Jiangnan Shipbuilding Successfully Delivers Type B Tank VLEC

2022-02-15LiYaner

Li Yaner

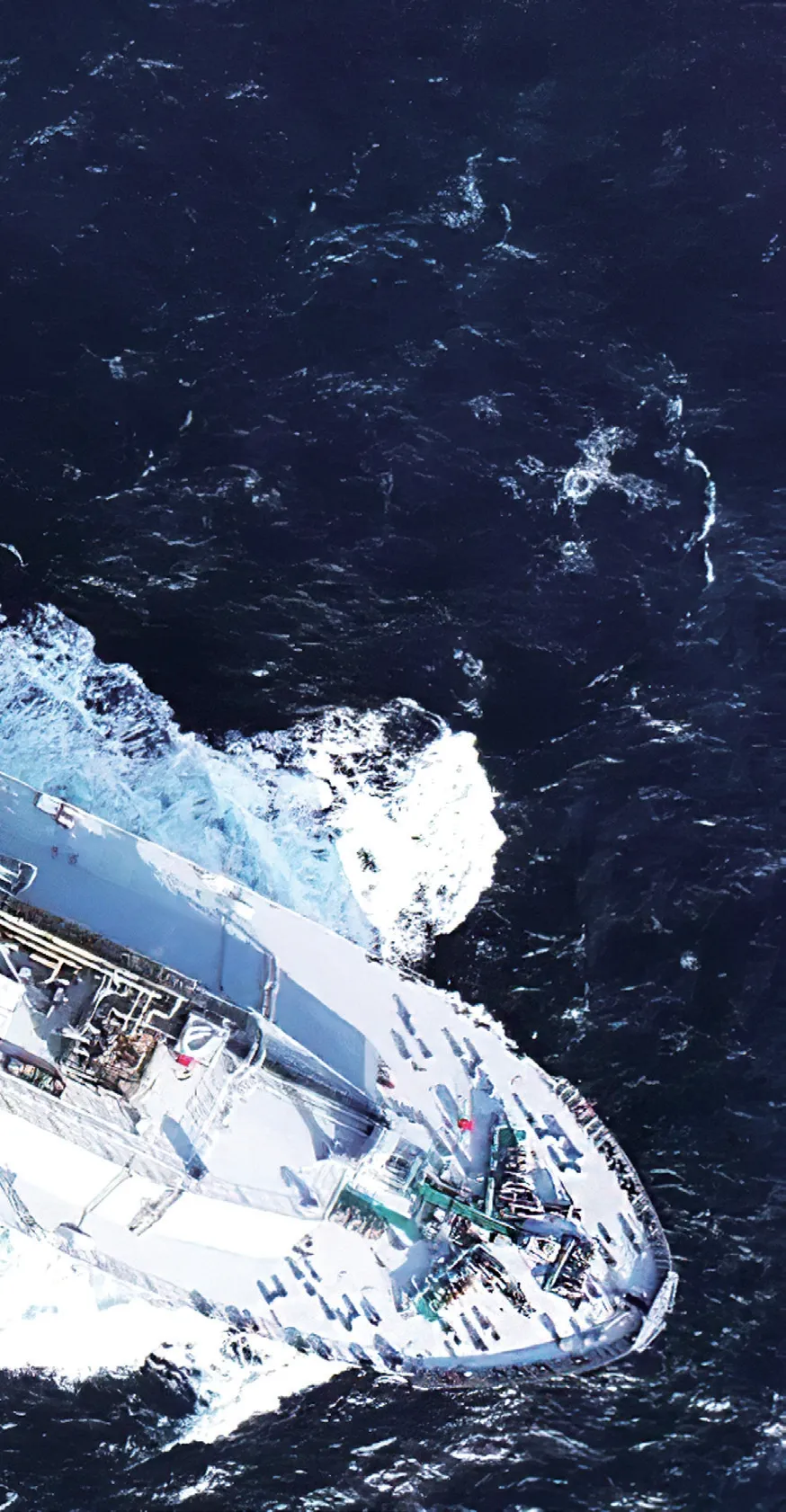

On December 28, 2021, the 99,000 m3 Type-B tank very large ethane carrier (VLEC) “Pacific Ineos Belstaff” built by Jiangnan Shipbuilding was officially delivered. Jiangnan Shipbuilding and China Shipbuilding Trading both under CSSC served as joint sellers. The vessel will execute a charterparty between INEOS and Pacific Gas, a subsidiary of Shandong Ocean Group, to ship U.S. ethane to a cracking plant in Europe. This is the first application of Jiangnan Shipbuilding's Type-B tank cargo containment system (BrilliancE) with completely independent intellectual property rights in the real ship project. This not only breaks the technical monopoly of the foreign liquefied gas cargo containment system, but also provides the technical solution of Chinese shipyards to the global liquefied gas ship market, and the expansion prospect of Type-B tank technology is quite promising, which is expected to leverage the LNG liquid cargo tank and fuel tank market.

This type of VLEC has universal applicability to the world's major liquefied gas terminals, is a VLEC with the world's largest capacity, and the largest scale liquefied gas ship that can operate in the Houston waterway. Designed by Jiangnan Shipbuilding, the ship has an overall length of 230.0m, a molded breadth of 36.6m, a molded depth of 22.5m, equipped with 4 Type-B liquid cargo tanks and 2 Type-C deck tanks, able to carry liquefied gas cargoes such as ethane, ethylene, LPG, and the maximum tank capacity is 99,000 m3. Classified into ABS and CCS, the ship meets the requirements of the latest IGC Code, IMO, USCG and other relevant rules; equipped with a shaft generator and dual-fuel main engine that can be fueled by ethane, the ship maintains high economy while meeting the most stringent emission requirements.

Why Type-B tank

Following the development policy set when relocating to the island in 2008, Jiangnan Shipbuilding has devoted itself to cultivating a number of liquefied gas ship fronts, and is currently the only shipbuilding enterprise in China with a full range of liquefied gas ship research and development, design and construction capabilities, and has the independent R&D, design and construction capabilities of various types of liquefied gas ships with various containment systems of Type-A tank, Type-B tank, Type-C tank and Mark III membrane tank. Liquefied gas ships have long become the company's competitive products, but it is no exaggeration to say that the delivery of the first ship with Type-B tank is also a milestone leap forward for Jiangnan Shipbuilding.

By liquefied gas containment system, the tank type of liquefied gas ship mainly includes Type-A tank, Type-C tank and membrane tank, Jiangnan Shipbuilding liquefied gas ships mostly contain Type-A tank, and the cumulative produced and installed Type-A tanks exceeded 100 in 2020; the containment system is not within the scope of Type-A tank, Type-C tank and membrane tank, but design according to the relevant engineering analysis process stipulated by the IGC can be classified into the category of Type-B tanks. MOSS spherical tank is a kind of Type-B tank, Jiangnan Shipbuilding previously conducted relevant research on the MOSS containment system, laying the foundation for the follow-up principled research of Type-B diamond-shaped tank. Nevertheless, what really lets the director of the Jiangnan Shipbuilding Science and Technology Committee Hu Ke come up with an idea, deciding to further deepen the study of the Type-B diamond-shaped tank and put it on the market, can be traced back to a piece of delivery news in 2016.

In year-end 2016, South Korea's Samsung Heavy Industries delivered two membrane type VLECs, which gave Hu Keyi, who is sensitive to cuttingedge technology, see a potential business opportunity - U.S. ethane exports could spawn a new ethane long-distance transport market. Since the boiling point of liquefied ethane is minus 88.6 degrees Celsius, which is far lower than the bearing range of the Type-A tank that uses the hull structure as a secondary divisional bulkhead, and the space utilization rate of the Type-C tank is low. The technology of Jiangnan Shipbuilding at that time was not enough to support the underpinning of undertaking orders for large ethane ships. The R&D personnel of Jiangnan Shipbuilding had two options - bearing high patent costs, launching a membrane type VLEC with the same technical route as the Korean shipyard; or giving it a go and deepen R&D of Type-B tank VLEC.

In April 2017, GasTECH was held at the Chiba Makuhari Convention and Exhibition Center in Japan, and Jiangnan Shipbuilding participated in the exhibition independently for the first time, "The booth of Jiangnan Shipbuilding was not large and faced the booth of the Korean shipyard. From many first-class shipbuilding and offshore engineering enterprises in the world, Jiangnan Shipbuilding observed the gap and accumulated new impetus for innovation." Hu Keyi recalled that he officially proposed on the scene to Lin Ou, chairman of Jiangnan Shipbuilding, to develop and launch the Type-B tank VLEC, "We have a certain foundation, we are confident of success, and we can do it." They chimed in easily. After returning from Japan, Jiangnan Shipbuilding pushed the development of the Type-B tank onto the fast track.

Shipyard selected before shipowner

Zhou Qinghua, deputy chief technologist of “Pacific Ineos Belstaff", also an important member for in-depth participation starting with the project R&D stage, said Type-B tank technology had an application precedent in Japan Marine United Corporation (JMU), but it involved high patent cost, in China, whether it is a shipyard or a classification society, it had no experience to follow, everything has to be explored from scratch, but Jiangnan Shipbuilding R&D team has the confidence - rich experience in the design and construction of Type-A tank is an irreplaceable advantage. The novel design of the Type-B tank is also composed of many mature technologies and components. Jiangnan Shipbuilding R&D team identified the technical route, and by surmounting difficulties for a long period, adhered to the innovative ideas -- "based on foresight, derived from selfconfidence, not afraid of challenges, transformation to the future", conducted fracture mechanics analysis verification, finite element calculation analysis, and engineering-oriented design in strict accordance with the IGC Code and relevant rules and regulations of classification societies, integrated Type-A tank structure and support system, secondary diversional bulkhead and insulation of the spherical tank and mature welding technology and process of Type-C tank 5% nickel steel. Meanwhile, for the overall layout, structure, insulation, secondary diversional bulkhead and other core technologies of the Type-B tank, they carried out special research, independently developed, designed and completed a whole set of "BrilliancE" containment system with complete intellectual property rights, applied for more than 30 patents, providing solutions for low-temperature refrigerated cargo containment system up to minus 104 degrees Celsius. They developed structural design technology of Type-B liquid cargo tank, realizing the completely autonomous and controllable design of the primary/secondary divisional bulkheads; established a set of calculation and analysis system of fatigue fracture mechanics of Type-B tank; and developed a new type of thermal insulation system, realizing the reliability, safety and functionality of the system.

The hammered-out new ship type solution was pushed to the market in this way - the IMO Type-B liquid cargo tank on the 99,000 m3 VLEC independently developed by Jiangnan Shipbuilding is a diamond-shaped standalone liquid cargo tank based on "BrilliancE" technology independently developed by the company on the basis of the mature construction experience of the VLGC Type-A tank. The uppercase letter "B" in "BrilliancE" stands for a Type-B tank, and the uppercase letter "E" stands for ethane and ethylene. Compared with other cryogenic liquid cargo containment systems, the "BrilliancE" Type-B liquid cargo tank has the advantages of high safety and reliability, low tank maintenance cost, flexible cargo loading, simple and efficient insulation system, no liquid level loading restrictions, and low remnant cargo volume in the tank. The"BrilliancE" Type-B liquid cargo tank technology can also be extended to LNG liquid cargo tank and fuel tank (Brilliance). In terms of ship type design, the 99,000 m3 Type-B tank VLEC adopts the second-generation VS-BOW bow line type of Jiangnan Shipbuilding, the CFD numerical simulation is closely combined with the ship model test verification, and considering the layout requirements of the standalone diamond-shaped liquid cargo tank, the hydrodynamic shape and internal space of the hull are comprehensively optimized, and the performance of all parties is excellent. It is worth mentioning that the Type-B tank liquid cargo containment system has great advantages in gas ships of below 100,000 m3, and the tank volume of this type of ship of 99,000 m3 can be called the maximum cargo capacity in the restrictive conditions of what is called the industry standard "The main scale envelope line of the Houston waterway in the United States", and currently ranks in the leading position in the market segment.

On January 9, 2020, Jiangnan Shipbuilding and China Shipbuilding Trading signed a contract with BOCOM Leasing Management Hong Kong Co., Ltd. and SPDB Financial Leasing Co., Ltd. each to build a VLEC, which will be delivered to a professional gas tanker company for operation after completion. "There was a rare situation when signing this batch of orders, the charterer used to select a shipowner, and then the shipowner used to select a shipyard; this time, the charterer first selected the shipyard, and then screened the shipowner." Hu Keyi said.

work of art

Allowing the charterer to make a rare decision on a shipyard first is inseparable from Jiangnan Shipbuilding's previous rich experience in liquefied gas ship construction. Prior to this, Jiangnan Shipbuilding had delivered a batch of VLGCs with Type-A tanks and liquefied gas carriers with Type-C tanks, and has a professional construction team, low temperature steel and nickel steel production experience and complete construction facilities, and has accumulated rich construction experience.

However, the Type-B tank adopts thinner domestic 5% nickel steel, which has much higher construction requirements for process and construction method, technical level, material quality control, assembly accuracy, welding technology, deformation control and insulation installation than Type-A tank, and puts forward higher requirements for lifting capacity, closed mounting and installation space.

In the construction process of the first tank, Jiangnan Shipbuilding set up several project research teams, which successively improved and solidified the process and construction method, welding procedures and related process innovations, providing a strong guarantee for the subsequent tank takt-time construction. The insulation system of Type-B tank adopts complex plate insulation and is an important part of the liquid cargo containment system. The insulation of each tank is composed of more than 6,000 insulation plates of different shapes, and the slope inclination of the tank is 450 and the height is nearly 9 m, which is difficult to install and has a high risk factor. How to transport the insulation panel to the correct installation location and ensure that it is installed correctly is the key to the construction of the project. The Jiangnan Shipbuilding project team, together with the insulation manufacturer, carried out threedimensional modeling decomposition in the early stage and used the QR code to manage and track the whole process of each plate. The team carried out a lot of researches, analyses, simulations and other planning work, produced a detailed "construction support plan", determined the temporary transit area, scaffolding and "insulated plate" transport channel among other planning we well as double-tank parallel installation methods, considerably shortening the installation cycle.

With the full support and close cooperation of shipowners, marine equipment manufacturers and classification societies, the construction team of Jiangnan Shipbuilding VLEC has overcome unfavorable factors the COVID-19 epidemic, paid attention to project management orientation, innovated the process and construction method, nickel steel welding procedure, sheet deformation control and optimized the construction process, and conquered the core and key technical difficulties of the Type-B tank. From the signing of the contract at the end of December 2019 to the completion and delivery of the first ship, the total construction cycle was 24 months, and the dock outfitting cycle was 4 months, which created the shortest cycle record of the first ship of Jiangnan Shipbuilding large liquefied gas carrier and realized the takt-time construction of complex ship type. Jiangnan Shipbuilding said this has laid a solid foundation for the company's low carbon and digital transformation and high-quality development.

Some regard Type-B tank as a "work of art" in liquefied gas ships. Hu Keyi believes that the design and construction of VLEC with Type-B tank is difficult, and if the Type-B tank containment system and the complex cargo system are combined, the difficulty is even significantly greater than that of the large LNG ship known as the "Pearl on the Crown". Not only that, the structural design concept of VLEC "feeds back" the updating ship of Jiangnan Shipbuilding VLGC. Jiangnan Shipbuilding's newly developed 93,000 m3 VLGC has won 11 real ship orders, and its comprehensive performance is fully ahead of the same type of ship of South Korean shipyards.

At present, Jiangnan Shipbuilding has three 99,000 m3 VLECs under construction, and follow-up orders will also be on the agenda. It is worth noting that the containment system with independent intellectual property rights in hand is more helpful to the shipyard taking orders and bargaining. After all, Type-B tank technology can be extended to the LNG cargo hold and fuel tank, realizing the replacement of foreign patents and breaking through the bottleneck monopoly. For example, Jiangnan Shipbuilding has developed 80,000 m3 Type-B tank LNG ships and 6,000-18,500 m3 LNG fuel tanks installed on large dual-fuel container ships. Can Type-B tank shake the absolute supremacy of the membrane containment system in the future? Let’s wait and see what will happen.