Comparison of grain yield and quality of different types of japonica rice cultivars in the northern Jiangsu plain,China

2021-06-24BIANJinlongRENGaoleiXUFangfuZHANGHongchengWEIHaiyan

BIAN Jin-long,REN Gao-lei,XU Fang-fu,ZHANG Hong-cheng,WEI Hai-yan

Jiangsu Key Laboratory of Crop Genetics and Physiology/Jiangsu Co-Innovation Center for Modern Production Technology of Grain Crops,Yangzhou University,Yangzhou 225000,P.R.China

Abstract In recent years,an increasing number of different types of japonica rice cultivars have been released in the southern rice region of China. The grain yield and quality of these new cultivars showed significant differences in large scale planting. However,the causes of the differences remain little known. Therefore,three typical types of japonica rice cultivars were used in this study to investigate their grain yield and quality. A scanning calorimeter (DSC),X-ray powder diffractometer (XRD),rapid viscosity analyzer (RVA) and taste analyzer were used to evaluate the cooking and eating properties. The results showed that the yield of non-soft hybrid japonica rice cultivars was significantly higher than that of non-soft inbred japonica rice cultivars and soft inbred japonica rice cultivars. Soft inbred japonica rice cultivars had a low amylose content and moderate protein content,which are the main reasons for the superior cooking and eating quality. In addition,the relative crystallinity of soft inbred japonica rice cultivars was significantly higher than that of non-soft inbred and non-soft hybrid japonica rice cultivars,which is considered the major factor resulting in higher transition temperature and gelatinization enthalpy (ΔHgel). Non-soft hybrid japonica rice cultivars had a higher number of large starch granules than soft inbred and non-soft inbred japonica rice cultivars. The setback value (SB) and breakdown value (BD),indirectly reflecting the cooking and eating quality of the three types of japonica rice cultivars,also confirmed that soft inbred japonica rice cultivars with a low SB value and a high BD value had better palatability than the other two types. This study provides guidance for future plantation of different types of japonica rice cultivars in large rice-producing areas.

Keywords:yield,eating and cooking quality,starch,amylose content,thermal properties

1.Introduction

Rice (Oryza sativaL.) is the largest cereal crop in Jiangsu Province,China,with an average annual planting area of 2.2 million hectares and an annual yield of 19 million tons,accounting for approximately 40 and 60% of the provincial total cropping area and grain yield,respectively (Zhanget al.2010). In the 1950s,the planting area ofindicarice,cultivated mainly in Jiangsu,accounted for nearly 56% of the province’s total rice planting area,which was considerably higher than that ofjaponicarice (35%).However,in the 1960s,with the improvement of fertilizer and water management,japonicarice gradually replacedindicarice to be the largest staple crop planted in Jiangsu. In 2010,the planting area ofjaponicarice was more than 80% of the total rice planting area in Jiangsu (Zhanget al.2010).Japonicarice cultivars have a stable yield with good disease resistance and strong regional adaptability. To obtain high yield,some non-soft hybridjaponicarice cultivars such as the Yongyou series were released around the year 2000 (Zhuet al.2017b). These non-soft hybridjaponicarice cultivars have a high yield potential. For example,the yield of some non-soft hybridjaponicarice cultivars,such as Yongyou,was 10-15% higher than that of non-soft inbred and hybridjaponicarice cultivars (Jianget al.2014). With an improved standard of living in China,the demand for high-quality rice has increased annually in the domestic market. In addition,the government of China proposed a supply-side structural reform in 2015,which called for high-quality production in agriculture. In order to meet increased rice demand,some inbredjaponicarice cultivars (mainly soft inbredjaponicarice) with high cooking and eating quality emerged. During the development ofjaponicarice production,there are few reports on the yield and quality of the three different types ofjaponicarice cultivars (soft inbred,non-soft inbred and nonsoft hybridjaponicarice). Therefore,this research seeks to provide valuable guidance in terms of yield and quality for future rice cultivar selection and production.

Genotype of seed is a major determination of yield and quality of crops (Krishnan and Surya 2005). A previous study that focused on the yield and rice quality of different types of non-soft hybridjaponicarice cultivars showed that non-soft hybridjaponicarice had higher yield and harder taste compared with non-soft inbredjaponicarice (Xuet al.2018). A previous study examined the yield and associated component characteristics of different types of rice cultivars and indicated that large panicles were the basis of high yield of non-soft hybridjaponicarice cultivars (Jianget al.2014). Research on the eating quality of three soft inbredjaponicarice cultivars showed that soft inbredjaponicarice had better palatability and was more sticky than cooked rice (Zhaoet al.2019). In addition to genetic factors,the cooking and eating quality traits of rice are also influenced by the environmental conditions and cultivation practices. Some researches indicated that under mechanical transplanting with carpet seedlings,the amylose content decreased,the gel consistency increased and the cooking and eating quality improved significantly (Huoet al.2012;Bianet al.2018). The physicochemical and structural properties of rice starches under different nitrogen management varied greatly,as the percentage of nitrogen used in the panicle initiation stage increased,the content of small starch granules improved,whereas the content of large granules decreased (Zhuet al.2016). In addition,previous research found that the cooking and eating quality has also long been ascribed to starch properties (Martin and Fitzgerald 2002) including the length of amylopectin chains,the gelatinization temperature and the granule structure of rice starch (Slade and Levine 1988;Hanashiroet al.1996;Zhuet al.2017a). Previous studies onjaponicarice quality mainly focused on single genotype or different cultivation practices. There is a lack of studies on the differences in rice quality and starch properties among different types ofjaponicarice cultivars,especially soft inbredjaponicarice cultivars. Therefore,it is imperative to undertake a detailed study on the three different types ofjaponicarice cultivars to provide a comprehensive understanding of their yield and quality variations.

2.Materials and methods

2.1.Plant materials and experimental design

The experiment was conducted at Huanghai Farm (38°39´6.48´´N and 104°04´35.11´´E),Jiangsu,during the rice cropping season in 2017 and 2018. The soil type of the field where wheat was previously cultivated was clay. The contents of total nitrogen,available phosphorus and available potassium in the soil were 1.5 g kg-1,34.4 mg kg-1and 88.6 mg kg-1,respectively. Two non-soft hybridjaponicarice cultivars (Yongyou 4949 and Yongyou 6763) and four conventionaljaponicarice cultivars were used in this study;the four conventional cultivars included two nonsoft inbredjaponicacultivars (Huaidao 5 and Wuyunjing 27) and two soft inbredjaponicacultivars (Nanjing 505 and Huzaoruanjing).

The cultivars were grown in completely randomized blocks.The plot area was 25 m2(5 m×5 m),with three replicates per cultivar. Seeds were sown on May 29,and the seedlings were transplanted on June 19,in both years. The transplanting density was 30.0 cm×12.0 cm. The total N application rate was 270 kg ha-1,and N was applied in four split doses:30% as basal fertilizer,30% at the initiation of tillering,20% at panicle initiation,and 20% when the rice had two leaves that were not fully formed. Nitrogen was applied as urea,with an N content of 45.6%. In each plot,calcium superphosphate (P2O5content:12%) was applied as basal fertilizer at the rate of 135 kg P2O5ha-1. Similarly,potassium chloride (K2O content:60%) was applied at rates of 135 and 135 kg K2O ha-1as basal fertilizer and at the panicle initiation stage,respectively.

Plots were kept flooded at 1-2 cm water depth when transplanting occurred. During the tillering phase,2-3 cm of water depth was retained in the plots,and then water was drained to control inefficient tillers when the number of stems and tillers was approximately 80% of the prospective panicles. After the stem elongation stage,alternate wetting and moderate soil drying irrigation management was used until 1 wk before the final harvest. Other field practices (weed,insect and disease control) conformed to local recommendations.

2.2.Harvesting and rice quality measurements

Grain yield was determined from all plants in a 5-m2area (except border plants) in each plot and was adjusted to a moisture content of 14%. For assay of grain yield components,we investigated panicle number from 50 hills in each plot,and 15 hills were collected in each plot to investigate the number of spikelet per panicle,filled grain percentage and filled grain weight. Filled grain weight was determined using 1 000 grains.

About 500 g of grains harvested from each plot were used for analysing the appearance quality and processing quality. A 150-g sample of rice grains was passed twice through a dehusker,then separated into broken and unbroken grains. The brown rice rate,milled rice rate and head rice rate were expressed as percentages of total (150 g) rice grains. Chalkiness was evaluated visually on 100 milled grains per plot. Grains were considered chalky if they contained 20% or more of white belly,white center,white back,or a combination of these.

Taste Analyzer STA 1 A (Satake,Japan) was used to assess the taste value of the rice grains. The apparent amylose content was measured according to the methods described by Zhuet al.(2017b). The apparent amylose content was calculated from the absorbance that was measured at a wavelength of 620 nm,with reference to a standard curve that was prepared using amylopectin from corn and amylose from potato. The Infrared 1241 Grain Analyzer from FOSS TECATOR (Sweden) was used to measure the protein content.

2.3.Starch properties

Starch isolationStarch was isolated from six rice cultivars according to the method in a previous study (Lu and Lu 2012). Rice flour (20 g) was steeped in a 0.45% sodium hydroxide solution with 10 mg g-1alkaline protease at room temperature for 24 h to remove the protein. The homogenate was sieved (200 mesh),and the residue remaining on the mesh sieve was collected. The residues were mixed with 30 mL of deionized water,stirred for 2 min,and then sieved (200 mesh) again. The filtered starch slurry was centrifuged at 3 000×g for 10 min. The supernatant was discarded,and the faintly colored upper residual layer was removed;the remaining white layer was resuspended with 20 mL of deionized water and centrifuged at 3 000×g for 10 min,after which the supernatant was removed. The above-mentioned centrifugal steps were repeated five times to ensure that the impurities were completely removed. Finally,the starch was then dried at 30°C at ambient pressure and collected with a 200-mesh sieve.

Analysis of granule sizeThe granule weight distribution of starch was measured using a laser diffraction particle size analyzer (Mastersizer 2000,Malvern,England) following the procedure described by Zhuet al.(2017b). Granule size distribution was recorded in terms of volume distribution and granules viewed by scanning electron microscopy.

Observation of starch granule morphologyThe observation of starch granule morphology was conducted using scanning electron microscopy (XL-30 ESEM,Philips) according to the method of Zhuet al.(2017b). A starch ethanol solution (2 mL) was dropped onto an aluminum foil film and dried at 40°C for 4 h. Then,starch samples were coated with gold dust,observed and photographed using scanning electron microscopy. The results of observation of starch granule morphology were consistent for two years,with only 2018’s data presented in Fig.1.

Fig.1 Scanning electron micrographs of starches isolated from three types of japonica rice cultivars (2018). Soft inbred japonica rice,Nanjing 505 and Huzaoruanjing;non-soft inbred japonica rice,Huaidao 5 and Wuyunjing 27;non-soft hybrid japonica rice,Yongyou 4949 and Yongyou 6763.

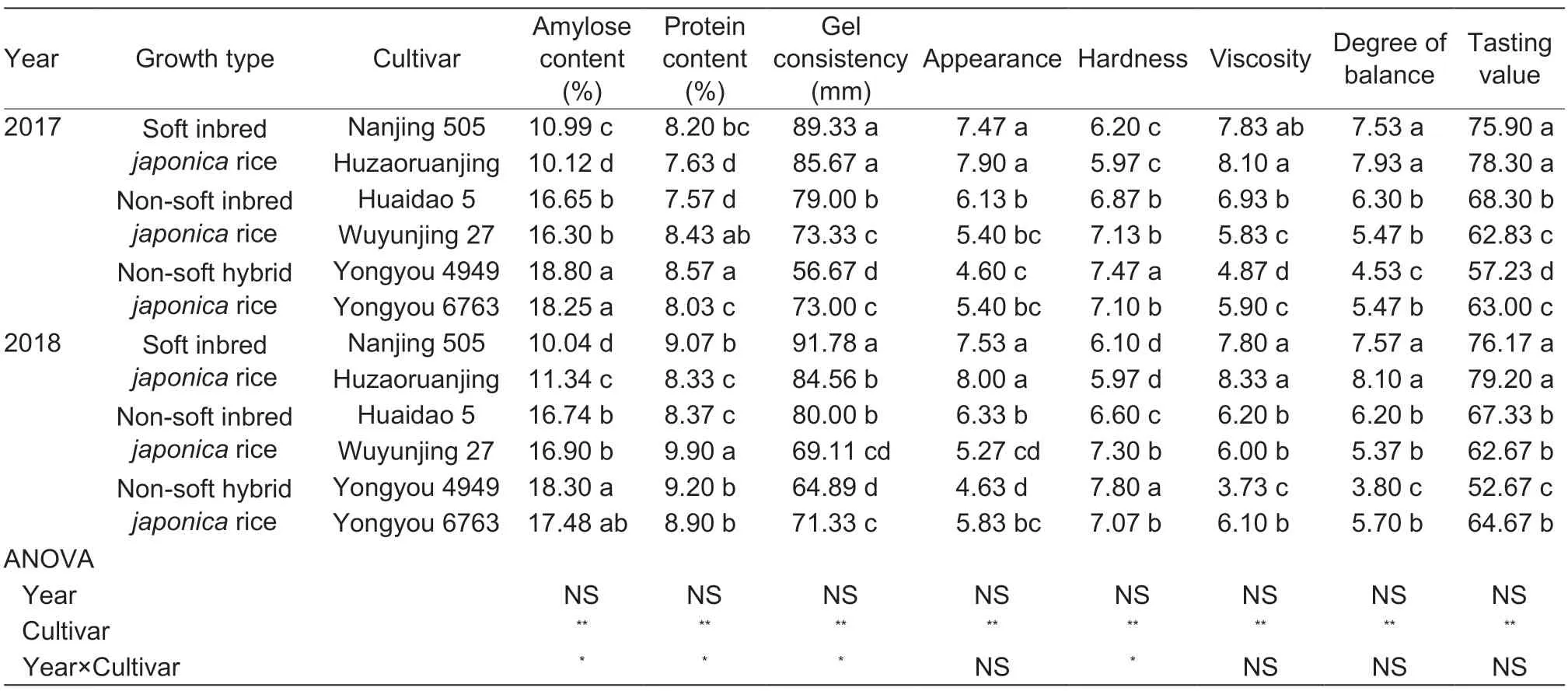

X-ray diffraction analysisX-ray diffraction patterns were generated using anX-ray powder diffractometer (XRD) (D8 Advance,Bruker-AXS,Germany) that was operated at 200 mA and 40 kV,over a diffraction angle (2θ) range of 3 to 40°,with a step weight of 0.02°,and a sampling interval of 0.6 s. Relative crystallinity (%) was calculated using MDI Jade 6 Software. The results ofX-ray diffraction analysis were consistent for two years,with only 2018’s data presented in Fig.2.

Fig.2 X-ray diffraction patterns of three types of japonica rice cultivars (2018). Soft inbred japonica rice,Nanjing 505 and Huzaoruanjing;non-soft inbred japonica rice,Huaidao 5 and Wuyunjing 27;non-soft hybrid japonica rice,Yongyou 4949 and Yongyou 6763.

Thermal properties of starch and pasting propertiesThe thermal properties of starch were determined using differential scanning calorimetry (DSC) (Model 200 F3 Maia,NETZSCH,Germany) according to the method of Lu and Lu (2012). Starch samples (5 mg,dry weight) were mixed with 10 μL of water and sealed in an aluminum pan at 4°C for 12 h. After equilibrating at room temperature for 1 h,the samples were scanned against a blank (empty pan) at a heating rate of 10°C min-1from 25 to 100°C. The retrogradation percentage (%R) was calculated as %R=ΔHret/ΔHgel×100,where ΔHret,retrogradation enthalpy;ΔHgel,gelatinization enthalpy.

In this experiment,the viscosity characteristics of rice flour were determined using an RVA (Model no.RVA-3D;Newport Scientific,Sydney,Australia) according to the method described by Hanet al.(2004). Viscosity values were recorded as centipoises (cP). The primary components of starch viscosity characteristics include peak viscosity,trough viscosity and final viscosity. The secondary components,such as breakdown and setback,were calculated from the primary components. The breakdown value was calculated by subtracting trough viscosity from peak viscosity,while the setback value was calculated by subtracting peak viscosity from final viscosity.

2.4.Statistical analysis

The data reported were the averages of triplicate observations.One-way ANOVA and Tukey’s test (P<0.05) were conducted using IBM SPSS Statistics 22.0 (Bakhshi 2009).

3.Results

3.1.Grain yield

The grain yield of the three different types ofjaponicarice cultivars varied greatly,as shown in Table 1. Yongyou 6763 had the highest yield in both years,while Wuyunjing 27 and Nanjing 505 had the lowest yield in 2017 and 2018,respectively. The yield of the two non-soft hybridjaponicarice cultivars was significantly higher than that of non-soft inbred and soft inbredjaponicarice cultivars.

Based on a comparison of the yield components of the three cultivar types,it was found that a high number of spikelets per panicle was the main reason for the high yield of non-soft hybridjaponicarice cultivars. The panicle number and filled grain percentage of the two non-soft hybridjaponicarice cultivars were significantly lower than those of non-soft inbred and soft inbredjaponicarice cultivars. The yield components were significantly different among rice cultivars,with no significant change between years.

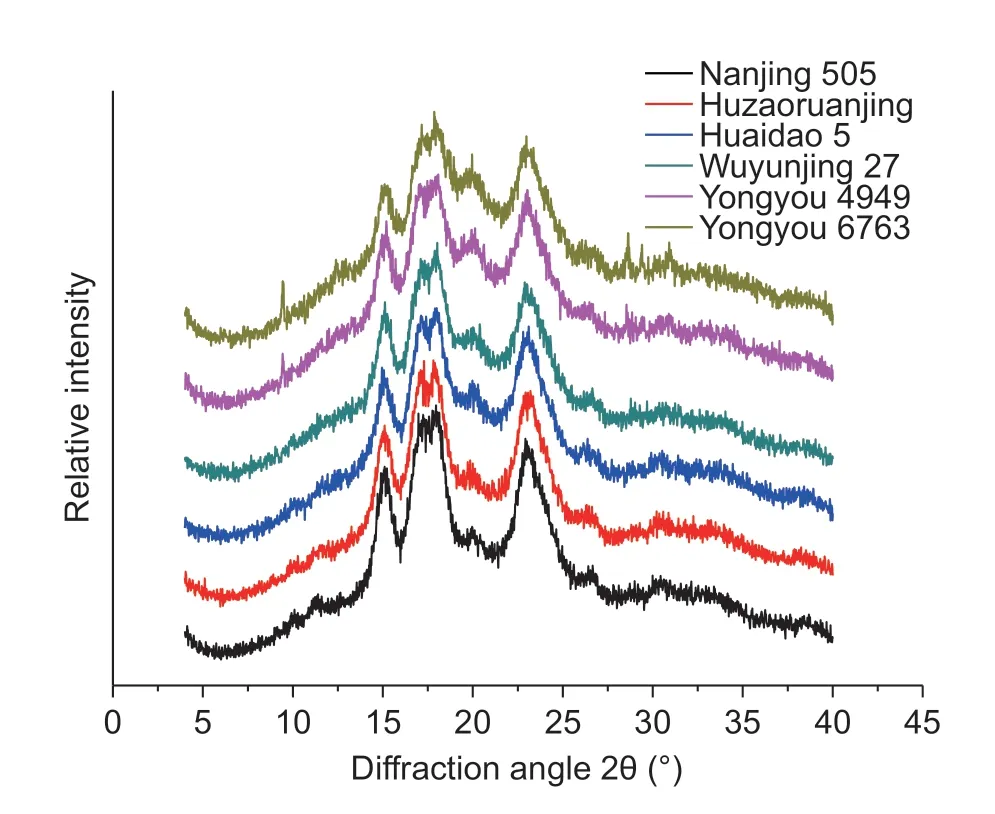

3.2.Processing quality and appearance quality

The two soft inbredjaponicarice cultivars exhibited a more stable processing quality than non-soft inbred and non-soft hybridjaponicarice cultivars (Table 2). The grain shape of the two non-soft hybridjaponicarice cultivars was slenderer than that of the non-soft inbred and soft inbredjaponicarice cultivars. The two soft inbredjaponicarice cultivars had a significantly higher chalk occurrence in rice grains than non-soft inbred and non-soft hybridjaponicarice cultivars. The processing quality and appearance quality were significantly different among rice cultivars,with no significant change between years.

Table 2 Processing quality and appearance quality of three types of japonica rice cultivars1)

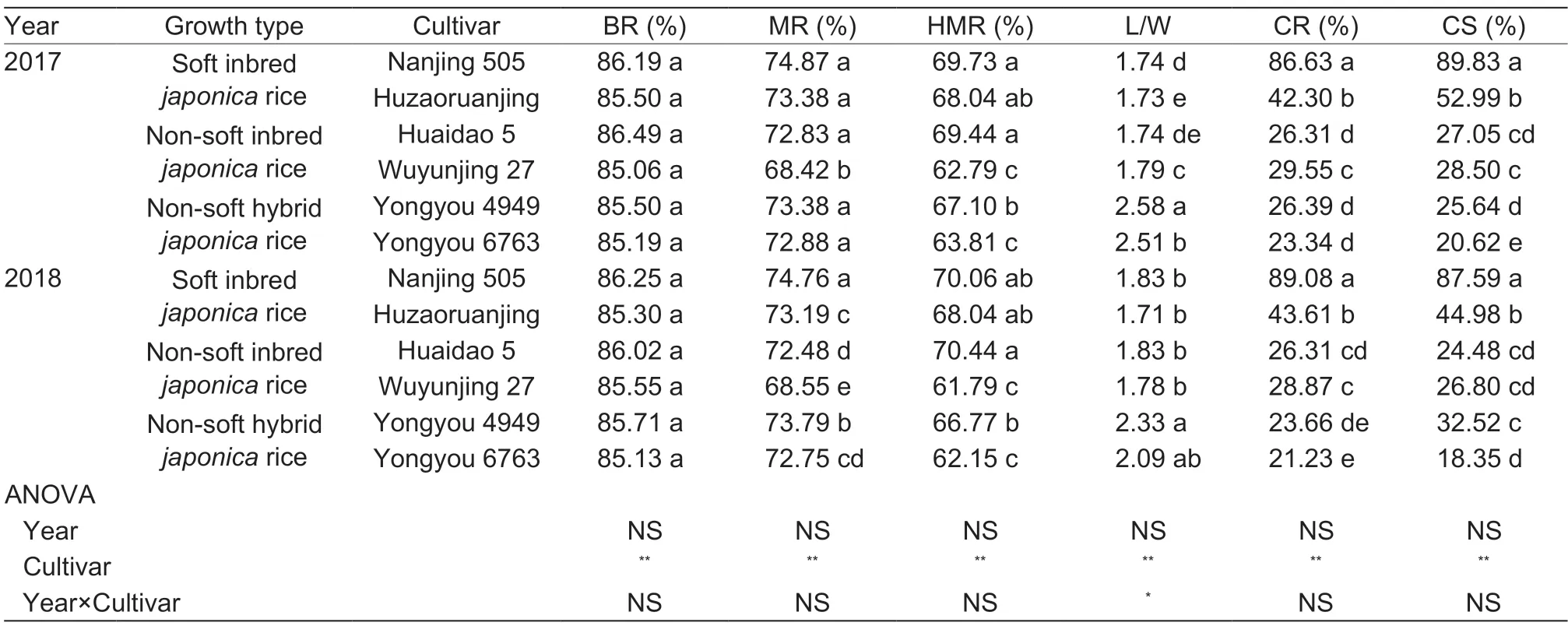

3.3.Cooking and eating quality

The tasting value was significant influenced by genetic characteristics of rice cultivars (Table 3). The tasting values ranged from 52.67 to 79.20;Huzaoruanjing and Yongyou 4949 had the highest and lowest tasting values,respectively. The tasting values of the two soft inbredjaponicarice cultivars were significantly higher than those of non-soft inbred and non-soft hybridjaponicacultivars.As shown in Table 3,there were significant differences in quality traits of cooked rice,such as appearance,hardness,viscosity,and degree of balance,among the three types ofjaponicarice cultivars.

3.4.Apparent amylose content,protein content and gel consistency

The apparent amylose content,protein content and gel consistency varied greatly among the three types of cultivars (Table 3). The apparent amylose content decreased from 18.80 to 10.04% in the following order:non-soft hybridjaponicacultivars,non-soft inbredjaponicacultivars and soft inbredjaponicarice cultivars. Huzaoruanjing had the lowest apparent amylose content while Yongyou 4949 had the highest.

Table 3 Cooking and eating quality traits of three types of japonica rice cultivars

The protein content of different types ofjaponicacultivars is shown in Table 3. Huzaoruanjing and Huaidao 5 had lower protein contents than the other four rice cultivars,while Yongyou 4949 and Wuyunjing 27 had the relatively high protein content.

Gel consistency differed significantly among the cultivar types (Table 3). The two soft inbredjaponicarice cultivars had significantly higher gel consistency than the non-soft inbred and non-soft hybridjaponicarice cultivars. Gel consistency ranged from 56.67 to 91.78 mm;Nanjing 505 had the highest gel consistency,whereas Yongyou 4949 had the lowest gel consistency.

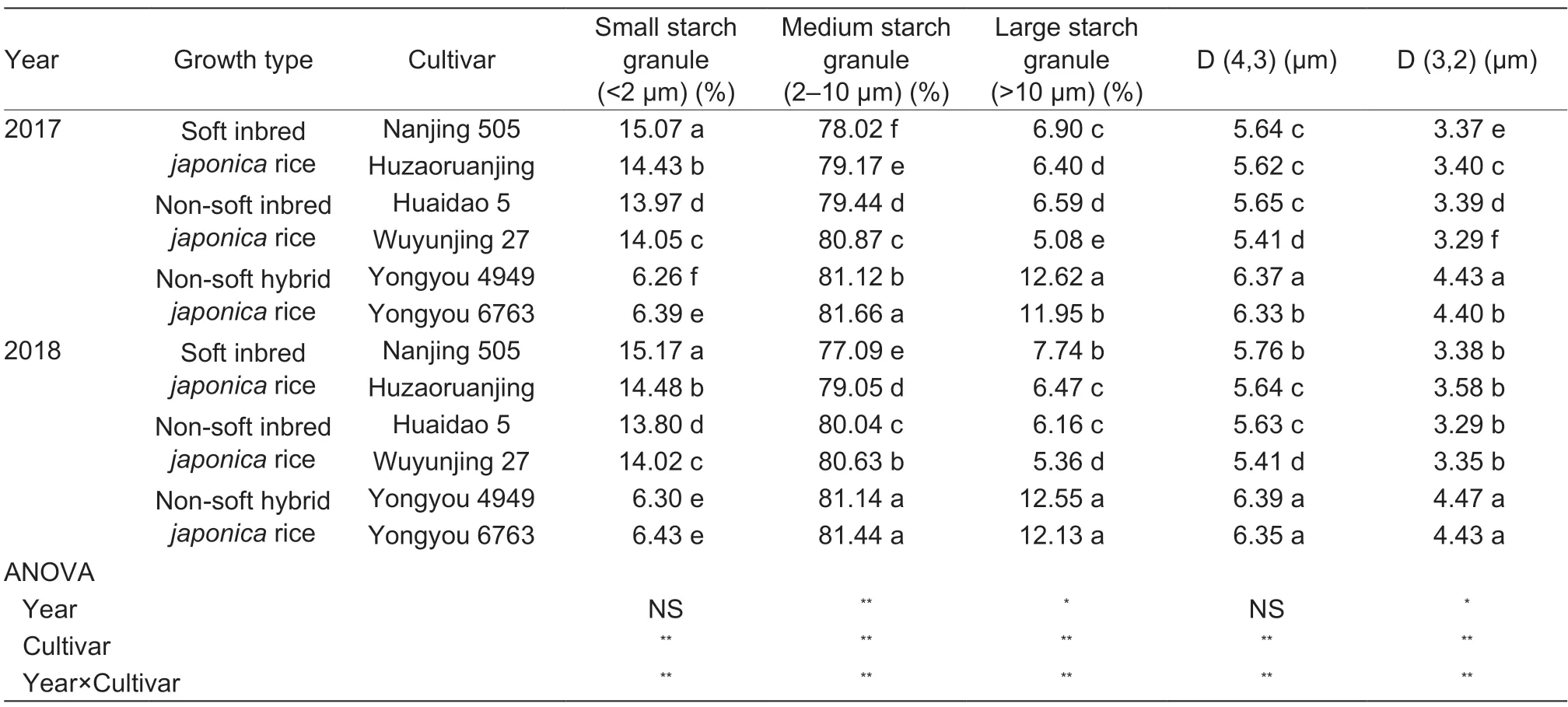

3.5.Morphological structure of starch

The morphological structure of the starch granules from three types ofjaponicarice cultivars is depicted in Fig.1. The shape of most granules was an irregular polyhedron,and the surface of most granules was smooth.We also observed large starch granules in the two non-soft hybridjaponicarice cultivars (Table 4).

The size distribution of starch granules showed significant variations among different types ofjaponicarice cultivars (Table 4). The distribution percentage of smallsized granules (<2 μm) varied from 6.26% (Yongyou 4949) to 15.17% (Nanjing 505),and the distribution percentage of large-sized granules ranged from 5.08% (Wuyunjing 27) to 12.62% (Yongyou 4949). The two non-soft hybridjaponicarice cultivars had more large and medium starch granules and fewer small starch granules compared with soft inbredand non-soft inbredjaponicarice cultivars. The D (4,3) and D (3,2) values represent the mean volume of the granules and the mean surface area of the granules,respectively. The D (4,3) and D (3,2) values of the two non-soft hybridjaponicarice cultivars were significantly higher than those of the soft inbred and non-soft inbredjaponicarice cultivars.

3.6.Crystalline structure of starch

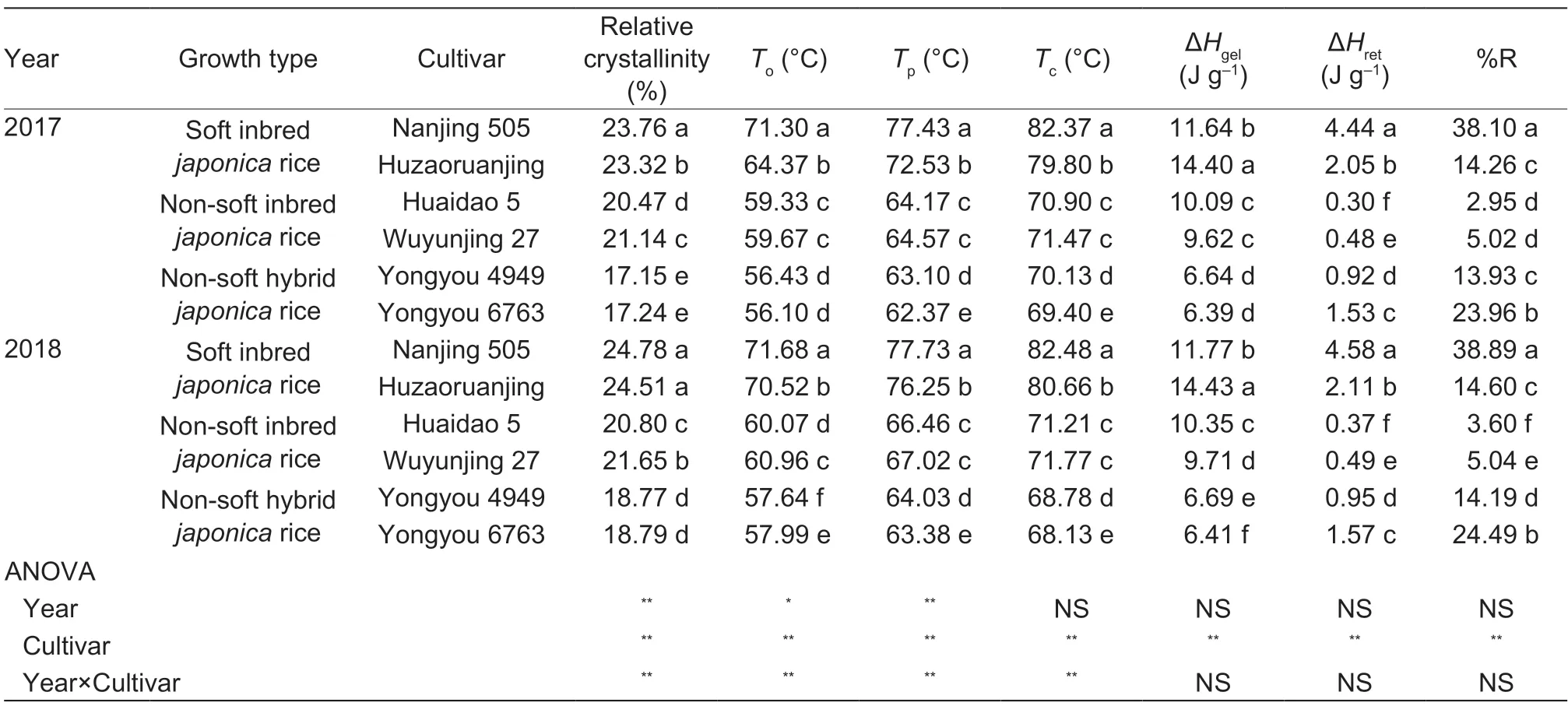

Based on theX-ray diffraction patterns of differentjaponicarice cultivars,as shown in Fig.2,all rice starch was type A. Strong peaks of the starch samples from the six cultivars emerged at approximately 15° and 23° 2θ,and an unresolved doublet peak was observed at 17° and 18° 2θ. The relative crystallinity among the three cultivar types was significantly different (Table 5),ranging from 17.15 to 24.78%. Relative crystallinity decreased successively from soft inbredjaponicarice cultivars to non-soft inbredjaponicacultivars and non-soft hybridjaponicacultivars.The starch observed in Nanjing 505 had the highest relative crystallinity while that in Yongyou 4949 had the lowest relative crystallinity in both two years.

3.7.Thermal properties of starch

The transition temperatures (To,TpandTc) and ΔHgelgradually declined in the order of soft inbredjaponicarice,non-soft inbredjaponicarice and non-soft hybridjaponicarice cultivars (Table 5). ΔHretshowed variations among the cultivars;the two non-soft inbredjaponicarice cultivars had low ΔHret,while the two soft inbred rice cultivars had high ΔHret. The soft inbredjaponicarice cultivar Nanjing 505 had the highest %R (38.89),while the non-soft inbredjaponicacultivar Huaidao 5 had the lowest %R (2.95).

Table 4 Starch granule size distribution of three types of japonica rice cultivars

Table 5 Thermal properties and relative crystallinity of three types of japonica rice cultivars1)

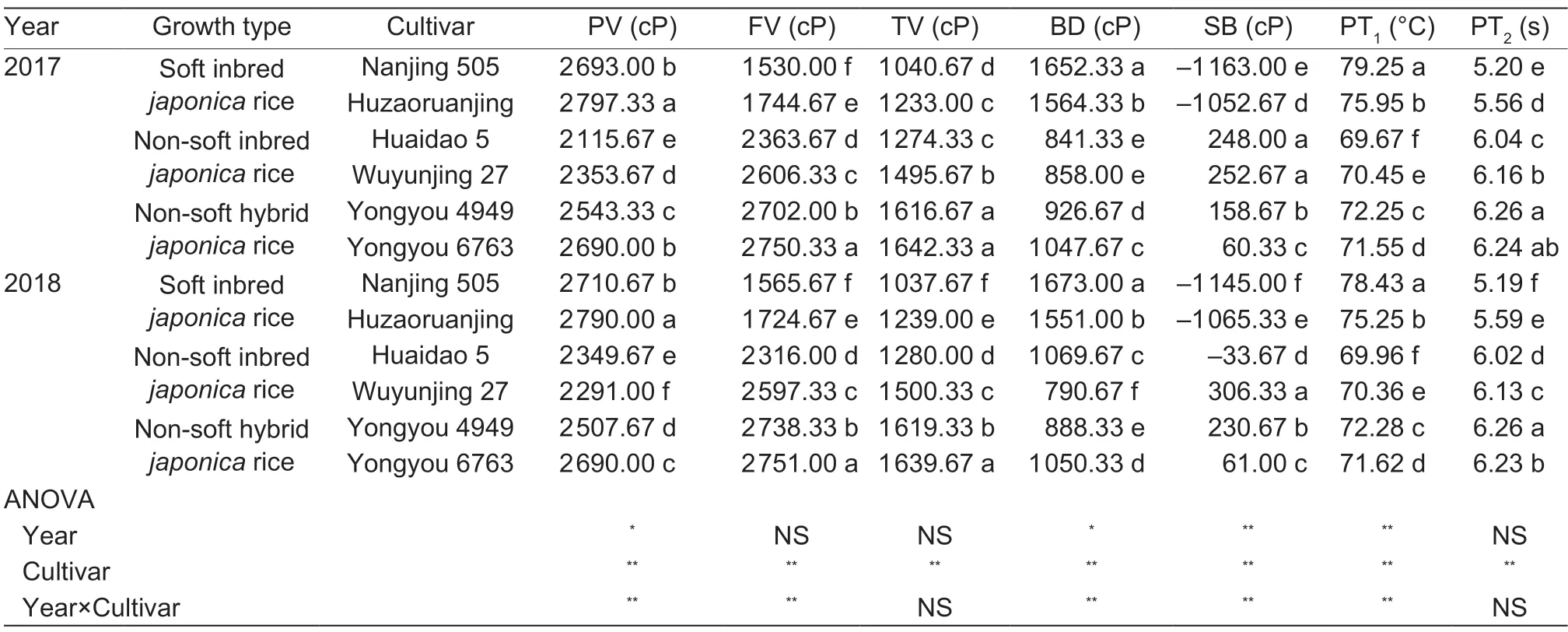

3.8.Pasting properties of rice grains

The rapid viscosity analyzer profiles are shown in Table 6.Final viscosity (FV),trough viscosity (TV) and pasting temperature (PT1) increased in the order of soft inbredjaponicarice,non-soft inbredjaponicarice and non-soft hybrid rice cultivars. The breakdown value of the soft inbredjaponicarice cultivars was significantly higher than that of the non-soft inbred and non-soft hybridjaponicarice cultivars. On the contrary,the soft inbredjaponicarice cultivars had the lowest setback value.

Table 6 Pasting properties of three types of japonica rice cultivars1)

4.Discussion

4.1.Grain yield

In recent years,there have been many reports on the yield of differentjaponicarice cultivars (Liet al.2012;Jianget al.2014). A previous study found that non-soft hybridjaponicarice has obvious advantages in yield compared with conventional hybrid and non-soft inbredjaponicarice cultivars (Jianget al.2014). Large panicles are the basis of the high yield potential of non-soft hybridjaponicarice cultivars. A low filled-grain percentage remains a constraint of further improving the yield of non-soft hybridjaponicarice cultivars. The number of spikelets per panicle of non-soft inbred and soft inbredjaponicarice cultivars was significantly lower than that of non-soft hybridjaponicarice cultivars in this study,so it is feasible to increase yield by increasing grain number per panicle (Zhouet al.1997).

4.2.Processing quality and appearance quality

Rice processing quality,also known as grinding quality,includes the values of brown rice rate,milled rice rate and head rice rate. Zhaoet al.(2005) hypothesized that processing quality was mainly affected by the extent of grain filling. Sufficient effective grain-filling time and stable grain-filling rate were conducive to improving the degree of grain filling,while insufficient grain-filling time and abnormal grain-filling speed deteriorated processing quality (Yanget al.2000;Yang and Zhang 2010;Huoet al.2012). This might be the main reason why the two soft inbredjaponicarice cultivars exhibited a stabler processing quality than non-soft inbred and non-soft hybridjaponicarice cultivars in this study. The grain shape of the two non-soft hybridjaponicarice cultivars was slenderer than that of the non-soft inbred and soft inbredjaponicarice cultivars. Some study showed that stubby rice was more difficult to break during processing (Wanget al.2012;Suiet al.2014).

Chalkiness is a complex trait controlled by multiple genes (Linet al.2015),and environmental factors during the grain-filling period also exert a significant effect on it (Bianet al.2018). The high chalkiness of the two soft inbredjaponicarice cultivars in this study was mainly due to genetic factors. Previous studies found that the deletion of certain genes (Wx or OsbZIP58) resulted in a significant decrease in the apparent amylose content,and the endosperm presented a powdery or opaque phenotype (Mikamiet al.1999;Wanget al.2013). The structure of amylopectin changed significantly while the apparent amylose content decreased. It was reported that short-chain amylopectin in the endosperm promoted chalkiness (Kohet al.1999;Sheet al.2010),and soft inbredjaponicarice cultivars tended to have more short chain amylopectin than other cultivars (Ong and Blanshard 1995). It seems reasonable that more short chain amylopectin in the starch of soft inbredjaponicarice might be an important reason for high chalkiness and high cooking quality of these cultivars. Therefore,the chain length distributions of different types ofjaponicarice cultivars deserve further studies.

4.3.Cooking and eating quality traits and starch properties

Cooking and eating quality is usually tested based on artificial sensory taste,which is an effective way to reflect people’s preference of cooked rice. Nevertheless,the result of artificial sensory taste depends on a tester’s preference,with strong subjectivity. The use of a taste analyzer is an objective and accurate way to evaluate cooking and eating quality (Zhanget al.2009). In this study,the two soft inbredjaponicarice cultivars had a significantly higher tasting value than non-soft inbred and non-soft hybridjaponicacultivars. The low apparent amylose content and high gel consistency were remarkable characteristics of the two soft inbredjaponicarice cultivars. Cooked rice with a low apparent amylose content is generally soft and sticky with individual grains adhering closely (Sandhya and Bhattacharya 1989). It is generally acknowledged that rice cultivars with higher gel consistency have better palatability (Donget al.2007). Protein is an important component of rice grain;a high protein content can decrease rice cooking and eating quality by increasing the hardness of cooked rice (Brendaet al.1999). We also observed that there was no significant difference in the apparent amylose content between the two non-soft inbredjaponicarice cultivars (Huaidao 5 and Wuyunjing 27),but their tasting value differed significantly. This was mainly caused by the protein content;if rice cultivars have little difference in the apparent amylose content,the higher the protein content,the harder the rice,the poorer the viscosity,and the worse the texture characteristics (Martin and Fitzgerald 2002).

Rapid viscosity analyzer (RVA) profiles are generally used as an indirect method for evaluating cooking and eating quality (Reddyet al.1994;Champagneet al.1999). The two non-soft inbredjaponicarice cultivars had lower PV values than soft inbred and non-soft hybridjaponicarice cultivars (Table 6). The main reason for the differences in PV values might be the differences in the apparent amylose content and protein content among the cultivars. Rice cultivars with a lower apparent amylose content have a higher PV value because amylose can prevent starch granules from swelling and help maintain the structure of swollen granules (Sanget al.2008;Zhuet al.2016). Protein and starch complexes have different structures and molecular masses,which can significantly affect the pasting properties of rice flour. A previous study found that peak viscosity increased after more glutelin was added to rice flour (Chrastil 1990). The high TV and FV values are attributed to the high apparent amylose content in rice grain (Arocaset al.2009). The two soft inbredjaponicarice cultivars had a significantly higher BD value and lower SB value than the other four cultivars,which indicates that soft inbredjaponicarice has better palatability,and its cooked rice does not become stiff or retrograde during cooking (Asanteet al.2013).

We observed some large starch granules in the two non-soft hybridjaponicarice cultivars Yongyou 4949 and Yongyou 6763,which was mainly due to their high apparent amylose content (Sladeet al.2012;Zhuet al.2017b). The morphological structure of rice starch granules depends on the biochemistry of the chloroplast,amyloplast and physiology of the plant (Singhet al.2003a). The variation in size distribution and shape of starch granules is mainly attributed to the genetic background (Singhet al.2003a;Zhuet al.2017b). Some previous reports revealed that large-sized starch granules were synthesized in the early grain-filling stage and then decomposed to medium-and small-sized starch granules (Wadugeet al.2013);therefore,the higher the content of medium and small granules,the lower the number of large granules (Zhuet al.2017b). The field environment and cultivation conditions such as the nitrogen level,temperature and light during the grain-filling period can affect the granule size distribution by affecting the time of grain filling (Nankishorea and Farrell 2016). In this study,the two non-soft hybridjaponicarice cultivars had more large-sized starch granules than soft inbredand non-soft inbredjaponicarice cultivars,which might be due to the difference in the number of days of grain filling among the three types ofjaponicarice cultivars (Table 1).

The gelatinization character reflects the quantity and quality of starch crystallinity (Hoover and Ratnayake 2002). We observed that gelatinization temperature and gelatinization enthalpy increased with the degree of relative starch crystallinity. In this study,the two soft inbredjaponicarice cultivars had the highest gelatinization enthalpy and relative crystallinity among all the tested cultivars (Table 5). The closely-packed crystalline structure within starch granules might be the main reason for the high gelatinization enthalpy of soft inbredjaponicarice cultivars (Tanget al.2000). It has been reported that amylopectin plays a primary role in starch crystallinity;high amounts of amylose can restrict the hydration of amorphous regions (Parket al.2007) and lower the melting point of crystalline regions as well as the energy required for initiating gelatinization (Fiipseet al.1996). The occurrence of chalkiness also has a close relationship with the gelatinization temperature. A previous study found that the transition temperatures (To,TpandTc) of chalky parts were higher than those of translucent parts in rice grain,and this might be because of the lower amylose and higher amylopectin contents in the chalky parts (Singhet al.2003b).The interior structure of a single starch granule is more rigid in chalky parts than in translucent parts;more energy is required during starch gelatinization for grains with a higher chalkiness rate and larger chalkiness size (Singhet al.2003b;Chenget al.2005). This is in accordance with our study,that is,soft inbredjaponicarice cultivars were chalkier and had a higher gelatinization temperature than other cultivars.

5.Conclusion

The present results demonstrated that soft inbredjaponicarice cultivars exhibited a more stable processing quality and significantly higher chalk occurrence in rice grains than non-soft inbred and non-soft hybridjaponicarice cultivars. Non-soft hybridjaponicarice showed a high yield potential but low cooking and eating quality. Soft inbredjaponicarice cultivars exhibited superior cooking and eating quality traits compared with its non-soft inbred and non-soft hybrid counterparts,mainly because of the low apparent amylose content and moderate protein content. Through this study,we speculated that the difference in the distribution of starch chain length might be the deep-seated reason for taste differences among differentjaponicarice cultivars.Breeding high yield and quality rice should focus on selecting large panicles,stabilizing the filled grain percentage,and controlling amylose content and protein content at a relatively low level.

Acknowledgements

We are grateful for grants from the National Key Research Program of China (2016YFD0300503),the earmarked fund for China Agriculture Research System (CARS-01-27),the National Natural Science Foundation of China (31971841),the Key Research Program of Jiangsu Province,China (BE2016344,BE2018355),the earmarked fund for Jiangsu Agricultural Industry Technology System,China (JATS[2018]298),and the Project Funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions,China.

Declaration of competing interest

The authors declare that they have no conflict of interest.

杂志排行

Journal of Integrative Agriculture的其它文章

- Adoption of small-scale irrigation technologies and its impact on land productivity:Evidence from Rwanda

- African swine fever and meat prices fluctuation:An empirical study in China based on TVP-VAR model

- The impacts of oxytetracycline on humification during manure composting can be alleviated by adjusting initial moisture contents as illustrated by NMR

- Effects of long-term straw incorporation on nematode community composition and metabolic footprint in a rice-wheat cropping system

- Functional diversity of soil microbial communities in response to supplementing 50% of the mineral N fertilizer with organic fertilizer in an oat field

- Nitrogen acquisition,fixation and transfer in maize/alfalfa intercrops are increased through root contact and morphological responses to interspecies competition