Real-Time Control System Adopted to Energy Storage for Smart Grid Low Wind Applications:A Part of Distributed Renewables in Smart City

2022-01-08MDShahrukhAdnanKhanYoongChoonChangMdAshrafulKabirMuhammadlzuanFahmiBinRomliChockalingamAravindVaithilingamJakirHosain

MD Shahrukh Adnan Khan| Yoong Choon Chang | Md Ashraful Kabir |Muhammad lzuan Fahmi Bin Romli | Chockalingam Aravind Vaithilingam |Jakir Hosain

Abstract—In this paper,extensive efforts have been undertaken to design and develop a control system,which is incorporated with an energy storage device that can store energy from low-voltage renewable sources.The developed device acts as a storage element,which can be used to charge small-scale batteries,cellular devices,and other applications in remote places where the grid connection is not available.The circuit is developed using a case-by-case analysis.In order to solve the low output voltage problem,a bipolar junction transistor-metal oxide semiconductor field-effect transistor (BJT-MOSFET) based switch control technology with the Arduino microcontroller has been implemented.The developed control system is extremely efficient in charging batteries through a supercapacitor for low-voltage sources.In this research,a small-scale 200-W portable vertical axis wind turbine is used at a wind speed of 3 m/s.The result shows the efficiency of the proposed system as compared with the conventional systems.The proposed system can be an important tool of the latest distributed energy generation technology which is an important part of a smart city.Lastly,the limitations and future scopes of the development of the control device are discussed for the future barrier.An important future scope identified is to integrate the Internet of Things based mobile interface for remote monitoring for any kind of pandemic situation like COVID-19.Now,it is high time to get our smart city concept aligned with the post COVID pandemic situation and get us prepared smartly for similar future occurrences.

Index Terms—Energy storage,low-voltage application,novel control system,post pandemic smart city.

1.lntroduction

Despite groundbreaking advancements in the sustainable energy sector,namely solar photovoltage (PV)and wind power,the proportion of renewable energy of the total energy has only improved slightly.The slight change is justified by the fact that the overall energy demand (not considering the temporary setback in 2009 due to global economic recession) has continuously increased,and this increase in turn has thwarted the development of modern renewable energy technologies[1]-[4].Moreover,conventional biomass,which accounts for more than 50% of all renewable energy,is used to produce heat;however,it has failed to meet the existing consumer demand[5]-[7].Energy harvesting is a novel approach that is rapidly flourishing.But few studies have been conducted in this field,which includes the innovative control system that is able to harvest energy from both wind and solar rays[8]-[10].

Sarkeret al.developed a control system for low energy,which harvested energy from the environment using the vibrating piezoelectric element with the help of a diode bridge rectifier (AC-DC converter)[11].A switch-mode step-down DC-DC converter was used for the low-powered circuit to control the amount of energy stored in the battery.However,the input AC voltage with the 0.4-V amplitude was rectified and stepped up to 3.3-V DC.And the system was not incorporated with solar energy.In another research,kinetic energy was harvested in the form of mechanical energy,which was later converted to electrical energy using the electromagnetic,piezoelectric,or electrostatic transduction mechanism[12].The positive cycles of the input AC voltage were controlled using the combination of the buck and buck-boost converters to reduce the circuit size and minimize the power loss.Poureet al.built a DC-DC step-up converter with a control interface between the renewable sources and power electronics circuit due to the mismatch in output voltage levels[13].Both the systems were insufficient in handling the low-voltage output from the wind turbine or solar energy system.Ugale and Dixit used a fuzzy logic controller for solar energy control to solve the variation of irradiation and temperature[14].The produced output voltage was used for low-voltage applications.However,the control system was incapable for the energy from wind turbines.Alippi and Galperti wrote an AdHoc adaptive algorithm to keep the maximum power point tracking (MPPT) circuit at its optimum operating conditions and ensure the maximum energy transferring from a solar cell to the batteries[15].Again,the system was not operational for the low wind speed.Tan and Panda harvested wind energy using a metal-oxidesemiconductor field-effect transistor (MOSFET) rectifier for the low AC voltage under low wind speed conditions[16].The circuit also employed a DC-DC converter with a resistor emulation technique to obtain MPPT[16].They also developed a hybrid light and thermal energy harvesting scheme that uses a microcontroller-based circuit for transferring the maximum power to the connected load.In addition,Weimeret al.have been able to store wind energy in a battery,using a buck-boost converter operated in a discontinuous mode[17].The alternator,which was rotated with the help of an anemometer shaft,was operated at its maximum power point by keeping the input resistance of the converter constant[18].However,all these cases failed to incorporate solar and low wind energy to be harvested even at a low-voltage output.

1.1.Problem Statement

Wind and solar hybrid energy harvesting is a new concept that is growing in popularity rapidly.However,significant challenges exist in the following two major fields.The first part is about the universal control system that may require both wind and solar energy and harvest these accordingly.Few studies have developed this kind of efficient technology[19],[20].The other part is about low wind speed areas.As we know,countries,such as Malaysia,Singapore,Thailand,and Bangladesh,have low wind speeds,such as 3 m/s to 4 m/s or even less[19],[21].In addition,many areas are with multidirectional wind.Most importantly,wind turbines in low wind areas provide a low-voltage output,which is difficult to work with an off-grid system.Not enough studies have been conducted in this area.

1.2.Research Contribution and Scope

This paper provides an original case-by-case solution to develop a universal hybrid control system that can work for a low wind speed and energy harvest.The proposed system can be an important tool for the latest distributed energy generation technology,which is an important part of the post COVID-19 pandemic smart city framework.A detailed study has been conducted for the transducer and data acquisition (DAQ)area.An innovative approach of incorporating the supercapacitors in the energy harvesting control system has been proposed,which can harvest energy for the small battery type load of the off-grid system.

2.Methodology

The trial-and-error method is used in three stages.In the first stage,a complete setup with a standard 1.5-kW permanent magnet synchronous generator (PMSG) was connected to a 3-bladed vertical axis wind turbine (VAWT) with a standard control system for charging a DC battery.The result was unsatisfactory;therefore,the second stage was introduced,where 200-W PMSG incorporated into hybrid VAWT was introduced with a standard control system.Again,the system did not perform well with the low wind speed that led to the third (final) stages.The final stage included a supercapacitor-based switch control system.Sections 3,4,and 5 describe each stage in detail with the result and analysis.

3.Stage 1:Full-Phased Control System Experimental Analysis

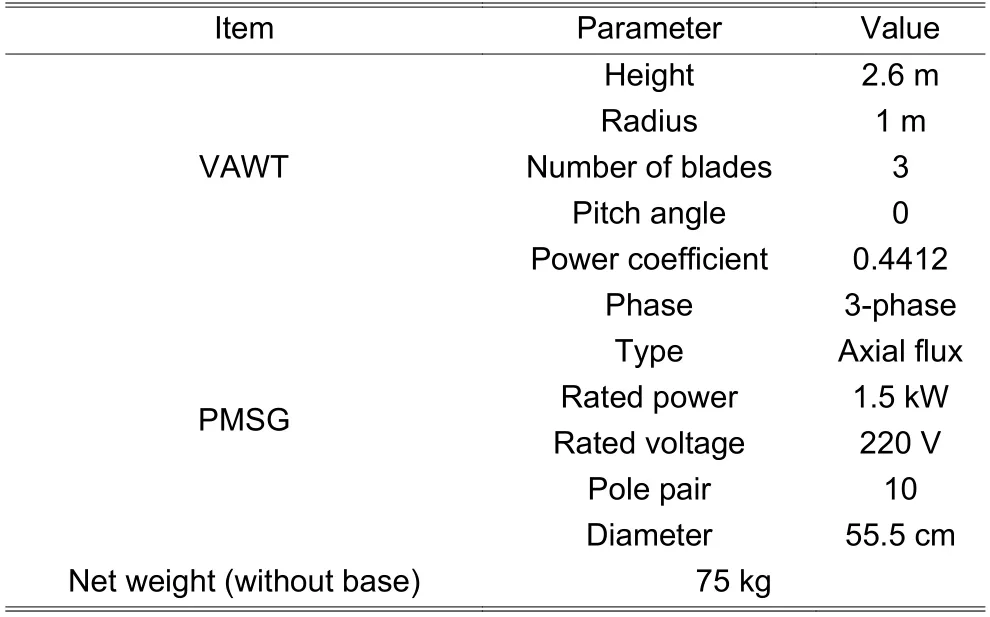

In the first stage,a full-phased control system was implemented for energy harvesting.The 1.5-kW PMSG was connected to a maglev 3-bladed VAWT.Fig.1shows the machine design andTable 1provides the specification.VAWT was selected over a horizontal axis wind turbine (HAWT),because wind flows horizontally,which will give more wind speeds to VAWT than HAWT.Magnetic levitation was used to minimize the friction.The turbine was designed thoughtfully with three blades.The turbine shaft was made of wood.

Fig.1.Machine design 1.

Table 1:Machine design configuration 1

3.1.Control System for Stage 1

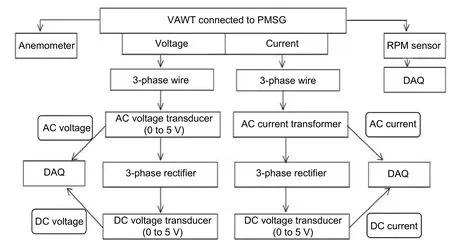

While VAWT was rotating,the voltage generated was measured by an AC voltage transducer.A rotary encoder kit (RE08A) was also connected with the turbine to measure the angular velocity.A DAQ device (NIUSB 6212 Driver) was connected with a laptop/personal computer (PC) for power.The rotary kit was not directly connected with the wind turbine;however,when the turbine rotated,it would get the rotary device signal so the device could measure the rotation.DAQ acquired and sent data to the laptop,which then displayed data in a presentable format,using the LabVIEW Signalexpress 2011 program.Next,the wind speed for the turbine was varied using two stand fans and the blade angle of the wind turbine was adjusted manually.The 3-phase voltage was fed to a control system with a full-wave diode bridge rectifier followed by a DC-DC step-up converter to give a constant voltage to the load (seeFig.2).

Fig.2.Stage 1 control strategy.

3.2.Experimental Setup

Fig.3shows the experimental setup placed at The University of Nottingham,Malaysia Campus(UNMC),Semenyih,Selangor,Malaysia.

3.3.Results and Discussion

The result from the proposed design was unsatisfactory at a low wind speed.A 6-V battery was connected as the load,and the turbine stopped rotating due to insufficient torque generated at a low wind speed of 3 m/s.In addition,the voltage drop was also significant due to the DC-DC converter and transducers.Therefore,the setup was insufficient to fulfill the objective.

Fig.3.Experimental set-up at research building,UNMC.

4.Stage 2:Lighter VAMT Experimental Analysis

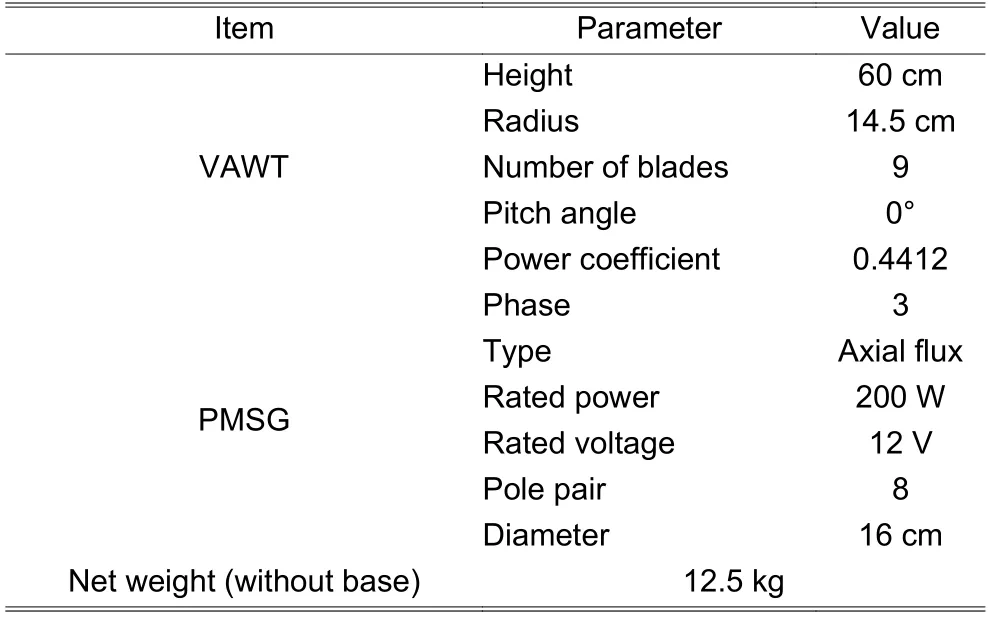

Stage 2 includes a lighter version of VAWT.Instead of 3-bladed turbines,the blade number was increased to nine,and a hybrid version was designed to increase the output torque efficiency of the turbine at a low wind speed.However,instead of the 1.5-kW PMSG,a 200-W generator was chosen,which is compatible with the low-voltage turbine output.Fig.4shows the machine design of the proposed turbine and generator,andTable 2displays the hardware configuration.

Table 2:Optimized system design configuration 2

Fig.4.Machine designing 2.

The same control system was applied in the second stage with improved VAWT connected to the maglev-based PMSG.However,the results were not promising yet.The turbine output voltage was insufficient to recharge a battery at a 3-m/s wind speed.

5.Stage 3:Supercapacitor Bank Experimental Analysis

To eliminate the problem and to offer a solution,the supercapacitor bank was included in the system.The problem of the first two stages was the low-voltage output from PMSG driven by the turbine at the 3-m/s low wind speed.As the purpose of the system was to charge a small off-grid load,which is a 6-V DC battery in this case,a constant voltage should be provided at the load terminal.Therefore,a full-wave diode bridge rectifier followed with a DC-DC step-up converter was placed.However,the output generator voltage was not sufficient to draw the converter and then charge the battery.To find a solution,the supercapacitor bank was positioned between the converter and the turbine.The idea was to charge the supercapacitor bank directly from the turbine via a full-wave rectifier.Then,the supercapacitor bank would charge the battery through the DC-DC converter.Therefore,the turbine output from PMSG did not require the DC-DC converter.Any output voltage,even if low,was not of concern,as the supercapacitor bank would take the current with any voltage as the input while charging.Two MOSFETs were used to control the charging and discharging processes for the supercapacitor bank.

5.1.Control Strategies in Stage 3

As a part of the hybrid energy harvesting,a supercapacitor bank with 8.75-F capacitance and a voltage of 10.8 V was assembled.In this energy harvesting system,a switching circuit plays a vital role.With the aid of the Arduino UNO microprocessor,two N-channel MOSFETs (P36NF06 model) were used in this project to create the switching condition in the energy harvesting circuit.A light-emitting diode (LED) was placed parallel to the gate-source pin of MOSFET for testing.The decision-making switching algorithm flowchart is illustrated inFig.5.For a lower threshold voltage,MOSFET 1 was switched to ON,so that the wind turbine could charge the supercapacitor bank.During this time,MOSFET 2 was switched to OFF which in turn isolated the battery from the supercapacitor bank.

WhenVSupercapwas greater or equal to 7.5 V,MOSFET 1 then was switched to OFF to prevent overcharging from the wind turbine.MOSFET 2 was then switched to ON.At this time,the rechargeable battery was charged to 6 V.MOSFET 1 would be switched to ON again as soon as the voltage of supercapacitor dropped to 4 V.The charging and discharging process would be continued until the battery was charged up to 6 V.MOSFETs were placed in the stripboard of the energy harvesting circuit.Two LEDs were aligned with the bias voltage,respectively for MOSFET 1 and MOSFET 2.To indicate the circuit close status (logic high),LED would light up whenever MOSFET was switched to ON and vice versa.

5.2.Low-Voltage Control System:Hardware and Software Designs

A.Wind Speed Measurement

A cup-type anemometer (Fig.6) was used for wind speed measurement.The anemometer used MOC7811 Optocoupler IC and provided DC output with the maximum of 5 V.Signals less than 5 V were moved to DAQ,which was transferred to the Labview interface (Fig.7).

Fig.5.Flowchart of control strategy for third stage analysis.

Fig.6.Anemometer.

Fig.7.Front panel screenshot of Labview interface.

B.Transducer

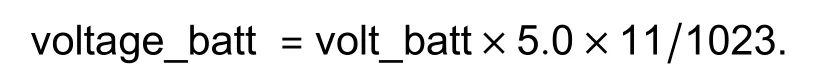

InFig.8,the setup function between the Arduino board and the computer is provided.In the main loop,a variable named volt_batt is declared to store the resistance value.The function analogRead is used to get the resistance value and fed into the Arduino microprocessor.A float-type variable (voltage_battery) was created to store the value in the range from 0 to 1023 obtained from the resistance value; the corresponding value of voltage could be converted by using the following equation:

The constant,11,was acquired from the fraction of

Fig.8.Sensing circuit coding in Arduino.

Hence,a constant of 11 is multiplied to the equation to obtain the actual input voltage across the terminals.The same concept was applied to the current sensing circuit.AsV=IR,the voltage value obtained was divided by the resistance to find the corresponding magnitude of the current flowing in the circuit.

C.DC-DC Boost Converter

A DC-DC boost converter was used to step up the input voltage from the wind turbine to a constant output voltage of 8 V,so that the overall efficiency of the system could be increased.By settingR1=100 kΩ andR2=560 kΩ,a constant output voltage of 8.18 V could be produced atVoutwith the minimum input voltage andVINis as low as 2.0 V.For testing,a variable power supply was used with the input voltage.As can be seen fromFig.9,the minimum input voltageVINof 2.0 V was required to provide an approximate output of 8 V.

Fig.9.Analysis of Vout (V) at different VIN values.

Fig.10.Switching Circuit Coding in Arduino IDE.

D.Energy Harvesting Circuit

After obtaining the desired voltage values,the switching circuit can be coded by setting the conditions of the switching algorithm in an “if”statement,as shown inFig.10.The basic working principle of this part of the code could be explained as follows.When the voltage across the supercapacitor bank was greater than 7.5 V,a signal“LOW” corresponding to 0 V was sent to the Arduino digital pin “MOSFET 1”,so that it could be switched to OFF to prevent overcharging.Simultaneously,a signal “HIGH”,which was equal to 5 V,was sent to the Arduino digital pin “MOSFET 2” and the rechargeable battery would be charged by using the supercapacitor bank.When the voltage across the supercapacitor bank was less than 4 V,a signal “HIGH” corresponding to 5 V was sent to the Arduino digital pin “MOSFET 1”,so that it could be charged up using wind power.Simultaneously,a signal “LOW”,which was equivalent to 0 V,was sent to the Arduino digital pin “MOSFET 2”until the voltage across the supercapacitor bank reached 7.5 V.This charging and discharging of the supercapacitor bank continued until the battery was charged.

5.3.Experimental Setup

The experimental setup was arranged at the Research Building,UNMC,as shown inFig.11.

5.4.Results and Discussion

The charging voltage with respect to charging time is depicted inFig.12.Although the supercapacitor bank was set to charge up to 7.5 V,it failed to achieve that.The main reason behind the failure was the low wind speed of 3 m/s,which did not provide sufficient mechanical power to PMSG.To avoid this problem,the charging voltage of the supercapacitor bank was reduced by reprogramming it to 6.8 V.A complete cycle took 95 minutes.The duration of the total charging processes (one cycle requiring 95 minutes) was calculated to be 38.4 hours to complete charging the 5-V battery from 4.2 V (saturation) to 5 V (referFig.13).

Fig.11.Experimental Setup for the integrated system,UNMC.

Fig.12.Supercapacitor bank voltage vs.charging time at the wind speed of 3 m/s.

Fig.13.Battery charging voltage using the supercapacitor bank concerning time for the wind speed of 3 m/s.

6.Conclusions and Future Work

To recapitulate,this paper provides original findings in a low-voltage hybrid energy harvesting sector.Detailed step-by-step experiments were performed to find a suitable hybrid control system,which is capable of harvesting energy even at the low output voltage,both from wind and solar energy.The experiments,following the trial-and-error method and with an implementation of a switch-controlled supercapacitor-based control strategy,can perform adequately to charge a 5-V DC battery at the 3-m/s wind speed.The control system can also be performed using the solar and wind hybrid configuration.

For the future scope,post COVID-19 pandemic smart city adopts the renewable energy generation in a different perspective.The vehicle to grid (V2G) and building to grid (B2G) are still in the infancy stage as a part of crowd energy.A real-time control system for energy storage with the supercapacitor could help for fast charging in these cases.Also,a network interface has been developed for the similar switched control device for real-time monitoring in Labview for the standalone energy storage system,which can be further developed to create the mobile Internet of Things based graphical user interface,so that the system can be remotely monitored from distant places.

In addition,the work has enough future research potential.As the groundwork has been completed,the findings allow researchers to work further to improve the DC-DC converter to increase the charging efficiency in the low-voltage output.Furthermore,a more powerful and efficient supercapacitor bank can be used to observe the performance.Lastly,researchers have the platform to take the necessary steps for business modeling.

Most importantly,for the last few years,distributed renewable energy is gaining popularity in smart city planning.This control system can make a key impact for an off-grid storage system for emergency back-up,when the grid is disconnected for any reason in a specific area.Moreover,this control system could be an option for distributed renewable generation for home energy that can also be connected to the grid system in the concept of crowd energy.

Few significant important research and models have been developed for grid-connected PV management and Geographic Information System (GIS) based solar irradiation forecasting in recent efforts.The supercapacitor based switch control energy storage device may also be integrated for hybrid PV management.With real-time monitoring,the forecasting would be more accurate and precise.

Acknowledgment

Authors would like to acknowledge the Center of Research—Innovation &Commercialization Center (ICC),Canadian University of Bangladesh,and Smart City Planning Cell (SCPC),Department of Electrical and Electronic Engineering,Canadian University of Bangladesh for making the platform of this research.

Disclosures

The authors declare no conflicts of interest.

杂志排行

Journal of Electronic Science and Technology的其它文章

- lmpact of Fiber Dispersion on Performance of Entanglement-Based Dispersive Optics Quantum Key Distribution

- Effect of lmpeller Solidity on the Generating Performance for Solar Power Generation

- Effects of Material and Dimension on TCF,Frequency,and Q of Radial Contour Mode AlN-on-Si MEMS Resonators

- Large-Capacity and High-Speed lnstruction Cache Based on Divide-by-2 Memory Banks

- Effect of Wall Thicknesses on Broadband Design of Ka-Band TE21-Mode Coupler

- Device-Free Through-the-Wall Activity Recognition Using Bi-Directional Long Short-Term Memory and WiFi Channel State lnformation