Analysis and Research on Control Strategies of 48 V Mild Hybrid Vehicle

2022-02-13YuChanghongWuQinglongWangYan

Yu Changhong·Wu Qinglong·Wang Yan

(1.New Energy Vehicle Development Institute,China FAW Corporation Limited,Changchun 130013;2.State Key Laboratory of Comprehensive Technology on Automobile Vibration and Noise & Safety Control,Changchun 130013)

【Abstract】In this paper,the control strategies of 48 V mild hybrid vehicle are analyzed,the topology of 48 V dynamic system is drawn and the vehicle operation principles are described.Moreover,the simulation models of 48 V mild hybrid vehicle are built as well.The vehicle power on control strategy,engine start-stop strategy,powertrain torque calculation and distribution strategy are developed,and the shift control strategy,brake energy recovery strategy and safety limp home strategy are analyzed.Meanwhile,the related intelligent development strategies,including vehicle start-stop prediction and energy management control are researched,so as to provide references for engineering designers.

Key words:48 V mild hybrid system,Powertrain system,Control strategy,Intelligent control,Energy management

BMS Battery Management System

BSG Belt-driven Starter/Generator

CAN Controller Area Network

EMS Engine Management System

ESP Electronic Stability Program

HCU Hybrid Control Unit

HEV Hybrid Electric Vehicle

MCU Motor Control Unit

TCU Transmission Control Unit

1 Introduction

With the increasing pressure of energy shortage and envi⁃ronmental pollution,the research and development of new energy vehicles have attracted the attention of major automobile manufacturers.Now,there are different kinds of hybrid vehicles have been produced in the market.The powertrain of hybrid electric vehicles are mainly composed of engine and motor.The hybrid system can be used to improve the vehicle performance and economy through advanced vehicle control strategies.

48 V vehicle is a type of mild hybrid vehicle,based on the traditional powertrain,it is matched with 48 V BSG motor and 48 V power battery pack.The increased cost of 48 V mild hybrid vehicle is less than other hybrid vehicles.48 V mild hybrid vehicle can be used to re⁃duce energy consumption and emissions,and it can be used to match with different kinds of traditional vehicles as well.

Based on a 48 V mild hybrid vehicle,the structure and operation principles are described,the vehicle simu⁃lation models are built,and the control strategies are ana⁃lyzed in this paper.These can be used to provide informa⁃tion references for relevant engineers.

2 48 V System Structure

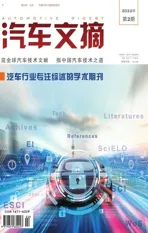

The powertrain system topology of 48 V mild hybrid vehi⁃cle is drawn in Fig.1.The 48 V mild is mainly composed of engine,gearbox,BSG motor,48 V battery,DCDC con⁃verter,clutch,and corresponding controller.The control⁃lers include HCU,EMS,MCU,BMS,TCU,and ESP.These controllers communicate with each other based on CAN-Bus.

Fig.1 48 V system structure diagram

HCU is the core controller of 48 V mild hybrid vehi⁃cle.In different driving conditions,HCU shall distribute the torque output of different power sources through the control strategies designed with EMS,MCU,BMS and TCU,in order to realize a variety of vehicle operation modes.

The control strategies are developed for 48 V mild vehicle include power on control strategy,vehicle mode control strategy,engine start-stop control strategy,torque calculation and distribution control strategy,shift control,strategy brake energy recovery control strategy and safety limp home control strategy.These control strategies will be introduced in this paper.

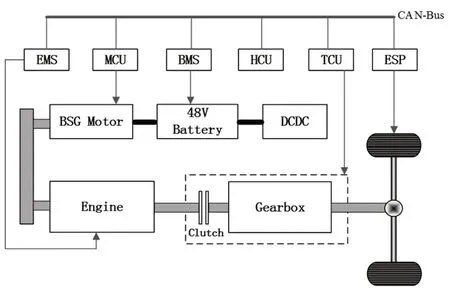

The hardware composition of 48 V system is shown in Fig.2.BSG motor is connected with the engine through belt pulley.BSG motor can not only provide motor drive,but also jointly drive the vehicle with the engine,so it can make the dynamic system output more power and torque.Meanwhile,BSG motor can also be used for brake energy recovery during vehicle running.

Fig.2 48 V system hardware diagram

3 48 V System Simulation Model

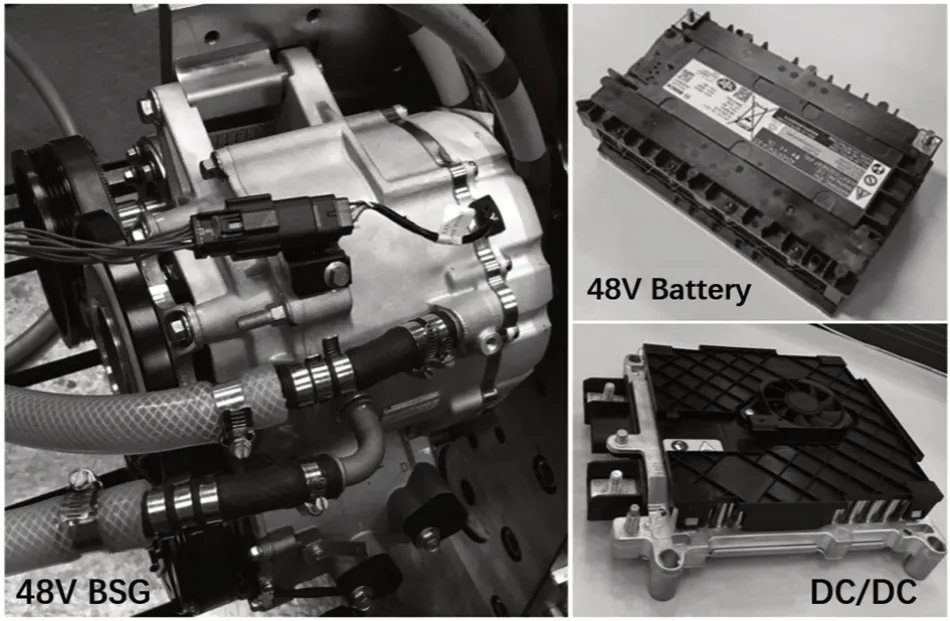

In this paper,the simulation models of a 48 V mild hy⁃brid vehicle are built for the research of vehicle control strategy and performance.Fig.3 is an interface of 48 V mild hybrid vehicle simulation model.By establishing the vehicle model,motor model,battery model,engine model and gearbox model,the simulation of different con⁃trol functions of the vehicle can be carried out through the models.

Fig.3 48 V mild hybrid vehicle simulation

Based on the development of control strategies,the driving requirements of 48 V mild hybrid vehicle under different driving conditions are realized,and the powerperformance and economy of the 48 V mild hybrid vehi⁃cle can be calculated effectively.

4 Driving Control Strategies of 48 V Mild Hybrid Vehicle

4.1 Power on Control Strategy

A power on and off control strategy for 48 V mild hybrid vehicle is developed.When the key is turned from igni⁃tion on to the start status,HCU will send an enable sig⁃nal to the relevant controller through the CAN-Bus to in⁃form the power system to prepare for high-voltage power on.The relevant controllers includes MCU,BMS,EMS and DCDC.Based on advanced power management and cooperative control technology,the operation modes of BSG motor are comprehensively processed.

At the same time,the risks of module breakdown of BSG motor and 48 V battery are avoided,the effective⁃ness of powertrain operation is ensured,and the high safety and reliability of vehicle driving are realized.The technologies of instrument displays for vehicles(such as,power on,engine start-up and powertrain fault occur⁃rence)are developed,which can be used to remind driv⁃ers of the current operation states and improve drivers'perceived quality.

4.2 Vehicle Mode Control Strategy

HCU manages the vehicle modes according to the vehicle speed,the driver's driving intention and the states of pow⁃er components.HCU receives BSG motor parameters from MCU and then controls the BSG motor to enter dif⁃ferent working modes,such as torque mode and speed mode.In order to meet the driving requirements of the drivers,HCU shall control the BSG motor and engine to output torque to realize the driver’s power demand.

HCU receives the parameters of battery voltage,cur⁃rent,and SOC from BMS.HCU cooperates with BMS to open or close the main relay of 48 V battery,in order to realize the power on and off function of the vehicle.

HCU receives the water temperature,warm-up re⁃quest and engine speed and torque signals from EMS.Based on the driving states of the 48 V mild hybrid vehi⁃cle,HCU cooperates with EMS to realize the engine start-stop mode,and control the engine to output the torque,and it can also control the engine to realize the fu⁃el cut-off function.

HCU receives the gearbox information signals from TCU,and then controls the clutch to open or close ac⁃cording to the driver’s operation behavior and vehicle status,so as to realize the shift control function of 48 V mild hybrid vehicle.

4.3 Engine Start-Stop Control Strategy

The strategies of engine start-stop function and state switching control based on multi road conditions are de⁃veloped for 48 V mild hybrid vehicle.In order to under⁃stand the starting process of the engine,the starting se⁃quence of 48 V mild hybrid vehicle is drawn here,as shown in Fig.4.The control flow of starting the engine shall be based on the signal command of HCU.Through the judgment of multiple working conditions,the func⁃tions of basic start-stop and coasting start-stop are devel⁃oped.

Fig.4 Engine start control scheme

Through the research and development of engine in⁃telligent start-stop strategy,the smoothness problems un⁃der complex working conditions and different tempera⁃ture environment are solved.The engine can be started up within 0.35 s by BSG motor,as shown in Fig.5.The starting performance of 48 V mild hybrid vehicle is much more efficient and stable than before.

Fig.5 Engine is started up by BSG motor[11]

4.4 Torque Capacity Calculation Strategy

In terms of torque capacity calculation strategy for 48 V mild hybrid vehicle,based on the available capacity ad⁃justment control method of multiple power sources,a multi-dimensional capacity model is established.An in⁃novative system torque calculation algorithm is proposedto solve the problem of inaccurate calculation of a single subsystem.

In the calculation of the maximum discharge torque and charge torque of 48 V mild hybrid vehicle,the maxi⁃mum discharge and charge torque of BSG motor,the max⁃imum torque and reverse drag torque of engine,and the transmission speed ratio of the gearbox are comprehen⁃sively considered,so that the torque output from the dy⁃namic system to the wheel end can be effectively calculat⁃ed.The control accuracy of torque from dynamic power output to wheel end is improved,and the problem of coor⁃dinated control of powertrain torque chain transmission is overcome.The rapid response and accurate output of wheel end torque under multiple working conditions are realized.

4.5 Torque Distribution Control Strategy

In terms of torque distribution control strategy for 48 V mild hybrid vehicle,based on multi-condition and multiobjective collaborative control methods,the strategies of driving torque demand and torque chain control are de⁃veloped,and the problems of dynamic and steady-state torque distribution have been solved.The strategies of torque distribution control and management based on op⁃timal handling are established,and the problems of vehi⁃cle jitter during vehicle modes switching are solved.

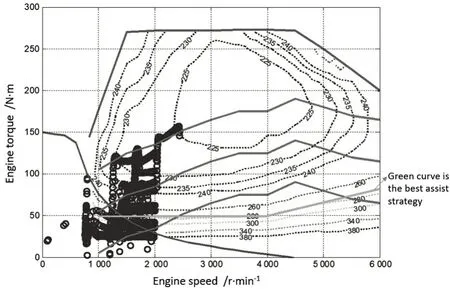

Based on the optimal system efficiency,an adjust⁃ment method for working point is developed.As shown in Fig.6,By optimizing the motor assist torque curve,the problems of coordinated control of engine torque and motor torque under multiple working conditions are solved.

Fig.6 Working point adjustment of 48 V system

4.6 Shift Control Strategy

When the driver operates the shift gear during driving,the shift function begins to work.HCU will calculate the maximum and minimum allowable shift limits based on the current vehicle states,including battery SOC,vehicle speed,accelerator and brake pedal.

HCU sends the signals of the calculated maximum and minimum gears to TCU,and then TCU selects the ap⁃propriate gear value based on the gear range,and TCU shall control the torque transmitted to the transmission in⁃put shaft to meet the target requirements.If there is a re⁃quest of torque or speed intervention from a controller,such as ESP,HCU shall control motor and engine to out⁃put the torque in order to meet the request of ESP and other controllers.

4.7 Energy Recovery Control Strategy

The negative torque is required when the vehicle deceler⁃ates.BSG motor can be controlled to convert part of the negative torque into the electric energy of the 48 V bat⁃tery for storage.Total braking torque of vehicle decelera⁃tion is jointly provided by mechanical friction torque and the negative torque of BSG motor.

The calculation formula of the total braking torque is T=T+T.In this formula,Tis the total brak⁃ing torque by the vehicle,Tis the mechanical friction torque of the brake,and Tis the regeneration torque of BSG motor.

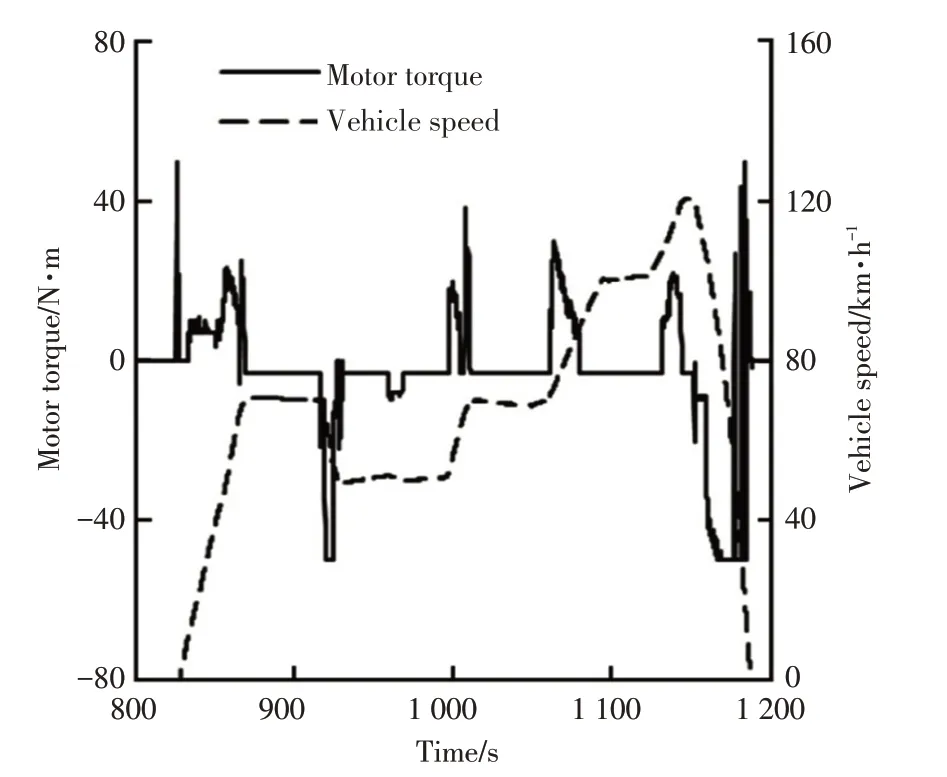

A test of 48 V mild hybrid vehicle on the test bench is shown in Fig.7.It can be seen from Fig.8 that the accel⁃eration section of NEDC cycle is BSG motor assistance mode.The deceleration section is BSG motor power gen⁃eration mode,and the output power is stored in the 48 Vbattery to maintain the balance of 48 V battery power.

Fig.7 BSG motor torque during vehicle running[18]

4.8 Safety Limp Home Control Strategy

A reasonable and advanced method of limp home control strategy for 48 V mild hybrid vehicle is developed.When a fault occurs in the 48 V mild hybrid system,it can be solved by voltage control strategy,if the battery relay is disconnected,the power balance output of the 48 V mild hybrid vehicle can still be maintained based on the prin⁃ciple of maximum energy utilization.

In safety limp home mode,the engine is started by the 12 V starter,and then BSG motor is driven to gener⁃ate power by the engine.Based on the power output cal⁃ibration,the DCDC is controlled to supply power to the 12 V electrical accessories and maintain BSG motor volt⁃age stabilization.When the vehicle has a driving fault,the 48 V mild hybrid vehicle is controlled to drive at a low speed to prolong the driving range.

5 Intelligent Driving Control Strategy

5.1 Intelligent Information Collection and Control Strategy

For 48 V mild hybrid vehicle,the strategies related to in⁃telligent driving are developed.In order to develop intelli⁃gent driving technology,it is necessary to collect vehicle running and road information through the automotive in⁃telligent network control system.The automotive intelli⁃gent network control system monitors vehicle running state,driving behavior state,road condition and environ⁃ment state.And then the intelligent network control sys⁃tem preprocesses the collected data information and sends parameters to HCU.

As is shown in Fig.8,for the vehicle running status monitoring,the parameters such as vehicle speed,accel⁃eration and gear information are obtained through sen⁃sors.For the driving behavior status monitoring,the ac⁃celerator pedal and brake pedal parameters are obtained through sensors,and the driving mode is obtained through the CAN-Bus.The driving mode is selected by the driver,such as economy mode,sport mode or snow mode.For the road condition and environmental status monitoring,based on the analysis of GPS navigation data,the traffic condition distribution,the congestion degree of each road section and the next traffic light distance are comprehensively judged.These collected parameters will be used to provide input sources for intelligent control.

Fig.8 Intelligent driving control system structure

5.2 Start-Stop Strategy Based on Active Prediction

According to the parameters collected and monitored by the intelligent network control system,HCU develops the start-stop prediction function based on multi-dimension⁃al and multi road conditions in combination with the sta⁃tus of MCU,BMS,EMS and TCU.Based on the parame⁃ters of engine speed,torque and throttle,transmission output shaft speed and torque,battery SOC,current and voltage,BSG motor speed and torque,HCU formulates start-stop strategy and optimizes engine working area in order to reduce the fuel consumption and emission.

Through the intelligent network control system,in⁃cluding sensors and communication equipment,HCU ob⁃tains the vehicle running status,the driving status of vehi⁃cles ahead and the traffic light time at the intersection in real time.For example,when it is found that there is atraffic light intersection ahead,and it is detected that the distance from the vehicle ahead is less than s1 and the speed difference between the 2 vehicles is less than V1,HCU will actively control the engine to enter coasting stop.At the same time,HCU can also actively control the engine to be started in advance,which can meet the us⁃er's driving intention.

Based on road condition information,through the en⁃gine start-stop prediction function,the road condition in⁃formation in front of the vehicle can be obtained by using radar,camera and GPS navigation.And the engine startstop prediction function has been developed so as to avoid emergency braking and stop when reaching the front of crowded road sections.The function has a great development prospect in intelligent driving in the future.

5.3 Energy Management Strategy Based on Driv⁃ing Behavior

Based on the intelligent network collaborative control strategy,the battery dynamic energy management system scheme is established and the high intelligent algorithm is developed.Obtained by the planned path information,the thresholds of key parameters of energy management are determined,BSG motor torque,engine torque and 48 V battery power are calculated by advanced algorithm.

The optimal energy output of each dynamic power source is controlled,which solves the technical problems that the energy cannot be dynamically and optimally dis⁃tributed under complex working conditions.And finally,the fuel economy of the vehicle is improved through the intelligent energy management strategy.

5.4 Energy Management Strategy Based on Com⁃plex Road Conditions

A method of battery energy management for predicting the road conditions in front of vehicle is developed.The available energy output is calculated in real time by pre⁃dicting the uphill,flat and downhill sections within the previous distance.The corresponding control strategy is developed to process different working conditions and control the power source to output energy reasonably.

Based on the road condition judgment results,48 V battery SOC and 12 V battery state,the forward and re⁃verse output of DCDC is intelligently controlled to im⁃prove the comprehensive utilization rate of energy man⁃agement system.Based on the driving route and extended driving range algorithm,the energy distributions under multiple road conditions are optimized,and the energy outputs of the power sources are effectively controlled.

6 Conclusion

The powertrain system and the control strategies of 48 V mild hybrid vehicle are analyzed and researched in this paper.48 V dynamic system is a hybrid energy-saving technology that can effectively compromise cost and fuel saving rate.48 V mild hybrid vehicle can realize the rap⁃id start-stop and optimize the operating efficiency area of the engine.48 V mild hybrid vehicle can realize the func⁃tions of motor assistance and braking energy recovery,re⁃duce the fuel consumption and COemission,and im⁃prove the dynamic performance and economy.

The relevant intelligent driving strategies for 48 V mild hybrid vehicles are introduced,including intelligent start-stop prediction control strategy,intelligent energy management strategy based on driving behavior and com⁃plex road conditions.These technologies can be used to provide references for correlative engineering designers.