基于太阳能光伏光热技术的灌溉水增温系统试验

2021-11-26张金珠王振华

张金珠,王 钦,王振华,徐 鑫

基于太阳能光伏光热技术的灌溉水增温系统试验

张金珠,王 钦,王振华,徐 鑫

(1. 石河子大学水利建筑工程学院,石河子 832000;2. 现代节水灌溉兵团重点实验室,石河子大学,石河子 832000)

为减弱低温灌溉水对中国西北地区作物带来的不利影响,减少农业灌溉中的能源消耗,该研究设计了一种基于太阳能光伏光热技术灌溉水增温系统。通过搭建测试平台,对该系统进行不同流量下的性能测试研究,分析初始水温和辐照度对系统性能的影响。结果显示,出水口水温和升温幅度与流量呈负相关关系,固定工况下,出水口水温及升温幅度最高可达20.9和12.5 ℃,光电、光热效率与流量呈正相关关系,最大分别为0.094和0.310,实际能量效率则先增后减,最大达到0.484。初始水温越低,光伏光热集热器内换热越剧烈,升温幅度越高,能量指标越大,但流量增加使得不同初始水温灌溉水升温幅度趋于一致,出水口水温变幅增大。辐照度越高,出水口水温及升温幅度越大,但流量增大会削弱辐照度对其产生的提升效果,光电、光热效率均与辐照度呈负相关关系,在流量小于0.06 kg/(s·m²)时,实际能量效率与辐照度呈负相关关系,在流量大于0.07 kg/(s·m²)时则相反。研究表明该系统总体性能良好,为不同工况下的流量选择提供了参考依据。

光伏光热;灌溉;辐照度增温;流量;初始水温;

0 引 言

世界能源与粮食的需求日益增加,将可再生能源应用于农业生产,提高作物的产量及品质,减少化石能源的消耗受到广泛关注[1-5]。近年来,太阳能以其分布范围广、环境友好等优势成为众多国内外学者的研究重点[6-9]。研究内容主要包括改善太阳能的利用方式[10-13],讨论不同气候条件下某一特定系统的经济性与可行性[14-15]等;研究方法包含模拟仿真[16-17]、建立微型试验系统进行试验研究[18-19]等。通过学者们的不断探索和研究,利用太阳能辅助农业生产的技术日益先进。

Amaducci等[20]设计了一种名为Agrovoltaico的农田光伏系统,并对该系统进行模拟研究发现相较于全光条件下,Agrovoltaico在生产电能的同时可为作物生长提供更有利的条件,土地当量比始终大于1。Xu等[21]研究了一种季节性能量储存系统,该系统将多余的太阳能转化为热能储存起来,应用于冬季温室供暖,结果发现该系统无需任何辅助增温设备可使温室温度提高13 ℃。Kabalci等[22]设计了一种可远程监控和控制的太阳能电站及灌溉系统,对其进行了大小和可行性分析,并对数据采集、远程监控和操作系统进行了优化。李加念等[23]研制了一种基于太阳能的微灌系统恒压供水自动控制装置,经过6个月的实际应用试验,装置运行稳定,水位误差小于1 cm。20世纪70年代光伏光热技术首次被提出[24],因其较高的能量转化效率和较广的适用范围,成为众多学者的研究对象[25-29]。Barnwal等[30]利用光伏光热技术设计了一种温室干燥机并建立热模型,通过试验得出总体热效率在33%~37.8%,热模型与试验数据吻合。但现有研究大多在能量转化和改善作物生长环境方面,利用太阳能对作物必需的要素(例如水)进行改善的探究相对缺乏。

在中国西北地区,初春时节灌溉水温较低,作物苗期对温度反应极为敏感,春灌时易出现冻坏、死苗现象[31],且灌溉时需要消耗电能。因此,本文基于光伏光热技术设计了一套灌溉水增温系统,拟通过试验研究的方式,对其进行不同流量下性能测试研究,并分析初始水温和辐照度对系统性能的影响,以期通过该系统减弱低温灌溉水给作物带来的不利影响,促使作物提质增效,一定程度上填补农业生产活动及农业自动化、智能化所带来的电能消耗。

1 基于PV/T技术灌溉水增温试验系统

1.1 系统的主要部件与仪器

如图1a所示,该试验模型系统主要由PV/T集热器、保温桶、潜水泵、变频器和钨卤素灯等部件组成。系统关键部件水冷型PV/T集热器采用管板式平板集热器,其外框尺寸为2 550 mm×808 mm×80 mm,有效采光面积为2 m²,主要由玻璃盖板、EVA胶膜、单晶硅电池、TPT背板、吸热板、吸热管和保温材料等部件组成。单块大光伏电池板由两块小光伏电池板并联组成,单块小光伏电池板由60块单晶硅电池串联组成,额定开路电压为37.9 V,额定功率为160 W。玻璃盖板采用透光率良好的低铁布纹玻璃铺设于最上方,其下是上层EVA胶膜主要用于对光伏电池的保护以及光伏电池与玻璃盖板的连接,光伏电池与吸热板间设有黑色TPT背板作为绝缘层,集热板背面采用激光焊接工艺的6根平行分布的铜管,铜管的两端嵌入集管之中。管的背面填充厚度为20 mm的岩棉和40 mm的橡塑海绵作为保温材料。最后采用3 mm厚钢板条将保温材料固定。PV/T集热器、系统管道、保温桶、潜水泵的详细材料及性能参数如表1所示。

试验中,使用变频器(220-004E21,广东东莞宇鑫科技有限公司)与潜水泵(QDX1-10-0.25,上海丰浪机电有限公司)相连,通过改变潜水泵交流电的频率,控制水泵电机转速,进而实现灌溉水的流量控制。钨卤素灯(QVF137,Philips)用于模拟太阳光,并采用TBQ-2太阳总辐射表测量PV/T集热器表面的太阳辐照度,采用Pt100铂热电阻监测进出口水温的变化,测量数据通过数据采集仪Agilent34970A进行采集,系统流量采用LXSR流量计测量,光伏电池板的阳极与阴极通过固定阻值的电阻及开关连接形成闭环环路,采用数字万用表检测光伏电池板的输出电量。所有测量均在关闭门窗并打开空调将温度设置为20 ℃的环境中进行。

表1 灌溉水增温系统主要部件参数

1.2 系统运行原理

本文探讨的基于太阳能光伏光热技术灌溉水增温试验系统如图1a所示,试验系统实物图如图1b所示。其工作原理如下:灌溉水由外部水泵从水源进入保温桶1,潜水泵提供动力使低温灌溉水依次经过叠片过滤器、流量计、调节阀、变径管后进入PV/T集热器中,流经背板铜管吸收热量,对灌溉水实现加热增温,然后进入保温桶2,由保温桶2中的潜水泵泵送灌溉。

1.3 试验设计

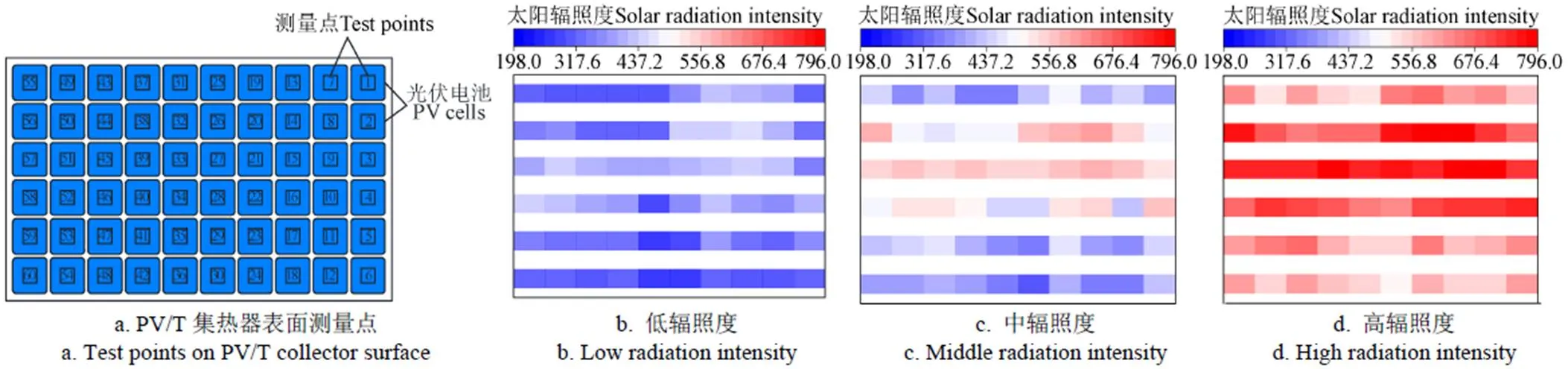

试验分别设置3种不同强度的辐照度[18]、3种不同的灌溉水初始水温、8种不同的流量,共72种工况。初始水温根据当地初春时灌溉所用河水与地下井水的平均温度设置,由高到低分别为10、7.5(中国西北初春灌溉水平均温度)、5 ℃。由于采用模拟太阳光,光照不均匀,故采用太阳辐射总表测量1/2 PV/T集热器表面1号到60号不同位置的太阳辐照度(由于钨卤素灯与PV/T集热器左右两侧完全对称,所以只测量1/2)如图2a所示。测量结果如图2b,2c,2d所示,高、中、低辐射强度下太阳辐照度的变化范围分别为499.37~795.11、311.47~600.83、198.68~445.58 W/m²,为减少试验中的不确定性,太阳辐照度取所测数据的平均值,高辐照度为650 W/m²,中辐照度为465 W/m²,低辐照度为320 W/m²。试验中流量变化范围为0.01~0.08 kg/(s·m²)。

图2 PV/T集热器表面测量点及太阳辐照度

2 主要性能指标计算方法

对所设计的基于光伏光热技术灌溉水增温系统做出以下假设[26](所做假设仅方便计算不影响结果及结论):

1)灌溉水在系统内流动时过流断面上的温度分布均匀;

2)由于在PV/T集热器背部设有隔热措施,故不计PV/T集热器背面漏热;

3)从PV/T集热器的自身结构来看,太阳辐射所产生的能量主要集中于除去隔热措施后的上层,上层厚度很小向四周散失的能量非常低,故认为四周绝热;

4)光伏电池板与集热板之间接触良好且集热板厚度很小,故忽略接触热阻;

5)PV/T集热器表面所受太阳辐射是均匀的。

2.1 温度指标

2.2 能量效率

图3为PV/T集热器模型图,其各部分能量间存在如下关系[29]:

1.光伏电池板 2.集热板 3.铜管 4.岩棉 5.橡塑海绵 6.铝合金外框 7. 玻璃盖板 8.上层乙烯-醋酸乙烯共聚物胶膜 9.光伏电池片 10.下层乙烯-醋酸乙烯共聚物胶膜 11.聚氟乙烯复合膜

1.PV panel 2.Heat collecting plate 3.Copper pipe 4.Rock wool 5.Rubber plastic sponge 6.Aluminum alloy frame 7.Glass cover 8.Ethylene-vinyl acetate copolymer_up 9.PV cells 10.Ethylene-vinyl acetate copolymer_down 11. Polyfluoroethylene composite membrane

注:字母参考式(3)解释。

Note: Letter refer to formula (3) for explanation.

图3 PV/T集热器模型图

Fig.3 Model diagram of PV/T collector

2.3 应用前景

采用全生命周期成本分析方法(Life Cycle Cost,LCC)[32-33]计算经济效益评估本系统的应用前景。

2.4 数据分析

采用EXCEL软件进行平均值计算和SPSS25.0统计软件进行相关关系分析。

3 试验结果与分析

3.1 不同灌溉水流量对系统性能的影响

由试验结果知,不同初始水温与辐照度,对由流量变化引起的分析指标的变化规律无影响,因此本文对固定工况(初始水温和辐照度分别为7.5 ℃和465 W/m2,接近中国西北初春实际工况)进行分析。如图4所示,出水口水温升温幅度随着流量的增加呈现逐渐减小的趋势,在流量为0.01 kg/(s·m2)时最高,此时出水口水温及升温幅度分别为20.9和12.5 ℃。流量增大,单位质量的灌溉水流经PV/T集热器的时间变短,所获得热量减少;此外,较大的流量使得吸热板的温度更低,0.08 kg/(s·m2)吸热板温度相较于0.01 kg/(s·m2)吸热板温度下降了7.15 ℃,进一步降低了系统的换热效率。

由图5可知,系统的光电效率和光热效率变化规律趋于一致,均随着流量的增加而逐渐增大,且增大趋势逐渐减缓。分析可知这是由于流量增加,更多的热量被灌溉水吸收,光伏组件温度下降,光电效率和光热效率有所增加,但灌溉水升温幅度逐渐减少,导致热量虽有所增加但增加量逐渐减少,光伏组件温度的变化也趋于平缓,光电效率和光热效率增长幅度减小,最高光电效率和光热效率分别为0.094和0.310。

流量对实际能量效率和水泵功率均有明显影响,如图6所示。试验结果显示随着流量的增加,实际综合效率先增后减,在小流量范围内增加,在大流量范围内减小,最大达到0.484,拐点在流量0.03 kg/(s·m2);水泵功率与流量为二次函数增长,质量流量越大增长速度越快。在小流量范围内,系统集热量、发电量之和远大于水泵耗电量,随流量增加,光热效率增幅较大,水泵功率增加速度较慢,因此系统实际能量效率呈上升趋势。质量流量增大至较大范围后,一方面光电效率、光热效率增长已趋于平缓,系统收益能量增加量少,另一方面水泵功率随流量的增加迅速变大,系统本身能量消耗不断增加,二者结合综合能量效率呈现明显降低的现象,且流量越大综合能量效率减少速度越快[28]。

3.2 灌溉水不同初始温度对系统性能的影响

不同初始温度灌溉水工况下出水口水温及升温幅度如图7所示,可以看出在相同流量下,初始温度为10 ℃时出水口水温最高,7.5 ℃居中(中国西北初春灌溉水平均温度),5 ℃最低,最高可达22.6 ℃。相较于固定工况,初始温度为10和5 ℃的出水口水温变幅随着流量增加逐渐增大,分别从0.01 kg/(s·m2)的7.9%和-11.8%增大至0.08 kg/(s·m2)的23.9%和-22.7%;升温幅度方面,初始温度为5 ℃时灌溉水升温幅度最高,7.5 ℃居中,10 ℃最低,随着流量的增大,不同初始水温的升温幅度逐渐接近。

由图8可以看出,灌溉水初始水温可影响系统的光电效率、光热效率和实际能量效率,3种能量指标与初始水温间呈负相关关系,流量为0.08 kg/(s·m2)时,5 ℃灌溉水光电效率和光热效率较固定工况分别增加了0.024%和1.619%,10 ℃灌溉水光电效率和光热效率较固定工况分别降低了0.048%和0.693%;流量为0.03 kg/(s·m2)时,5 ℃和10 ℃实际能量效率相较固定工况分别增加和减少了1.598%、2.058%。

综上分析可知相同辐照度下,初始温度相对更低的灌溉水吸收PV/T集热器光伏组件上的热量更多[34],使得光伏组件温度更低,进而能量方面表现为光电效率更大,光热效率更高、实际能量效率更大;温度方面表现为升温幅度更大,但不足以超越原本初始温度之间的差值,因此初始水温仍是决定出水口水温的重要因素;随着流量增加,单位质量的灌溉水获得的热量逐渐接近,灌溉水的初始温度成为重要因素,因而升温幅度逐渐接近,出水口水温变幅逐渐增大。

3.3 不同辐照度对系统性能的影响

由图9可以看出,相同流量下出水口水温和升温幅度与辐照度呈正相关关系,流量为0.01 kg/(s·m²)时,高辐照度工况出水口水温及升温幅度相较于固定工况分别提高了3.38和3.47 ℃,低辐照度工况出水口水温及升温幅度相较于固定工况分别降低了4.42和3.6 ℃。随着流量的增加,辐照度对出水口水温及升温幅度产生的影响逐渐减弱,流量增大至0.08 kg/(s·m²)时,出水口水温均在10 ℃左右。这是由于较高的辐照度意味着PV/T集热器可接收更多的太阳能,有更多的能量转化为灌溉水的内能,因而在流量较小时升温明显;随着流量的增加,单位质量灌溉水流经PV/T集热器时间变短,换热量趋于一致,因此对灌溉水的增温效果也逐渐相同。

由图10可知,系统光电效率、光热效率与辐照度呈负相关关系,最大光电效率和光热效率分别达到0.096和0.417。这是由于PV/T集热器处于较高的辐照度工况下时,光伏组件获得的能量更多,表面温度相对更高,对外界环境产生的热辐射和在光伏组件表面产生的对流更加剧烈,散失的能量更多且占比更大,造成光电效率和光热效率更低。系统实际能量效率与辐照度间的关系还与灌溉水的流量有关,当灌溉水流量较小(<0.06 kg/(s·m²))时,实际能量效率与辐照度之间呈负相关关系;当流量较大(>0.07 kg/(s·m²))时,实际能量效率与辐照度之间呈正相关关系。实际能量效率方面,实际能量收益量(即产生的电能与灌溉水增加的内能)与辐照度呈正相关关系,流量较小时,水泵功率较小,对实际能量收益影响不大;流量较大时,水泵功率较大,实际能量收益越小的工况受到的影响越大,因而相关关系发生变化。

3.4 应用前景分析

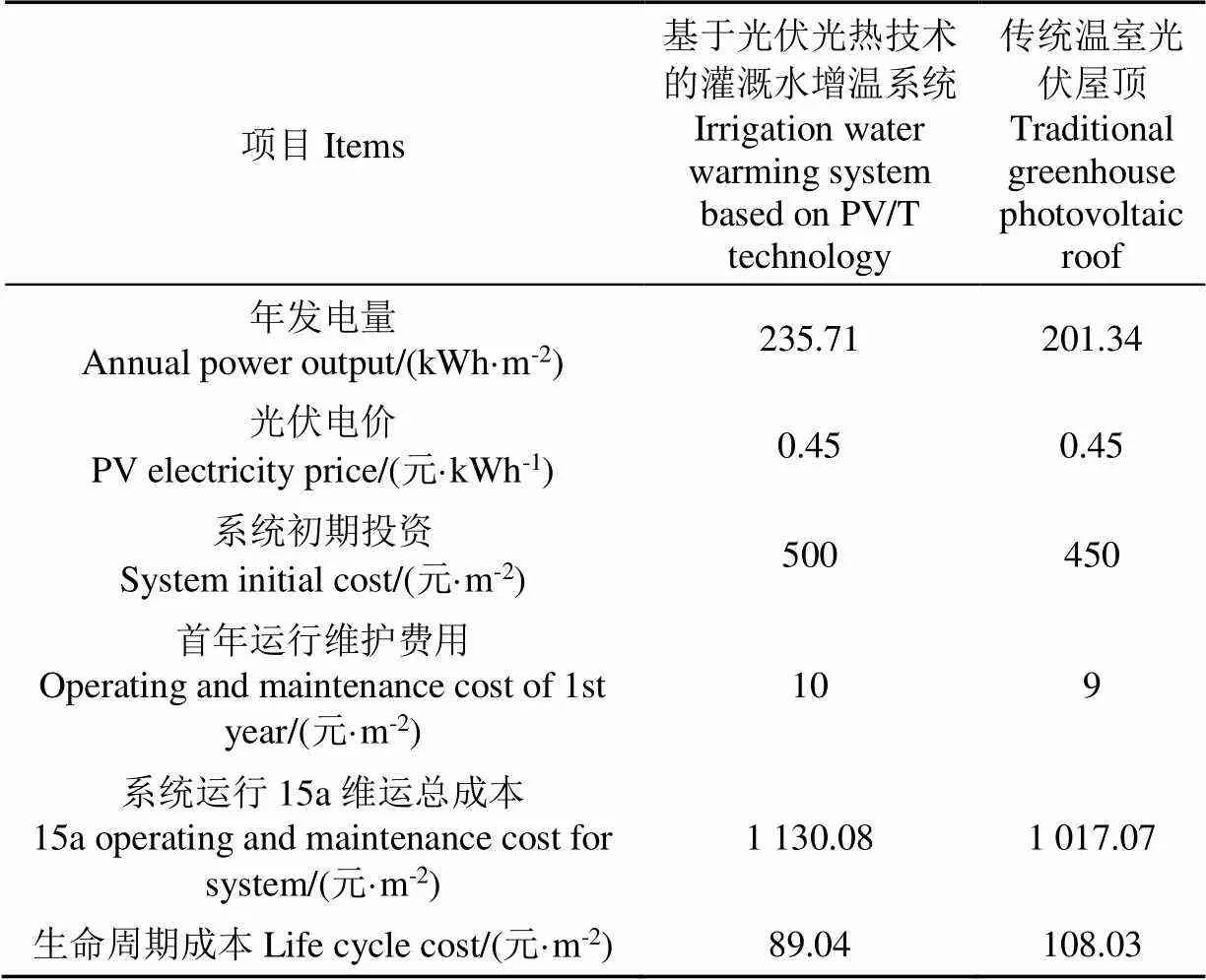

系统初期投资根据所需各部件在当地的平均价格计算,首年运行维护费为按初期投资的2%,通胀率按5%计算,将系统折旧考虑到维运总成本中。将光伏发电收益考虑到全生命周期成本中。计算结果如表 2所示。

图10 7.5 ℃灌溉水不同辐照度下运行的光电效率,光热效率和实际能量效率

表2 基于光伏光热技术的灌溉水增温系统与传统温室光伏屋顶的LCC(Life Cycle Cost)分析

由表2可以看出,与传统温室光伏屋顶相比,本研究提出的基于光伏光热技术的灌溉水增温系统初期投资及生命周期维运总成本较高,均为传统温室光伏屋顶的1.11倍,然而,全生命周期成本较低,LCC减少17.6%,综合考虑作物增产、提质、增效提高的收益,应用前景将更好。

本系统还尚处于研发与试验研究阶段,其实际安装面积还应根据户外实际辐照度、灌水量、灌溉时间和所需灌溉水温度等因素进一步讨论。

4 结 论

本文以基于太阳能光伏光热技术灌溉水增温系统为研究对象,研究分析了系统在不同流量运行下的系统性能,以及灌溉水初始水温和辐照度对系统运行的影响。主要结论如下:

1)出水口水温及升温幅度与流量呈负相关关系,以中等辐照度下初始水温为7.5 ℃灌溉水为固定工况,其出水口水温和升温幅度最高达20.9和12.5 ℃;光电效率和光热效率与流量呈正相关关系;随流量增加,实际能量效率呈先增后减的趋势,最大达到0.484,拐点在0.03 kg/(s·m2)。

2)低温灌溉水与光伏组件换热更为剧烈,升温幅度与初始水温呈负相关关系,但初始水温仍是决定出水口水温的重要因素,具体表现为正相关关系,最高出水口水温达到22.6 ℃,随着流量的增加,升温幅度逐渐接近,出水口水温的变幅增大;3种能量指标均与初始水温呈负相关关系。

3)出水口水温和升温幅度均与辐照度呈正相关关系,流量增加会削弱辐照度对出水口水温及升温幅度产生的影响,流量增大到0.08 kg/(s·m²)时,出水口水温趋于一致,均在10 ℃左右;光电效率和光热效率与辐照度均呈负相关关系,最大分别为0.096和0.417;在流量较小(<0.06 kg/(s·m²))时,实际能量效率与辐照度之间呈负相关关系,当流量较大(>0.07 kg/(s·m²))时,实际能量效率与辐照度之间呈正相关关系。

4)与传统温室光伏屋顶相比,基于太阳能光伏光热技术灌溉水增温系统初期投资较高,但综合电能收益,全生命周期成本较小,LCC(Life Cycle Cost)减少17.6%。本系统还尚处于研发与试验研究阶段,其实际安装面积还应根据户外实际辐照度、灌水量、灌溉时间和所需灌溉水温度等因素进一步讨论。

[1] Mostafaeipour A, Rezaei M, Moftakharzadeh A, et al. Evaluation of hydrogen production by wind energy for agricultural and industrial sectors[J]. International Journal of Hydrogen Energy, 2019, 44(16): 7983-7995.

[2] Chacon M C, Rodriguez D J A, Garcia M J, et al. Evaluation of the design and performance of a micro hydropower plant in a pressurised irrigation network: Real world application at farm-level in Southern Spain[J]. Renewable Energy, 2021, 169: 1106-1120.

[3] Ridzuan N, Marwan N F, Khalid N, et al. Effects of agriculture, renewable energy, and economic growth on carbon dioxide emissions: Evidence of the environmental Kuznets curve[J]. Resources Conservation and Recycling, 2020, 160: 12.

[4] 刘厚林,崔建保,谈明高,等. 光伏离心泵负载匹配研究[J]. 农业机械学报,2014,45(7):98-102.

Liu Houlin, Cui Jianbao, Tan Minggao, et al. Investigation on load matching characteristics of photovoltaic centrifugal pumps[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(7): 98-102. (in Chinese with English abstract)

[5] Riaz M H, Imran H, Younas R, et al. Module technology for agrivoltaics: Vertical bifacial versus tilted monofacial farms[J]. IEEE Journal of Photovoltaics, 2021, 11(2): 469-477.

[6] Hassanien R H E, Li Ming, Dong L et al. Advanced applications of solar energy in agricultural greenhouses[J]. Renewable and Sustainable Energy Reviews, 2016, 54: 989-1001.

[7] Trommsdorff M, Kang J, Reise C, et al. Combining food and energy production: Design of an agrivoltaic system applied in arable and vegetable farming in Germany[J]. Renewable and Sustainable Energy Reviews, 2021, 140: 13.

[8] Vengadesan E, Senthil R. A review on recent development of thermal performance enhancement methods of flat plate solar water heater[J]. Solar Energy, 2020, 206: 935-961.

[9] Pang Wei, Cui Yanan, Zhang Qian, et al. A comparative analysis on performances of flat plate photovoltaic/thermal collectors in view of operating media, structural designs, and climate conditions[J]. Renewable and Sustainable Energy Reviews, 2019, 119: 109599

[10] Yang L H, Huang B H, Hsu C Y, et al. Performance analysis of an earth–air heat exchanger integrated into an agricultural irrigation system for a greenhouse environmental temperature-control system[J]. Energy and Buildings, 2019, 202: 109381

[11] Fu X Q, Zhou Y Z, Yang F F, et al. A review of key technologies and trends in the development of integrated heating and power systems in agriculture[J]. Entropy, 2021, 23(2): 260

[12] Chilundo R J, Neves D, Mahanjane U S. Photovoltaic water pumping systems for horticultural crops irrigation: Advancements and opportunities towards a green energy strategy for Mozambique[J]. Sustainable Energy Technologies and Assessments, 2019, 33: 61-68.

[13] Amad F, Kamaruzzaman S, Mohammad H Y et al. Performance analysis of photovoltaic thermal(PV/T) water collectors[J]. Energy Conversion and Management, 2014, 78, 641-651

[14] 谈明高,田骁,吴贤芳,等. 基于日照概率分布的光伏水泵系统供水可靠性研究[J]. 太阳能学报,2020,v. 41(12):130-137.

Tan Minggao, Tian Xiao, Wu Xianfang, et al. Investigation on water supply reliability of photovoltaic pumping system based on solar irradiation distribution probability[J]. Acta Energiae Solaris Sinica, 2020, v 41(12): 130-137. (in Chinese with English abstract)

[15] Hilarydoss S. Suitability, sizing, economics, environmental impacts and limitations of solar photovoltaic water pumping system for groundwater irrigation-a brief review[J]. Environmental Science and Pollution Research, 2021. http://doi.org/10.1007/s11356-021-12402-1

[16] Arslan E, Aktaş M, Can Ömer F. Experimental and numerical investigation of a novel photovoltaic thermal (PV/T) collector with the energy and exergy analysis[J]. Journal of Cleaner Production, 2020, 276: 123255

[17] 李欣然,王立舒,李闯,等. 光伏温差界面热耦合特性及混合发电效率[J]. 农业工程学报,2021,37(1):233-240.

Li Xinran, Wang Lishu, Li Chuang, et al. Thermal coupling characteristics of photovoltaic-thermoelectric interface and efficiency of hybrid power generation[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(1): 233-240. (in Chinese with English abstract)

[18] Pang W, Cui Y N, Zhang Q, et al. Experimental effect of high mass flow rate and volume cooling on performance of a water-type PV/T collector[J]. Solar Energy, 2019, 188: 1360-1368.

[19] 杜建强,德雪红,王洪波,等. 牧草干燥太阳能折射式线聚焦平板聚光镜设计与试验[J]. 农业机械学报,2021,52(1):129-138.

Du Jianqiang, De Xuehong, Wang Hongbo, et al. Design and experiment of solar refractive line focusing flat plate condenser for forage drying[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(1): 129-138. (in Chinese with English abstract)

[20] Amaducci S, Yin X Y, Colauzzi M. Agrivoltaic systems to optimise land use for electric energy production[J]. Applied Energy, 2018, 220: 545-561.

[21] Xu J, Li Y, Wang R Z, et al. Performance investigation of a solar heating system with underground seasonal energy storage for greenhouse application[J]. Energy, 2014, 67: 63-73.

[22] Kabalci Y, Kabalci E, Canbaz R, et al. Design and implementation of a solar plant and irrigation system with remote monitoring and remote control infrastructures[J]. Solar Energy, 2016, 139: 506-517.

[23] 李加念,洪添胜,倪慧娜. 基于太阳能的微灌系统恒压供水自动控制装置研制[J]. 农业工程学报,2013,29(12):86-93.

Li Jianian, Hong Tiansheng, Ni Huina. Constant pressure water supply automatic device designed for micro-irrigation system based on solar energy[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(12): 86-93. (in Chinese with English abstract)

[24] Chow T T. A review on photovoltaic/thermal hybrid solar technology[J]. Applied Energy, 2010, 87(2): 365-379.

[25] 李洪,侯平炜,孙跃,等. 太阳能光伏环路热管热水系统光电光热性能试验[J]. 农业工程学报,2018,34(7):243-248.

Li Hong, Hou Pingwei, Sun Yue, et al. Photoelectricity and photothermal performance experiment on solar photovoltaic/loop-heat-pipe water heating system[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(7): 243-248. (in Chinese with English abstract)

[26] 梁子伟,简林桦,闫金州,等. PV/T集热器优化设计及实验[J]. 化工进展,2016,35(5):1326-1331.

Liang Ziwei, Jian Linhua, Yan Jinzhou, et al. Optimization design and experimental study on collector of photovoltaic/thermal[J]. Chemical Industry and Engineering Progress, 2016, 35(5): 1326-1331. (in Chinese with English abstract)

[27] Jia Yuting, Alva Guruprasad, Fang Guiyin. Development and applications of photovoltaic–thermal systems: A review[J]. Renewable and Sustainable Energy Reviews, 2019, 102: 249-265.

[28] 王博飞,李舒宏. 光伏光热一体化系统流量的分析与优化[J]. 化工进展,2018,37(10):133-138.

Wang Bofei, Li Shuhong. Analysis and optimization of the flow rate of the PV/T system[J]. Chemical Industry and Engineering Progress, 2018, 37(10): 133-138. (in Chinese with English abstract)

[29] 张龙灿,裴刚,张涛,等. 新型光伏-太阳能环形热管/热泵复合系统[J]. 化工学报,2014,65(8):3228-3236.

Zhang Longcan, Pei Gang, Zhang Tao, et al. A new photovoltaic solar-assisted loop heat pipe/heat-pump system[J]. CIESC Journal, 2014, 65(8): 3228-3236. (in Chinese with English abstract)

[30] Barnwal P, Tiwari G. N. Experimental validation of hybrid photovoltaic-thermal (PV/T) greenhouse dryer under forced mode[J]. International Journal of Food Engineering, 2010, 6(176): 17

[31] Zhang S H, Zheng J S, Liu B, et al. Identification of QTLs for cold tolerance at seedling stage in rice (Oryza sativa L. ) using two distinct methods of cold treatment[J]. Euphytica, 2014, 195(1): 95-104.

[32] Arat Halit, Arslan Oguz. Exergoeconomic analysis of district heating system boosted by the geothermal heat pump[J]. Energy, 2017, 119: 1159-1170.

[33] Li H, Sun Y. Performance optimization and benefit analyses of a photovoltaic loop heat pipe/solar assisted heat pump water heating system[J]. Renewable Energy, 2019, 134: 1240-1247.

[34] 陈剑波,于海照,岳畏畏. 太阳能光伏光热一体化组件的应用特性实验研究[J]. 太阳能学报,2015:36,154-161.

Chen Jianbo, Yu Haizhao, Yue Weiwei. Experimental research on application characteristic of solar photovoltaic and photothermal integration components[J]. Acta Energiae Solaris Sinica, 2015: 36, 154-161. (in Chinese with English abstract)

Experimental study on irrigation water warming system based on solar photovoltaic/thermal technology

Zhang Jinzhu, Wang Qin, Wang Zhenhua, Xu Xin

(1.,,832000,; 2.,,832000,)

The purpose of this study was to present a dedicated experimental investigation on the performance of a novel irrigation water warming system using solar photovoltaic/thermal technology. A combination was designed, including a flat-plate PV/T collector, the insulation barrels, the submerged pump, the frequency changer, the tungsten halogen lamp, and the system pipe. The cold irrigation water absorbed the heat through the flat-plate PV/T collector, where the temperature of photovoltaic modules was reduced for higher photoelectric efficiency. The experimental platform for the irrigation water warming system was built, where a series of tests were conducted under different working conditions, including the liquid mass flow rates 0.01-0.08 kg/(s·m2), initial water temperatures (5,7.5, 10 ℃), and the radiations (320, 465, and 650 W/m2). All 72 working conditions in total were conducted in the test, where the door and windows were closed in the room, and the temperature was controlled at 20 ℃ by the air conditioner. An analysis was made on the irrigation water temperature, the extent of temperature, photoelectric efficiency, solar thermal efficiency, and practical energy performance of the system. The results show that the outlet water temperature and the increasing extent of temperature reached 20.9 and 12.5 ℃, both of which were negatively correlated with the mass flow rate, particularly under the fixed condition, where the initial water temperature was 7.5 ℃, and the radiation was 465 W/m2. Nevertheless, the solar electric and thermal efficiency were positively correlated with the mass flow rate. The practical energy efficiency increased first and then decreased with the mass flow rate up rating, reaching a maximum of 0.484, where the inflection point was 0.03 kg/(s·m2). Besides, the irrigation water temperature, the extent of temperature, and energy performance of the system were compared under the middle radiation and different initial working condition of water temperatures. The heat transfer was much more intense, as the initial water temperature decreased, thereby causing the higher increasing extent of temperature. The initial water temperature was still an important factor to determine the water temperature of the outlet, indicating a positive correlation, and the maximum water temperature of the outlet of 22.6 ℃. Additionally, the solar electric efficiency, solar thermal efficiency, and practical energy efficiency were negatively correlated with the initial water temperature. Furthermore, irrigation water temperature and extent of temperature were relatively larger, when the system was under the higher solar radiation, but the increase of mass flow rate weaken the influence on the two indexes. The outlet water temperatures were maintained at about 10 ℃ when the system operated at 0.08 kg/(s·m2) with 7.5 ℃ irrigation water under different solar radiation. The solar electric efficiency and solar thermal efficiency were also negatively correlated with the solar radiation, where the maximum values were 0.096 and 0.417, respectively. Moreover, the practical energy efficiency was negatively correlated with the solar radiation, when the mass flow rate was less than 0.06 kg/(s·m2). It was just the opposite trend, when the mass flow rate was greater than 0.07 kg/(s·m2). In terms of application prospect, the initial investment of irrigation water heating system was higher using solar photovoltaic technology, compared with the traditional greenhouse photovoltaic roof, but the whole life cycle cost was smaller, and the LCC was reduced by 17.6%, considering the comprehensive energy benefits. The system was still in the stage of research and experimental study. The actual installation area can be further addressed, according to the actual outdoor irradiance, irrigation amount, irrigation time, required irrigation water temperature.

photovoltaic/thermal; irrigation; solar radiation warming; mass flow rate; initial water temperature;

张金珠,王钦,王振华,等. 基于太阳能光伏光热技术的灌溉水增温系统试验[J]. 农业工程学报,2021,37(16):72-79.doi:10.11975/j.issn.1002-6819.2021.16.010 http://www.tcsae.org

Zhang Jinzhu, Wang Qin, Wang Zhenhua, et al. Experimental study on irrigation water warming system based on solar photovoltaic/thermal technology[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(16): 72-79. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2021.16.010 http://www.tcsae.org

2021-04-10

2021-07-01

国家自然科学基金资助项目(51869028)

张金珠,博士,副教授,研究方向为干旱区节水灌溉理论与技术。Email:xjshzzjz@sina.cn

10.11975/j.issn.1002-6819.2021.16.010

S214

A

1002-6819(2021)-16-0072-08