基于DSC技术构建甲基丙烯酰胺接枝蚕丝的接枝率定量检测方法

2022-02-14方帅军陈梦婕舒可人岳心茹

方帅军 陈梦婕 舒可人 岳心茹

摘要: 为了建立甲基丙烯酰胺接枝蚕丝(polyMAA-SF)的定量分析模型,本文通过自由基引发方式将甲基丙烯酰胺单体(MAA)与蚕丝接枝聚合,得到梯度接枝率的蚕丝组样,使用DSC技术对其进行表征分析。接枝后的蚕丝在DSC曲线中出现新的吸热峰,新峰面积随着接枝率的增加而增加。根据DSC分析方法作基线,建立新峰热焓比值与接枝率(称重法)的线性关系函数模型,并采用已知接枝率polyMAA-SF样品进行验证。结果表明,DSC定量分析得到的蚕丝接枝率相对误差均小于5%,该函数模型适用于蚕丝接枝率的检测。

关键词: DSC;MAA;蚕丝;接枝率;定量分析

中图分类号: TS141.8 文献标志码: A 文章编号: 1001-7003(2022)01-0020-05

引用页码: 011103DOI: 10.3969/j.issn.1001-7003.2022.01.003

蚕丝具有轻柔、滑爽、优良光泽和悬垂性等优点,属于天然纤维材料,普遍应用于服饰和家纺等领域,深受消费者喜爱。随着技术革新,传统的锡增重、单宁增重和丝胶固着增重[1]逐渐向接枝增重[2-3]转变,以弥补因脱胶而引起的蚕丝重量损失。近年来,研究者用单烯类和环氧化合物类进行了大量对蚕丝的改性研究[4]。自由基引发接枝乙烯基单体[5]得到的乙烯基接枝蚕丝存在疏水性高,静电大,纤维硬度高和可染性下降等缺点。甲基丙烯酰胺单体与蚕丝接枝共聚不仅保留了蚕丝织物良好的手感、光泽,还提高了其接枝率[6-7]、含潮率、悬垂性[8]、拒油性[9]和耐碱性[10],是当前广泛应用的蚕丝接枝增重技术。

研究者对蚕丝接枝前后的内在性能进行了深入探究,包括采用近红外光谱[11-12]、XRD、SEM、NMR和DSC[13]等手段。研究发现,接枝后的蚕丝在光谱吸收、热性能及表面形貌等方面均有变化。Paola等[10]通过红外和拉曼表征发现MAA接枝蚕丝出现了新的吸收峰,同时在5%氢氧化钠溶液中的稳定性测试,表明了接枝蚕丝具有更好的分解稳定性。Tsunenori等[13]通过DSC测试发现MAA接枝蚕丝出现了新的吸热峰,新峰热焓与MAA接枝率存在一定关系。Franco等[14]也证实了上述结果,但實验数据离散性较大,系统性不足,没能建立热焓关于接枝率的数学模型。本文采用DSC对不同接枝率蚕丝进行表征,基于此建立吸热峰的热焓比值与接枝率之间的函数关系,开发一种蚕丝接枝率的定量分析方法。

1 实 验

1.1 材料、试剂及仪器

材料:脱胶桑蚕丝(浙江雅士林集团有限公司),甲基丙烯酰胺接枝蚕丝(浙江巴贝领带有限公司)。

试剂:甲基丙烯酰胺(阿拉丁化学试剂有限公司)、过硫酸钾(国药集团化学试剂有限公司)、甲酸(无锡市纯阳化工有限公司),均为分析纯。

仪器:L-12C型振荡染色机(厦门瑞比精密机械有限公司),UF75烘箱(德国美墨尔特有限公司),DSC差示扫描量热仪(瑞士梅特勒—托利多集团有限公司)。

1.2 接枝蚕丝样的制备

称取已脱胶的蚕丝0.5 g,在140 ℃条件下烘60 min至恒重W1。甲基丙烯酰胺投入量为0.6~3.0 g,甲酸为3%,以3%过硫酸钾作为引发剂。在85 ℃,浴比为1 ︰ 30(蚕丝 ︰ 处理液体积)条件下采用吸尽法处理40 min,通过浸润和多次热水洗涤去除未反应的MAA和物理黏附的均聚物,得到不同接枝率的甲基丙烯酰胺接枝蚕丝(polyMAA-SF)组样。上述百分含量均表示相对原蚕丝的质量。将接枝蚕丝样品在140 ℃条件下烘至恒重为W2,按下式分别计算接枝率和接枝效率:

接枝率/%=W2-W1W1×100(1)

接枝效率/%=W2-W1Wm×100(2)

式中:W1为接枝前蚕丝的质量,g;W2为接枝后蚕丝的质量,g;Wm为投入的MAA单体质量,g。

1.3 DSC表征与分析

将未接枝蚕丝和不同接枝率的polyMAA-SF样品剪碎,称取5 mg左右,在DSC差示扫描量热仪中进行测定:测试温度由25 ℃开始,升温速率为10 ℃/min,在30 mL/min氮气流量下升至400 ℃,获得DSC曲线。每个样品分别测试3次,通过对系列样品曲线作基线得到相应热焓值和温度等数据,优选出最接近接枝率平均值的数据。

2 结果与分析

2.1 单体MAA含量对蚕丝接枝率及单体接枝效率的影响 甲基丙烯酰胺单体在接枝聚合过程中受各条件的影响,其中浴比影响很大,为了让MAA单体在蚕丝织物上最大化接枝聚合,需要尽量控制接枝反应浴比。文献[7]提出当浴比在1 ︰ 20~1 ︰ 40时,接枝率和接枝效率均会随着单体含量的增加而快速增大,因此本文采用了1 ︰ 30的浴比。由图1可知,蚕丝接枝率随着MAA单体投入量的增加而不断增大。从接枝效率变化可以看出,在MAA单体投入量为1.6 g之前接枝效率快速攀升,随后逐渐放缓,保持在25%左右且有下降趋势,说明在该浴比条件下接枝聚合反应,MAA单体不断反应接枝,接枝率明显提升;而接枝效率在蚕丝接枝率60%后,不再随着MAA单体浓度增加而增加,说明接枝共聚的反应能力降低,已逐渐达到了蚕丝的固有接枝量。

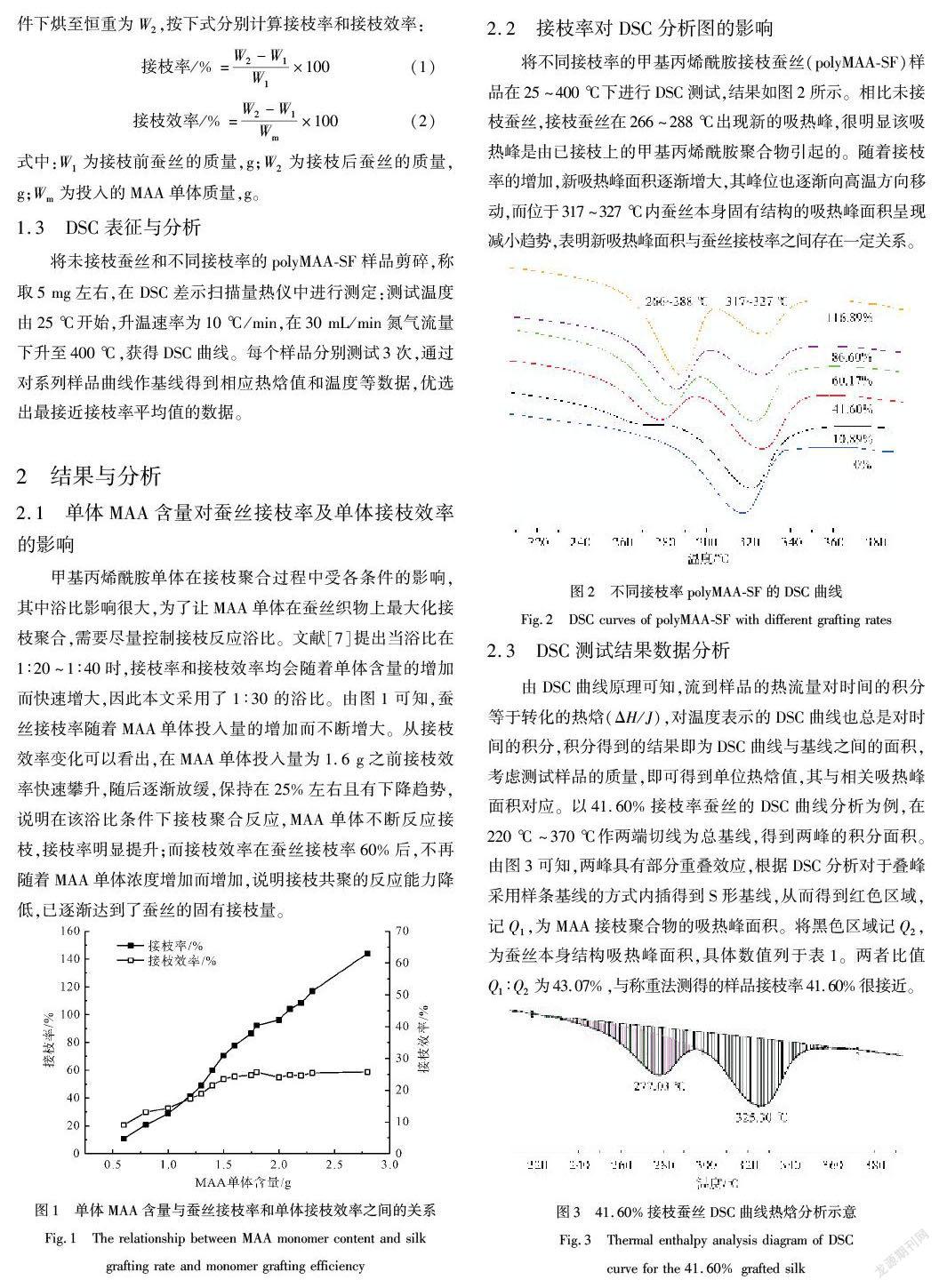

2.2 接枝率对DSC分析图的影响

将不同接枝率的甲基丙烯酰胺接枝蚕丝(polyMAA-SF)样品在25~400 ℃下进行DSC测试,结果如图2所示。相比未接枝蚕丝,接枝蚕丝在266~288 ℃出现新的吸热峰,很明显该吸热峰是由已接枝上的甲基丙烯酰胺聚合物引起的。随着接枝率的增加,新吸热峰面积逐渐增大,其峰位也逐渐向高温方向移动,而位于317~327 ℃内蚕丝本身固有结构的吸热峰面积呈现减小趋势,表明新吸热峰面积与蚕丝接枝率之间存在一定关系。

2.3 DSC测试结果数据分析

由DSC曲线原理可知,流到样品的热流量对时间的积分等于转化的热焓(ΔH/J),对温度表示的DSC曲线也总是对时间的积分,积分得到的结果即为DSC曲线与基线之间的面积,考虑测试样品的质量,即可得到单位热焓值,其与相关吸热峰面积对应。以41.60%接枝率蚕丝的DSC曲线分析为例,在220 ℃~370 ℃作两端切线为总基线,得到两峰的积分面积。由图3可知,两峰具有部分重叠效应,根据DSC分析对于叠峰采用样条基线的方式内插得到S形基线,从而得到红色区域,记Q1,为MAA接枝聚合物的吸热峰面积。将黑色区域记Q2,为蚕丝本身结构吸热峰面积,具体数值列于表1。两者比值Q1 ︰ Q2为43.07%,与称重法测得的样品接枝率41.60%很接近。

2.4 DSC分析方法的数学建模

根据41.60%接枝率蚕丝DSC分析方法,以同样的方式分别对不同接枝率蚕丝的DSC曲线作基线,得到在266~288 ℃和317~327 ℃温度内的单位热焓值,标记为Q1和Q2。从表2可知,Q1热焓值随着接枝率的增大而增大,而Q2热焓值呈现下降趋势,两者比值与接枝率都很接近。将接枝率和吸热峰的热焓比值Q1 ︰ Q2作图,如图4所示,优选的热焓比值Q1 ︰ Q2与接枝率之间存在良好的线性关系,如下式所示,其拟合系数R2为0.994 9。

y=1.024x-0.071(3)

式中:y为Q1 ︰ Q2;x为接枝率(称重法)。

结果表明,通过上述线性函数能够精确计算出未知polyMAA-SF的接枝率。

2.5 DSC数学模型的验证

将已知接枝率(F)的增重蚕丝在不同部位取4个点,分别进行DSC测试、作总基线和样条基线、计算新吸热峰面积比值(Q1 ︰ Q2),并以m表示,得到m1、m2、m3、m4。通过下式对其平均计算得到峰面积比平均值m:

m/%=m1+m2+m3+m44×100(4)

再将平均值 m代入线性函数关系式(3)中,计算得到接枝率 M,验证结果如表3所示。

由线性函数关系式(3)计算得到的接枝率分别为2356%和67.10%,与已知接枝率之间的误差分别为4.52%和0.85%,两者均小于5.0%。结果表明,通过DSC法定量分析可以较为准确地得到甲基丙烯酰胺接枝蚕丝的接枝率。

3 結 论

本文采用差示扫描量热仪对不同接枝率的甲基丙烯酰胺接枝蚕丝进行测试,由DSC曲线可知,接枝后的蚕丝在266~288 ℃出现新的吸热峰,该吸热峰面积随着接枝率的增加而增大,说明该峰是由接枝的MAA聚合物引起。而位于317~327 ℃吸热峰逐渐减小,该峰为蚕丝固有结构的吸热峰。将新吸热峰与蚕丝固有吸热峰的单位热焓比值和蚕丝接枝率(称重法)作图拟合,发现两者之间存在良好的线性关系,并得到了相应的函数关系式。通过企业蚕丝样验证发现,数学模型计算得到的蚕丝接枝率与实际接枝率均非常接近,且两者相对误差小于5.0%。说明DSC定量分析技术对蚕丝接枝率的测定不仅有效且准确度较高,这对蚕丝接枝应用与检验检测带来积极的推动作用。

参考文献:

[1]金美菊, 刘优娜. 蚕丝增重方法探讨[J]. 上海纺织科技, 2015, 43(6): 68-70.

JIN Meiju, LIU Youna. Discussion on weighting methods of silk[J]. Shanghai Textile Science & Technology, 2015, 43(6): 68-70.

[2]LI Guohong, LIU Hong, LI Tianduo. Surface modification and functionalization of silk fibroin fibers/fabric toward high performance applications[J]. Materials Science and Engineering, 2012, 32(4): 627-636.

[3]白秀娥, 陈国强. 甲基丙烯酸甲酯在真丝上接枝共聚反应条件的优化[J]. 蚕业科学, 2005(1): 83-87.

BAI Xiu’e, CHEN Guoqiang. Optimized conditons for the grafting reaction of methyl methacrylate on silk fiber[J]. Sericultural Science, 2005(1): 83-87.

[4]朱正华, 朱良均, 闵思佳, 等. 蚕丝蛋白纤维改性研究进展[J]. 纺织学报, 2002, 23(6): 83-85.

ZHU Zhenghua, ZHU Liangjun, MIN Sijia, et al. Research progress of silk protein fiber modification[J]. Journal of Textile Research, 2002, 23(6): 83-85.

[5]TSUKADA M, ARAI T, FREDDI G, et al. Grafting vinyl monomers onto silk (Bombyx mori) using different initiators: Properties of grafted silk[J]. Journal of Applied Polymer Science, 2010, 81(6): 1401-1409.

[6]张智辉, 沈一峰, 杨雷, 等. MAA/疏水性单体与蚕丝纤维的接枝共聚合反应[J]. 丝绸, 2013, 50(7): 1-4.ZHANG Zhihui, SHEN Yifeng, YANG Lei, et al. Graft copolymerization of MAA/hydrophobic monomer and silk fiber[J]. Journal of Silk, 2013, 50(7): 1-4.

[7]江崍, 沈一峰, 黄晴. 复合引发体系引发MAA接枝真丝工艺研究[J]. 丝绸, 2012, 49(11): 11-14.

JIANG Lai, SHEN Yifeng, HUANG Qing. Research on grafting silk with methacrylamide initiated by composite initiation system[J]. Journal of Silk, 2012, 49(11): 11-14.

[8]高树珍, 唐蓉蓉, 刘款款. 桑蚕丝织物的接枝改性整理[J]. 毛纺科技, 2021, 49(9): 58-61.

GAO Shuzhen, TANG Rongrong, LIU Kuankuan. Properties of grafting-modification of silk fabrics[J]. Wool Textile Journal, 2021, 49(9): 58-61.

[9]TSUKADA M, FREDDI G, ISHIGURO Y, et al. Structural analysis of methacrylamide-grafted silk fibers[J]. Journal of Applied Polymer Science, 2010, 50(9): 1519-1527.

[10]PAOLA T, ELEONORA P, MASUHIRO T. Stability toward alkaline hydrolysis of B.mori silk fibroin grafted with methacrylamide[J]. Raman Spectroscopy, 2016(47): 731-739.

[11]ZOCCOLA M, BOSCHI A, AROSIO C, et al. Silk grafting with methacrylamide: A near-infrared spectroscopy study[J]. Journal of Applied Polymer Science, 2011, 120(1): 253-262.

[12]PAVONI E, TOZZI S, TSUKADA M, et al. Structural study on methacrylamide-grafted Tussah silk fibroin fibres[J]. International Journal of Biological Macromolecules, 2016, 88: 196-205.

[13]KAMEDA T, MASUHIRO T. Structure and thermal analyses of MAA-grafted silk fiber using DSC and 13C solid-state NMR[J]. Macromolecular Materials & Engineering 2007, 291(7): 877-882.

[14]FRANCO F, MONICA P, MARCO L. Silk grafting with methacrylic monomers: Process optimization and comparison[J]. Journal of Applied Polymer Science, 2007(103): 4039-4046.

Abstract: Silk is a kind of high-quality natural fiber loved by people for its softness, smoothness, excellent luster and drape properties. In actual applications, it is necessary to remove the sericin part of silk through degumming, resulting in the quality loss of nearly 25% during silk pretreatment and causing huge losses for silk production enterprises. With the development of silk technology, silk weighting process has developed from traditional methods such as tin weighting, tannin weighting and sericin-fixed weighting to silk graft weighting, among which methacrylamide graft weighting is one of the most widely used silk graft weighting technologies. This method can not only solve the problem of silk quality loss, but also retain the hand-feel and luster of silk fabric, and improve the drapability of silk and other properties. However, different grafting rates with different effects on the quality of silk also affect the price of silk. The grafting rate of silk after weighting is often decided by the producer, while the next-step-processing enterprises and silk consumers are often unable to accurately judge the specific silk grafting rate. Despite different signal peaks found in grafted silk by silk researchers through characterization and analysis of the grafted silk by infrared spectroscopy, XRD, scanning electron microscopy and Raman spectroscopy, few researchers have carried out accurate analysis and research on silk with unknown grafting rate.

In order to figure out the thermal properties of methacrylamide grafted silk and calculate the grafting rate of unknown grafted silk, potassium persulfate was used as initiator for graft polymerization of different concentrations of methyl acrylamide monomer and the degummed silk, to get a series of grafted silk with different grafting rates, and the accurate grafting rate was obtained by weighing method. Subsequently, grafted silk samples of this batch were tested three times by differential scanning calorimeters, and corresponding DSC curves were obtained. Compared with the ungrafted silk, the grafted silk showed a new endothermic peak in the range of 266-288 ℃, which was obviously caused by the grafted methacrylamide polymer in the grafted silk. With the increase of grafting rate, the area of new endothermic peak gradually increased, and its peak position gradually moved towards high temperature direction, while the endothermic peak area of the intrinsic structure of silk in the range of 317-327 ℃ showed a decreasing trend, indicating that there is a certain relationship between the area of new endothermic peak and grafting rate of silk. Then, the baseline and integral of DSC curves were calculated to obtain the enthalpy value and the peak position, and the data closest to the average value of grafting rate was optimized. The mathematical relation between unit enthalpy ratio and grafting rate was found and established by using Origin data processing software. Finally, through DSC characterization of grafted silk samples with known grafting rate and the calculation of the unit enthalpy ratio, the linear function was used for verification. In this paper, the intrinsic relationship between the thermal property of methacrylamide grafted silk and silk grafting rate was found by means of DSC characterization data. The study shows that there exists a linear function between the ratio of unit enthalpy of grafted silk and the grafting rate, with a relative error of less than 5.0% by verification, indicating that the grafting rate of unknown methacrylamide grafted silk can be calculated accurately by DSC quantitative analysis.

With the combination of DSC characterization technology and calculation software, the accurate grafting rate for the unknown grafted silk can be obtained, which effectively solves the problems on grafting rate quality control and testing appraisal for silk production enterprises, providing a good reference for the applications of the grafted silk testing appraisal, and greatly promoting the development of the silk weighting field.

Key words: DSC; MAA; silk; grafting rate; quantitative analysis