蝼蛄前足爪趾三维几何构形的减阻机理

2021-12-28乔超雄王天琪曹佳丰王鹏飞

张 琰,乔超雄,王天琪,曹佳丰,王鹏飞,石 磊

·研究速报·

蝼蛄前足爪趾三维几何构形的减阻机理

张 琰1,2,乔超雄1,2,王天琪1,2,曹佳丰1,2,王鹏飞1,2,石 磊3

(1. 天津市轻工与食品工程机械装备集成设计与在线监控重点实验室,天津 300222;2. 天津科技大学机械工程学院,天津 300222;3. 天津市利民调料有限公司,天津 300308)

触土部件的阻力直接影响耕作机械和工程机械的作业效率,该研究利用工程仿生设计方法,基于蝼蛄前足爪趾优异的地下掘进能力,提取前足爪趾的三维几何构形特征用于仿生试件设计,通过土槽切削阻力试验和有限元模拟,分析蝼蛄前足爪趾几何构形的减阻性能和机理。研究结果表明,前足爪趾的构形特征对切削阻力有显著影响(<0.05),仿生试件的切削阻力较楔状体试件最高可降低56.96%,三维仿生构形的减阻性能优于一维和二维构形。蝼蛄前足爪趾构形能使被切削土壤沿挖掘面顺畅移动,避免了土壤在仿生试件尖部的堆积和对中后部的挤压,实现切削阻力的减小。该基于蝼蛄前足爪趾的工程仿生研究可为耕作和工程机械触土部件的减阻设计提供理论基础。

农业机械;仿生;设计;优化;减阻;切削阻力试验;蝼蛄

0 引 言

在耕作机械和工程机械作业中,其主要触土部件(犁铧、深松铲、挖掘机斗齿等)的磨损、土壤黏附、触土阻力过大等问题直接影响整机的效率[1]。在农业机械向低排放、低污染、高能效、高效率方向发展的背景下,国内外研究者在触土部件的材料、表面形态、几何构形优化和物理辅助技术等方面进行了大量研究。在材料优化方面,Keles等[2]研究了钛添加量对钢制挖掘机斗齿的力学性能和耐磨性的影响,发现当钛的添加量为0.15%(质量百分比)时,斗齿有较好的耐磨性和力学性能;王少伟等[3]开展了齿形开沟刀的优化研究,利用表面热处理提高齿形开沟刀的耐磨性能。在表面形态优化方面,Li等[4]采集穿山甲鳞片的表面形貌并将其用于仿生减黏马铃薯挖土铲设计,与原型挖土铲相比,仿生挖土铲在田间测试时的减阻率为14.19%;贾洪雷等[5]针对普通开沟器在工作过程中土壤黏附严重和运行阻力大等问题,基于蚯蚓头部体表形态设计了一种仿生波纹形开沟器,其减黏降阻效果优于普通开沟器。在构形优化方面,通过优化耕作机械触土部件的构形,可有效减小工作阻力,实现节能降耗[6]。郑侃等[7]针对传统深松铲作业阻力大、能耗高等问题,通过构形优化设计了一种可以有效减阻并降耗的折线破土刃深松铲,其阻力减少约11.52%;马跃进等[8]设计了一种凸圆刃深松铲,田间试验结果表明,凸圆刃式深松铲耕作阻力比与国标深松铲平均降低了10.24%。刘晓鹏等[9]研究了具有不同导曲线类型开沟犁的阻力特性,与直线和指数线型相比,抛物线型最高可减阻31.58%。在物理辅助技术方面,研究者基于蚯蚓体表的电渗现象,提出了基于弱电场的仿生电渗技术,可以有效降低触土部件表面的土壤黏附[10-11];也有研究者将机械振动施加在触土部件上,取得了很好的减黏脱附效果[12-13];周华等[14]设计了一种滑切型自激振动深松铲,其相对于传统弧形深松铲,在各工作速度下可实现减阻15.45%~20.05%。

在材料优化、表面形态优化、几何构形优化和物理辅助技术4种提高触土部件工作效率的方法中,优化触土部件构形的方法实现起来较为简单,其不需要使用外界能源和辅助装置,且减阻效果显著,减阻率普遍大于10%。耕作机械和工程机械触土部件的构形多为三维结构,涉及大量相互关联的几何参数,给构形优化工作带来了困难。因此,大量研究者借助仿生学的方法优化构形,并取得了诸多创新性的成果[15-16]。例如,基于夏威夷贝表面形貌设计的仿生深松器,可有效降低土壤深松过程中的耕作阻力[17-18];基于蝼蛄前足爪趾构形设计的仿生挖掘机斗齿,其挖掘阻力最高减小了 12%[19];基于鸵鸟趾甲三维构形设计的仿生铲具有更优的土体插入性能,其内凹弯曲面可减少土颗粒的堆积,从而减小了阻力[20];基于鼹鼠多趾组合结构和趾间轮廓曲线特征设计的仿生旋耕刀,可以降低整机功率16%以上[21]。上述针对触土部件的仿生构形研究一类是将仿生对象的主要构形特征进行二维投影,另一类则采用三维逆向的方式直接移植生物的三维构形。但是其均没有从机理上利用三维构型特征对触土部件进行设计或优化,性能上仍有很大的提升空间。

综上,随着耕作机械的作业速度不断提升,对节能减排要求的不断提高,以往研究中的仿生构形设计方法难以满足实际需求。本研究进一步拓展了针对蝼蛄前足爪趾的工程仿生研究,将爪趾构形仿生由二维拓展到三维,采用土槽切削试验和有限元模拟方法,分析仿生试件的切削减阻机理,以期为耕作机械和工程机械触土部件的减阻设计提供理论基础,实现进一步提高耕作机械等的工作效率的目的,并进一步丰富仿生构形设计方法。

1 材料与方法

1.1 蝼蛄前足爪趾三维构形特征的提取

蝼蛄前足高度特化为挖掘足,其前端的胫节特化为多齿铲状结构,为主要挖掘部件(图1a)。特化的胫节上连续排列有4个爪趾(爪趾1~爪趾4)和2个跗爪趾,其中4个爪趾是挖掘时的主要触土部位,也是本研究的研究对象。使用三维扫描技术提取蝼蛄前足爪趾(以爪趾1为例)的三维轮廓并用于逆向建模,其具体步骤为:1)使用三维扫描仪(ZWSJ3D,中沃世纪三维,深圳市中沃世纪自动化技术有限公司)获得爪趾1三维轮廓的点云信息并生成三维逆向模型(图1b)。2)以爪趾基部截面中心为原点建立坐标系,为前足爪趾1基部截面的中心,为垂直于挖掘面(内凹的曲面)的轴,为由爪趾基部指向尖部的轴,为垂直于和的轴。3)利用截面法提取前足爪趾1在纵截面平面和横截面平面上的截面构形,利用投影法提取前足爪趾1构形在平面的投影构形。

1.爪趾1 2. 爪趾2 3.爪趾3 4.爪趾4 5.胫节 6.跗爪趾

1.Claw toe 1 2. Claw toe 2 3. Claw toe 3 4.Claw toe 4 5.Tibia 6.Tarsus

注:为前足爪趾基部截面的中心,为垂直于挖掘面的轴,为由爪趾基部指向尖部的轴,为垂直于和的轴。

Note:is the center of the base section of the foreleg’s claw toe,is the axis perpendicular to the excavation surface,is the axis points from the base of the claw toe to the tip,is the axis perpendicular toandaxis.

图1 蝼蛄前足爪趾结构及其三维逆向模型

Fig.1 Foreleg’s claw toe structure of mole cricket and its 3D inverse model

1.2 蝼蛄前足爪趾构形特征曲线的拟合与定义

以蝼蛄前足爪趾1为例,首先,本研究使用投影法获取了蝼蛄前足爪趾1在平面的投影面,为平面构形,使用截面法分别获取了蝼蛄前足爪趾在平面和平面的截面,分别为平面构形和平面构形;其次,利用数据分析软件MATLAB由蝼蛄前足爪趾的投影面和截面构形,提取出可反映蝼蛄前足爪趾几何构形的特征曲线,并进行多项式拟合与平滑处理,得到平面、平面和平面的特征曲线多项式表达式,分别如式(1)~式(3)所示.

=76+65+54+43+32+21+1(1)

=76+65+54+43+32+21+1(2)

=76+65+54+43+32+21+1(3)

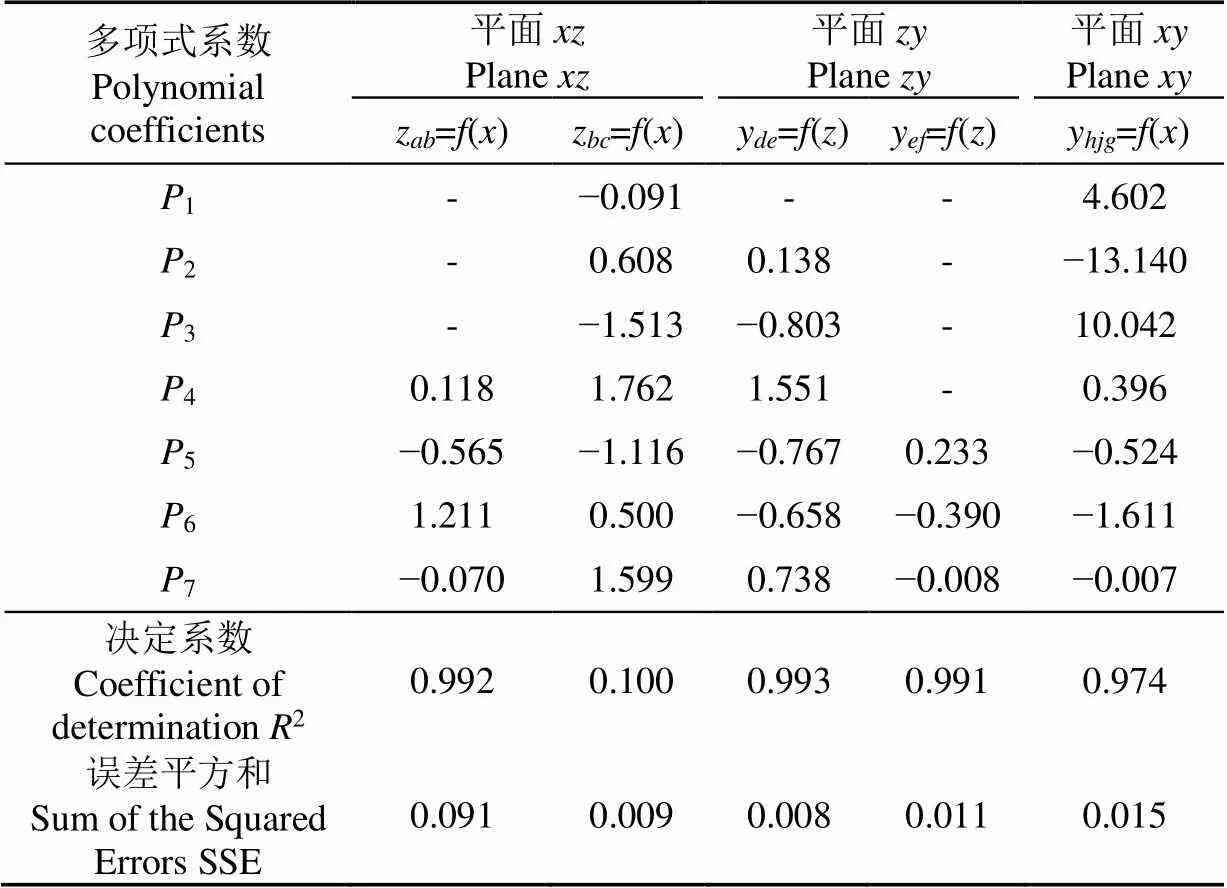

式中系数1~7取值如表1所示。由表1可知,蝼蛄前足爪趾1在平面、平面和平面多项式拟合后特征曲线的决定系数(coefficient of determination,2)均大于0.97,误差平方和(Sum of the Squared Errors,SSE)很小,表明前足爪趾1的特征曲线与其轮廓特征的拟合度较好。

表1 蝼蛄前足爪趾1特征曲线的多项式系数及其拟合结果

注:z和z为平面的特征曲线,y和y为平面的特征曲线,y为平面的特征曲线。

Note:zandzare the characteristic curves in plane,yandyare the characteristic curves in plane, andyis the characteristic curve in plane.

根据式(1)~式(3)多项式绘制出的蝼蛄前足爪趾1的特征曲线如图2所示。将平面的特征曲线z=()、轴和轴围成的面定义为A(图2a),将平面的特征曲线z=()、轴和轴围成的面定义为B(图2a);将平面的特征曲线y=()、y=()和轴围成的面定义为S(图2b);平面的特征曲线y=()近似为与轴平行的直线,为直线与轴的交点,平面的特征曲线y=()与轴的交点为,将曲线y=()和轴围成的面定义为C(图2c),将曲线y=()与轴围成的面定义为D(图2c)。

1.3 仿生试件的正交试验设计

通过正交试验设计的方法,可以组合设计出具有不同三维构形的仿生试件,寻求影响试件切削阻力的主次因素、各试验因素的优水平和试验范围内的最优组合。本研究以仿生试件的切削阻力作为试验指标,设计了3因素4水平的正交试验,编制好的正交试验因素水平如表2所示。正交试验的3个因素分别为平面构形、平面构形和平面构形。正交试验的4个水平包含蝼蛄前足爪趾1的三维构形、爪趾2和爪趾3的平面构形和工程及农业触土部件经常采用的楔状体的三维构形。其中,平面构形因素的4个水平分别取面B镜像形成的BB、楔状体的等腰三角形(高36 mm和底边22 mm)投影面T1、面A镜像形成的对称面AA、面A和面B形成的AB;因蝼蛄前足不同爪趾的触土面曲率不同,平面构形的4个水平分别取楔状体的直角三角形(直角边36 mm和直角边8 mm)纵截面T2、爪趾1的纵截面S1、爪趾2的纵截面S2和爪趾3的纵截面S3;平面构形的4个水平分别取楔状体的矩形(长×宽为22 mm×8 mm)横截面R、面C镜像形成的对称面CC、面D镜像形成的DD、面C和面D形成的CD。

表2 正交试验的因素与水平对照表

注:根据图2对A、B、S、C和D的定义,AA为面A镜像形成的对称面,AB为面A和面B组成的面,BB为面B镜像形成的对称面,T1为楔状体的等腰三角形投影面,T2为楔状体的直角三角形投影面,S1、S2、S3分别为爪趾1、爪趾2和爪趾3的纵截面,R为楔状体的矩形投影面,CC为面C镜像形成的对称面,DD为面D镜像形成的对称面,CD为面C和面D组成的面。

Note: Based on the definition of A, B, S, C and D in Fig.2, AA is the area formed by the mirror image of plane A; AB is the area composed of plane A and plane B; BB is the area formed by the mirror image of plane B; T1 is the isosceles triangle projection area of the wedge; T2 is the right triangle projection area of the wedge; S1, S2, S3 are the longitudinal sections of the claw toe 1, the claw toe 2 and the claw toe 3, respectively; R is the rectangular projection area of the wedge; CC is the area formed by the mirror image of plane C; DD is the area formed by the mirror image of plane D; and CD is the area composed of plane C and plane D.

正交试验设计[22]的仿生试件共有16种,此外,将楔状体试件(T1-T2-R)作为对照试件。采用三维建模软件SolidWorks2016建立由3个平面构形因素组合构形的仿生试件的三维模型,并利用3D打印方法获得聚乳酸材质的仿生试件,试件的投影长度均为36 mm,约为蝼蛄实际爪趾1长度的15倍。制作的仿生试件如图3所示。

1.4 仿生试件的切削阻力测试

采用自行搭建的土槽测试系统[23]对仿生试件的切削阻力进行测试(图4)。所用传感器为JNNT-2型双法兰静态扭矩传感器(蚌埠中皖传感器有限公司,中国),量程为0~50 N∙m,精度为0.1 N∙m。水平切削阻力与扭矩的对应关系如式(4)所示:

=∙(4)

式中为水平切削阻力,N;为测得的扭矩,N∙m;为力臂,m。

考虑到不同仿生试件有不同的底面积,为避免试件底面与土壤摩擦对切削阻力造成的影响,切削阻力测试时,将不同仿生试件的后角均设为5°(图5)。此外,测试前通过预试验分别调整每个仿生试件的入土深度,尽可能使所有仿生试件的切土截面积相等,从而避免切削面积不同导致的误差,本研究将初始切削深度设置为15 mm,每个仿生试件的实际切削深度在初始切削深度上下浮动。为了避免土壤黏附的影响,本研究将发泡酚醛塑料(俗称“花泥”)在水中浸没60 s,使其含水率达到饱和用以模拟土壤,其优点是材料结构均一,硬度和孔隙度与土壤相似。令切削速度为10 mm/s,切削时间20 s,对每个仿生试件进行3次重复切削阻力试验,结果以均值±标准差表示,取均值绘制切削阻力变化曲线,以切削阻力稳定阶段的值作为最终切削阻力结果。

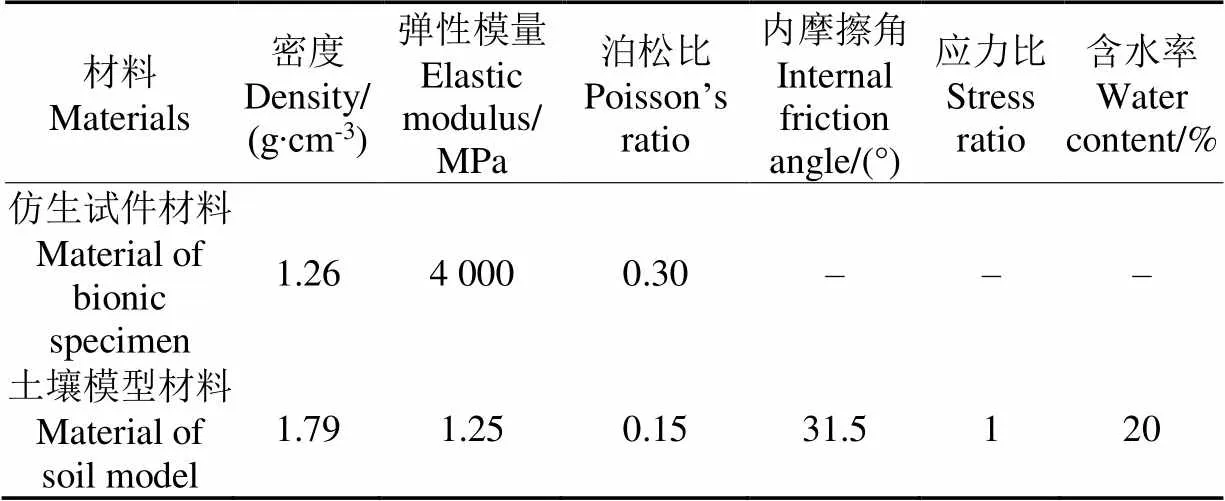

1.5 有限元模型的建立和仿真

采用显式动力学分析软件ANSYS LS-DYNA进行仿生试件切削土壤过程的模拟。将在SolidWorks2016中建立的仿生试件模型和土壤模型导入有限元前处理软件HyperMesh中,进行有限元网格划分、材料参数的设置、边界约束条件的设置、仿生试件切削运动设置、仿生试件与土壤接触条件、求解时间等的设置。其中,仿生试件模型采用Solid147实体单元,划分为边长1 mm的四面体网格;土壤模型采用Solid147实体单元,划分为边长1.2 mm的六面体网格;有限元模型所用的材料参数如表3所示。边界约束条件设置为固定土壤模型的侧面和底面;仿生试件模型的切削运动方向设置为沿土壤模型长度方向,切削速度设置为10 mm/s;仿生试件模型与土壤模型的接触条件设置为点-面单向侵蚀接触;求解时间设为10 s。将有限元模型及设置导入ANSYS LS-DYNA中进行切削过程计算求解。

表3 有限元模型所用的材料参数

2 结果与分析

2.1 切削阻力结果

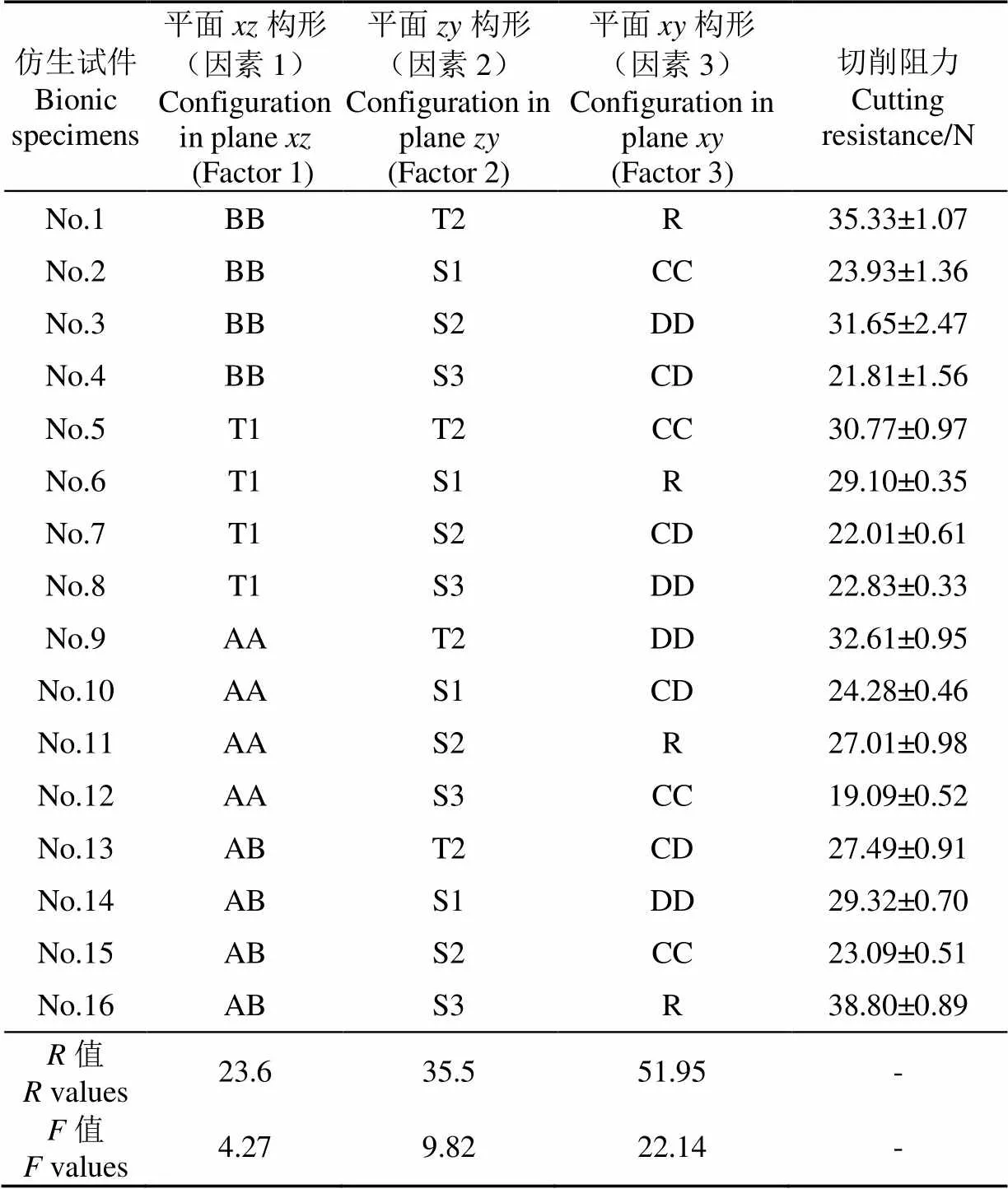

根据不同仿生试件切削阻力随时间变化的曲线(图6),仿生试件的切削过程可以分为2个阶段,阻力增大阶段和阻力平稳阶段。0~3 s为阻力增大阶段,随着仿生试件逐步切入模拟土壤,切削阻力逐渐增大;3 s以后进入切削阻力平稳阶段,仿生试件的切削阻力基本稳定。由图6可知,切削阻力最大的仿生试件为仿生试件No.16(AB-S3-R),(38.80±0.89)N,其次为仿生试件No.1(BB-T2-R),(35.33±1.07)N,切削阻力最小的仿生试件为仿生试件No.12(AA-S3-CC),(19.09±0.52)N,其次为仿生试件No.4(BB-S3-CD),(21.81±1.56)N。

各因素下不同仿生试件的切削阻力及其正交试验结果如表4所示。极差分析结果显示,影响切削阻力的因素权重(值)由大到小依次为平面构形、平面构形和平面构形;最优设计组合为仿生试件No.12(AA-S3-CC)。与之对比,仿生试件No.16(AB-S3-R)的切削阻力最大,而用作对照试验的楔状体试件(T1-T2-R)的切削阻力为(44.35±0.71) N。该结果表明,具有三维几何构形的仿生试件No.12(AA-S3-CC)可以实现更低的切削阻力,与楔状体试件相比,其切削阻力可降低56.96%。由重复试验方差分析的检验结果可知,蝼蛄爪趾平面构形的值均高于临界值(2.92),可认为显著性水平0.05,表明平面构形、平面构形和平面构形3个因素均对切削阻力有显著影响,其中平面构形为主要影响因素。

2.2 仿生试件切削的有限元模拟结果

根据土槽切削试验测试结果,选择平均切削阻力最小的仿生试件No.12和平均切削阻力最大的仿生试件No.16进行有限元模拟结果的对比。切削阻力平稳阶段的仿生试件No.12和仿生试件No.16表面压力云图如图7所示。

试件在切削过程中的受力主要为其与土壤的摩擦力和土壤被压缩后对试件的反作用力,这两种力的合力为试件所受的总压力。由仿生试件No.12的表面压力云图(图7a)可知,高压力区在试件挖掘面的中部,表面压力约为30 MPa,试件尖部所受的压力较小,表面压力为−2.79~4.67 MPa,表明与试件尖部接触的土壤没有被过度压缩,在切削过程中土壤能沿着挖掘面顺畅流动,有利于仿生试件的持续楔入。由仿生试件No.16的表面压力云图(图7b),由试件尖部到试件根部表面压力逐渐增大。仿生试件No.16尖部的表面压力为4.32~44.54 MPa,大于仿生试件No.12在同位置的表面压力,土壤在仿生试件No.16的尖部形成堆积,导致试件中后部受到更大的表面压力。仿生试件No.16的挖掘面上零星分布的低压力区表明被切削后的土壤在试件挖掘面上的流动不顺畅,存在一定跳动。

表4 各因素下不同仿生试件的切削阻力及其正交试验结果

注:对每个仿生试件进行3次重复切削阻力试验,切削阻力结果数据以平均值±标准差表示。

Note: Cutting resistance test is repeated 3 times for each bionic specimen, and cutting resistance results are expressed as mean ± standard deviation.

有限元分析结果表明,应用仿生几何构形能有效缓解土壤在触土部件尖部的堆积,并使被切削后的土壤顺畅地沿挖掘面流动,避免了土壤堆积对部件中部和后部的挤压,从而减小了切削阻力。

3 讨 论

生物触土部件(爪趾、前足等)的外部构形均为由多条特征曲线构成的三维曲面,这是生物体高效挖掘与减阻功能实现的原因。目前,针对耕作机械和工程机械触土部件的仿生优化设计已取得了一系列的成果。郭俊等[24]将鼹鼠爪趾的二维曲线应用于旋耕锯齿刀设计,在秸秆覆盖量为50%时扭矩与功耗优于国标旋耕刀。Zhang等[19]将蝼蛄前足爪趾二维轮廓曲线用于挖掘机斗齿设计,使挖掘阻力最高减小12%。Zhang等[25]将家鼠爪趾的二维曲线应用于深松铲设计,使耕作阻力平均减小19%。Li等[26]将野猪头部三维构形逆向应用于起垄犁设计,使耕作阻力减小7%~14%。分析发现,在已有的相关研究中,一类是将仿生对象的主要构形特征进行二维投影,另一类是采用三维逆向的方式直接移植生物的三维构形。随着耕作机械的作业速度不断提升,以及对节能减排要求的不断提高,需要进一步丰富仿生构形设计方法。

本研究的切削试验和有限元模拟结果表明,具有三维几何构形的仿生试件的减阻性能明显优于只有二维仿生构形的试件。例如仿生试件No.12在平面、平面和平面上具有AA-S3-CC仿生构形,其切削阻力为(19.09±0.52)N;而仿生试件No.1(BB-T2-R)、No.5(T1-T2-CC)和No.6(T1-S1-R)仅在一个平面上具有仿生构形,其切削阻力分别为(35.33±1.07)、(30.77±0.97)和(29.10±0.35)N。该结果表明本研究采用的设计思路是可行的,丰富了仿生构形设计方法,可为开沟器、深松铲等以土壤切削为主的耕作机械触土部件的设计提供仿生设计思路和方法。但本研究中以探讨不同三维几何构形对切削阻力的影响为目的,仅以楔状体为原形进行了具有不同三维几何构形的仿生试件的设计和减阻机理研究,后续研究会进一步将三维几何构形应用于实际的耕作机械或工程机械的触土部件减阻设计中。

4 结 论

本研究通过三维建模、切削阻力试验和有限元模拟,研究了蝼蛄前足爪趾三维几何构形对其切削阻力的影响,结论如下:

1)具有三维几何构形的仿生试件可以实现更低的切削阻力,其切削阻力低于只具有二维仿生构形的试件,与楔状体试件相比,切削阻力降低56.96%。

2)切削阻力试验结果表明,蝼蛄爪趾三维构形特征均对切削阻力有显著影响(<0.05),其中爪趾横截面的构形特征对切削阻力的减小起主要作用。

3)有限元模拟结果表明,蝼蛄爪趾构形能有效缓解土壤在仿生试件尖部的堆积,并使土壤沿挖掘面流动,避免了土壤堆积对仿生试件中部和后部的挤压,从而减小了切削阻力。

[1] 贾洪雷,王万鹏,陈志,等. 农业机械触土部件优化研究现状与展望[J]. 农业机械学报,2017,48(7):1-13.

Jia Honglei, Wang Wanpeng, Chen Zhi, et al. Research status and prospect of soil-engaging components optimization for agricultural machinery[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(7): 1-13. (in Chinese with English abstract)

[2] Keles A, Yildirim M. Improvement of mechanical properties by means of titanium alloying to steel teeth used in the excavator[J]. Engineering Science and Technology, an International Journal, 2020, 23(5): 1208-1213.

[3] 王少伟,李善军,张衍林,等. 鼹鼠趾仿生及表面热处理提高齿形开沟刀减阻耐磨性能[J]. 农业工程学报,2019,35(12):10-20.

Wang Shaowei, Li Shanjun, Zhang Yanlin, et al. Mole toe bionics and surface heat treatment improving resistance reduction and abrasion resistance performance of toothed ditching blade[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(12): 10-20. (in Chinese with English abstract)

[4] Li J W, Jiang X H, Ma Y H, et al. Bionic design of a potato digging shovel with drag reduction based on the Discrete Element Method (DEM) in clay soil[J]. Applied Sciences, 2020, 10(20): 1-22.

[5] 贾洪雷,郑健,赵佳乐,等. 仿蚯蚓运动多功能开沟器设计及参数优化[J]. 农业工程学报,2018,34(12):70-79.

Jia Honglei, Zheng Jian, Zhao Jiale, et al. Design and parameter optimization of earthworm-like multi-function opener[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(12): 70-79. (in Chinese with English abstract)

[6] 丁启朔,葛双洋,任骏,等. 水稻土深松阻力与土壤扰动效果研究[J]. 农业机械学报,2017,48(1):47-56,63.

Ding Qishuo, Ge Shuangyang, Ren Jun, et al. Characteristics of subsoiler traction and soil disturbance in paddy soil[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(1): 47-56, 63. (in Chinese with English abstract)

[7] 郑侃,何进,李洪文,等. 基于离散元深松土壤模型的折线破土刃深松铲研究[J]. 农业机械学报,2016,47(9):62-72.

Zheng Kan, He Jin, Li Hongwen, et al. Research on polyline soil breaking blade subsoiler based on subsoiling soil model using discrete element method[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(9): 62-72. (in Chinese with English abstract)

[8] 马跃进,王安,赵建国,等. 基于离散元法的凸圆刃式深松铲减阻效果仿真分析与试验[J]. 农业工程学报,2019,35(3):16-23.

Ma Yuejin, Wang An, Zhao Jianguo, et al. Simulation analysis and experiment of drag reduction effect of convex blade subsoiler based on discrete element method[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(3): 16-23. (in Chinese with English abstract)

[9] 刘晓鹏,张青松,刘立超,等. 基于微分几何与EDEM的船型开畦沟装置触土曲面优化[J]. 农业机械学报,2019,50(8):59-69.

Liu Xiaopeng, Zhang Qingsong, Liu Lichao, et al. Surface optimization of ship type ditching system based on differential geometry and EDEM simulation[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(8): 59-69. (in Chinese with English abstract)

[10] Yu H Y, Han Z W, Zhang J Q, et al. Bionic design of tools in cutting: Reducing adhesion, abrasion or friction[J/OL]. Wear, 2021, 482-483, [2021-05-21], https://doi.org/10.1016/j.wear. 2021.203955.

[11] Massah J, Fard M R, Aghel H. An optimized bionic electro-osmotic soil-engaging implement for soil adhesion reduction[J]. Journal of Terramechanics, 2021, 95(5): 1-6.

[12] Ma W, Li J, Cai Q, et al. Influence of surface roughness on the adhesion force between the titanium plate and deep-sea sediment[J]. Marine Georesources and Geotechnology, 2020, 2: 1-9.

[13] Zenkov S A. Application of ultrasonic exposure for reducing material adhesion[J/OL]. Journal of Physics: Conference Series, 2019, 1399(4), [2019-12], https://iopscience.iop.org/ article/10.1088/1742-6596/1399/4/044004/pdf.

[14] 周华,张文良,杨全军,等. 滑切型自激振动减阻深松装置设计与试验[J]. 农业机械学报,2019,50(5):78-78.

Zhou Hua, Zhang Wenliang, Yang Quanjun, et al. Design and experiment of sliding cutting self-excited vibration drag reduction subsoiling device[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(5): 71-78. (in Chinese with English abstract)

[15] Sun Z Q, Yang Z, Duan J L, et al. Design and application of multifunctional performance test platform for soil-engaging tillage components[J]. Inmateh Agricultural Engineering, 2020, 62(3): 351-360.

[16] Ani O A, Uzoejinwa B B, Ezeama A O, et al. Overview of soil-machine interaction studies in soil bins[J]. Soil and Tillage Research, 2018, 175: 13-27.

[17] Feng T T, Xu L F, Song Y P, et al. Design and analysis of bionic rib subsoiling shovel based on Hawaiian shell[J]. IOP Conference Series: Earth and Environmental Science, 2019, 267(3): 32048-32048.

[18] Xu L F, Feng T T, Song Y P, et al. Research on drag reduction mechanism of bionic rib subsoiling shovel based on discrete element method[J/OL]. IOP Conference Series: Earth and Environmental Science, 2019, 267(3), [2019-03-08], https://iopscience.iop.org/article/10.1088/1755-1315/267/3/ 032049/pdf.

[19] Zhang Z F, Zhang Y, Zhu Y Y, et al. Design of bionic bucket teeth and drag reduction analysis[J]. Advances in Intelligent Systems Research, 2017, 154: 670-674.

[20] Zhang R, Han D L, He Y, et al. Drag reduction and wear resistance mechanisms of a bionic shovel by discrete element method simulation[J]. Simulation, 2019, 95(3): 231-239.

[21] 杨玉婉,佟金,马云海,等. 鼹鼠多趾结构特征仿生旋耕刀设计与试验[J]. 农业工程学报,2019,35(19):37-45.

Yang Yuwan, Tong Jin, Ma Yunhai, et al. Design and experiment of biomimetic rotary tillage blade based on multiple claws characteristics of mole rats[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(19):37-45. (in Chinese with English abstract)

[22] 任露泉. 优化试验设计及其优化[M]. 北京:科学出版社,2009.

[23] 张琰. 仿生触土试件挖掘阻力测试系统:CN201821985694.9[P]. 2019.

[24] 郭俊,张庆怡,Muhammad Sohail Memon,等. 仿鼹鼠足趾排列的旋耕-秸秆粉碎锯齿刀片设计与试验[J]. 农业工程学报,2017,33(6):43-50.

Guo Jun, Zhang Qingyi, Muhammad Sohail Memon, et al. Design and experiment of bionic mole's toe arrangement serrated blade for soil-rototilling and straw-shattering[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(6):43-50. (in Chinese with English abstract)

[25] Zhang J B, Yang C H, Ge Y Y, et al. Design and experiments of bionic subsoiler with ribbed structure[J]. International Agricultural Engineering Journal, 2019, 28(1): 147-152.

[26] Li J Q, Yan Y P, Chirende B, et al. Bionic design for reducing adhesive resistance of the ridger inspired by a boar’s head[J/OL]. Applied Bionics and Biomechanics, 2017, 2017, [2017-07-03], https://doi.org/10.1155/2017/8315972.

Drag reduction mechanism of the 3D geometry of foreleg’s claw toe of the mole cricket ()

Zhang Yan1,2, Qiao Chaoxiong1,2, Wang Tianqi1,2, Cao Jiafeng1,2, Wang Pengfei1,2, Shi Lei3

(1.-&,300222,; 2,&,300222,; 3..,.,300308,)

Biological plane geometry has been unable to meet the harsh requirements of bionic design in most soil contacting parts of tillage machinery in recent years, particularly on the operating speed, energy-saving, and emission reduction. In this study, a bionic investigation was performed on the toe of the foreleg claw in the mole cricket using the three-dimensional (3D) geometry. Projection and segmentation were also used to extract the 3D characteristic curves of claw toe in three orthogonal planes. The MATLAB platform was selected to determine the characteristic curves via the polynomial fitting and smoothing processing. An orthogonal experiment of bionic samples was carried out, where three plane configurations were taken as factors, while the different characteristics of configuration as levels. A total of 16 bionic specimens and 1 wedge-shaped comparison specimen were constructed by SolidWorks software and then fabricated using 3D printing (polylactic acid material). A test system of soil groove was utilized to evaluate the cutting resistance of each specimen, where the soil was assumed as the foamed phenolic plastics, the cutting speed was 10 mm/s, the cutting depth was 15 mm, and the cutting time was 20 s. The explicit dynamic Finite Element (FE) software ANSYS LS-DYNA was used to simulate the cutting process of the specimen, in order to determine the relationship between the 3D geometrical toes of the foreleg claw in the mole cricket and the drag reduction performance. It was found that the cutting process of the specimen was divided into the drag increase and stable phase. Furthermore, the drag reduction performance of specimens with 3D biological geometries was significantly better than that with one- and two-dimension, as well as the wedge shape. All configurations in the three planes also presented a significant impact on drag reduction. Correspondingly, the main influencing factor of drag reduction was the cross-sectional configuration perpendicular to the growth direction of claw toes. More importantly, the cutting resistance of the specimen was reduced up to 56.96% with 3D biological geometries. The FE analysis results showed that the 3D geometrical toes of the foreleg claw in the mole cricket effectively alleviated the accumulation of soil on the tip of the specimen. As such, the soil moved smoothly along the excavation surface, thereby avoiding the accumulation of pressure on the middle and back of specimens. This process was the reason for the reduction of cutting resistance. Furthermore, an optimal configuration of soil-contacting components was also achieved to reduce the cutting resistance, while effectively improving the working efficiency of machinery without the use of external energy and auxiliary devices. Nevertheless, the actual configuration was a 3D structure of soil-contacting parts in farming and engineering machinery, where many interrelated geometric parameters were involved during optimization. Consequently, the biological geometry can widely be expected to optimize soil-contacting parts, whether to project the main configuration of bionic objects in two dimensions, or to directly transplant the 3D biological geometry with 3D reverse. The characteristic curves of 3D biological geometry were also coupled to design bionic specimens. The feasible idea can also provide an insightful promising bionic design on soil cutting parts of tillage machinery, such as openers and subsoilers.

agricultural machinery; bionics; design; optimization; drag reduction; cutting resistance test; mole cricket

张琰,乔超雄,王天琪,等. 蝼蛄前足爪趾三维几何构形的减阻机理[J]. 农业工程学报,2021,37(19):309-315.doi:10.11975/j.issn.1002-6819.2021.19.036 http://www.tcsae.org

Zhang Yan, Qiao Chaoxiong, Wang Tianqi, et al. Drag reduction mechanism of the 3D geometry of foreleg’s claw toe of the mole cricket ()[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(19): 309-315. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2021.19.036 http://www.tcsae.org

2020-08-27

2021-09-15

国家自然科学基金项目(51405341);天津市自然科学基金(15JCYBJC19300);天津市重点实验室开放基金(2019LIMFE05)

张琰,博士,副教授,研究方向为仿生机械设计原理。Email:y.zhang@tust.edu.cn

10.11975/j.issn.1002-6819.2021.19.036

S220.1

A

1002-6819(2021)-19-0309-07