transition temperature refers to the temperature at which the polymer material is at the critical point between the high elastic state and the glass state[24]. As the temperature gradually rises and crosses the glass transition temperature, the phase state of polymer material changes from the glass state to a highly elastic state[24-25]. During this process, the internal molecular chain segments change from the stationary state to the moving state. Therefore, the glass transition temperature characterizes the temperature, at which the segment movement of polymer material can start or can be frozen.Based on this, the glass transition temperature can be used to evaluate the low-temperature stability of asphalt.

Figure 9 Infrared spectrogram of the modified asphalts

Figure 10 An example of virgin asphalt: (a) Establishment of baseline, (b) Calculation of peak area

Figure 11 IAR, IAL and ILC of the asphalt samples

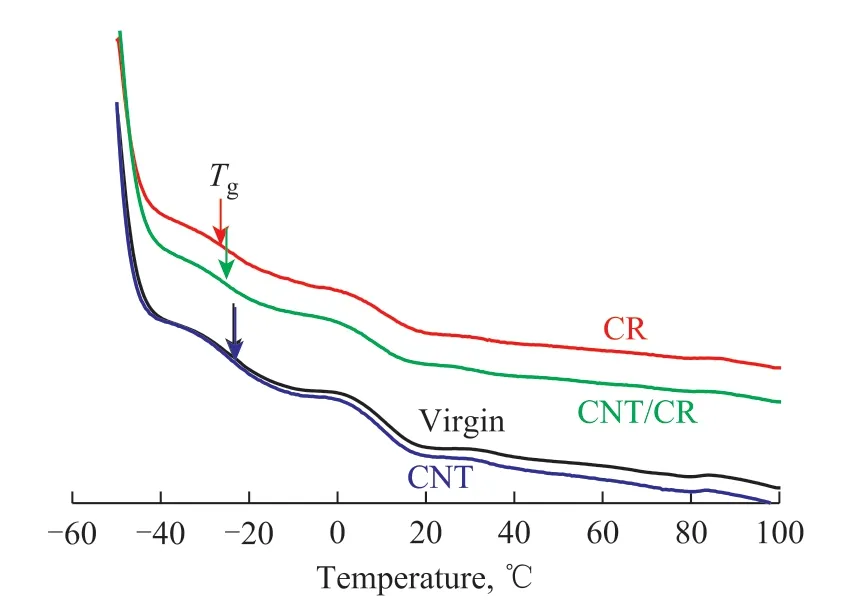

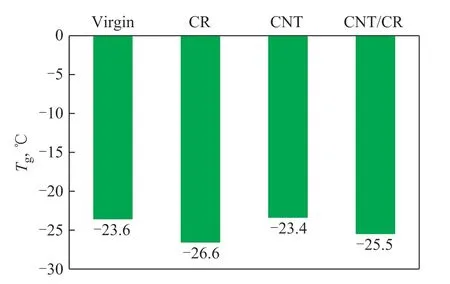

The results of DSC tests are presented in Figures 12 and 13. It can be seen from Figure 12 that the added CNTs slightly increased the glass transition temperature of the virgin asphalt, while CR significantly decreased the glass transition temperature of the virgin asphalt. This result indicated that CR could markedly improve the lowtemperature stability of the asphalt, while CNTs had a slightly negative effect. Combined with the quantitative analysis results of FTIR test, it can be inferred that the relative increase of aromatic and aliphatic components caused by adding CR improved the low-temperature stability of asphalt, which enabled the asphalt to withstand lower temperature without phase transition.Similarly, the added CNTs could not markedly change the amount of aliphatic components or aromatic components in the asphalt, so that CNTs had little effect on the lowtemperature stability of asphalt. Moreover, the glass transition temperature of the composite-modified asphalt was by 1.9 °C lower than that of the virgin asphalt, and by 1.1 °C higher than that of the CR-modified asphalt,demonstrating that CR had an observable effect on enhancing the low-temperature stability of asphalt. The reason revealing why the glass transition temperature of the composite-modified asphalt was slightly higher than that of the CR-modified asphalt might be that a certain amount of the aromatic and aliphatic components in asphalt was attached to the surface of CNTs.

Figure 12 The DSC curves of the asphalt samples

Figure 13 The glass transition temperatures of the asphalt samples

4 Conclusions

This study investigated the low-temperature performance of the modified asphalts containing CR and CNTs by a series of property tests and micro-analysis techniques.Based on the experimental results, the primary conclusions are presented below.

(1) The addition of CR and CNTs increased the hardness and toughness of the virgin asphalt. In addition, the two modifiers decreased the ductility of the asphalt. This might be due to the fact that the added CNTs and CR caused the stress concentration at the interface between the modifiers and the asphalt, resulting in rapid fracture of the modified asphalts in the tensile process.

(2) The results of BBR test were consistent with the fitting results of Burgers model and Zener model. These results indicated that CR can significantly improve lowtemperature flexibility and stress relaxation ability of the asphalt, while CNTs had little effect.

(3) The released components from CR during degradation increased the amount of aromatic and aliphatic components, and shortened the average length of long chains in asphalt. However, CNTs had little effect on the average length of aliphatic chains and the amount of aromatic and aliphatic components for asphalt.

(4) The DSC test results verified that CR decreased the glass transition temperature of virgin asphalt, indicating that CR ameliorated low-temperature stability of asphalt.However, the added CNTs slightly increased the glass transition temperature of asphalt.

Acknowledgments:The authors appreciate the support from the National Natural Science Foundation of China (Grant No.52078051), the Technology Innovation Project of Department of Industry and Information Technology of Shandong Province (Grant No. Lugongxinji (2020) 8), the Transportation Department of Shandong Province (Grant No. Lujiaokeji(2017) 28), the Traffic Science and Technology Project of Xixian New District Management Committee of Shaanxi Province (2017 44), and the Zhuhai Transportation Group Co.Ltd. (JT-HG-2020-21).

杂志排行

中国炼油与石油化工的其它文章

- Study on Viscosity Reducing and Oil Displacement Agent for Water-Flooding Heavy Oil Reservoir

- Electrospinning Nanofiber Membrane Reinforced PVA Composite Hydrogel with Preferable Mechanical Performance for Oil-Water Separation

- Preparation of Solid Waste-Based Activated Carbon and Its Adsorption Mechanism for Toluene

- Antibacterial and Corrosion Inhibition Properties of SA-ZnO@ODA-GO@PU Super-Hydrophobic Coating in Circulating Cooling Water System

- Investigation of Nitrite Production Pathway in Integrated Partial Denitrification/Anammox Process via Isotope Labelling Technique and the Relevant Microbial Communities

- Heteroatom-Doped Carbon Spheres from FCC Slurry Oil as Anode Material for Lithium-Ion Battery