Whether the Microemulsion is a Nano-pesticide: Exploration from the Perspective of Particle Size and Morphology

2022-02-17JingliCHENGWenlongLIANGJiadongZHANGQiuyuXIONGJinhaoZHAO

Jingli CHENG, Wenlong LIANG, Jiadong ZHANG, Qiuyu XIONG, Jinhao ZHAO

Ministry of Agriculture Key Lab of Molecular Biology of Crop Pathogens and Insects, Key Laboratory of Biology of Crop Pathogens and Insects of Zhejiang Province, Zhejiang University, Hangzhou 310058, China

Abstract [Objectives] The paper was to explore whether the microemulsion is a nano-pesticide. [Methods] Several microemulsions commonly available on the market were studied from the perspective of particle size and morphological characteristics. With ZIF nano-pesticide prepared earlier as the control, the changes in particle size of microemulsions diluted at different concentrations and the microscopic morphology of dispersed particles were tested and compared by dynamic light scattering laser particle size analyzer combined with scanning electron microscope. [Results] Conventional microemulsions were in dynamic equilibrium, and the particle size changed irregularly after dilution at different concentrations. Especially under scanning electron microscope, the particle distribution of pesticide-bearing droplets were uneven after drying, with aggregation and precipitation of large particles, while the particle size of nano-pesticide changed little after dilution at different concentrations, ranging from 1 to 300 nm. Moreover, the microscopic morphology of nano-pesticide observed under scanning electron microscope was in monodisperse nano state, without aggregation. [Conclusions] The particle size measured by dynamic light scattering alone can not judge whether the microemulsion is a nanometer pesticide, and it is necessary to observe the microscopic disperse state and particle size distribution with the help of electron microscopy.

Key words Nano-pesticide; Microemulsion; Particle size distribution; Dynamic light scattering; Morphology; Scanning electron microscope

1 Introduction

With the rapid growth of the global population, which is expected to reach over 9 billion by 2050[1], food security production has become a crucial global challenge. The use of a large number of agricultural chemicals, especially pesticides, can effectively reduce the stress of disease, insect and grass damage and increase global food production by more than 30% each year[2]. However, due to the interfacial tension[3], spraying conventional pesticide preparations will cause bounce slip[4]or convergence loss[5], which not only causes low utilization rate of existing pesticides and short duration, but also leads to continuous enrichment of off-target pesticides into the environment, resulting in the decline of agricultural ecosystem and soil. Furthermore, it will bring risks to the safety of ecology and agricultural products[6], and ultimately affects human health and the sustainable development of agriculture[7]. Therefore, it is urgent to develop new technology of pesticide preparation to solve these problems.

Optimization of pesticide preparations and their delivery system is an effective approach to improve the utilization rate and safety of pesticides[8-9]. In recent years, nanoscale (1-100 nm) materials have been widely used in the fields of chemistry, materials, medicine, energy and life science due to the characteristics of high penetration, permeability and specific surface area[10]. And an emerging interdiscipline has gradually formed in the field of agriculture[11]. In 2019, the International Union of Pure and Applied Chemistry (IUPAC) listed nano-pesticide as the top ten emerging chemical technologies for global sustainable development for the first time[12]. But for the definition of nano-pesticide, various countries and international organizations have not achieved the unification. At present, particle size is commonly used to define nano-pesticide. For example, Kahetal.[13]broadly defined pesticide formulations less than 1 000 nm, or with new characteristics related to small size, or prefixed with "nano" as nano-pesticides based on particle size. Among traditional pesticide formulations in China, the microemulsion is generally 10-100 nm in particle size[14], with transparent appearance, and its particle size is far lower than general emulsion (such as emulsion in water), but is relatively close to nano-pesticide. Some products are promoted with the concept of nano-pesticide, and there are also reports that microemulsions are included in nano-pesticides[15].

The definition of nano-pesticide is first judged by particle size, as well as some better bioactivities. Huang Qiliangetal.[16-17]loaded pesticides with nano-silica, which could improve the absorption and transport of pesticides in crops, and some also improved the penetration of pesticides in mycelia; the average particle size of nano-pesticides formed after loading was 200-300 nm. Zhao Jinhaoetal.[18-19]improved the absorption and conduction ability of fungicide by rapeseed by using the metal-organic framework material ZIF-8 loaded with prochloraz or pyraclostrobin, and the average particle size of nano-pesticides prepared was about 150 nm. Zhao Jinhaoetal.[20]prepared nano thiazole-Zn by nanoreactor construction, with a particle size of only about 35 nm, which increased the efficacy of thiazole-Zn by more than 10%. Xu Hanhongetal.[21]loaded typical non-systemic pesticide abamectin with polymer nanomaterials, the particle size was only about 60 nm. In addition to significantly increasing biological activity, abamectin could also be absorbed through crop leaves and transportedinvivo. However, commercial avermectin microemulsions have not been reported to have internal absorption conductivity even though they have reached a nanoscale of about 100 nm. So far, the average particle size of most reported nano-pesticides is 1-300 nm. In addition to laser particle size measurement based on dynamic light scattering (DLS), the test method is also combined with electron microscopy (SEM or TEM) for comprehensive judgment.

Therefore, based on the research basis and technical means for the preparation of nano thiazole-Zn, nano-prochloraz (PD@ZIF-8) and nano-pyraclostrobin (Pyr@ZIF-8), our research group analyzed the particle size and morphology of several commercial microemulsions available on the market by DLS nanoparticle size analyzer and scanning electron microscope from the perspective of particle size.

2 Materials and methods

2.1 MaterialsCommercial microemulsions (names of manufacturers were withheld to avoid ambiguity and dispute): 4.5% beta-cypermethrin· emamectin benzoate microemulsion (microemulsion 1, ME-1), 5% lambda-cyhalothrin microemulsion (ME-2), 5% tetramethrin·permethrin microemulsion (ME-3), 5% emamectin benzoate microemulsion (ME-4) and 0.1% triacontanol microemulsion (ME-5). ZIF-8 nano-pesticide: nano-prochloraz with ZIF-8 as the carrier (PD@ZIF-8) was prepared as the control sample. Detailed preparation methods and structural characterization were derived from the literature[18].

2.2 InstrumentsZetasizer Nano S90 laser particle size analyzer (Malvern, UK); JSM5600LV scanning electron microscope (JEOL, Japan); G300 field emission scanning electron microscope (Zeiss, Germany).

2.3 Methods

2.3.1Determination of microemulsion particle size. The particle size distribution of different commercial microemulsions was measured by ZS-90 Malvern laser particle size analyzer. The instrument used 633 nm laser as the light source, with the scanning angle of 90° and the measured range of 0.3 nm-5 μm. The samples were diluted with water to 10 000, 1 000 and 100 μg/mL solutions before determination.

2.3.2Observation of particle morphology of microemulsion. Different commercial microemulsions were diluted with water to 100 μg/mL solutions, which were dripped onto conductive silicon wafers, and dried for metal spraying. The particle morphology of dried microemulsions was observed by thermal field emission scanning electron microscope (Zeiss G300).

3 Results and analysis

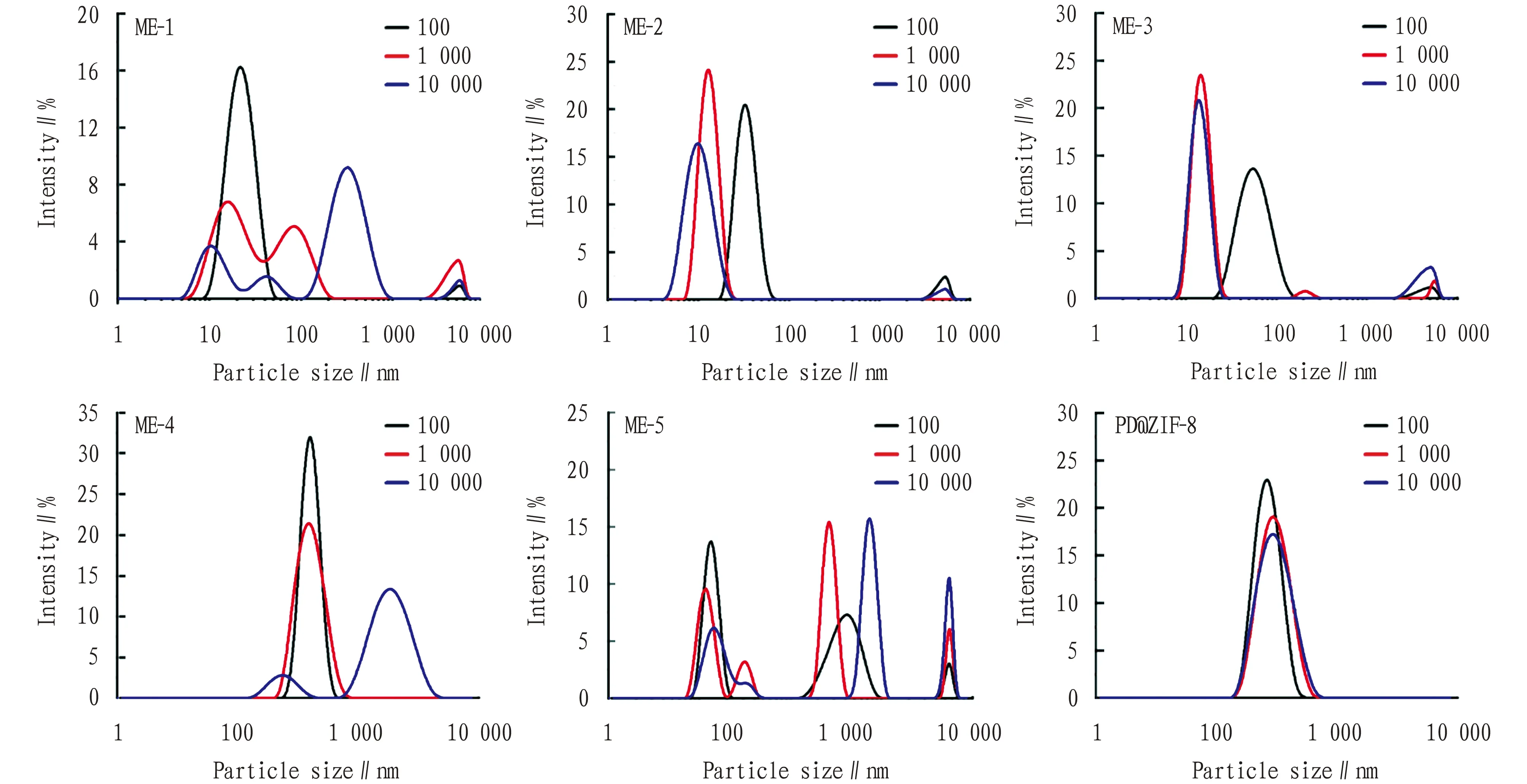

3.1 Particle size and distribution of microemulsionsFive different commercial microemulsions were diluted with water to effective concentrations of 100, 1 000 and 10 000 μg/mL, and determined by Marvin laser particle size analyzer to obtain particle size. Meanwhile, ZIF nano-pesticide (PD@ZIF-8) synthesized by Ministry of Agriculture and Rural Affairs Key Laboratory of Molecular Biology of Crop Pathogens and Insects was used as the control sample. The particle size distribution diagram of each reagent at different concentrations was obtained (Fig.1). The particle size distribution of the five microemulsions at different concentrations was not uniform, with large difference. The particle size distribution of the control reagent ZIF-8 nano-pesticide at different concentrations had little difference, and the average particle size ranged from 250 to 300 nm, with little change.

Fig.1 Particle size distribution of commercial microemulsions at different dilution concentrations (with PD@ZIF-8 as the control)

Particle size was measured based on DLS, and the main statistical data such as average particle size, polydispersity index, particle size with 50% cumulative particle size distribution (D50) and particle size with 90% cumulative particle size distribution (D90) can be obtained. Among them, polydispersity index, namely relative deviation, is an important index indicating the degree of dispersion. The specific particle sizes of various agents are shown in Table 1. The average particle sizes of ME-1, ME-2 and ME-3 had little difference at different dilution ratios, all of which were within the range of 100 nm. However, forD90, ME-1 and ME-3 had the maximum particle sizes of 2 320 and 3 730 nm, respectively. ME-4 and ME-5 showed a wider trend of particle size variation at different dilution ratios, with the average particle sizes up to 868.6 and 851.0 nm, and the maximum particle sizes ofD90up to 2 850 and 5 350 nm, respectively. This indicated that the formation of pesticide micelles in microemulsions was in dynamic equilibrium, and the particle size changed irregularly with different dilution ratios in the process of dilution. There may be the phenomenon of large pesticide particles crystallization after demulsification, resulting in uneven particle sizes, which were not all in the category of nano-pesticides defined by particle size. On the contrary, by comparing ZIF nano-pesticides (PD@ZIF-8) with the same content of active component, it was found that the average particle size was 250-300 nm, andD50andD90had no significant changes. The results showed that the particle size distribution of microemulsions in liquid form would change dynamically and widely under different concentrations, while the loaded nano-pesticides existed in the form of solid particles, and the particle size would not be changed by different concentrations of dilution.

Table 1 Particle size parameters of commercial microemulsions at different dilution concentrations

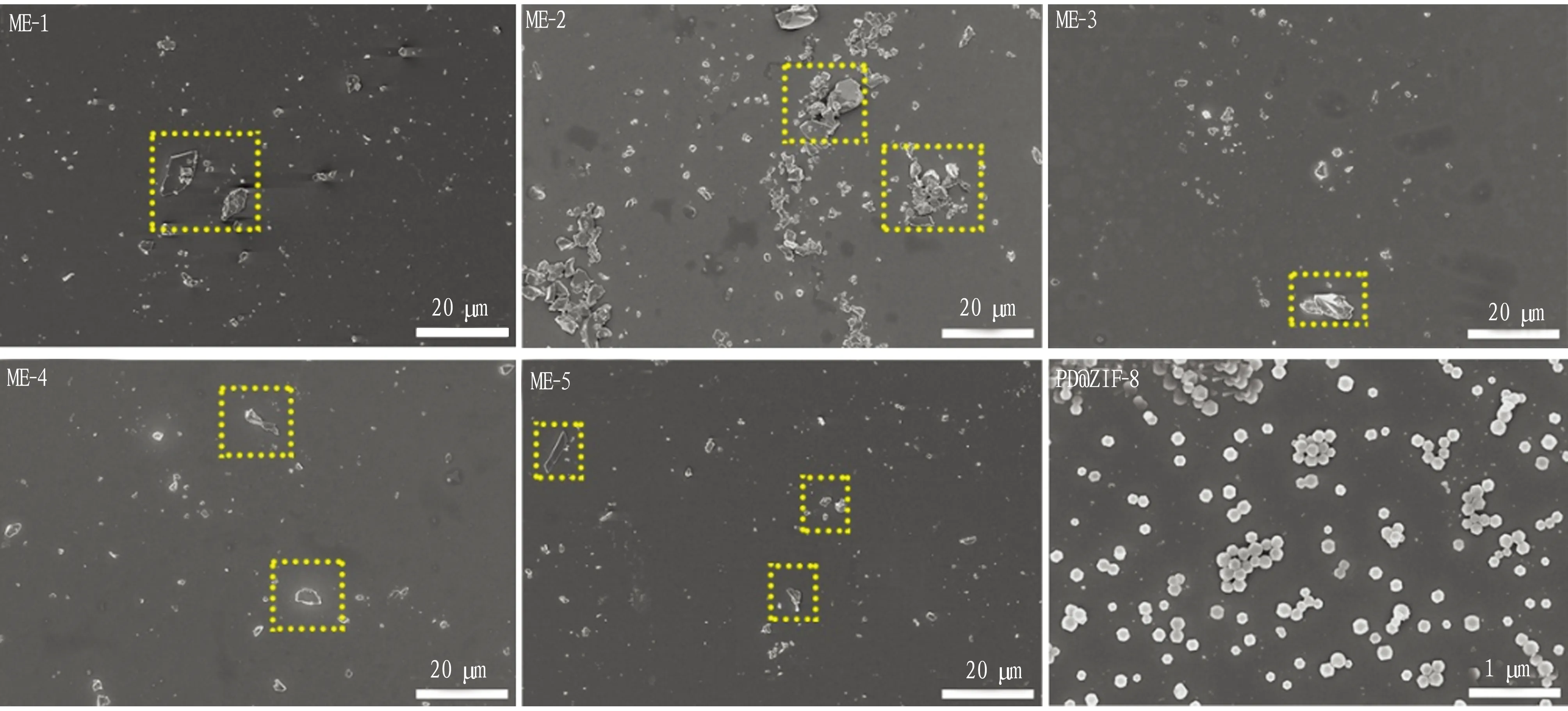

3.2 Microscopic morphology of microemulsion under electron microscopeAfter spraying, pesticides will adhere to the surface of crops in the form of droplets for a short period of time. With the evaporation of water, pesticides gradually dry on the leaf surface, and finally still exist in a solid state at the microscopic level. Therefore, the particle morphology and size of commercial microemulsions and dried ZIF nano-pesticide droplets with the same active ingredient content were investigated by scanning electron microscope. As shown in Fig.2, although a small number of pesticide crystal particles at nanoscale still existed after commercial microemulsion droplets were dried, a large number of pesticide particles with uneven distribution and aggregation or up to micron level could be observed. Uneven distribution and agglomeration of pesticides cause high local contact concentration, which may be a main reason affecting the effective utilization of pesticides and chemical injury of crops. After drying of ZIF nano-pesticide (PD@ZIF-8) droplets, monodisperse nanoparticles could still be observed, with an average particle size of about 129 nm[18]. The particles were relatively independent from each other, and there was no obvious caking phenomenon except for the adsorption caused by weak interaction force between small particles. Microemulsions did not show the advantages of higher duration, slow-release capacity and absorption and transport ability of crops that nanoparticles had, which may be related to that uneven particles at the micro level, aggregation and caking resulted in insufficient absorption and transport of crops.

Fig.2 Scanning electron micrographs of different commercial microemulsions and PD@ZIF-8

The active components of microemulsions dispersed in water are small in size and transparent, which are mainly oil-in-water (O/W) micelles formed by evenly dispersing liquid or solid active compound in water with the help of solubilization of surfactant. The dosage of surfactant is generally more than twice that of the active substance, and a certain amount of organic solvents and solubilizers are required. The choice of surfactants and solvents is critical, otherwise crystallization and phase conversion can easily occur. In view of particle size and formation mechanism of pesticide micelles in microemulsions, micelles should be classified as amphiphilic colloid, rather than solid nanoparticles, because unimolecules or monomers that make up micelles are in dynamic equilibrium, and the morphology and particle size of pesticide micelles may change under specific scenes, such as the change in micellar solution concentration or drying[22]. This is also consistent with the results in Table 1 that there were large differences in particle size under different dilution ratios and microscopic morphology after drying (Fig.2). From the scientific nature of nano-pesticides, the most important technical index is nanoscale. In order to exert nanoscale effects, nano preparations must be guaranteed to be nanoscale when sprayed on the leaf surface of target crops or used directly[13], and it is not enough for the dispersion form of preparation to be nanoscale. Like microemulsions, they must be diluted with water, and the dilution process changes the dispersion of preparations and brings about new dispersion, not necessarily a nanoscale monodisperse state on the leaf surface.

4 Conclusions

Based on particle size determination by DLS and combined with SEM technology, several commercial microemulsions commonly available on the market were tested and analyzed in detail from the perspective of particle size and micromorphological features, and compared with the ZIF nano-pesticide prepared by our research group. It was found that the particle size of several commercial microemulsions changed irregularly during the dilution process. Especially under scanning electron microscope, the particle distribution of pesticide-bearing droplets were uneven after drying, with aggregation and precipitation of large particles, while the particle size of nano-pesticide changed little after dilution at different concentrations, ranging from 1 to 300 nm. Moreover, the microscopic morphology of nano-pesticide observed under scanning electron microscope was in monodisperse nano state, without aggregation, indicating that all of them existed stably in nanoscale disperse state in practical application scenes. Therefore, the particle size measured by dynamic light scattering alone can not determine whether the microemulsion is a nano-pesticide, and it is also necessary to observe the microscopic disperse state and changes in particle size using electron microscope technology. This study provides analysis and identification techniques for the development of nano-pesticides and also provides data support for the standard establishment of nano-pesticides in China.

杂志排行

植物病虫害研究(英文版)的其它文章

- Preparation and Characterization of Nano-ZnO Precursor for the Antibacterial Activity against Thielaviopsis paradoxa

- Applied Technology of Botanical Pesticides against Empoasca pirisuga Matumura

- Characterization of Neopestalotiopsis clavispora, A New Etiological Agent of Leaf Spot Isolated from Banana