Display Engineers Pack the Pixels

2021-12-25MitchLeslie

Mitch Leslie

Senior Technology Writer

With their crisp images and striking contrast, organic lightemitting diode (OLED) displays with hundreds of pixels per inch(ppi) have become the screen technology of choice for most smart phones and many high-end televisions (TVs) [1]. But some applications, especially improved virtual reality (VR), augmented reality (AR), and mixed reality (MR) devices will require higher pixel densities than current OLED displays provide [2]. In late 2020, researchers at Stanford University in Palo Alto, CA, USA,and the Republic of Korean company Samsung described a design that yields more than 10 000 ppi,an OLED record[3].The discovery could allow development of a variety of new OLED-based electronics. However, experts caution, technical constraints and competition from other types of displays could curb adoption of such very high-resolution OLED screens.

Apple made a splash in 2010 when it introduced the iPhone 4,which featured a liquid–crystal display with 326 ppi, four times higher than the previous model [4]. Since then, manufacturers have squeezed even more pixels onto their screens. Today most smart phones feature OLED displays that deliver 400–500 ppi [5].Similarly,the pixel densities of TVs have increased over time,with many OLED sets now offering 100–200 ppi,depending on their size[6].For cell phones and other mobile devices,added pixels come at a cost, draining the battery more rapidly [7]. Moreover, whether human eyes can discriminate among the screens of phone models with different pixel densities remains a matter of dispute [8,9].

There is no doubt, however, that VR, AR, and MR devices need much higher pixel densities. They either place users into a computer-generated world, as in the case of VR, or add graphics to the user’s view of the real world [10]. The technologies are already commonplace in games such as Pokemon Go and in a variety of industrial, military, and educational applications, but the visual experience can be disappointing. For instance, the gaps between pixels may be visible, producing what is known as the screen door effect [11]. The design of a standard VR headset explains why visual flaws are more noticeable in such devices.Not only is the display just a few centimeter from the user’s eyes,rather than the 25–30 cm that is typical for a cell phone, but the headset also contains magnifying lenses[11].Researchers estimate that smoother,more realistic displays will need to be substantially brighter and will require pixel densities of more than 5000 ppi[3].Discovering new ways to increase the number of pixels ‘‘is a very important issue,” said Jiun-Haw Lee, a professor of electrical engineering at the Taiwan University in Taipei, China who is not connected to the Stanford–Samsung research.

To increase OLED display resolution,the Stanford and Samsung team had to contend with two limitations of current technologies.The process for manufacturing the OLED displays of most smart phones involves applying light-emitting organic compounds to a surface through a fine metal mask, a thin sheet of material dotted with numerous microscopic holes [12]. The mask allows precise positioning of red, green, and blue subpixels within each pixel,and these subpixels light up in various combinations to produce different colors [13]. Adding more holes to the masks can boost pixel density,but cramming in more and more of them eventually leads to poorer images.As a result,most cell phone displays remain between 400 and 500 ppi [12]. A different constraint applies to OLED TVs. As fine metal masks become larger, they tend to droop,so manufacturers typically use a different process for making big screens[12].A subpixel on the screen of one of these TVs includes three layers of organic compounds,each of which emits red,green,or blue light [1]. Together, the layers produce white light, which passes through filters that block certain wavelengths, generating different colors on the screen [1,12]. The drawbacks of this approach are inefficiency and limited luminance, Lee said. ‘‘It wastes two-thirds of the energy”used to power it,he said,because the filters obstruct most of the emitted light.

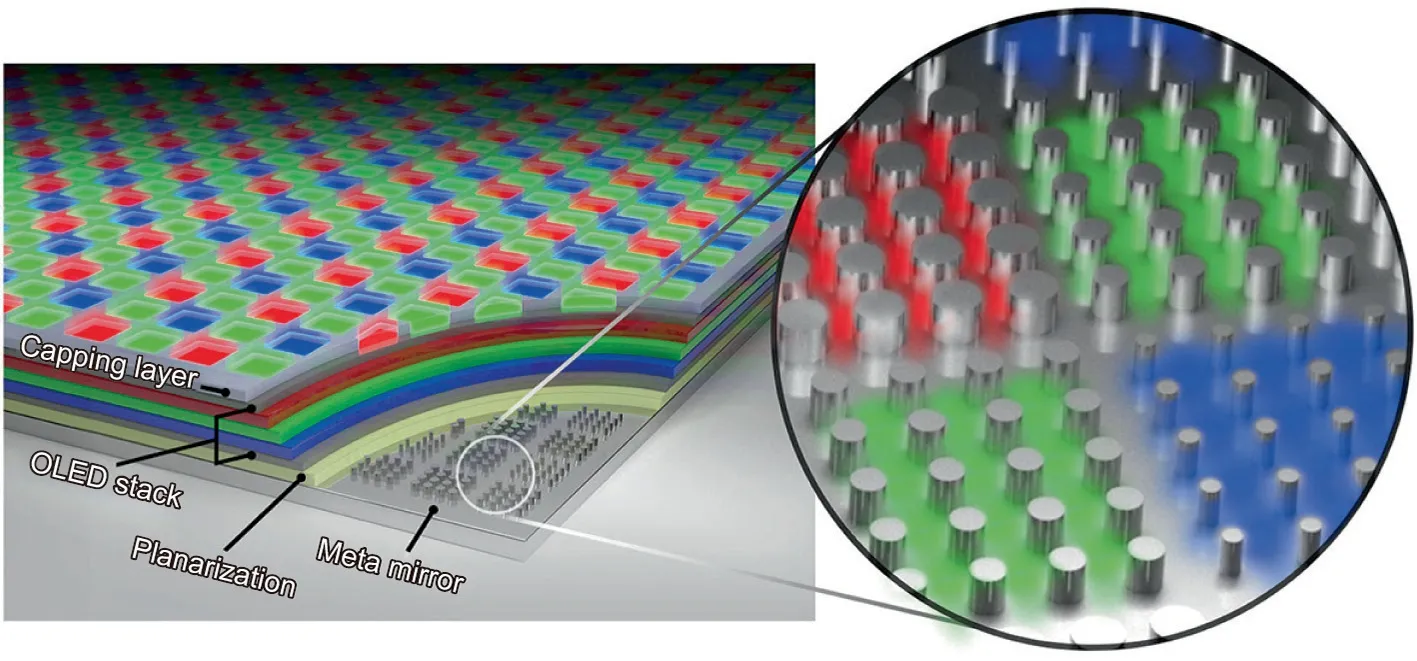

The design from the Stanford and Samsung researchers resembles the core of an OLED TV screen in that each pixel contains layers of organic compounds that generate red, green, and blue light. However, they positioned the layers between two mirrors,one of which is studded with arrays of ‘‘nano-pillars” that are 80–120 nm in diameter (Fig. 1) [12]. White light from the OLED layers reflects between the mirrors, but it also bounces back and forth among the nano-pillars.This arrangement creates resonance,amplifying certain wavelengths. The researchers demonstrated that they could adjust the color of light that emerges by altering the size and packing of the nano-pillars. For example, arrays crowded with the tiny columns emitted red light, whereas sparse formations produced blue[5].By tweaking the nano-pillar pattern,the scientists could generate all the wavelengths of visible light[3].

Fig.1. The new OLED design from researchers at Stanford and Samsung sandwiches light-emitting layers between two reflecting surfaces,the meta mirror and a silver and magnesium cathode just beneath the capping layer.The surface of the meta mirror is dotted with tiny pillars that change the distance that reflected light travels.What color of light emerges from an array of the pillars depends on their size and density (inset). Credit: Samsung Advanced Institute of Technology (public domain).

Because the team did not use fine metal masks,they could fit in more pixels—their calculations suggest the design could attain even more than 10 000 ppi [3]. And because no color filters are required,devices that use the technology should be more efficient and brighter;the researchers reported that their design resulted in double the luminescence efficiency of a comparable OLED set-up.Another advantage is that mirrors patterned with nano-pillars can be made with a technique called nanoimprint photolithography that is already standard for manufacturing solar cells and other products.‘‘The paper is very important,”said optical researcher Tao Zhan of the University of Central Florida in Orlando, FL, USA, who was not connected to the study. The work shows, he said, that‘‘you can simplify the manufacturing process and significantly increase the pixel density.”

The Stanford–Samsung Group analyzed a small test array but did not build a full screen or connect the array to a cell phone or other device. Still, said Lee, the team demonstrated that the nano-pillar approach‘‘is doable.”Now,he said,the group can start trying to fabricate displays with patterned mirrors and determine what products they are suitable for.

But OLEDs have some downsides that could reduce their popularity, Lee cautioned. The devices can suffer from burn-in, in which images become permanently imprinted on the screen [14].Burn-in is not a big problem for cell phones because users typically buy new models every few years. However, it would be a disaster for a VR, AR, or MR device, he said. In addition, other display technologies are vying for a share of the market. The Canadian company VueReal (Waterloo, ON, Canada) already sells displays incorporating micro-light-emitting diodes(microLEDs)that deliver 30 000 ppi [5]. Each pixel in a microLED display is a microscopic indium gallium nitride semiconductor, and large-screen TVs that use this technology are just entering the market [15,16]. Like OLEDs, microLEDs create crisp images, but they may be less susceptible to burn-in [16]. MicroLEDs also have several drawbacks, however. They consume large amounts of power, produce large amounts of heat,and are expensive,so which technology will light up the displays of the future is not clear [16].

Lee added that researchers who are trying to develop more detailed, vivid, and realistic VR, AR, and MR products face other design challenges as well,including boosting data delivery speeds.‘‘High-resolution is essential,”he said,‘‘but it is not the only problem that has to be solved.”

杂志排行

Engineering的其它文章

- COVID-19 Vaccine Allocation: Modeling Health Outcomes and Equity Implications of Alternative Strategies

- Fast Marching Method for Microseismic Source Location in Cavern-Containing Rockmass: Performance Analysis and Engineering Application

- Non-Communicable Diseases During the COVID-19 Pandemic and Beyond

- Next Steps for Efficacy Evaluation in Clinical Trials of COVID-19 Vaccines

- Facilities for Centralized Isolation and Quarantine for the Observation and Treatment of Patients with COVID-19

- Temporal Profiles of Antibody Responses, Cytokines, and Survival of COVID-19 Patients: A Retrospective Cohort