Aerodynamic performance enhancement of co-flow jet airfoil with simple high-lift device

2021-10-27HaolinZHIZhenhaoZHUYujinLUShuanghouDENGTianhangXIAO

Haolin ZHI, Zhenhao ZHU, Yujin LU, Shuanghou DENG, Tianhang XIAO

College of Aerospace Engineering, Nanjing University of Aeronautics and Astronautics, Nanjing 210016, China

KEYWORDS Airfoil;Co-flow jet;Flow control;Aerodynamic performance enhancement;Simple high-lift device

Abstract The present study performed a numerical investigation to explore the performance enhancement of a co-flow jet(CFJ)airfoil with simple high-lift device configuration,with a specific goal to examine the feasibility and capability of the proposed configuration for low-speed take-off and landing. Computations have been accomplished by an in-house-programmed Reynoldsaveraged Navier-Stokes solver enclosed by k-ω shear stress transport turbulence model.Three crucial geometric parameters, viz., injection slot location, suction slot location and its angle were selected for the sake of revealing their effects on aerodynamic lift, drag, power consumption and equivalent lift-to-drag ratio.Results show that using simple high-lift devices on CFJ airfoil can significantly augment the aerodynamic associated lift and efficiency which evidences the feasibility of CFJ for short take-off and landing with small angle of attack. The injection and suction slot locations are more influential with respect to the aerodynamic performance of CFJ airfoil compared with the suction slot angle. The injection location is preferable to be located in the downstream of the pressure suction peak on leading edge to reduce the power expenditure of the pumping system for a relative higher equivalent lift-to-drag ratio.Another concluded criterion is that the suction slot should be oriented on the trailing edge flap for achieving more aerodynamic gain,meanwhile,carefully selecting this location is crucial in determining the aerodynamic enhancement of CFJ airfoil with deflected flaps.

1. Introduction

An ultimate target of aircraft high-lift system design is to define the simplest configuration for prescribed constraints to meet the requirements of take-off, climbing, descending and landing in the flight envelop. High-lift system design is one of the essential tasks throughout the entire aircraft design process to efficiently achieve maximum lift-to-drag ratio and/or lift coefficient.For a given airfoil,high lift systems can be categorized into active (e.g., increasing airfoil camber and wing area) and passive (e.g., boundary layer control via reorganizing the flow topology on the airfoil by means of feeding high-energy or removing the boundary layer) ways.

A basic principle of high-lift system design is to make it as simple as possible so as to reduce the weight penalty and fabricating complexity. Currently, existing mechanical high-lift devices with complicated mechanism generally bring extra airframe weight which limits the performance gain.This expectation can be alternatively realized by ‘‘smart wing” (or morphing wing) concept, which is regarded as a prospective solution of the wing design to further diminish the acoustic emission, aerodynamic drag and weight. The concept has drawn considerable attentions during the past decade.One of the most distinguishing features of ‘‘smart wing” is to achieve a hingeless and gapless high-lift device,e.g.,the leading edge droop nose deviceand trailing edge morphing flapusing flexible and morphable shape memory alloy. Although the future smart wing is able to improve the flight performance dramatically,seeking a better aerodynamic efficiency via developing new technologies and concepts never stops.

Active Flow Control (AFC) has drawn a considerable attention during the past decades which is regarded as an efficient means to improve aircraft aerodynamic performance,including circulation control airfoil, synthetic, plasma flow controland recently co-flow jet (CFJ).Most of the aforementioned AFC techniques aim to enhance the performance near/beyond stall point to expend the operation margin and at the same time augment the maximum lift, particularly in large angle of attack regime. The co-flow jet methodology proposed by Zha and Paxtonis a Zero-Net Mass-Flux(ZNMF) active flow control means which has demonstrated radical lift augmentation,stall margin increase,drag reduction and moderate nose-down moment for both stationary and pitching airfoils.In CFJ airfoil, an injection slot near the LE and a suction slot near the TE on the airfoil suction surface are implemented together to a pumping system embedded in the airfoil.A small amount of mass flow is withdrawn into the TE oriented suction slot, pressurized and energized by the pumping system,and then injected out of the injection slot near the LE tangentially to the main flow.The outward energized jet flow will assist in overcoming the adverse pressure gradient for large incident angle and introducing extra positive circulation.As a result,the CFJ airfoil is evidenced to augment lift, reduce drag and increase stall margin. The whole process of CFJ concept does not add additional mass flow throughout the whole process and thus it is a ZNMF flow control method which in principle minimizes the power expenditure.Investigations have been conducted to examine the feasibility and capability of CFJ technique in the aerodynamic performance enhancement,pointing out that the CFJ would benefit the cruise efficiency in both subsonic and transonic regimes.Meanwhile, Wang and Zhafound that using an intensive jet momentum, the flow can even maintain attaching on the suction surface of single-element CFJ airfoil when the angle of attack reaches to 70°. With the gained knowledge of CFJ concept, Lefebvre and Zhadesigned a conceptual 4-seats electric airplane with high wing loading and a compact size for the sake of carrying more battery with longer range. By applying CFJ technique, the designed aircraft is able to cruise with a very high lift and wing loading, which is about 3 times than the conventional general aviation airplanes. Moreover,the lift coefficient reaches 4.8 when pivoting the wing to 25°,allowing an excellent short takeoff and landing capability.The CFJ concept is believed to promote the design principle for general aviation airplanes, however, using rotatable wing via a pivot to achieve high incident angle is inappropriate for large and high-speed aircrafts in terms of structural tolerance.For low-speed take-off and landing regime, a potential solution is to combine the CFJ airfoil with the high-lift devices,or using multi-element CFJ airfoil. Zhang et al.applied the CFJ technique on a 2D vertical tail with TE flap,while the suction slot was located directly in front of the TE flap control surface. Their results stated that the CFJ technique will energize the low-speed boundary layer to alleviate the flow separation on the flap, the Cvalue reaches to 4.0 when the flap deflects at 8°.Later on,Xu and Zhahave numerically studied the effect of CFJ technique on attenuating the flow separation on the deflect TE flap of a 3D vertical tail,similar results were obtained.

Till now, the pioneer studies of CFJ technique are narrowed in examining its aerodynamic enhancement in cruise flight configuration. The applications of CFJ in efficient low speed takeoff and landing configuration are focused on the TE control surfaces except the only study by Lefebvre and Zhausing a pivot wing to obtain higher angle of attack. It is therefore we herein for the first time combine the simple high-lift devices with CFJ concept for the sake of obtaining efficient aerodynamic performance for take-off and landing via re-organizing the flow structures on airfoils. As aforementioned, the simple high-lift devices on smart wing are highly integrated which provides a huge flexibility to randomly orient the injection/suction slots on the airfoil. In the present study,the injection and suction slots of the CFJ system are oriented on the LE and TE flaps,respectively, to examine the potential in aerodynamic enhancement performance during low speed take-off and landing.

The main efforts of the present study are dedicated to explore the feasibility of combining CFJ technique with simple high-lift devices on a 2D airfoil for small angle of attack, particular attention will be given to explore the influential effects of several sensitive geometric parameters. This paper is organized as follow: in Section 2, the concept of CFJ airfoil and some crucial CFJ parameters are described. Section 3 subsequently illustrates the numerical methods employed in the present study and validations. Results are presented in Section 4 where the effects of various geometric parameters of suction/injection slots on the aerodynamic performance enhancement is given in detailed followed by the conclusions in Section 5.

2. Models and parameters

2.1. CFJ airfoil with simple high-lift devices

Fig. 1 Diagram of CFJ airfoil with simple high-lift devices.

Fig. 1 shows the diagram of CFJ airfoil with simple high-lift devices,in which the black solid line represents the cruise configuration, while the high-lift devices (rendered by blue line)deflect for low-speed take-off and landing. Lengths of the LE and TE flaps are 0.15c and 0.3c, respectively. In order to efficiently alleviate the flow separation during take-off and landing, the injection and suction cavities are mounted on the flaps and moved simultaneously with the high lift devices.A micro compressor is embedded in the airfoil to pump the air tangentially through the injection slot and withdraw the flow by suction cavity which results in a zero-net mass-flow. The crucial geometric parameters of the CFJ airfoil as shown in Fig. 1, viz., the height (l, l), angle (θ, θ) and location (x,x)of injection and suction slots,are influential to the CFJ performance in practical.The injection and suction slot heights in this study are set to 0.65%c and 1.3%c, respectively, see for examples in Zha et al.and the references therein. Given the baseline airfoil of NACASC(2)0712,the injection slot angle is set to 27°to ensure the blowing jet is locally tangential with respect to the airfoil upper surface. Among the geometric parameters in Fig.1,the effect of cavity heights of CFJ airfoil on its aerodynamic performance has been massively studied particularly emphasizing on their aerodynamic benefit.As documented,the injection location(see xin Fig.1)is more influential to the aerodynamic performance of CFJ airfoil for low speed flight.For the CFJ airfoil with high lift devices,the flow separation can be more serious on the TE which could result in a decent in the aerodynamic efficiency. In view of this circumstance, the suction slot located on the TE will play a pivotal role in alleviating the large-scale separation and therefore deserves more attentions.

2.2. CFJ airfoil parameters

This section will introduce the definition and formulation of several important parameters with respect to the aerodynamics of CFJ airfoils.

2.2.1. Jet momentum coefficient

The jet momentum coefficient Cis a parameter to quantify the jet intensity. It is defined based on the mass flow passing the injection slot, formulated as:

where ˙mand Vare the injection mass flow rate and velocity magnitude,ρand Vdenote the density and velocity of freestream, and Sis the reference area.

2.2.2. Power coefficient

The power consumption P required by the compressor in CFJ airfoil can be determined by the mass flow rate ˙mand the total pressure ratio of the compressor Γ=P/Pexpressed as:

where cis the constant pressure specific heat, Pand Pdenote the total pressure in the injection and suction cavities,Tis the total temperature in the suction cavity, and γ means air specific heat ratio. The compressor efficiency η is set to 100%, which assuming no loss in the pumping system. Here,a non-dimensional parameter denoted as power coefficient Pis applied to describe the power consumption, which can be written as:

2.2.3. Effective lift and drag coefficients of CFJ airfoil

CFJ technique will produce reaction forces on the airfoil via a pumping system,which is difficult to calculate in the numerical simulation.As stated by Zha et al.,the reaction forces can be obtained by the momentum and pressure at the injection and suction slots using control volume analysis. They also derived the mathematical formulations to estimate the effective lift and drag in consideration of reaction forces for a single-element CFJ airfoil.Note that for using high-lift devices on CFJ airfoil,some adjustments have been applied accordingly as:

Fig. 2 CFJ airfoil mesh system.

As seen, the new defined equations are exactly identical to those defined in Zha et al.if the deflection angles βand βequal to zero.

The effective drag and lift coefficients can be then expressed as:

where Rand Rare the surface integrals of pressure and shear stress in drag and lift directions.

2.2.4. Equivalent aerodynamic efficiency

The aerodynamic efficiency of airfoil is conventionally evaluated by the lift-to-drag ratio. However, it may fail to describe the efficiency of CFJ airfoil since using CFJ technique could to some cases produce thrust rather than drag if applying large jet momentum. CFJ technique consumes extra energy where the power consumption has to be considered to get the equivalent aerodynamic efficiency.The expression of the equivalent aerodynamic efficiency for CFJ airfoil is formulated as:

Fig.3 Computational mesh of ADVINT 5%-scale airfoil model.

3. Numerical setups and validations

Numerical simulations in the present study were carried out using an in-house-developed CFD solver. The solver solves the 2D compressible Reynolds-Average Navier-Stokes(RANS) equations in finite volume method and enclosed by the two-equation k-ω Shear Stress Transport(k-ω SST)turbulence model. A second-order upwind scheme for the inviscid flux and a central difference scheme for the viscous flux were employed to discretize the governing equations, in which the gradients are reconstructed by a least square method. Further information can be seen in Ref. 33.

3.1. Computational mesh

The mesh of NACASC(2)0712 supercritical airfoil with simple high-lift devices and CFJ system is constructed using O-mesh topology for the sake of guaranteeing high quality around the airfoil as shown in Fig. 2. The total quadrilateral cell size is around 1.0×10. To resolve the turbulent boundary layer,the first layer of airfoil was refined to y=1.

The pumping system inside the CFJ airfoil inherently does not add any mass flow to the system which is regarded as a zero-net mass-flux flow control. It is therefore the mass flow rate of the injection slot was set exactly identical to the mass flow withdrawn by the suction slot by adjusting the mass flow rate to a specific Cwithin a ±0.2% disparity.

Fig. 4 Comparison between the present computational results and experimental data34 varying jet moment.

3.2. Validations

3.2.1. ADVINT active flow control problem

The first validation is carried out to examine the feasibility and accuracy of the developed numerical solver for predicting active flow control problems.The ADaptive flow control Vehicle INtegrated Technologies (ADVINT) 5%-scale airfoil was chosen due to its adequate archived experimental data and similar geometry configuration,i.e.,using high-lift airfoils with simple flaps.As shown in Fig.3,the ADVINT 5%-scale airfoil model lengths at 14 inch with a slat leading edge and a simple flap. The AFC slot (width=0.02 inch) is located on the TE flap at 64%c and the slot exit angle is tangential to the upper surface of the flap.

The computational mesh is shown in Fig. 3 with a total mesh number around 1.1×10, where the boundary layer is meshed by quadrilateral grid with y=1 and the mesh of the jet actuation is also refined to capture the detail flow structure.

To examine the effect of jet momentum intensity on the aerodynamic performance, four cases with different C, viz.,0, 5.71×10, 2.40×10and 9.61×10, are tested. During the wind tunnel test, the freestream velocity Vwas set at 20 m/s resulted in a chord-based Reynolds number at 5.0×10and the incident angle is 11°. Comparison between the computed surface pressure coefficient Cdistributions and the experimental datais shown in Fig. 4. As seen for all the cases,the numerical results show a good agreement with the experimental data, although large deviation is found near the slot when using AFC.

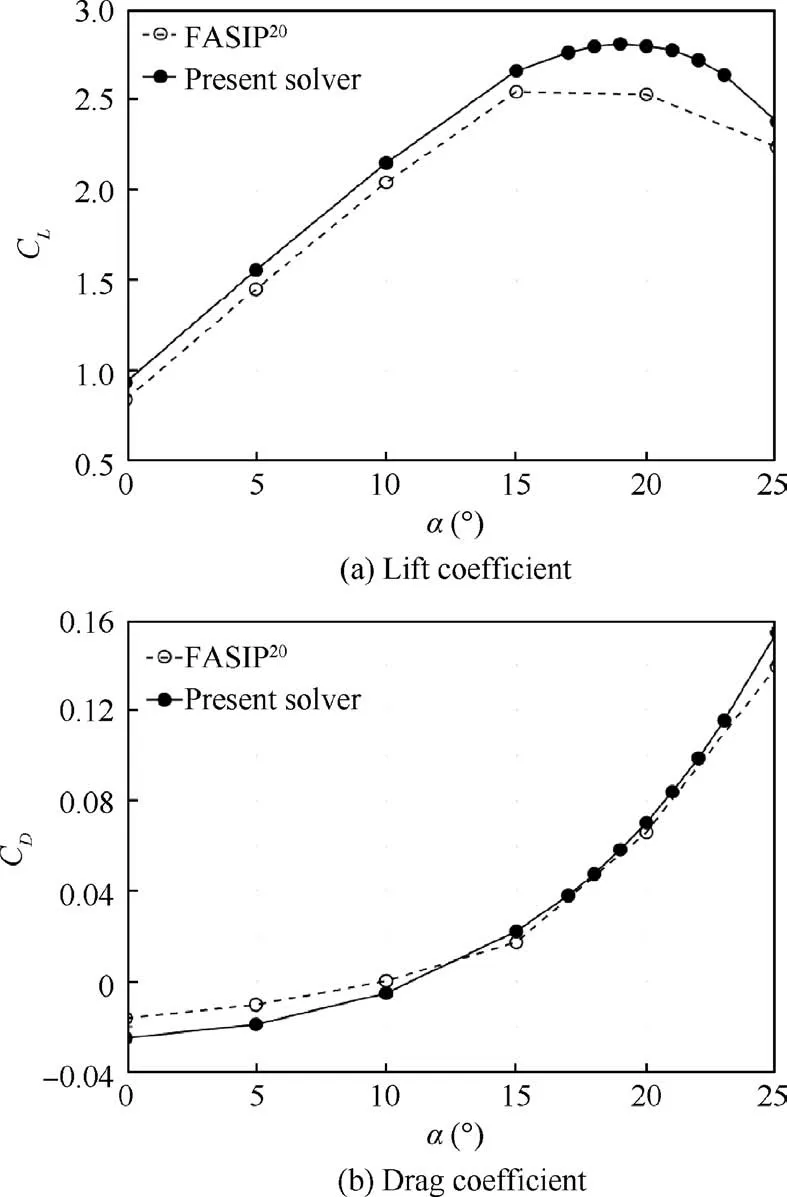

3.2.2. Co-flow jet of NACA6415

Another code-to-code validation has been carried out to verify the accuracy of the developed solver for simulating CFJ using the archived data computed by Flow-Acoustic-Structure Interaction Package (FASIP) CFD code.Fig. 5 shows the NACA6415 airfoil with CFJ system employed in Lefebvre et al.The case when Ma=0.3, Re=2.078×10,C=0.08 was selected for comparison.The injection and suction slot heights are 0.65%c and 1.30%c,which is exactly identical with respect to their computational setup. Additionally,the angle of attack was varied from 0°to 25°with an increment at 5° while the angle of attack interval is set as 1° around the stall region. The comparison of computational aerodynamic lift and drag between the present developed CFD solver and the data from Lefebvre et al.is shown in Fig.6.It can be seen that the present solver slightly overestimates the lift and underestimate the drag. However, the largest disparity for both lift and drag is below 8% which can be evidenced as a good agreement.

Fig. 5 Geometry of CFJ 6415 airfoil.

Fig. 6 Comparison of lift and drag coefficients of CFJ6415 and NACA6415 at Ma=0.3.

4. Results and discussion

As aforementioned in Section 2.2.2, three CFJ geometric parameters, viz., the injection slot location, the suction slot location and the suction slot angle, play a pivotal role to the aerodynamic performance of CFJ airfoil. The present section,hereby, is dedicated to examine the effect of the three parameters on the aerodynamic performance.Additionally,the effect of deflect angle of LE and TE when using high-lift devices is also assessed.

4.1. Aerodynamic enhancement performance of CFJ airfoil with simple high-lift devices

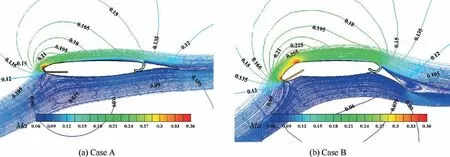

As mentioned above, the present study will examine the aerodynamic performance enhancement for CFJ airfoil equipped with simple high-lift devices, aiming to reveal its feasibility and capability for efficient take-off and landing. Therefore,computation was performed on two configurations, i.e.,single-element CFJ airfoil(denoted as Case A)and CFJ airfoil with deflecting simple high-lift devices (denoted as Case B) as schematically shown in Fig. 7. The slot angles, heights and locations of the two configurations are identical in the computation,while the deflected angles for both the LE and TE flaps are both set to 30°.The jet momentum Cand angle of attack are selected as the variables for examining the aerodynamic performance as shown in Fig.8.It is clearly observed that with LE and TE flap mounted,the aerodynamic associated lift generation is significantly higher than the single-element CFJ airfoil which is beneficial from the camber increment due to the presence of LE and TE flaps. However, increased camber enlarges the effective angle of attack and thus the stall margin of CFJ airfoil with flaps becomes narrow with respect to single-element airfoil particular for small jet momentum scenarios. From the comparison of flow field shown in Fig. 9 where the airfoil of Case B has stalled while the airfoil of Case A has not yet, Case B has a larger high-speed region on the upper surface than Case A though a flow separation occurs at the TE flap. For Case A, the jet out of the injection slot at a low momentum coefficient is not powerful enough to overcome the adverse pressure gradient at such a high angle of attack.In comparison,the similarly intense jet of Case B accelerates along the LE flap to a higher speed when it reaches at the main element of airfoil, which allows the flow to remain attached to the upper surface,greatly enhancing the lift generation as shown in Fig. 8(a). Moving to the aerodynamic associated drag coefficient plot in Fig. 8(b), drag of Case A for all the jet momentum is larger than Case B below α=5°,and the tendency was reversed afterward. In general, the drag coefficients for the aforementioned two configurations are not varied too much. Fig. 8(c) shows an approximate collapse of the power consumption of CFJ airfoil with/without flaps for different jet momentums, indicating that the mass flow rate and pressure ratio of the pumping system is not sensitive to the flow field as evidenced in Eqs. (2) and (3). The equivalent lift-to-drag ratio as shown in Fig. 8(d) gives positive results of the new configuration (Case B) and implies the simple high-lift device on CFJ airfoil is aerodynamically efficient for low-speed take-off and landing.

Fig. 7 Configurations of CFJ airfoil with/without simple high-lift devices.

Fig. 8 Aerodynamic performance comparison of CFJ airfoil with/without simple high-lift devices versus angle of attack and jet momentum coefficient.

Fig. 9 Mach contours and streamlines of Case A and Case B when α=14°, Cμ=0.08 and V∞=40 m/s.

4.2. Effect of injection slot location

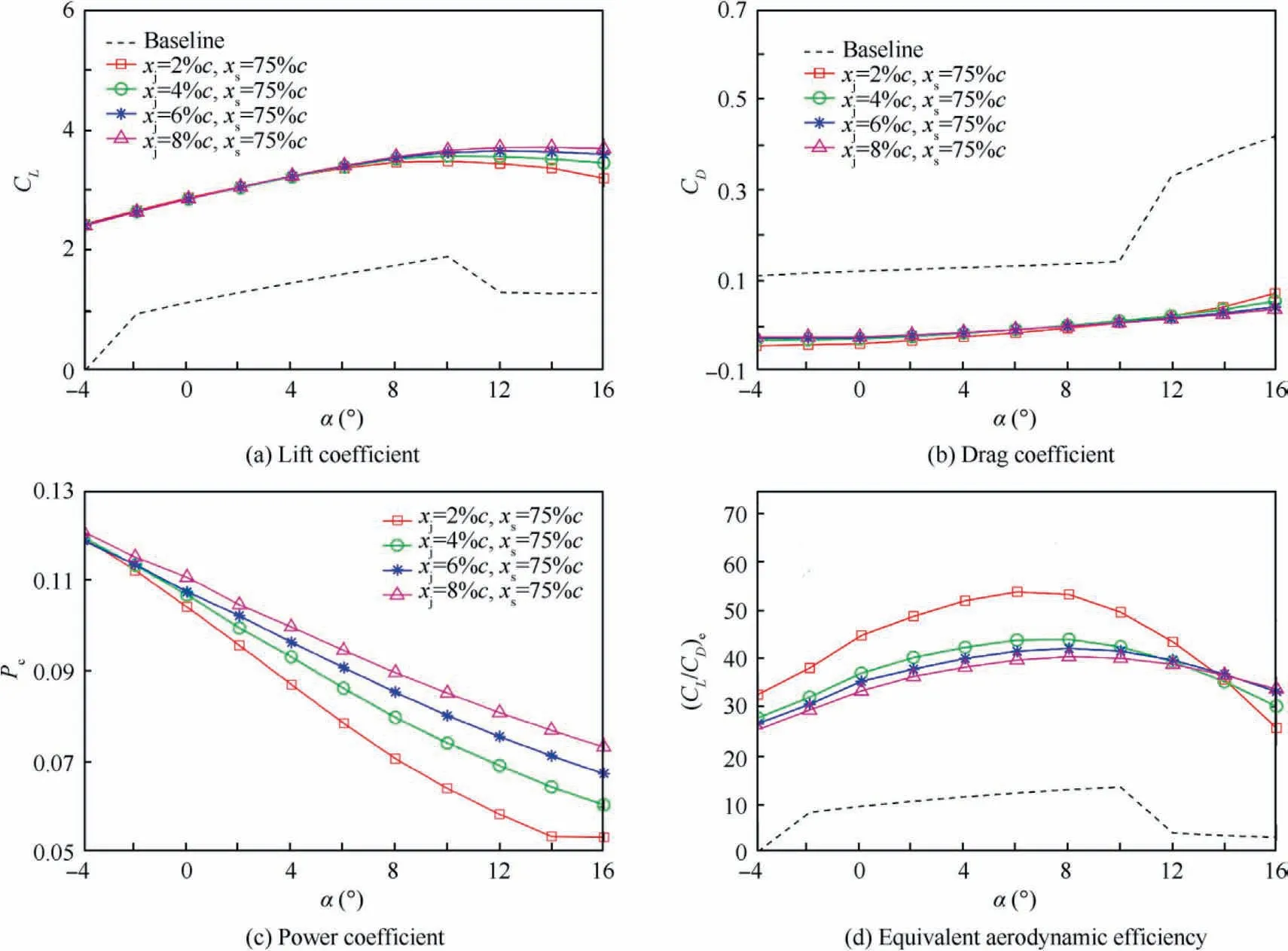

Fig. 10 Aerodynamic performance of CFJ airfoil for different injection slot locations.

Fig.11 Configuration of clean baseline airfoil with simple highlift device.

The injection slot location, denoted by xin Fig. 1, is first defined at 2%c and moves downstream to 8%c with an increment at 2%c,while the suction slot angle θis fixed to 75°and located at 75%c. The freestream velocity is defined at 40 m/s,which represents the low-speed takeoff and landing phases.The jet strength is set at C=0.08. Additionally, the angle of attack varies from -4° to 16° with an increment at 2°.Meanwhile,the flaps on LE and TE deflect at 30°.The aerodynamic coefficients versus angle of attack by varying the injection slot locations are shown in Fig. 10, compared with the results of the clean baseline airfoil without CFJ technique which can be seen in Fig. 11. As expected, using CFJ active flow control technique on the airfoil with simple high-lift devices is able to significantly enhance lift and at the meantime alleviate drag (as seen in Fig. 10(a) and (b)) via enhancing the boundary-layer momentum and thus increasing airfoil circulation. Additionally, the injection and suction mechanism on CFJ airfoil allow a mixing between the jet and main-flow to energize the wall boundary layer, where the mixture is further enhanced by the adverse pressure gradient and large vortex structures. Such a mixing allows the flow to remain attaching on the upper surface at high angle of attack so as to enlarge the stall margin. As can be seen from Fig. 10(a) and (b), the injection slot position shows a sluggishness for both the lift and drag coefficients at small angle of attack, when the flow on the upper surface of the airfoil is still attached without large-scale separation. When the angle of attack increased to 6°, the aerodynamic beneficial gain on the lift production for the tested injection slot locations becomes more noticeable.Fig. 10(a) shows the stall margin increases from α=10° for x=2%c to α=14° when x=8%c, which indicates that moving the injection slot location downstream is able to enlarge the stall margin as well as increasing the lift production.

Fig. 12 Comparison of pressure distribution on baseline and CFJ airfoil when α=12°, Cμ=0.08 and V∞=40 m/s.

For the case of x=2%c, the distance between injection and suction slots reaches its maximum allows sufficient mixing of the injection jet and main flow.Hence,the energized boundary layer would in practical result in a relatively lower viscous drag as seen in the drag plot in Fig. 10(b). The power consumption in Fig. 10(c) shows a monotonous decreasing tendency when moving the injection slot upstream. A principle of CFJ is that the injection slot should be located downstream of the LE suction peak where the pressure is low, therefore, a favorable pressure condition is achieved for injecting with less energy expenditure.As seen from the surface pressure distribution in Fig.12,case of x=2%c has the nearest distance at the downstream to the suction peak of the airfoil,thus results in a lower power consumption. The equivalent aerodynamic efficiency in Fig. 10(d) indicates moving the injection slot upstream for CFJ airfoil with simple high-lift devices can argument the efficiency when the angle of attack below 14°.

Fig. 13 Mach contours and streamlines varied with different injection slot locations of CFJ airfoil when α=12°, Cμ=0.08 and V∞=40 m/s.

The Mach contour and the free-streamline is shown in Fig. 13, it can be clearly known that moving the injection slot location downstream is effective to diminish the flow separation at the trailing edge. With identical jet momentum, the jet injected from larger xallows a stronger mixing of the jet and main flow to overcome the adverse pressure gradient occurs on the flap due to the large curvature and thus delay the separation.This is also the reason why the case with injection slot located downstream has larger lift generation at high angle of attack, seen in Fig. 10(a).

Fig. 14 Schematics of baseline and CFJ airfoil with various suction slot locations.

4.3. Effect of suction slot location

The second geometric parameter of CFJ airfoil using simple high-lift devices is the suction slot location, denoted by xin Fig. 1. As described in Fig. 14, four suction slot locations oriented at 65%c,70%c,75%c and 80%c away from LE are considered, while the injection slot position xis fixed at 2.0%c and the suction slot angle θis set at 75°.

Fig. 15 shows the aerodynamic coefficients for different suction slot position together with the baseline case. In view of the CFJ case with suction slot position locates at 65%c, it generates the lowest lift among the other cases, as shown in Fig.15(a).In addition to the low lift generation,the stall margin for x=65%c (α=6°) is even lower than the baseline(α=10°). By looking into the flow field for α=6° as shown in Fig.16,locating the suction slot on the TE flap is more beneficial in alleviating the flow separation on TE flap since the separated flow is sucked back to reattach. Additionally, as long as the suction mechanism is implemented on the movable flap, the aerodynamic characteristics in terms of lift and drag are not varied too much. However, this is not always the case for x=80%c that a steep drop in lift production occurs when the angle of attack keeps increased to 14°.The sudden decrease in lift of x=80%c for large angle of attack can be evidenced from the flow field topology in Fig. 17 where the suction does not influence the large separation on the TE at all.The reason is that the suction slot is too far away downstream on the TE where the flow was dominated by separation and vortices,it is difficult to eliminate the separation by certain jet momentum.A potential solution is to introduce a powerful pumping system, i.e., increasing the jet momentum. However, the aerodynamic efficiency could be further decreased which is not ideal for the CFJ system. For xequals to 70%c and 75%c, they almost have identical lift and drag variation.As the flow passes the LE, it will be further speeded up until reach the deflected TE flap, causing a second suction peak around 70%c, seen in the pressure distribution in Fig. 18. Since the case of x=70%c is near the suction slot with a fairly low static pressure, the embedded compressor required more power to pressurize the suction flow, and thus weakening the equivalent aerodynamic efficiency, which is evidenced in Fig. 15 (c) and(d).

Fig. 15 Aerodynamic performance of CFJ airfoil for different suction slot locations.

Fig. 16 Mach contours and streamlines varied with different suction slot locations of CFJ airfoil when α=6°, Cμ=0.08 and V∞=40 m/s.

Fig. 17 Mach contours and streamlines varied with different suction slot locations of CFJ airfoil when α=14°, Cμ=0.08 and V∞=40 m/s.

Fig. 18 Airfoil pressure distribution for different suction slot locations.

In a word, for the case of x=75%c, it has a relatively higher lift generation,a moderate drag production and the best equivalent aerodynamic efficiency. Carefully selecting the suction slot location is crucial in terms of power consumption as well as efficiency.

4.4. Effect of suction slot angle

The present section is to test the aerodynamic characteristics of varying the suction slot angle, where three angles are selected,viz., 35°, 55° and 75° as shown in Fig. 19. The injection and suction slot positions during the computation are fixed at 2.0%c and 75%c away from the LE, respectively.

Fig. 19 Schematic geometries overlapped of CFJ airfoil for different suction slot angles.

Fig. 20 shows the aerodynamic coefficients of various suction slot angles, in comparison with the results of baseline.As seen from Fig. 20(a), varying the suction slot angle does not influence the life generation at all, which also can be revealed from the flow field in Fig. 21. However, increasing the suction slot angle can slightly reduce the effective drag.Actually, the tendency of the drag variation in Fig. 20(b) can be also theoretically derived from Eq. (4) that increasing the suction slot angle will augment the reaction force and thus decrease the effective drag. Increasing the suction slot angle makes the cross-section of the suction tube more parallel to the tangential freestream and intuitively require more energy expenditure, which can be evidenced from the power coefficients plot in Fig. 20(c). Although the largest suction slot angle, say θ=75° is the most power consuming case, the resulted efficiency in Fig.20(d)indicates the best aerodynamic performance within the entire range of angle of attack.

5. Conclusions

(1) With mounted simple high-lift devices,i.e.,deflected LE and TE flaps, the aerodynamic lift generation and the equivalent lift-to-drag ratio are significantly enhanced compared with single-element CFJ airfoil,while the negative effect of doing so is mildly sacrificing of stall margin. However, using simple high-lift devices on CFJ airfoil is a potential and convincible configuration for a specific requirement of lift and lift-to-drag ratio for small angle of attack.

(2) Moving the injection slot location downstream can alleviate the flow separation on the TE flap which would slightly increase the lift production and the stall margin is also extended. The suction location should be located at the downstream of the pressure suction peak on LE so as to reduce the power expenditure of the pumping system and improve the aerodynamic efficiency,i.e.,equivalent lift-to-drag ratio for CFJ airfoil.

(3) Varying the suction slot location is able to delay the separation on TE flap,however,the lift coefficient and stall margin are not sensitive with respect to the suction slot location.Locating the suction slot on the deflected TE is better than that on main airfoil in terms of separation alleviation. The flow on the TE flap is massively separated for high angle of attack that the suction slot location should be located upstream on the TE flap to efficiently alleviate the flow separation. A solution is to increase the suction flow momentum for delaying the separation, however, the aerodynamic efficiency becomes worse due to the extra power consumption. It is therefore properly orienting the suction slot location according to the flight envelop is very crucial in determining the aerodynamic performance.

Fig. 20 Aerodynamic performance of CFJ airfoil for different suction slot angles.

Fig. 21 Mach contours and streamlines varied with different suction slot angles of CFJ airfoil when α=14°, Cμ=0.08 and V∞=40 m/s.

(4) Suction slot angle is barely influential to the lift coefficient,while increasing the suction slot angle will increase the reaction force towards the LE direction and hence result in a slight decrease in drag. Because increasing the suction slot angle will allow the cross-section of the suction tube more parallel to the tangential boundary layer and intuitively require more energy expenditure.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

The present work is supported by the National Natural Science Foundation of China (No. 11672133), and the Research Funds for Central Universities (No. kfjj20180104).The support from Rotor Aerodynamics Key Laboratory (No.RAL20190202-2) is acknowledged as well.

杂志排行

CHINESE JOURNAL OF AERONAUTICS的其它文章

- Optimal trajectory and downlink power control for multi-type UAV aerial base stations

- Effects of flow parameters on thermal performance of an inner-liner anti-icing system with jets impingement heat transfer

- Effects of wing flexibility on aerodynamic performance of an aircraft model

- Adaptive fuzzy terminal sliding mode control for the free-floating space manipulator with free-swinging joint failure

- Influence of longitudinal-torsional ultrasonicassisted vibration on micro-hole drilling Ti-6Al-4V

- Response and stabilization of a two-stage axial flow compressor restricted by rotating inlet distortion