深部厚煤层动静载荷下区段煤柱损伤演化分析

2022-03-17雷照源李团结崔峰郭超奇易瑞强

雷照源 李团结 崔峰 郭超奇 易瑞强

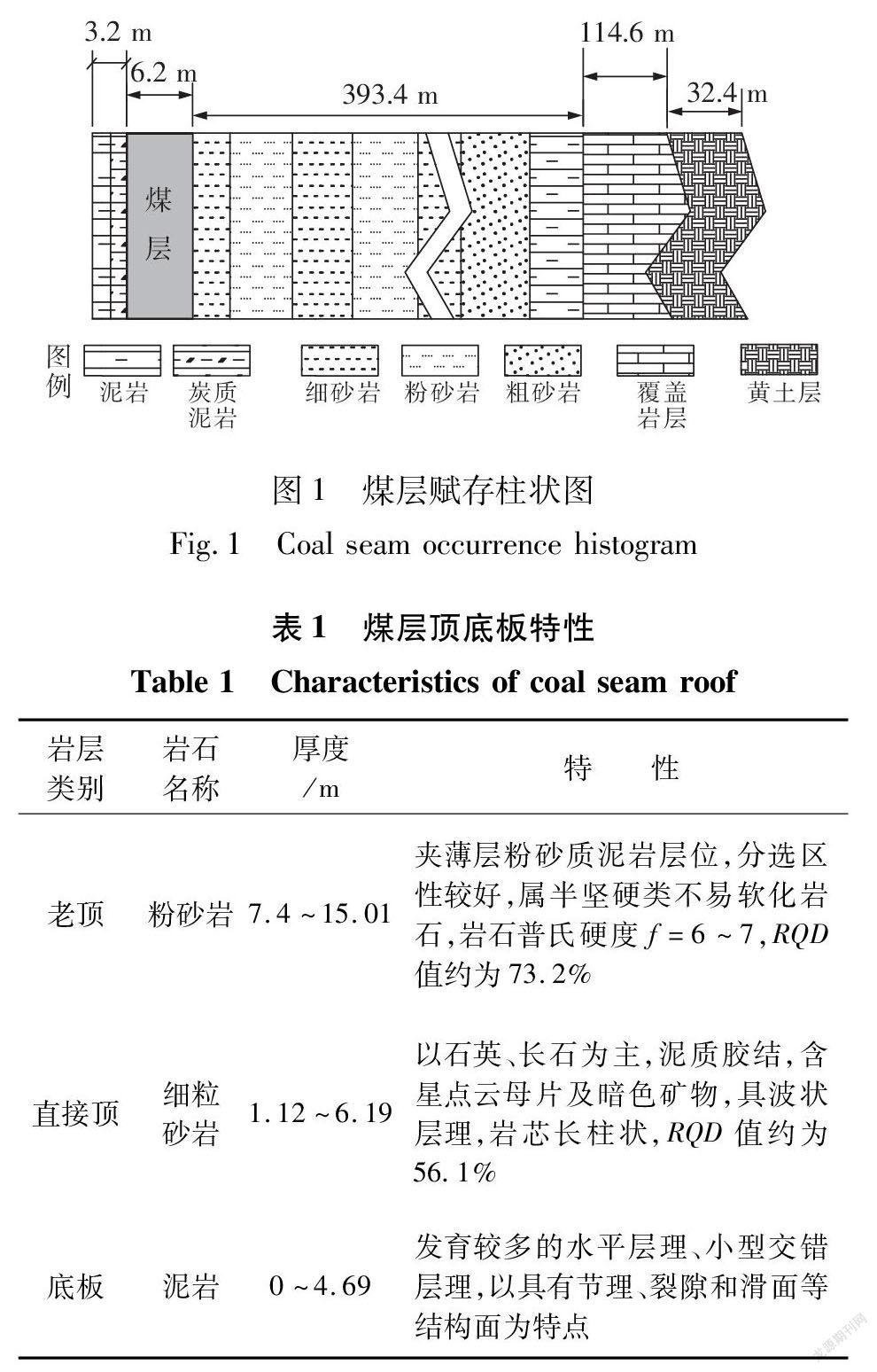

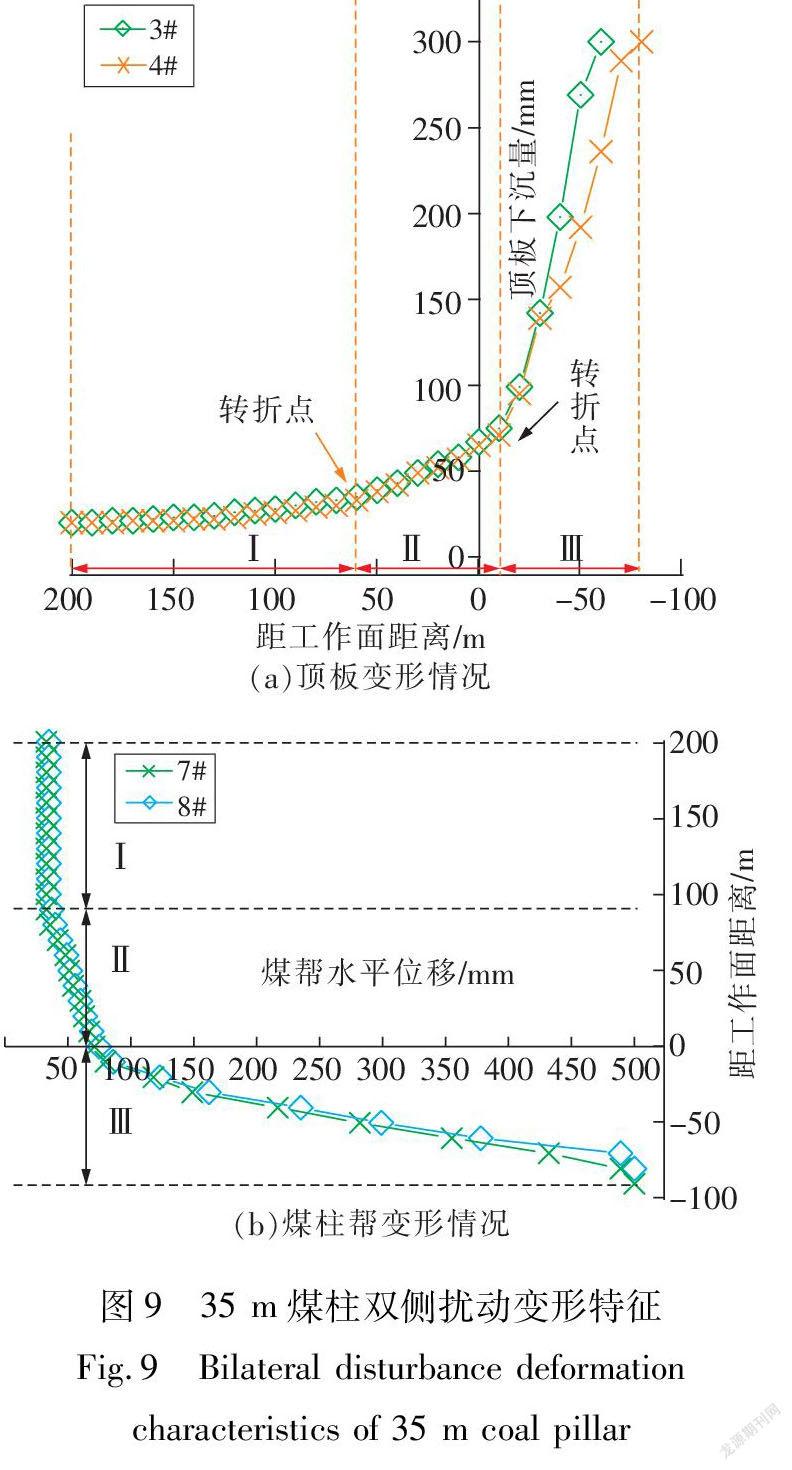

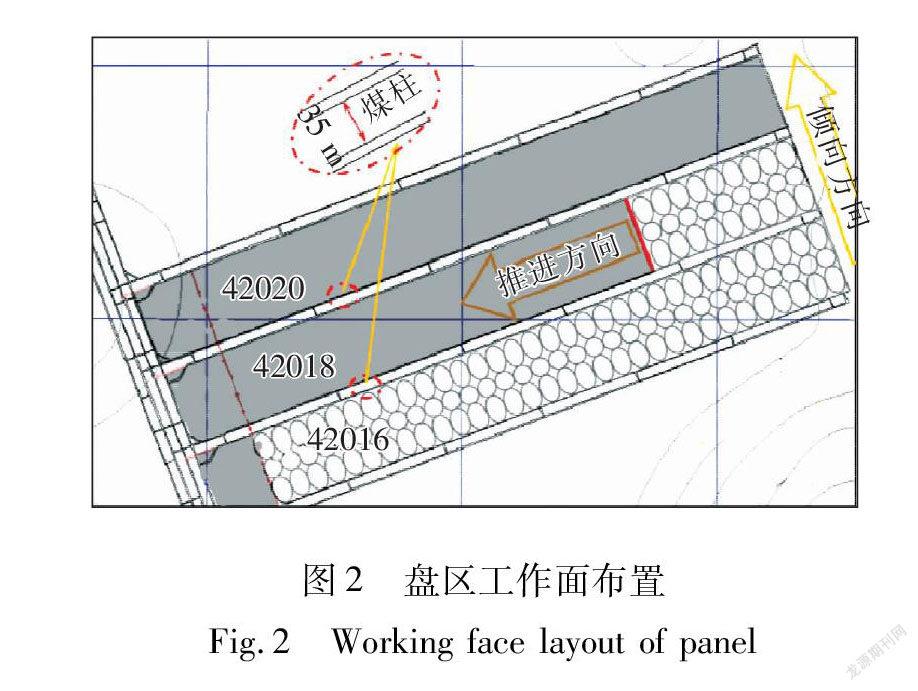

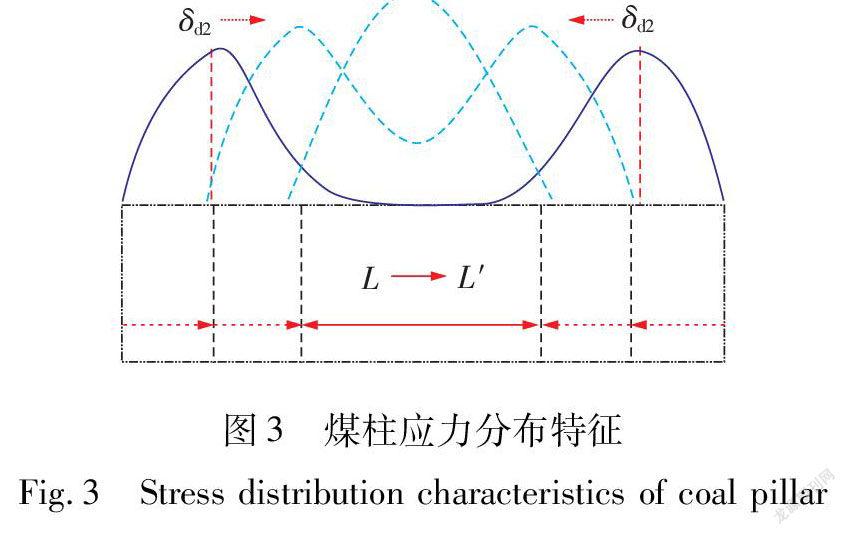

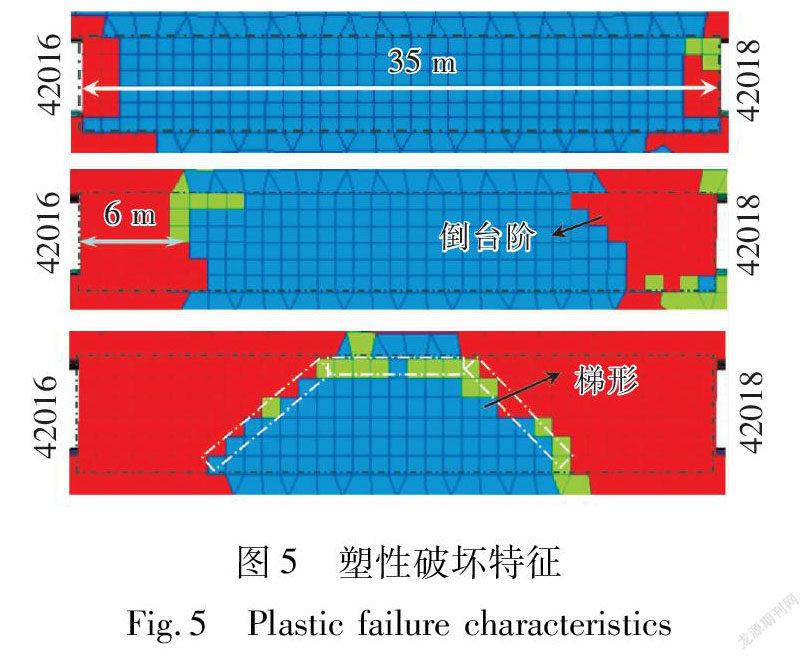

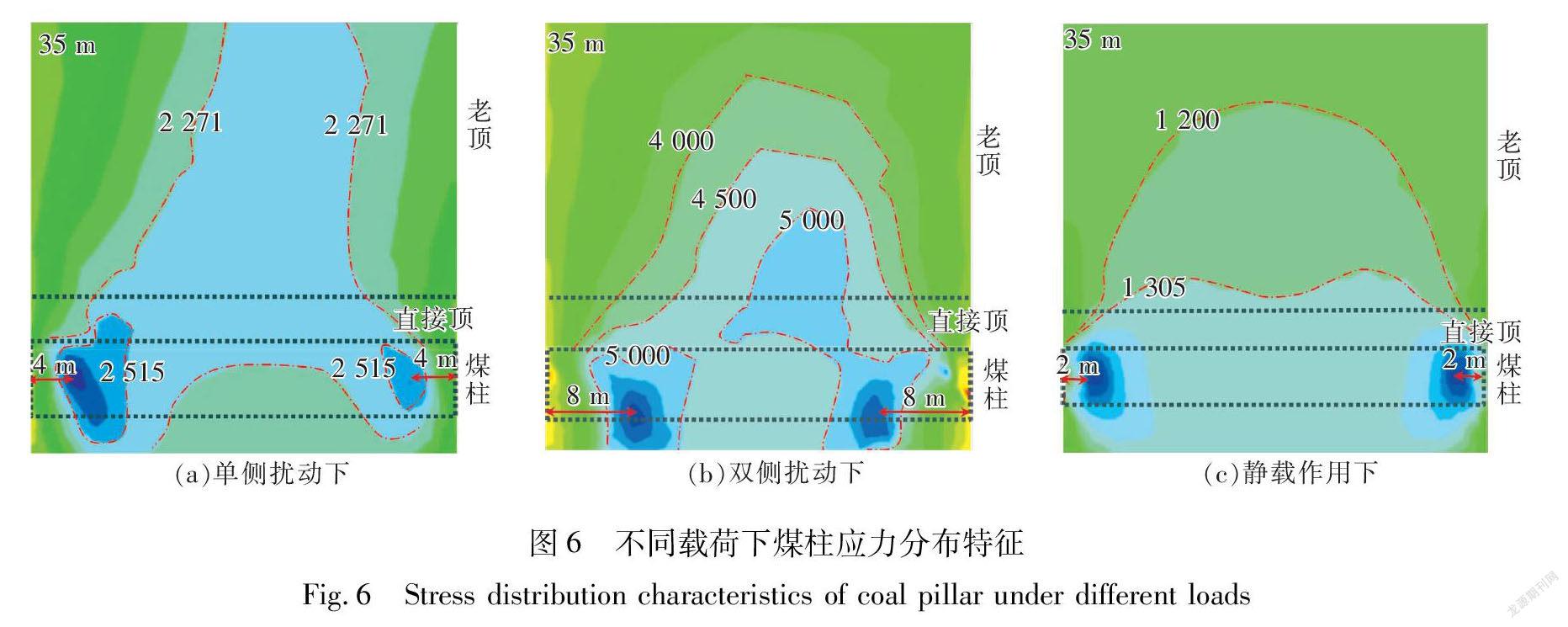

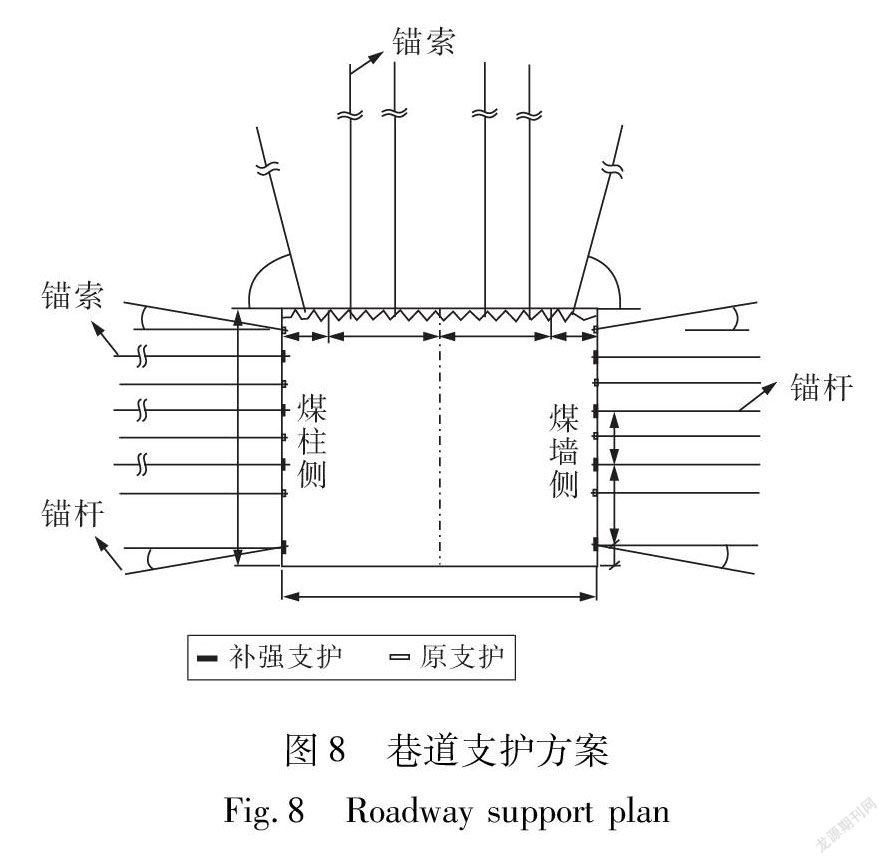

摘 要:深部厚煤層综采工作面沿空开采下引发的煤柱动力失稳,是严重影响矿井的安全生产条件之一。以陕西某矿区留设35 m段煤柱稳定性为研究对象,通过赋存条件调查、理论分析、数值计算、现场监测等方法,分析区段煤柱在动、静载荷下的演化特征。研究表明:煤柱在静载向动载荷的转化过程中,35 m煤柱内部两侧的应力峰值从2 m迁移至8 m,双侧扰动下的应力明显高于煤体的抗压强度;内部的塑性破坏占比从9.52%增加至40%,最终35 m煤柱内部形成“梯型”稳态结构。根据现场煤柱动载荷影响,结合巷道布置方式提出进行分区支护原则。实践表明:巷道顶板及煤柱帮经历3种变化的位移特征,在距采空区70~90 m范围的运动达到极限。因此,35 m煤柱能满足开采极限条件下的支撑作用,满足生产的实际需要。关键词:深部厚煤层;动载荷;静载荷;区段煤柱

中图分类号:TD 324

文章编号:1672-9315(2022)01-0091-08 文献标志码:A

DOI:10.13800/j.cnki.xakjdxxb.2022.0113开放科学(资源服务)标识码(OSID):

Damage evolution analysis of section coal pillar under

dynamic and static load in deep thick coal seam

LEI Zhaoyuan1,2,4,LI Tuanjie4,CUI Feng1,2,3,GUO Chaoqi4,YI Ruiqiang4

(1.College of Energy Science and Engineering,Xi’an University of Science and Technology,Xi’an 710054,China;

2.Key Laboratory of Western Mine Exploitation and Hazard Prevention,Ministry of Education,

Xi’an University of Science and Technology,Xi’an 710054,China;

3.Key Laboratory of Coal Resource Exploration and Comprehensive Utilization,

Ministry of Land and Resources,Xi’an University of Science and Technology,Xi’an 710054,China;

4.Shaanxi Shanmei Huangling Mining(Group)Co.,Ltd.,Huangling 727307,China)Abstract:The dynamic instability of coal pillar caused by gob mining in fully mechanized mining face of deep thick coal seam seriously affects the safety of mine production.

The section coal pillar(35 m) at a coal mine in Shaanxi province is taken as the research object.The research means are applied including occurrence condition investigation,theoretical analysis,numerical calculation and field monitoring to study evolution characteristics of section coal pillar under dynamic and static loads.Research shows that:under different loads,the peak stress on both sides of the 35 m coal pillar moves from 2 m to 8 m,and the stress under bilateral disturbance is obviously higher than the compressive strength of the coal.The proportion of plastic failure inside increases from 9.52% to 40%,and a trapezoidal structure is formed inside of 35m pillar.According to the different mining influence of roadway in the field,the principle of partition support is proposed.It turns out that roof and coal pillar undergo three kinds of displacement characteristics,and the movement of goaf reaches the limit at 70 to 90 m.Therefore,35m coal pillar can play a good supporting role under the mining limit conditions and meet the production needs.Key words:deep thick coal seam;dynamic load;static load;section coal pillar

0 引 言

深部煤层赋存原岩应力大,厚煤层回采扰动应力及影响范围大,易导致回采期间面临矿压显现强烈、巷道变形量大等现象的发生[1]。根据煤柱作用不同,主要分为4类[2]。区段煤柱作为工作面形成的基础,合理的煤柱尺寸在其内部弹性核的作用下起到保护巷道安全的作用。巷道成型及回采过程中,煤柱内部应力释放分别呈现缓慢释放和快速释放2种不同模式,深部厚煤层开采进一步导致煤柱剧烈变形,给灾害防治带来的挑战。近年来众多学者充分考虑地质构造、开采时空关系等影响因素,分析了地表与采动的关系[3-5]。随着煤柱型动力灾害在采动下发生,通过多手段相结合模式,针对“一矿一特色”提出了与之相适应的煤柱监控检测技术[6-9]。宋录生等提出并建立了立“顶板-煤层”结构体模型,通过对4种不同模型的冲击倾向性试验,得出“顶板-煤层”结构体冲击倾向性高于纯煤层或岩层测定结果[10]。陈绍杰等对不同高比的5组顶板砂岩-煤柱结构体进行单轴压缩试验,得出不同的3种结论和砂岩破坏的动态过程[11]。祁和刚等针对深部高应力区段煤柱留设合理性,开展了并提出了“一高一低”的高应力区段煤柱综合卸荷技术的研究[12]。付玉凯等在分析煤柱留巷围岩破坏机制的基础上,提出深部煤柱留巷“卸-支-注”协同控制原理,术有效改善了煤柱留巷的围岩力学属性和应力状态[13]。王涛等分析了临空煤柱巷道侧冲击地压的成因和受夹持煤体的冲击失稳过程,得出了断顶卸压爆破可以有效切断坚硬悬板对煤柱的应力传递[14]。伍永平等基于大倾角煤层长壁工作面“R-S-F”系统,研究了区段煤柱的应力分布规律和失稳破坏准则,最终确定了区段煤柱宽度k满足kZH