Engineered to Go Fast, Maglev Trains Inch Forward

2021-12-25ChrisPalmer

Chris Palmer

Senior Technology Writer

In January 2021, a prototype of a high-temperature superconducting (HTS), magnetic levitation—‘‘maglev”—train with an intended maximum speed of 620 km∙h-1rolled onto a 165 m track for its first public viewing in Chengdu, the capital city of Sichuan Province,China[1].Built of lightweight carbon fiber,the 21 m long aerodynamic locomotive and its test track represent an important move forward for China’s high-speed rail future.

‘‘While the HTS technology is not a huge innovation, the big news is that they are really working toward building it,” said Tsung-Chung Kao,professor of engineering at Hong Kong Polytechnic University and the University of Illinois at Urbana–Champaign and an expert in high-speed rail planning, engineering, and operation.

Maglev trains have been hailed as the future of rail since the beginning of the 20th century, when Americans Robert Goddard and Emile Bachelet first conceived of frictionless trains levitated and propelled forward by the force of magnetic fields[2]. The technology failed to progress until the concept was demonstrated in the 1930s, by German engineer Hermann Kemper [2]. A few decades later, in the 1960s, American scientists James Powell and Gordon Danby received the first patents for maglev train technology, including one for the linear electric motor concept underlying all maglev designs developed to date [2].

The magnetic levitation systems for these trains fall into two categories: electrodynamic suspension (EDS) and electromagnetic suspension(EMS).In EDS,developed most extensively by Japanese engineers beginning in the 1970s, superconducting magnets on both the track and the train exert opposing magnetic fields and the repelling forces lift the train above the track. EMS, largely pushed forward by German engineers, works the opposite way,through magnetic attraction. Imagine picking up a large ‘‘T”-shaped block. Your hand (the train), curls around the block (the rail). Magnets on your fingertips are attracted to magnets on the underside of the horizontal part of the ‘‘T,” essentially lifting the train. Meanwhile, magnets on the inside of your thumb and pointer-finger knuckles are attracted to magnets on the ends of the horizontal part of the ‘‘T,” providing guidance as the train moves forward along the track.For both the EDS and EMS schemes,trains are suspended 1–10 cm above the rails.Electrified propulsion loops built into the tracks with alternating current generate magnetic fields that both pull the train forward from the front and push it forward from behind.

Despite traveling at speeds that can exceed 600 km∙h-1,maglev riders experience less turbulence than on conventional steel wheel trains because the only source of friction is air. Another benefit is safety. Maglev trains traveling the same route are all powered to drive at the same speed, so they cannot catch up and crash into one another. Accidents can still happen, though; a maglev train built by German firm Transrapid slammed into a service vehicle during a test run in 2006,killing 25 people and leading the country to completely abandon the technology for domestic projects [3].Derailment due to cornering too quickly is also not possible with maglev trains—the further a maglev train strays from its location between the guideway walls,the stronger the magnetic force moving it back into place becomes. Additionally, maglev trains can climb gradients as high as 10%, double that of conventional trains.

In general, the vast majority of concepts underlying maglev trains were worked out years ago. ‘‘The basic technology is pretty much the same as 50 years ago,”said Kao.‘‘It is already extremely good. What can be improved is quite limited.”

One aspect of the technology that has seen recent innovation,though, is the superconducting magnets. China’s new prototype,an EDS design, incorporates a new type. Conventional superconducting magnets are cooled with liquid helium to a temperature of -269 °C in order to generate the strong magnetic fields—up to ten times stronger than ordinary electromagnets—necessary to levitate and propel railcars. In contrast, the HTS magnets, first implemented in a 3.5 m prototype built by engineers at Chengdu’s Southwest Jiaotong University(SWJTU) in 2000 [4] achieve superconductivity at -196 °C using more readily available liquid nitrogen, at one-fiftieth the cost of liquid helium systems.

While China is home to the world’s largest high-speed rail network, covering over 37 900 km, the country currently has just three maglev lines in operation. The first, a high-speed maglev train employing German EMS technology, launched in 2003 and is the world’s longest and oldest maglev line (Fig. 1). Reaching a top speed of 431 km∙h-1, the train connects a 30 km stretch between Shanghai’s Pudong Airport and Longyang Road on the eastern side of the city. The other two maglev trains, both built with Chinese EMS technology, have lower maximum speeds. One started operations in 2016 in Changsha, Hunan Province, China,and reaches a top speed of 160 km∙h-1on its 18 km long track[5]. The other went into operation a year later in 2017, running on a 9 km section of the Beijing subway with a maximum speed of 100 km∙h-1[6].

SWJTU’s HTS innovations are part of a drive by the Chinese government to boost the country’s home-grown maglev technology,which so far has involved building a handful of prototypes on which to perform extensive tests. In addition to the ultra-high speed HTS prototype unveiled in Chengdu—a collaboration between SWJTU, China Railway Rolling Stock Corporation (CRRC),China Railway Group Limited, and other universities and companies—another prototype intended to travel at greater than 600 km∙h-1was developed by a similar consortium and successfully run on a short test line at Tongji University in Shanghai, China in June 2020 [7]. The SWJTU engineering efforts have focused on lighter designs that provide improved handling [8,9].

The primary factor holding back the building of additional maglev lines, however, is not the technology, according to Kao.‘‘The challenge is probably more political than financial and more financial than technological,” he said. The current cost of a highspeed maglev train is about 20% higher than that of conventional bullet trains [10,11] which have an average top speed of 350 km∙h-1.But because magnetic fields power maglev trains and they have very few moving parts,they produce little pollution and,with fewer parts to replace,require less maintenance.Therefore,its supporters argue,maglev could prove more cost effective than conventional high-speed rail from a long-term perspective [12].Meanwhile,critics suggest any such cost savings could be negated by the increased expense of maintaining the complex instrumentation to achieve the highly precise alignment between train and track [13].

Chinese officials appear to believe in the technology enough to move forward with building two much longer maglev lines:a 164 km long route between Shanghai and Hangzhou first proposed in 2006 and now expected to be ready for commercial use by 2025,and a 110 km, mostly underground, route connecting Guangzhou with Hangzhou[14].‘‘The hope is that by constructing more lines,the cost will decrease,” Kao said. ‘‘That is definitely the benefit of the Chinese market.”

China is also reportedly building a 200 km long vacuum-sealed tunnel in Hubei Province that would eliminate the air resistance faced by a maglev train, potentially allowing speeds of up to 1000 km∙h-1[15]. This so-called hyperloop concept, most famously promoted by American Tesla and SpaceX entrepreneur Elon Musk[16]requires an extremely straight,flat corridor,potentially limiting the routes it could service.

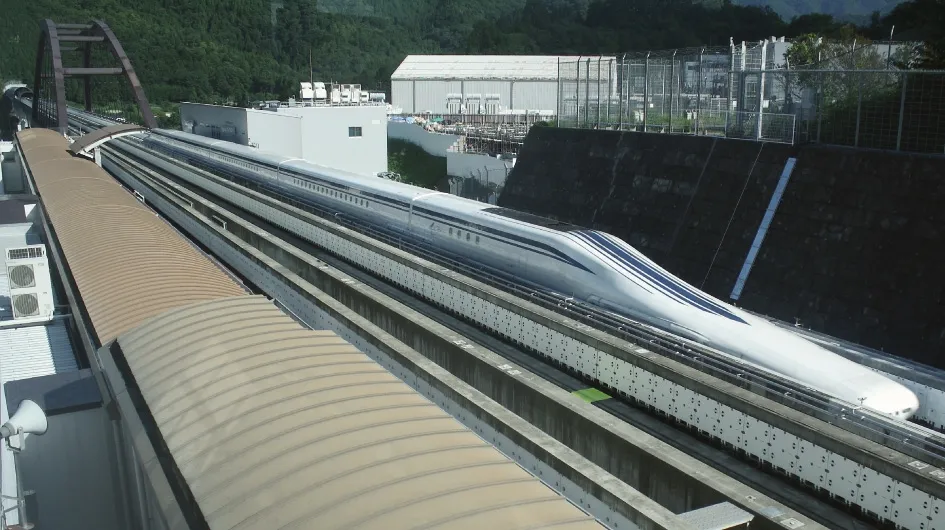

Though nearly a dozen countries are exploring proposals for maglev trains, including several spearheaded by CRRC [17], the Republic of Korea and Japan are the only other countries currently operating maglev lines.Running on a 25 km long test track in 2015,Japan’s Yamanashi maglev set the speed record for a train of 603 km∙h-1(Fig.2)[18].‘‘Without question it is a technological marvel,but it has never been put into the everyday business of carrying commercial passengers,” said Tony Morris, chief executive officer of American Maglev Technology (Marietta, GA, USA), an American firm that develops maglev technology with the goal of building commercial systems.

Fig.1. Running at a top speed of 431 km∙h-1,the world’s longest and oldest maglev line spans the 30 km stretch between Shanghai’s Pudong Airport and Longyang Road on the eastern side of the city. Credit: Alex Needham (public domain).

Fig. 2. Japan’s Yamanashi maglev, which runs on a 25 km long test track, set the speed record for a train of 603 km∙h-1 in 2015. Credit: Saruno Hirobano (public domain).

According to Kao, perhaps the primary challenge in building commercially viable maglev lines is finding the right place to build them.‘‘There are not that many corridors that can financially support the technology,”he said.‘‘You are looking for something with extremely high demand, like New York to Washington, DC or Tokyo to Osaka.”

In 2009,in fact,Japan began constructing a commercial maglev service spanning the 286 km between Tokyo and Nagoya.The service, expected to open in 2027 and run at a top speed of 500 km∙h-1, would connect the two cities in 40 min, less than half the current time for the journey[18].But cost estimates for the line are close to 1.1×1010USD,in part due to the more than 80%of the route needing to run through expensive subterranean and mountain tunnels. The country plans to expand the route to Osaka by 2045, cutting the time of the 550 km Tokyo-to-Osaka journey in half, to just over an hour [18].

Like China, Japan hopes to sell its high-speed rail technology abroad.During a 2013 visit to the United States,Japan’s then prime minister, Shinzo Abe, promoted the construction of a high-speed rail link between New York City and Washington, DC, using Japanese technology and partially funded by Japan [19].Abe again pitched the idea to the US president in 2017 [20]. So far, however,no deal has been reached.

‘‘If you talk about economics, each of these projects requires hundreds and hundreds of millions of operating cost subsidies,and potentially hundreds of millions or more in capital cost subsidies,” Morris said. ‘‘The systems do not make money. So, even though the technology is there, if you are looking for financial or economic success, right now, you have to keep looking.”

杂志排行

Engineering的其它文章

- Visible Light-Induced 3D Bioprinting Technologies and Corresponding Bioink Materials for Tissue Engineering: A Review

- Temporal Profiles of Antibody Responses, Cytokines, and Survival of COVID-19 Patients: A Retrospective Cohort

- The East–West Divide in Response to COVID-19

- COVID-19 Vaccine Allocation: Modeling Health Outcomes and Equity Implications of Alternative Strategies

- Facilities for Centralized Isolation and Quarantine for the Observation and Treatment of Patients with COVID-19

- Next Steps for Efficacy Evaluation in Clinical Trials of COVID-19 Vaccines