Response and stabilization of a two-stage axial flow compressor restricted by rotating inlet distortion

2021-10-27JiaLIXuDONGDakunSUNRuizeXUXiaofengSUN

Jia LI, Xu DONG, Dakun SUN, Ruize XU, Xiaofeng SUN

Fluid and Acoustic Engineering Laboratory, School of Energy and Power Engineering, Beihang University, Beijing 100083, China

KEYWORDS Axial compressors;Casing treatment;Inlet distortion;Stall margin;Stall precursor

Abstract This paper considers effects of Rotating Inlet Distortion(RID)on a two-stage axial compressor and the stabilization effects of a casing treatment subjected to the considered RID.In multispool engines, the downstream compressor suffers a RID when the upstream fan/compressor is in rotating stall. A controlled rotating sectional screen upstream of the compressor was adopted to generate the RID in different intensities, and co- or counter spinning direction compared with the rotor.The response of the compressor to inlet distortion was interpreted as the changes of stall margin.Results show that there are two peaks for the stall margin degradation where the distortion screen rotates near 20% and 70% of the rotor’s rotational frequency, respectively. Based on the measurements taken during the pre-stall process, it is suggested that the two frequencies are associated with the eigen frequencies of the compressor. Specifically, the first is associated with a stall precursor that is suspected as an initial disturbance existing in compressor and the second is related to a spike-type stall precursor.At last,a kind of Stall Precursor-Suppressed(SPS)casing treatment was applied to enhance the compressor stability in RID conditions. The result indicates that the stall margin is improved by 6% at an average level and there is nearly no efficiency loss caused by the application of such casing treatment.

1. Introduction

Although uniform inlet conditions are greatly desirable for ensuring flight safety, aero-engine compressors frequently suffer from inlet distortion problem due to changes in maneuvering and weather condition. Inlet distortions always adversely affect the performance hence the stability of a compressor.For this reason,the inlet distortion problem received considerable attention,series of theoretical and experimental work has been carried out to address this issue.

Typically, inlet distortion consists of total pressure distortion, total temperature distortion and swirl distortion etc.This is not a strict classification because they are in most cases related to each other. For example, the total temperature distortion is usually caused by ingestion of the hot gas. This is often the case in vertical taking off and landing, carrier catapult operation and launching missiles.The swirl distortion can appear in many conditions. Such as the ingestion of the vortex due to engine operating close to ground and inlet structure induced issues (for example, the serpentine duct or the bifurcated intake). And apparently, swirl distortion may usually induce both non-uniform inlet total pressure and total temperature as the consequence of the viscosity of air. The steady-state total pressure distortion can be further classified into circumferential distortion,radial distortion and their combination. Commonly, total pressure distortion arises from a high-angle or strong cross-winds take off condition, which causes a growth,or even partial flow separation,of the boundary layer at the nacelle lip.

This paper considers a kind of time-resolved total pressure distortion named Rotating Inlet Distortion (RID) that occurs in multi-spool engines. Specifically, when the upstream fan or compressor works in unstable conditions like rotating stall,the downstream compressor will operate with a dynamic inlet circumferential nonuniformity that rotates around the annulus.In the open literatures, there are several investigations conducted to address this issue. The detailed experimental work was first carried out by Longley et al.on a low-speed axial compressor with four different blade configurations.The rotating speed and direction of RID were found to be responsible for the change of compressor stability.They linked the distortion speed rates, corresponding to the operation range degradation peaks, to the different stall inceptions.For compressors existing single degradation peak, the peak appears when the distortion is rotating near the propagating speed of the modal precursor or developed stall cell. And for compressors having two degradation peaks, they suggested that the first peak is associated with the response of the modal precursor and the second peak is relative to the spike-type stall inception.After experimentally investigating the effect of RID on a high-pressure compressor, Peters et al.pointed out that the first stall margin degradation peak occurs at a fixed frequency of 30 Hz which may be an eigen frequency of compressor rather than being related to the modal precursors since no existence evidence of modal precursor was found. Subsequently,Zhang et al.studied the RID in an axial compressor with spike feature stall inception numerically and experimentally. They observed that the largest loss in stall margin is found when the distortion rotates at the propagating speed of the spike-type disturbance. The same conclusion was also drawn by Yan et al.but in a compressor with modal-type stall inception.Recently,Dong et al.tested a casing treatment in RID condition.They found that the casing treatment produces less stall margin improvement when distortion speed consists with the stall precursor traveling speed.

Although a great progress has been made in investigating the effects of RID on compressor stability, researchers have not reached consensus on this topic because rotating stall may be triggered by various disturbances.More efforts should be put on unsteady pre-stall process to further understand the mechanism of the stall onset.This paper later will demonstrate that an initial disturbance, not directly associate with the stall onset, can trigger compressor stall if it is energized by the imposed forcing. Besides, a sequent concern of interest is how to enhance the stability of the compressor subjected to the RID. Attempts were made to enhance the stability with the restrictions of radial or circumferential distortion through active control technique,however little work was reported on compressor stabilization at the RID scenario. So, another emphasis in this paper is the improvement of stall margin in these conditions. In recent years, a type of Stall Precursor-Suppressed (SPS) casing treatment was proposed and experimentally verified in both sub- and transonic compressors by Sun et al..The idea originated from the control of the stall precursors in a passive way rather than only improving the blade tip flow environment. They point out that the casing treatment can be modeled as an impedance boundary condition that can suppress the flow disturbances in compressor and the relative mechanism can be physically interpreted as the wave-vortex interaction. Consequently, the effects of the casing treatment can be considered into the stability model and in turn to evaluate the resulting stability of compressor.Being successively tested in various distorted inlet conditions,the SPS casing treatment was proved to generate a mount of stall margin in all cases concerned.

This paper will first investigate the response of the compressor to the artificial RID and find the eigen frequency accounting for the instability. Next is to stabilize the instability using the SPS casing treatment in distorted inlet conditions.The stall precursors are captured in detailed measurements and the interaction between distortion and precursors is also analyzed and discussed.

2. Experimental facility

2.1. Two-stage compressor TA66

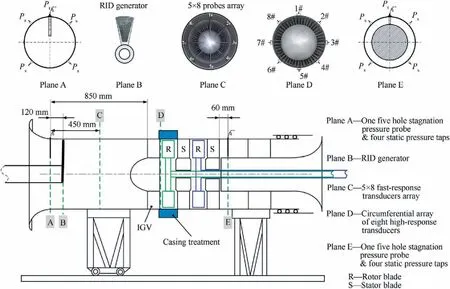

The experimental investigation in this paper was performed on a two-stage axial flow compressor named TA66. It is designed by the Fluid and Acoustic Engineering Laboratory of Beihang University and is a large-scale model of a high-pressure compressor. A cross-sectional schematic of TA66 is given in Fig.1.The air flows into the compressor through a bell mouth and is controlled by a sleeve throttle valve at the end.The compressor has two identical stages preceded by an Inlet Guide Vane rows(IGV).The blade numbers of IGV,rotor and stator are 38,47 and 45,respectively.Each rotor is driven by a sets of AC motor. In the present experiment, the rotational speeds of two rotors are set to be same.The design speed of the compressor is 3000 r/min resulting a rotor tip tangential speed of 94.2 m/s, which indicates that the flow can be considered as incompressible. It should be note that to allow higher distortion screen-to-compressor speed ratios the compressor speed is reduced to 2000 r/min in the present experiment. Therefore,the design parameters herein refer to that based on the operation speed of 2000 r/min.The detailed information of the compressor is summarized in Table 1.

2.2. Instrumentation

Fig. 1 A cross-sectional schematic of TA66 and the layout of instrumentation.

Table 1 Design parameters of compressor TA66.

The arrangement of transducers adopted is also given in Fig.1.There are four measuring cross-sections labeled Plane A,C,D and E.Plane A as well as Plane E include a five-hole total pressure probe and four equally spaced static pressure tappings for determining the steady performance (the flow coefficient, the efficiency and the total-to-static pressure rise) of the compressor. The measurement accuracy of steady pressure transducer and torque transducer are 0.2%and 0.1%of full scale,respectively. A sets of 5×8 probe array is placed in Plane C to measure the inlet distortion. It is eight equiangularly spaced rakes with five probes per location at the centroids of equal areas.The transducer at each probe is Kulite XT-140 and data are sampled at 10 kHz which is enough to capture the inlet distortion characteristics. There are 15 flush mounted fast response pressure transducers (Kulite XT-190) in the casing,eight of which are distributed uniformly along the circumference 10 mm ahead of the rotor leading edge to capture the evolution feature of the disturbance.Another 7 transducers follow one of the eight circumferential-placed transducers and are equally placed in chordwise direction end at 5.4 mm downstream of the rotor trailing edge as shown in Fig.2.The chordwise layout of transducers is designed to obtain the casing wall pressure distribution. The sampling frequency of 15 pressure transducers are set as 50 kHz giving approximately 32 samples per passage.Another signal is from a sensor embedded in rotor shaft to provide one trigger pulse per rotor revolution allowing for the phase-locked processing of the pressure data recorded.

Fig. 2 Layout of eight pressure transducers in chordwise direction.

2.3. Rotating inlet distortion (RID) generator

A distortion generator is designed to produce a pressure disturbance propagating along the compressor annulus at a given frequency.Specifically,it is configured as a sectorial screen driven by a servo motor and an aluminum sim for the balance.This distortion generator allows the screen to rotate at speeds from 0 to 90% of the rotor design speed, co- or counterrotating directions. So, intensities (i.e. the rotating direction and speed) of the inlet distortion are controlled simultaneously.

The screen is placed 1.2 compressor diameter upstream of the IGV, denoted by Plane B, as shown in Fig. 1. It is far enough to minimize the potential field interaction between the distortion and the compressor blades.

2.4. Stall Precursor-Suppressed casing treatment (SPS)

The configuration of the SPS casing treatment designed for the TA66 is given in the left part of Fig. 3. Generally, it is composed of an annular backchamber and a perforated plate with slots. In the present experiment, the height (h) as well as the length (l) of the backchamber are 65 mm and 82 mm, respectively. There are up to 48 equal spacing slots crossing with the blade chord. Each slot has an axial length of 35 mm and 50% overlap ratio. In particular, the 3D-printing plugs are used to adjust the perforated ratio of the SPS casing treatment.The perforated ratio is 12% when the whole 48 slots are opened. And 6%, for example, is achieved if half of the slots are stuffed with plugs. Note that the slots are always distributed evenly. The perforated ratio adopt in the present experiment is 8%.

The SPS casing treatment is designed with a target that to affect the evolution of the stall precursors rather than to improve the flowfield condition in some specific regions of the compressor. Its mechanism accounting for stability improvement is interpreted as a vortex-wave interaction problem. Specially, when the casing treatment is installed over the blade tip with an overlap ratio, the radial flow is pumped into the chamber at the downstream of the slots and subsequently blows into main flow ahead of the blades. It is apparent that the recirculating flow powered by the rotating blades will always exist in an operating compressor. At the same time,the vortex shedding, as a result, forms and these vortexes will interact with the pressure disturbances in main flow as presented in Fig. 3. Physically, the casing treatment acts as an unsteady boundary or ‘‘soft” boundary to influence the origination and evaluation of the initial perturbations which are related to stall inception resulting an improvement in stability.

3. Experiment results

3.1. Uniform inlet characteristics

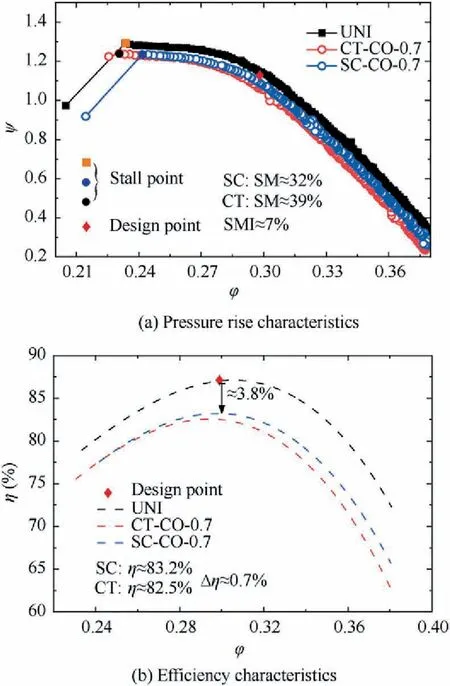

The total-to-static pressure rise as well as the efficiency characteristics of the compressor in uniform inlet condition are shown in Fig. 4. In Fig. 4(a), the ordinate is the pressure rise coefficient ψ

Fig. 3 Configuration and mechanism of SPS casing treatment.

Fig.4 Characteristics of compressor in uniform inlet conditions.

where the ρ is density and the Uis the tangential speed in mid span of the rotor blade.The ΔPis the total-to-static pressure rise overall stages. The abscissa is the flow coefficient φ

where the Vis the axial velocity in inlet and is determined by the volume flow Q. In this paper, the stall point is defined as the last stable operation point of the compressor as marked by a solid circle in the pressure rise characteristic curve.Additionally in Fig. 4(a), the design point presented using a solid diamond is given as a reference. The comprehensive Stall Margin (SM) considering both operating range and pressure rise is used to assess the compressor stability.The SM is calculated from

where the subscripts ‘‘s” and ‘‘d” refer the stall point and the design point, respectively; and the SM is 43% for compressor in uniform inlet condition.

In Fig.4(b),the open circles refer to the raw data measured for efficiency characteristic and the design point is also marked. The efficiency η is expressed as

in which the ΔPis the total pressure rise over stages and the Pis motor shaft effective power. For the sake of comparison and evaluation in different inlet cases, a smooth efficiency curve fitted by a cubic polynomial method is shown in Fig. 4(b). It is seen that the efficiency at design point is 87%. Taking the performance data obtained in UNiform Inlet (UNI), with datum Solid Casing conditions(SC) as a basic reference, the effects of inlet distortion as well as the SPS casing treatment on compressor stability can be evaluated.

3.2. RID distortion characteristic

With an aim to investigate the effects of RID on compressor stability, it is necessary to characterize the RID first. The RID was generated by a sectorial screen rotating in co- or counter direction of rotor. Each RID condition is distinguished by the combination of letters and numbers, which specified the rotation direction and speed. For example,CO-0.5 identifies a RID rotating in co-direction of rotor and at 50% of the rotor speed. For the compressor operating at the design point, the total pressure distribution was measured at each time interval by a5×8 probes array and the total pressure contours shown are the results obtained by subtracting the ambient atmospheric pressure (P) from the measured total pressure. As seen in the left part of Fig. 5(a), a total pressure contour measured as the plane rotating at 50% of the rotor speed presents a transient distorted inlet condition. Specifically, the screen produces a roughly 60total pressure distortion in circumferential extent. The total pressure contours changing in one period of RID is presented in Fig. 5(b). In the right part of Fig. 5(a), a fast Fourier transform result is given based on the data acquired by one of the 40 fast response pressure transducers. The ordinate is the frequency nondimensionalized by the rotor rotation frequency fand the abscissa is the amplitude. There are two leading frequency components: one is the rotor frequency and the other is the RID frequency which consists with the rotation frequency of the screen. It is thus concluded that the RID generator produces a square-wave-like total pressure structure propagating at a specific frequency.

Furthermore, each transducer in measure Plane C recorded the variation of the entire circumferential pressure as the screen rotates. The total pressure distribution was obtained as a function of time as shown in Fig. 6. The vertical axis with a unit scale of 250 Pa is the relative total pressure rise, i.e. the pressure measured at the specific condition(for example, CO-0.2 RID and the compressor operated at a fixed throttle point) minus the data obtained before the machine operates, or to put it in another way, the baseline atmosphere pressure. The gray and the red lines represent the original and the filtered data, respectively. In order to highlight the comparison among three cases, a unified blue dot box was used to quantify the pressure loss. One can see from the figure is that the difference between the plateau and the trough of the curve is increasing when the screen-to-rotor speed ratio raises from CO-0.2 to CO-0.5 but little changed further to CO-0.9. Another feature is that the largest pressure nonuniformity i.e. the fluctuation amplitude in the entire 360flowfield occurs at CO-0.9 speed ratio, which may be due to the strong interaction between the airflows in the spoiled region and the relatively uniform region.

3.3. Response of compressor to RID

Fig.7 shows variations of the stall flow coefficient of the compressor (φ) as a function of the distortion screen speed nondimensionalized by the rotor speed. As a comparison, the stall point in uniform inlet condition is also give in the figure marked by a star. Note that negative screen speeds shown in the abscissa correspond to the condition that the screen rotates in counter-rotation direction of the rotor.And the screen speed of zero refers to the static inlet distortion. There are three observations should be considered.First,all tested RIDs varying from-0.9 to 0.9 of the rotor speed rate result in an increase in stall flow coefficient, which indicates that RID narrows the operation range of the compressor. Second, the largest degradation of compressor operation range occurs near the certain screen-to-rotor speed ratio of 0.2.Moreover,the next degradation peak is observed near that ratio of 0.7. These two points are labeled as Peak 1 and Peak 2,respectively,in Fig.7.Third,in comparing with the co-rotating inlet distortion,the counterrotating distortion leads to a gentle fluctuation in the trend of the resulting stall flow coefficient although there are also two small rises at -0.2 and -0.8, respectively.

Comparison was also made in compressor pressure rise characteristics measured in uniform and distorted inlet conditions as shown in Fig. 8. Distorted inlet cases of CO-0.2 and CO-0.7 are chosen as examples. The solid symbols refer to the stall point in each curve. It is observed in the enlarged figure that the RID has least two deleterious effects on compressor performance, one is to trigger compressor to stall at the larger flow coefficient than that in uniform inlet condition and the other is to decrease the compressor capacity of raising the gas pressure especially in regions near the stall points.

Taking both effects of the RID on the flow coefficient and the pressure rise at stall point into account, the calculated SM as a function of the screen-to-rotor ratio is presented in Fig.9.The SM in uniform inlet condition is also plotted in the figure as a reference. It is observed that generally the SM trends to decrease with the increased speed of the distortion screen,regardless of the certain ratios near the CO-0.2 and CO-0.7,rotating in either direction. This is mainly because the screen in higher speed resulting in a larger inlet flow nonuniformity.However there still show two local peaks of SM degradation near CO-0.2 and CO-0.7, which is suggested that the loss of SM is not only caused by the flow nonuniformity but also related to the circumferential propagating speed of the distortion.

3.4. Stall inception analysis

Eight fast response pressure transducers(CH1 to CH8)evenly mounted in circumferential direction, 10 mm upstream of the rotor leading edge, were used to capture the transient stall inception process. Time traces of measured wall pressure in uniform inlet condition during nearly 30 revolutions are shown in Fig. 10. Two types of stall precursors, long-length-scale‘‘modal-type disturbance” and short-length-scale ‘‘spike-type disturbance”, were detected, respectively. The modal-type disturbance is firstly captured at 5 rotor revolutions and travels in the circumferential direction at about 37% of the rotor speed as indicated by long black arrows. However, it decays and disappears in subsequently 8 rotor revolutions or it is too weak to be captured since then. The secondary ephemeral existence of the modal-type disturbance is initially found at 20 rotor revolutions and end up with splitting into two decaying smallerlength-scale disturbances. After about 2 revolutions, a spiketype disturbance emerges from a modal-type disturbance and grows in size and amplitude as it travels around the compressor annulus at about 71.5% of rotor speed. Within few revolutions the spike-type disturbance evolves into the developed rotating stall cell which propagates at about 33.3% of rotor speed.

Fig. 5 A typical characteristic of RID (CO-0.5).

Fig. 6 Distorted total pressure distributions measured in Plane C.

Fig.7 Flow coefficients at stall point of compressor vs screen-torotor speed ratio.

Fig. 8 Pressure rise characteristics of compressor in uniform inlet and distorted inlet conditions (CO-0.2 and CO-0.7).

Fig. 9 Calculated SM of compressor vs screen-to-rotor speed ratio.

Fig. 10 Time traces of wall pressure measured by eight equallyspaced transducers during slow throttled closing to rotating stall(uniform inlet).

Besides, existence of the modal-type disturbance is confirmed by a Power Spectrum Density (PSD) analysis based on a spatial–temporal Fourier transform.Concretely,the pressure disturbance of interest can be decomposed into Fourier series. Using a set of N circumferential measurements of pressure, the spatial Fourier coefficient can be obtained by conducting the spatial Fourier transform

At each spatial mode k, the C(t) contains both phase and amplitude information as a function of time. Then a Fourier analysis of C(t) yields a spectrum distribution at any specific spatial mode k.The PSD analysis can therefore be carried out based on the temporal Fourier coefficient. The PSD spectrum of the first harmonic of pressure disturbance is shown in Fig. 11. The data analyzed were taken in two seconds prior to stall so the rotating stall behavior was not included. The highest peak in the figure indicates that the modal-type disturbance propagates at 37% of the rotor speed.

In analyzing the stall inception process of the compressor in uniform inlet condition, three characteristic frequencies of the compressor are confirmed.First is 37%of rotor speed at which the modal-type disturbance propagates circumferentially. Second is 71.5% of rotor speed corresponding to the travelling speed of the spike-type disturbance. And third is related to the fully developed stall cell speed which travels at 33.3% of the rotor speed. According to the results presented in Figs. 7 and 9, when the distortion rotates near the spike-type disturbance propagating speed, there will be a peak degradation in compressor operation range. However, the distortion rotates in either modal-type disturbance speed or fully developed stall cell speed imposes a normal effect on compressor performance.It is implied that the spike-type disturbance propagating frequency may be the dominant eigen frequency among these three frequencies for the present compressor case.

Fig. 11 PSD result of pressure disturbance in first harmonic(two seconds data prior to stall, uniform inlet).

Fig. 12 Contours of static pressure coefficient and corresponding pressure trace showing the typical ‘‘spike” characteristic (uniform inlet).

We hence renamed the spike-type disturbance as the spiketype stall precursor based on the results above. Traditionally this type of precursor is known to occur at tip region of rotor,occupying several blade pitches, with a high rotation speed which decreases as the size of embryonic stall cell increases. In the present experiment, the snapshots of the spike-type stall precursor per revolution of compressor in the uniform inlet condition is given in Fig. 12. Note that the data were measured by an array of fast response transducers mounted in the casing in which the rotating blades moved past.The top and bottom are contours of nondimensional static pressure coefficient Cwhich is defined as the static pressure rise over the dynamic pressure head in rotor midspan, respectively.The middle part is the instantaneous trace measured by pressure transducer labeled as CH9, 7% ahead of the rotor leading edge.Time scale for one rotor revolution is also drawn below the trace as a reference.The spike-type stall precursor at two time instants are marked by black boxes and red arrows,respectively.The‘‘spike”is characterized as an up-down waveform i.e.a sudden rise in pressure followed by a rapid pressure drop. As point out by Pullan et al.that the pressure rise is related to the blockage in the particular blade passage and the pressure drop is associated with the shed vortex. For the present compressor, there are two ‘‘spikes” spaced by five blade pitches as shown in Fig. 12. Initially the low-pressure region is just separating from the blade suction surface and moving to the adjacent blade pressure surface against the blade rotation direction. When it is captured by transducers next time,part of which has been extending forward out of the leading edge in another blade passage causing a larger local blockage region. Once the ‘‘spike” is formed, it will propagate in a way proposed by Emmons et al.and evolve into rotating stall.

In consist with the classical viewpoint, the spike-type stall precursor is considered as a local flowfield-dependent disturbance.Supposing that for a uniform inlet compressor throttled to a critical point,a spike is triggered by an initial disturbance at a specific region and it will propagate blade by blade.If the spike moves into the high-flow regions, it will be damp out quickly but if the damping is not enough the spike will grow till into stall cell. For compressor operating with CO-0.7 inlet distortion, the rotating spoiled inlet will impose least two effects on compressor. First, the blades operating in spoiled region have a more severe loading condition than that in clean region. So, at a critical throttle point the blades in spoiled region are tend to trigger a ‘‘spike”. Second, once created,the spike will propagate around the annulus. When the rotation speed of the spoiled region is nearly consisted with the‘‘spike”propagating speed,the‘‘spike”covered by the spoiled region grows in size and strength until to slow down the propagating speed to leave from the spoiled region, generally in which condition the grown ‘‘spike” is always evolving into rotating stall quickly. The time-resolved pressure measurements of compressor with CO-0.7 RID are shown in Fig. 13.The shaded gray bars indicate the trace of the distortion.One can see from the figure that the ‘‘spike” originates from the distorted region and rapidly evolves into stall cell.This validates the mechanism accounting for the second degradation peak of SM.

With a goal to understand the mechanism for the first peak in SM degradation, the FFT results of the time-resolved pressure measured by CH9 at three fixed throttle points with uniform inlet condition are shown in Fig. 14. The abscissa is the frequency nondimensionalized by the rotor frequency and the ordinate is the amplitude. Aside from the rotor frequency,a frequency band of 0.12 to 0.22 covered by a gray box is of great interest because it presents a distinct evaluation in throttle process. It is observed in the right enlarged plot that the pressure oscillating amplitude in this band is increasing with the decreased flow coefficient, as marked by black arrows.

Fig. 13 Time traces of wall pressure measured by eight equallyspaced transducers during slow throttled closing to rotating stall(CO-0.7 RID).

Fig. 14 FFT results of pressure signals measured by CH9 at three flow coefficients.

Fig. 15 PSD results showing evolution of disturbance.

To further investigate the unsteady characteristic in band 0.12 to 0.22, PSD analysis was adopted to confirm the propagating pressure disturbances at some specific frequencies. The PSD results of the first harmonic are shown in Fig. 15. The results in different flow coefficient are plotted in blue, red and black lines,respectively.The rotor frequency is filtered for clarity. Energy of disturbances in a large frequency band are increased when the compressor is throttled to a lower flow coefficient. Especially the disturbance propagating in frequency of 0.19 is turn to be dominant during flow coefficient decreases from 0.262 to 0.250.

It is suggested that the frequency of 0.19 may be another eigen frequency of the compressor and worthy to be discussed further.The compressor in CO-0.2 RID is stalled at about the flow coefficient 0.251. However, the disturbance in frequency of 0.19 is not always dominant when the compressor is continuously throttled into rotating stall from the flow coefficient of 0.250,in uniform inlet condition. Although not reported here,the PSD results calculated two seconds prior to stall indicate that the disturbance in frequency of 0.37 have a higher energy level than that in 0.19 during this process. It is thus suspected that the disturbance propagating in frequency of 0.19 may be an initial disturbance of the compressor. Based on the ‘‘resonant theory”, if the imposed forcing (the rotating distortion) is corresponding to the eigen mode of the compressor,the related disturbance will develop quickly and the instability occurs. Fig. 16 shows the time traces of the pressure signals.The distortion region and the damped disturbances are marked by gray bar and dashed arrows, respectively. As indicated by solid arrows, the spike-type precursors are born from the distorted regions and evolve into stall cells immediately. In comparing with the stall inception process depicted among Figs. 10, 13 and 16, i.e. the stall inception in uniform inlet,CO-0.7 inlet and CO-0.2 inlet conditions,one can observe that it takes the least time for ‘‘spikes” from birth to growing into stall cell in CO-0.2 RID condition,which again imply that the 0.19 is an eigen frequency of the compressor.

Fig. 16 Time traces of wall pressure measured by eight equallyspaced transducers during slow throttled closing to rotating stall(CO-0.2 RID).

Fig. 17 Comparison in compressor characteristics with and without SPS casing treatment in uniform inlet and CO-0.7 RID conditions.

In summary, for the present compressor, there are four characteristic frequencies but two ‘‘dangerous” eigen frequencies, one is the 0.19% of the rotor rotation frequency and the other is the propagating frequency of the spike-type stall precursor. If the distortion rotation speed matches one of these two speeds, the compressor will suffer a severe degradation in stability.

Fig. 18 SM and SMI as functions of nondimensional screen rotation frequency.

3.5. Effects of SPS casing treatment

The results above show that RID adversely affects the stability of the compressor, especially when the distortion frequency matches the eigen frequency of the compressor. The control method is therefore considered in this section. As mentioned in Introduction,the SPS casing treatment is designed to extend the stall margin of the compressor. Fig. 17 shows the typical characteristics of compressor with and without the SPS casing treatment in CO-0.7 RID and uniform inlet conditions,respectively. For clarity, the CT refers to compressor outfitted with the SPS casing treatment and the SC represents that in the solid wall casing condition. Comparison in pressure rise characteristics shows that in CT the characteristic curve extends to a smaller stall flow coefficient. The calculated Stall Margin Improvement (SMI) is increased by 7%. It can be seen in efficiency characteristics that the additional efficiency loss caused by the casing treatment is about 0.7 %.

The SM and the SMI as functions of nondimensional screen rotation frequency are summarized in Fig. 18. The SM of the compressor in uniform inlet condition is also depicted as a reference.One can clearly see from the figure that the SPS casing treatment extends the SM in any RID condition tested. Additionally, the calculated SMI is plotted in the form of bar graph at the bottom.It is indicated that the SMI varies in 2.5%(static distortion)to 9.4%(CO-0.2 RID)and the averaged SMI in all cases is about 6%.

PSD analysis of the first harmonic pressure disturbances with and without casing treatment in CO-0.7 RID is performed to validate the stall precursor-suppressed mechanism of the casing treatment. Data (in both CT and SC cases) were taken in two seconds prior to stall in SC case with a slow throttling process.In Fig.19,the two plots on the left correspond to SC case and those on the right to CT case.Moreover,the bottom two plots are the partial enlarged drawings covered by gray boxes in the top two plots, respectively. In top plots,the PSD results reveal a dominant first harmonic disturbance traveling along the annulus and this disturbance is related to the imposed distortion. Comparison in PSD results with SC and CT indicate that the energy of the traveling disturbance is attenuated by the casing treatment as labeled by a pointing downwards arrow. Besides, one can see in enlarged plots is that traveling disturbances in a large frequency band are suppressed by the casing treatment.In support of the comments in Introduction, the inference we draw is that the SPS casing treatment is able to restrain the development of the stall precursors by imposing the damping into the compressor system hence to improve the compressor stability.

4. Conclusions

Fig. 19 PSD results of pressure disturbance taken in same flow range in SC and CT cases.

In this paper, effects of the rotating inlet distortion on a twostage compressor were studied.The SPS casing treatment used as a control method to enhance the compressor stability in these distorted inlet conditions was also investigated and analyzed. The conclusions are summarized as follows:

(1) The compressor stability is strongly related to the rotating frequency of the upstream distorted inlet. When the distortion frequency matches the eigen frequency of the compressor, there is a severe degradation for stall margin.

(2) The stall margin decreases with the increase of the distortion frequency for both co–and counter-rotation distortions. It is most possibly because the level of the pressure nonuniformity is also responsible for the degradation of the stall margin. But in comparison with the co-rotation distortion, the counter-rotation distortion shows less deleterious effect on stall onset.

(3) For the present compressor,there are two eigen frequencies for its pre-stall behavior. One is corresponding to the propagating frequency of the spike-type stall precursor and the other is about 0.19 of the rotor rotation frequency. The second eigen frequency is of great interest for that it is not always dominant in pre-stall process but still influence the compressor stability. This type of disturbance is suspected as an initial disturbance which should be investigated further.

(4) Under RID conditions, the SPS casing treatment has a capability of improving the stall margin by 6% in an averaged level without any performance accommodations to withstand the additional secondary flow. Based on the PSD analysis, the suggested mechanism of the SPS casing treatment is associated with suppressing the evolution of the stall precursors.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

This research is supported by the National Natural Science Foundation of China (Nos. 51822601, 51790514 and 51906004).

杂志排行

CHINESE JOURNAL OF AERONAUTICS的其它文章

- Optimal trajectory and downlink power control for multi-type UAV aerial base stations

- Effects of flow parameters on thermal performance of an inner-liner anti-icing system with jets impingement heat transfer

- Effects of wing flexibility on aerodynamic performance of an aircraft model

- Aerodynamic performance enhancement of co-flow jet airfoil with simple high-lift device

- Adaptive fuzzy terminal sliding mode control for the free-floating space manipulator with free-swinging joint failure

- Influence of longitudinal-torsional ultrasonicassisted vibration on micro-hole drilling Ti-6Al-4V