Simulation of temperature distribution and discharge crater of SiCp/Al composites in a single-pulsed arc discharge

2021-10-27JipengCHENLinGUWanshengZHAOMarioGUAGLIANO

Jipeng CHEN, Lin GU, Wansheng ZHAO, Mario GUAGLIANO

a School of Mechanical and Electronic Engineering, Nanjing Forestry University, Nanjing 210037, China

b State Key Laboratory of Mechanical System and Vibration, School of Mechanical Engineering, Shanghai Jiao Tong University, Shanghai 200240, China

c Department of Mechanical Engineering, Politecnico Di Milano, Piazza Leonardo da Vinci, 32, Italy

KEYWORDS Arc discharge;Discharge crater;SiCp/Al composites;Single-pulsed;Temperature distribution

Abstract SiCp/Al composites are difficult-to-cut materials.In recent years,electrical arc discharge machining has been developed to improve the machinability of these materials.However,there is a big challenge to build a satisfactory heat transfer model of SiCp/Al composites in the arc machining.This is not only because of the material property difference between the reinforcement and matrix material but also because of the micro-dimension SiC reinforcements.This paper established a new heat conduction simulation model considering the SiC particle-Al matrix interface and the phase change effects in a single-pulsed arc discharge of SiCp/Al composites. A novel SiC particle-Al matrix cell geometric model was designed firstly. Then, the temperature distribution at a different depth from the workpiece surface was analyzed,the influence of sic volume fraction on temperature field was studied, and the contribution of the interface thermal resistance and latent heat were explained. To demonstrate the validity of the new numerical model, comparisons and verifications were employed. Finally, the method of improving the model was proposed and the machining mechanism of arc discharge of SiCp/Al matrix materials was discussed.It was found that high temperature is prone to concentrate on the surface layers of the workpiece especially when the SiC fraction is high,also,the temperature fluctuates respectively at the evaporation point of aluminum and SiC, and the SiC-Al resistance has less influence on temperature distribution compared to latent heat, etc. The model build in this work improves the simulation accuracy observably compared to the previous model,and the simulation work will help to acquire a detailed mechanism of material removal of SiCp/Al composites in the arc discharge machining.

1. Introduction

SiC/Al composites have high specific strength, specific stiffness and wear resistance, low thermal expansion coefficient,good fatigue resistance, thermal conductivity, and electrical conductivity. They have attracted much attention in the military, aerospace, and automotive industry, besides the electronic packaging and optics.It is known that SiC/Al composites consist of reinforcement particles(SiC)and matrix material (aluminum alloys). Although the SiCAl composites possess numerous excellent physical and mechanical properties, its natural characteristics of SiC particle’s high hardness and high wear resistance lead to low tool life and poor machined surface quality, especially in machining aluminum matrix composites (AMCs) reinforced with a high fraction of SiC particulate.Besides traditional cutting processes, e.g.,turning,milling,drilling,grinding,nontraditional processes have also been adopted to machine SiC/Al. Among them, the Electric discharge machining (EDM)processis widely employed. EDM process is a material removal process that relies on heat generation to melt and vaporize a select portion of the workpiece material by ionization within the dielectric medium, in which the workpiece is dipped.One of the deficiencies of the EDM process lies in its limited machining efficiency. In EDM, the discharges between the electrode and workpiece are generally electrical sparks.Compared to spark discharges,electrical arc discharge has a lager discharge energy because a higher peak current and a longer pulse duration are generally employed.Hence,arc discharge machining processes, such as arc dimensional machining (ADM),short electric arc machining,combined machining of electrical discharge machining and arc machining,electro-arc machininghave been proposed to improve the material removal ability of EDM.

Blasting erosion arc machining (BEAM) is also a typical applicable arc discharge process which was developed by Zhao and Gu around 2012.BEAM has been used to machining difficult-to-cut materials such as titanium alloys,nickelbased alloysand demonstrated a very high material removal rate (MRR). Since 2014, Gu and Chenconducted experiments on the machining of SiC/Al composites with BEAM and studied relevant processing properties. It was found that the MRR of machining 20vol%and 50vol%SiC/Al composites could be as high as 10,000 mm/min, and 7500 mm/min respectively. At present, research about heat transfer simulation of discharge machining SiC/Al composites has been conducted, for example, Gu et al.built a heat transfer model to explain the heat affect zone (HAZ) of arc machining SiC/Al composites, Tang et al.established an EDM continuous multi-pulse discharge temperature simulation model to explore characteristics of EDM of SiC/Al composite materials. However, the SiC/Al composites in the reported models are generally simplified as an isotropic homogeneous material,SiC particle-Al matrix interface effect, and phase change are normally not considered. It is predicted that the interfaces in composites materials seriously affect the thermal properties of the composites.The interfacial thermal resistance reduces the conductivity of the composites, and this reduction can be very pronounced for small reinforcement particles.

There is a big challenge to build a heat transfer model of SiC/Al l composites in the arc machining not only because of the material property difference but also because of the micro-dimension SiC reinforcement(e.g.,10 μm)which makes the geometry model very difficult. This paper attempts to establish a heat conduction simulation model with the consideration of the SiC particle-Al matrix interface and phase change effects during the single arc discharge. The simulation model will be verified and compared, the influence of SiC volume fraction and discharge energy on temperature field and crater dimension will also be researched.The simulation work will help to acquire a detailed mechanism of material removal of SiC/Al composites in arc discharge machining.

2. Simulation approach

2.1. Single arc discharge process

The schematic of a single pulse arc discharge is shown in Fig. 1. The copper electrode is fixed on the spindle of a CNC machine. The electrode moves with the spindle without rotating. The workpiece immerses in the dielectric (deionized water). The dielectric breaks down and an arc forms when the distance of the electrode and the workpiece is within the discharge gap. The power works in single discharge mode,hence there is one pulsed arc generates and forms one crater on the workpiece surface.

The occurrence of arc discharge and its heat conduction to SiC/Al composite workpiece is very complex, hence, necessary simplifications are employed.

Fig. 1 Schematic of a single-pulsed arc discharge.

(1) Neglecting the influence of the external environment on the arc plasma discharge.Assuming the energy of the arc discharge plasma assigned to the workpiece is constant.

(2) Neglecting the effect of working fluid on the heat transfer process of workpieces. Assuming that the phase changed material is removed from the workpiece and forms craters on the workpiece.

(3) Assuming the reinforcement particles are sphere-shape and uniformly distributed in the matrix material.

(4) Neglecting the chemical reactions between SiC reinforcement and Al matrix material (e.g., the occurrence of AlC) and not consider their influence on temperature.

(5) The computational domain is axisymmetrical and can be modeled in a two-dimensional coordinate.

2.2. Numerical model

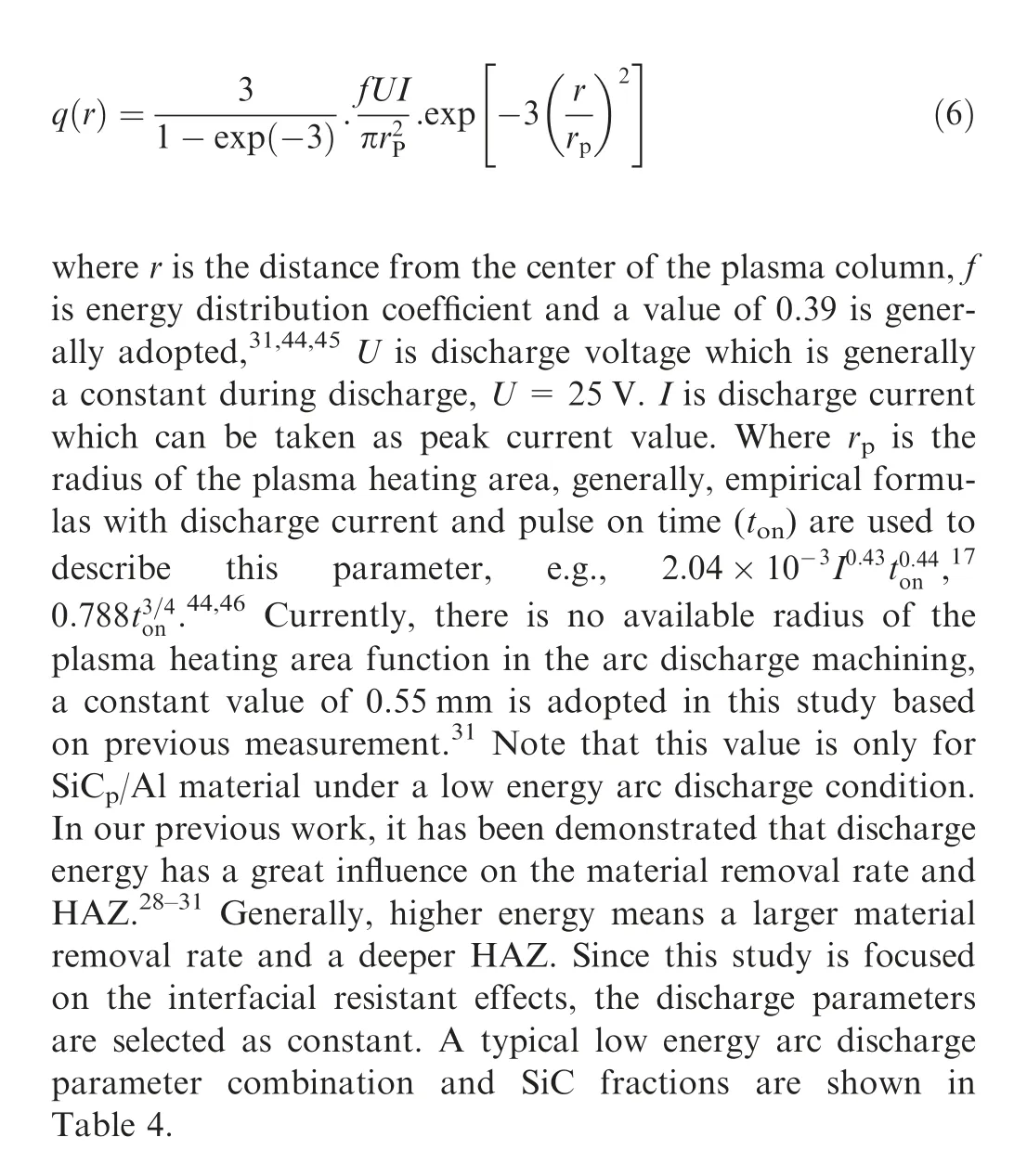

In this study,the construction of the numerical model is based on COMSOL Multiphysics 5.4. The Fouriers law of heat conduction and heat balance equation in solid is expressed as

where k is the thermal conductivity(W/(m·K)),ρ is the density(kg/m), Cis the specific heat capacity at constant pressure(J/(kg·K)), u is the velocity vector (m/s), q is the heat flux by conduction (W/m), α is the coefficient of thermal expansion(1/K), S is the second Piola-Kirchhoff stress tensor (Pa), Q is additional heat sources (W/m), T is temperature.

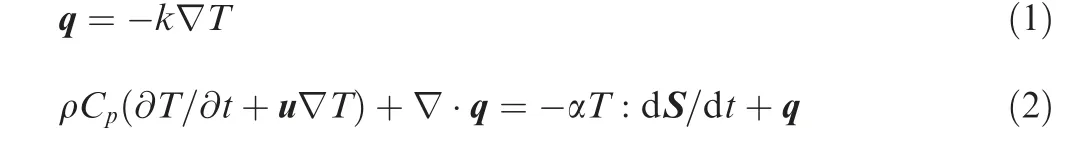

To build a heat conduction model considering the interfacial effects of reinforcement particles and matrix material, a geometrical model containing both particle domain and matrix domain should be employed.However,the construction of the geometrical model will be very complex if a real-scale particle dimension is adopted, this is because the size of a SiC particle can be as small as 10 μm. Consequently, a compromised method is adopted. A square cell which contains SiC particle domain and the matrix domain is proposed,as shown in Fig.2.

The length of the square cell (L) is set as a constant, and L=0.1 mm in this study.The radius of the particle is written as

where fis the volume fraction of SiC particles. With this method, the radiuses of SiC particles are 25.2 μm and 39.8 μm respectively when SiC volume fractions are 20% and 50%. Note that if the radiuses of SiC particles in the model are too small, the calculation will be very difficult and timeconsuming, even not convergence. A full-length geometric model (two-dimensional axis-symmetry) with meshes (mesh size is chosen as ‘‘extra coarse”) is shown in Fig. 3.

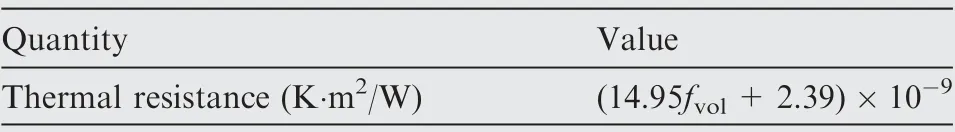

On most occasions, essential thermal properties of SiC are taken as constant. In this study, the temperature- dependent properties of SiC are taken into account, which is given by

where C(T)is specific heat capacity function of temperature,λ(T) is thermal conductivity function of temperature.

It is known that the aluminum solid changes to liquid/gas at the temperature of 933 K/2743 K, the corresponding latent heats are 390 kJ/kg and 11,834 kJ/kg respectively.The thermal properties of the liquid and gas states are expressed as a piecewise function of temperature. Here we use the piecewise functions that have been built in the COMSOL material database.Different from aluminum, it is generally regarded that SiC decomposes (SiC →Si+C) and evaporates at a temperature of 3100 K. Sometimes, a melting process is also observed, for example, a cloud of ejected liquid SiC material right above the target surface starts being observable from 1000 ns in a laser machining process.Reference 37–39 explained that SiC becomes a solution of carbon in liquid silicon above melting temperature, and the thermal parameters of liquid SiC are represented by those of liquid silicon.In some study cases,the melting or evaporation of SiC is generally not considered.In this study, we consider the evaporation of SiC but neglect its melting process since the pulse duration adopted in this research is less than 2 ms. The latent heat of SiC evaporation is 530 kJ/mol,and the molecular weight of SiC is 40 g/mol,so we take a value of 1.325×10kJ/kg as the latent heat of SiC evaporation in the calculation.Furthermore,we take aluminum as matrix material and consider both the melting and evaporation of aluminum. We set the thermal parameters of aluminum as constants in the solid phase(<933 K). While in the liquid phase, the thermal conductivity is 33.9+0.07892 T-2.099×10TW/(m·K) (933–1491 K)and 105 W/(m·K) (>1491 K), and the specific heat is 1127 J/(kg·K) as reported in reference.

Fig. 2 Construction of geometric model.

Fig. 3 Full length geometric model with meshes.

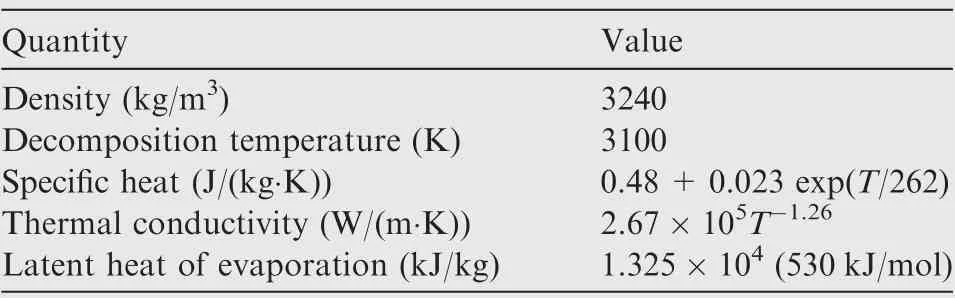

In terms of interfacial resistance between SiC and Al, a value of 5.38×10K·m/W for 20 vol.% SiC/Al and value of 8.37×10K·m/W for 40vol% SiC/Al are reported.The interfacial thermal resistance value for 20vol% SiC/Al is a little lower than that for 40vol% SiC/Al, which is also due to the dislocations induced by SiC-particle loading.In this study,we use a linear fitting function to describe the interfacial resistance of different volume fraction SiC/Al composites based on the above two values. The thermal parameters of Al, SiC, and Al-SiC interface are also listed in Tables 1–3.

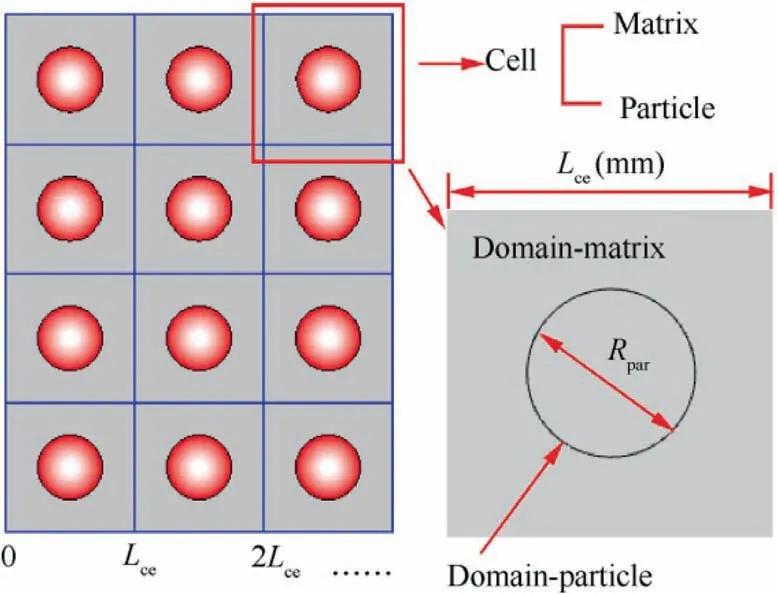

A Gaussian distribution heat flux q(r)is employed as a heat source,which is expressed as

3. Results, comparison and verification

3.1. Results

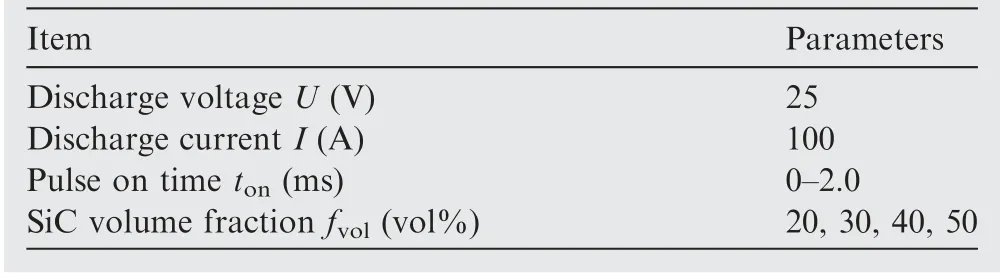

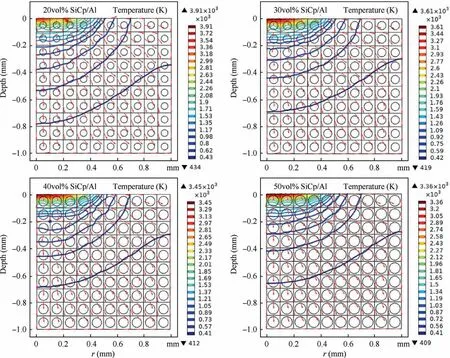

Fig.4 shows a simulative 3D temperature calculation result of single-pulsed arc discharge of SiC/Al composites (20vol%and 50vol% SiC/Al), detailed temperature distributions are shown in Fig. 5 (20vol%, 30vol%, 40vol% and 50vol% SiC/Al). When the pulse on time reaches 2 ms, the peak surface temperature of SiC/Al workpiece is generally higher than 3300 K. At this temperature, the evaporations of both matrix material and SiC particles will happen. Also, the high temperature is found to concentrate on the surface layers of the workpiece,especially when the sic fraction is higher,it indicates that the SiC particles have a strong thermal resistant characteristic which is not conducive to thermal machining.There is another trend that the peak value of workpiece surface decreases with the increasing SiC fraction, which indicates that the SiC tends to absorb more heat energy and leads to a decline of temperature. The detailed mechanism has been discussed in reference.

A detailed temperature increasing process at different depth(r=0.1 mm) is shown in Fig. 6.The workpiece with different SiC fractions appears a similar temperature increasing tendency.Once the heat source acts on the workpiece,the temperature increases quickly to the evaporation point of aluminum within 0.25 ms at the surface layers. Then, the temperature rises slowly. At the evaporation point of aluminum and SiC,the temperature fluctuation can be found respectively because of the high latent heat of aluminum (11834 kJ/kg) and SiC(13,250 kJ/kg). Compared to latent heat,the SiC-matrix interface resistance has less influence on temperature distribution.At the depth of -0.1 mm, the temperatures of different SiC fraction workpiece increases over aluminum melting point within 5 ms respectively, and then slowly increases with time.The overall temperature is much lower than that of the surface layers. At this depth, the main phase change is the melting of the matrix material. At the depth of -0.2 mm, the material temperature is around the melting point of aluminum after 1.25 ms. Based on the temperature distribution observation,two mechanisms in the temperature increasing process can be known, i.e., the evaporation of SiC and aluminum, and the melting of aluminum. The former occurs on the surface of the workpiece, the later exits in the material interior.

Table 1 Thermal properties of Al.

Table 2 Thermal properties of SiC.

Table 3 Al-SiC interfacial thermal property.

Table 4 Study parameters employed in simulations.

Fig. 4 Simulative 3D temperature calculation result (ton=2 ms).

Fig. 5 Temperature distribution in SiCp/Al composites (ton=2 ms).

3.2. Comparison and verification

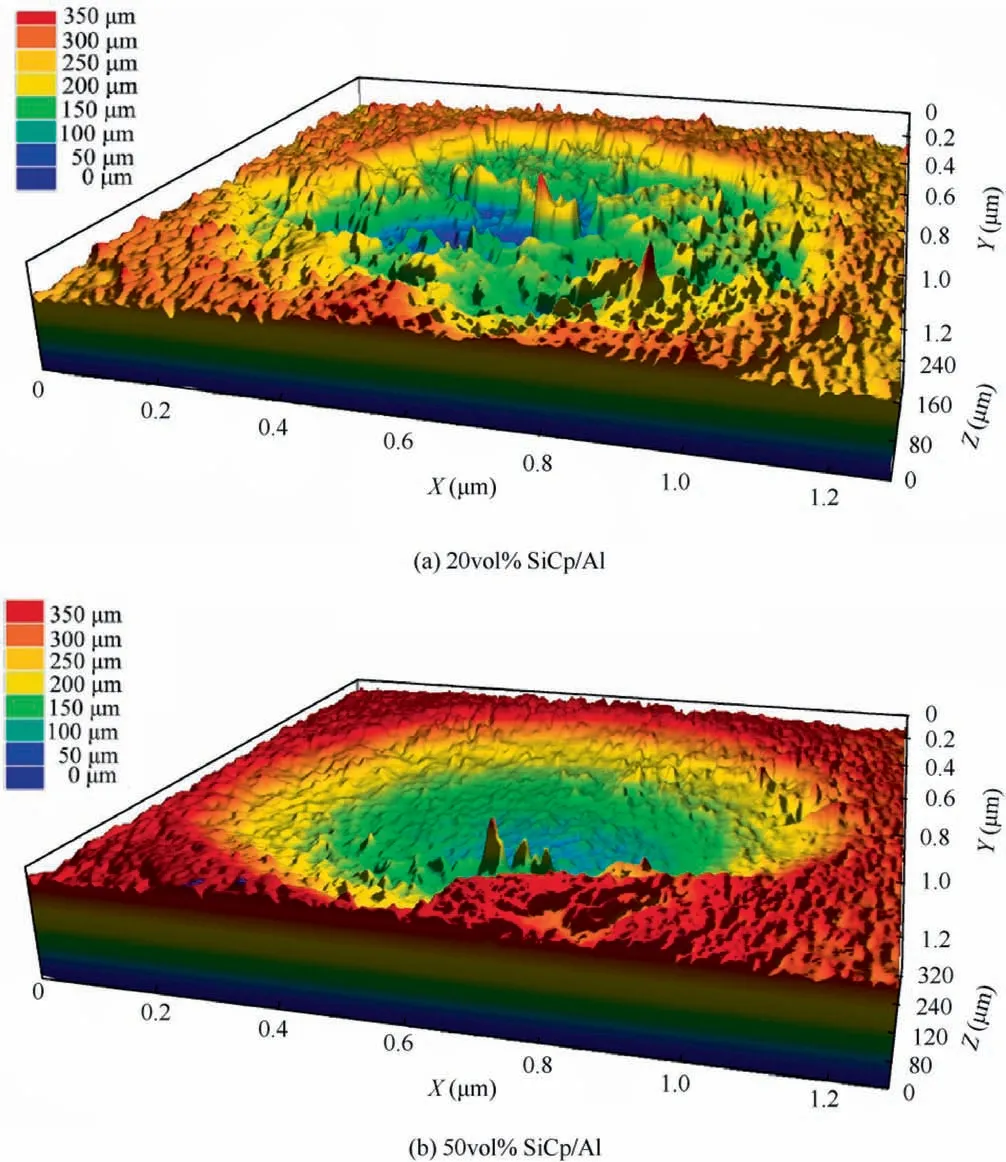

In previous work, an equivalent heat conduction model (Gu’s model)was built to demonstrate the influence of Sic particle on the arc machining.However, the workpiece materials are considered as homogeneous in Gu’s model, and the thermal properties of the workpiece were calculated according to a combination of Al and SiC considering reinforcement fractions. To verify the advantage of the simulation model built in this work, the comparisons between the Gu’s model and experiment results are conducted. The experimental setup was based on a needle-plane single arc discharge device. The workpiece materials used for single discharge experiments were 20vol% SiC/Al and 50vol% SiC/Al composites respectively.The experimental setup,results,and the discharge cater observations (with a laser confocal microscopy-ZEISS LSM700, as shown in Fig. 7) are available in reference.

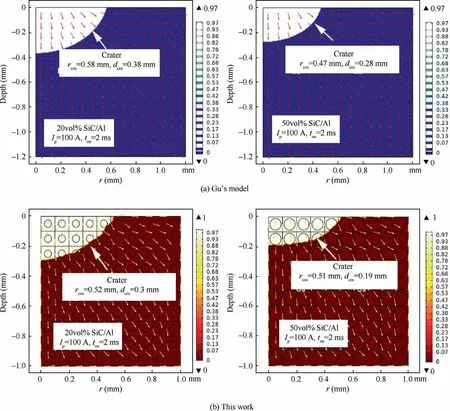

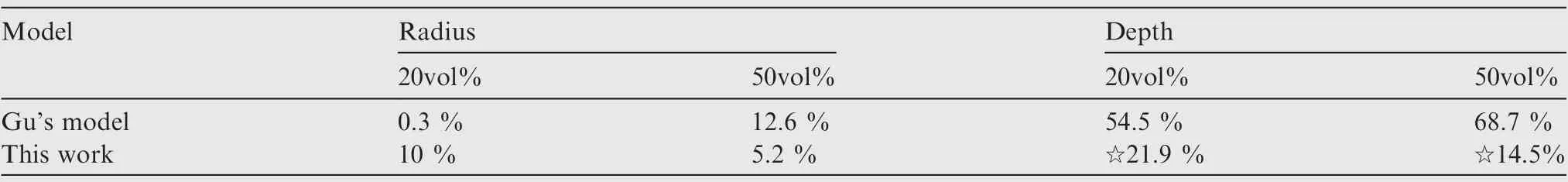

A comparison of a single discharge crater in Gu’s model and this work is shown in Fig. 8. The crater in this work is smaller than that of Gu’s model under the same discharge parameters. The surface of the discharge crater is also not as smooth as that of Gu’s model,this phoneme demonstrates that the SiC particles tend to cause uneven microscopic surfaces(i.e., burr and flashing) which can be observed in Fig. 7. Both Gu’s model and this work are compared with experimental results, as shown in Fig. 9. The maximum crater radiuses of the two models are close to the experimental values, this is because the plasma heating area value adopted in the models is based on the measurement, i.e. a constant value 0.55. However,the crater depths of Gu’s model are much larger than the experimental values. Table 5 shows the error comparison with Gu’s model. The errors of 20vol% SiC/Al and 50vol% SiC/Al crater depths can be as high as 54.5% and 68.7%, which indicates that the previous model method is far from satisfactory.In this work,a new modeling method is adopted,and the errors of crater depth can be reduced to 21.9% and 14.5%respectively, which improves the simulation precision greatly.It is noted that the reason why the new model not showing good enough characteristics for the radius of the discharge crater is that the actual radius of the plasma heating area is not the same for the different SiC/Al composites with different SiC fractions according to measurement value, however, this model uses a uniform value for simplification.Thus,compared to the discharge crater,the crater depth is paid more attention.

4. Discussion

Many factors affect the precision of the simulation model. In this study,an energy distribution value of 0.39 is adopted.This energy distribution coefficient is widely used in traditional EDM studies.However, in the arc discharge, the energy distribution coefficient is likely lower than this value,because the discharge gap in an arc discharge can be higher than 0.2 mm, which is larger than the EDM discharge gap.Thus, the arc plasma is easier to be involved in the heat exchange with the surrounding dielectric and leads to an extra energy loss. A correction coefficient can be employed to overcome this problem since the precise value of arc discharge distribution is not available currently. Table 6 shows the error values when adopting different correction coefficients. When the coefficients change from 1 to 0.8,the average error reduces and then increases.Considering a balance combination of discharge crater radius and depth,the coefficient value 0.85 is recommended in the simulation of arc discharge machining of SiC/Al composites.

Fig. 6 Temperature increasing process at different depth(r=0.1 mm).

Fig. 7 Single pulsed arc discharge crater measured with a laser confocal microscopy.30,31

Fig. 8 Comparison of single-pulsed arc discharge crater of SiCp/Al composites.

Fig. 9 Comparison with Gu’s model and experimental results.

Gu et al.and Chen et al.studied the processing and mechanism of machining SiC/Al composites, and it was found that SiC reinforcement has a negative influence on the machining efficiency, and HAZ thickness, etc. In term of the different discharge crater dimensions,it has been revealed that the extreme temperature-dependent prosperities of SiC reinforcement is the main reason. As shown in Fig. 10, the reinforcements tend to absorb more energy when the temperature increases, as a result, higher reinforcement fraction will lead to a smaller discharge crater and lower machining efficiency. The viewpoint can be proved with the temperature distribution. For instance, the surface temperature of 20vol% SiC/Al material can be 550 K higher than that of 50vol% SiC/Al material. It is found that the higher temperature concentrates on the surface layers of the workpiece, especially when the sic fraction is higher.Since the heat is not easy to conduct and dissipate, the higher SiC fraction workpiece will have a thicker HAZ. For example, the HAZ thickness of 50vol% SiC/Al composites can be 2 times higher than that of 20vol% SiC/Al composites.

Fig.11 shows that the debris size and shape of blasting erosion arc machining SiC/Al materials are quite different. The low SiC fraction SiC/Al material debris has a larger size and contains full SiC particles inside, while most of the high SiC fraction SiC/Al material has a smaller size and even without containing SiC particle interiorly.Gu et al.explained the above phenomenon with a hypothesis: a molten pool is filled with liquidated aluminum and solid SiC particles,the flowability of the molten aluminum with higher SiC fraction is much worse than that of the lower SiC fraction SiC/Al composites.Because the solid SiC particles are too much for the molten aluminum to take away, they tend to be left on the workpiece surface and sublimated by the arc plasma.

The temperature distribution observed in this work can be used to support Gu et al.’s hypothesis.The temperature of the workpiece surface layer is higher than the evaporation point of both Al and SiC, which will cause the sublimation of SiC and evaporation of Al. And the temperature is lower than 2743 K(evaporation point of Al) at a depth range from -0.1 mm to-0.3 mm, which will form a molten aluminum pool. Since the temperature increasing tendency is almost the same regardless of the SiC fractions,the melting and evaporation of different SiCp/Al composites should be similar.The difference lies in the ejection process of the melton material. Since high SiC fraction material contains more SiC particles, they are overheated by plasmas without the full protection of aluminum liquid and sublimate. The sublimation of SiC absorbs plasma heat, which will also decline the temperature of the plasma.As evidence, the surface temperature of 20vol% SiCp/Al is higher than that of 50vol% SiCp/Al composites.

Table 5 Error comparison with Gu’s model.

Table 6 Crater errors using different correction coefficients.

Fig. 10 Equivalent thermal parameters of SiCp/Al composites.

Fig. 11 Discharge debris of SiCp/Al composites.

5. Conclusions

This work built a new simulation model of single-pulsed arc discharge of SiC/Al matrix materials, the following conclusions can be drawn.

(1) The SiC-matrix cell geometric model for the heat conduction calculations of SiC/Al matrix materials is feasible. The model build in this work improves the simulation accuracy observably compared to the previous model.

(2) The highest surface temperature of SiC/Al workpiece is higher than 3300 K and the high temperature is found to concentrate on the surface layers of the workpiece,especially when the SiC fraction is high.Also,the peak value of the workpiece surface temperature decreases with the increase of SiC fraction.

(3) At the evaporation point of Al and SiC,the temperature fluctuation can be found respectively because of the high latent heat of Al and SiC. Compared to latent heat, the SiC particle-Al matrix interface resistance has less influence on temperature distribution.

(4) Two mechanisms in the temperature increasing process can be known, i.e., the evaporation of SiC and Al, and the melting of Al, the former occurs on the surface of the workpiece, the later exits in the material interior.

(5) Temperature increasing tendency is almost the same regardless of the SiC fractions,the melting and evaporation of different SiC/Al composites should be similar,and the difference lies in the ejection process of the melton material.

Acknowledgments

This work was supported by the following foundations:Natural Science Foundation of China (Nos. 51975371, 51575351),Innovation and Entrepreneurship Project for High-level Talents in Jiangsu Province (No. 164040022), Youth science and Technology Innovation Foundation of NJFU of China(No. CX2018017).

杂志排行

CHINESE JOURNAL OF AERONAUTICS的其它文章

- Optimal trajectory and downlink power control for multi-type UAV aerial base stations

- Effects of flow parameters on thermal performance of an inner-liner anti-icing system with jets impingement heat transfer

- Effects of wing flexibility on aerodynamic performance of an aircraft model

- Aerodynamic performance enhancement of co-flow jet airfoil with simple high-lift device

- Adaptive fuzzy terminal sliding mode control for the free-floating space manipulator with free-swinging joint failure

- Influence of longitudinal-torsional ultrasonicassisted vibration on micro-hole drilling Ti-6Al-4V