初级励磁型永磁直线电机研究现状与展望

2021-06-10沈燚明卢琴芬

沈燚明 卢琴芬

初级励磁型永磁直线电机研究现状与展望

沈燚明 卢琴芬

(浙江大学电气工程学院 杭州 310027)

初级励磁型永磁直线电机是从传统永磁直线电机衍生而来的一类新型特种电机,具有高推力密度、高效率、高精度和高可靠性等优点。在长行程直驱式直线运动领域,该类电机有其独特的性能与成本优势,具有很高的研究价值和广阔的应用前景。该文针对初级励磁型永磁直线电机,回顾并总结了国内外相关研究的技术现状和发展趋势。从磁场调制理论出发,揭示了初级励磁型永磁直线电机气隙磁场谐波分布与推力产生原理。从拓扑结构的角度,梳理了各类永磁直线电机的技术要点及研究进展。从初级励磁型永磁直线电机的特征出发,介绍了高性能控制策略。最后,对比分析了各类初级励磁型永磁直线电机的综合性能,并探讨了未来的发展方向。

永磁直线电机 初级励磁 双凸极 磁场调制原理 高推力密度 长行程

0 引言

随着我国国民经济的高速发展和制造强国战略的深入部署,高性能电机系统成为装备制造业向高端化发展的关键与核心[1]。在直驱式直线运动领域,永磁直线电机(Permanent Magnet Linear Machines,PMLM)集成了永磁电机与直线电机的特性,具有高推力密度、高效率、高精度和高可靠性等显著优点,目前广泛应用于高档数控机床、极大规模集成电路制造装备、3C产品制造装备、高速物流系统与无绳电梯等领域[2]。

传统PMLM电枢与磁极分别在动、定子两侧,可分为具有高推力密度的有铁心结构和高动态响应的无铁心结构。针对高精度应用场合的直线伺服系统领域,传统PMLM已在工业界得到了广泛的应用。目前,国内外知名的供应商有德国Siemens、美国Kollmorgen、荷兰Tecnotion、瑞士ETEL、日本Yaskawa、新加坡Akribis、深圳大族和广州数控等公司[3]。在工业界广泛应用的同时,传统PMLM面临着两大问题:①磁极需面贴于次级全行程范围,永磁体用量大且成本高;②次级带有强磁性,需要额外安装隔磁防护装置。随着长行程直驱式应用领域的不断拓展,上述两大问题越发突出,工业界急需具有高推力密度和低成本的PMLM新拓扑结构。

近年来,初级励磁型PMLM成为直线电机领域的一大热点,逐步得到了深入的研究。顾名思义,初级励磁型PMLM将电枢和磁极均放置于初级侧,次级仅由铁心构成,且通常是短初级长次级结构。在长行程应用时,永磁体仅位于短初级侧而无需面贴于次级全行程范围,用量与成本均大幅降低。同时,次级在全行程范围内不再具有强磁性,无需额外安装隔磁防护装置,可以应用的领域得到大幅扩展。由此可见,初级励磁型PMLM相比于传统PMLM具有独特的性能与成本优势,在长行程直驱式直线运动领域,如长行程直线伺服系统、高速物流系统和高速无绳电梯等,具有很高的研究价值和广阔的应用前景。

本文主要针对初级励磁型PMLM,回顾并总结了国内外相关研究的技术现状和发展趋势。从基本原理和结构出发对初级励磁型PMLM进行分类,梳理了各类电机的技术要点及研究进展,指出了目前尚存在的一些问题。最后,总结了各类初级励磁型PMLM的综合性能,并探讨了未来的发展方向。

1 基本结构分类与工作原理

1.1 基本结构分类

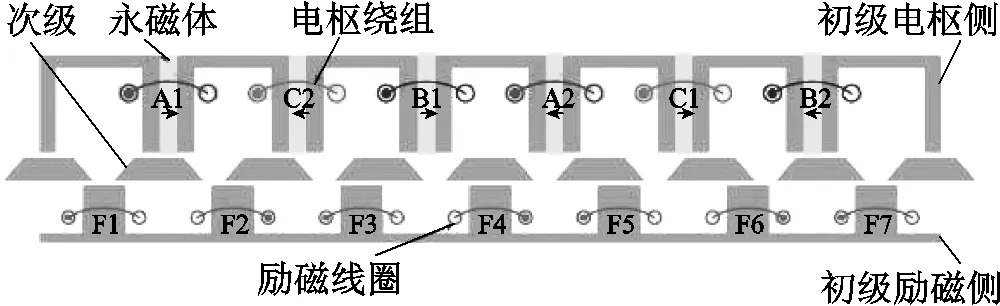

图1所示为初级励磁型PMLM的分类。从空间结构来看,可分为单边型、双边型和圆筒型三种结构;从励磁方式来看,主要有永磁励磁和混合励磁两种方式;从磁场分布来看,可分为纵向磁通和横向磁通。按照永磁体在初级铁心中的相对位置,可进一步将其分为以下几种类型:①永磁体与电枢分离在初级两侧的初级分裂型PMLM;②永磁体嵌于电枢齿中的磁通切换型PMLM;③永磁体贴于电枢齿面的磁通反向型和游标型PMLM,若永磁体只有单极性,则可构成交替极型PMLM;④永磁体嵌于初级铁心轭部的磁通偏置型PMLM;⑤永磁体嵌于初级铁心槽口的槽口永磁型PMLM。

图1 初级励磁型PMLM分类

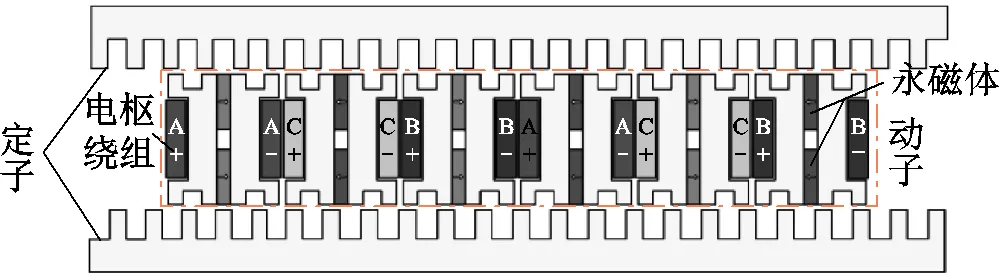

初级励磁型PMLM拓扑结构种类繁多,但仍具有以下几个共同特点:

(1)电枢和磁极均放置于短初级侧,长次级仅由硅钢片叠成的凸极铁心构成,初、次级均为凸极结构。

(2)磁极的极对数较高,通常为槽数的一半或整数倍槽数,电枢绕组常采用端部非重叠集中绕组,且运动一个次级极距对应一个电周期。

(3)推力的产生遵循磁场调制原理,即静止的初级励磁磁场被次级铁心调制后在气隙处产生运动的行波磁场,该行波磁场与电枢磁场构成有效谐波对,从而产生推力。

1.2 工作原理

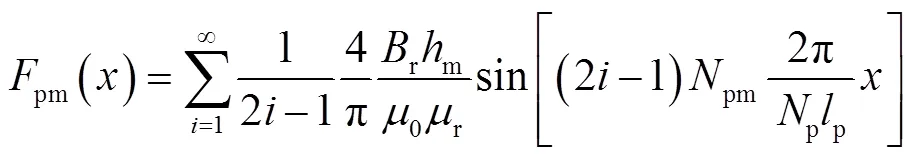

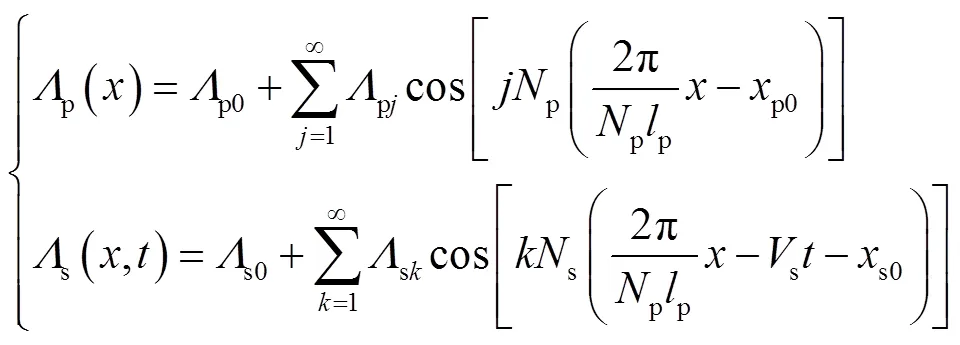

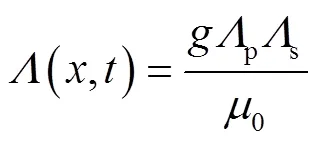

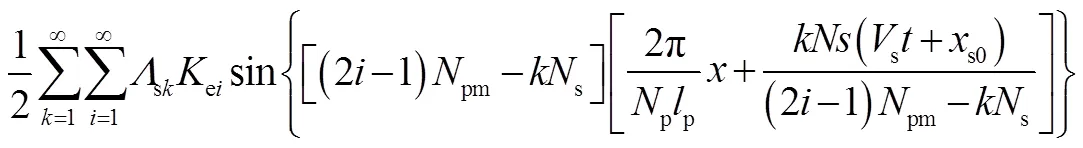

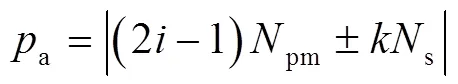

初级励磁型PMLM推力的产生可用磁动势-磁导模型进行解析计算。其中,永磁磁动势为

初级励磁型PMLM为双凸极结构,其初级、次级磁导均需要考虑铁心开槽的影响,初、次级磁导p和s进行计算式为

将永磁磁动势(式(1))与合成气隙磁导(式(4))相乘,即可得到气隙磁通密度表达式为

空载气隙磁通密度各次谐波组成见表1。其中,极对数为(2-1)pm的各次谐波由永磁磁动势与次级平均磁导相乘得到,其运动速度为0,不能用于产生推力。经次级铁心调制后,剩余两种极对数为|(2-1)pm±s|的谐波为运动的行波磁场,与电枢磁场相互作用后可以产生推力。

表1 初级励磁型PMLM空载气隙磁通密度谐波成分

Tab.1 Distribution of air gap harmonics of PE-PMLM

由于行波磁场中低次谐波的幅值较大,为了充分利用低次谐波,式(6)中一般取低次谐波的极对数作为电枢绕组的极对数,即= 1,= 1,由此可以确定电枢绕组的联结方式。

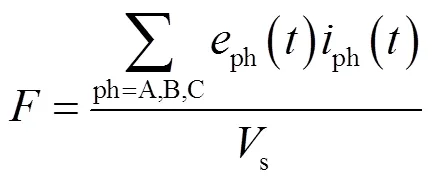

在确定电枢绕组联结方式后,将气隙磁通密度在初级长度范围内积分,可得到三相绕组所匝链的磁链,再进一步对磁链微分即可得到各相反电动势为

式中,ph()为绕组函数;sk为电机叠厚。当电枢绕组中通入三相正弦交流电时,初级励磁型PMLM的推力计算式为

由此可以看出,初级励磁型PMLM相比于传统PMLM具有更加丰富的气隙磁场谐波,其本质上是一类由多种有效谐波对共同产生推力的谐波电机。

2 电机本体拓扑结构研究现状

2.1 磁通切换型PMLM

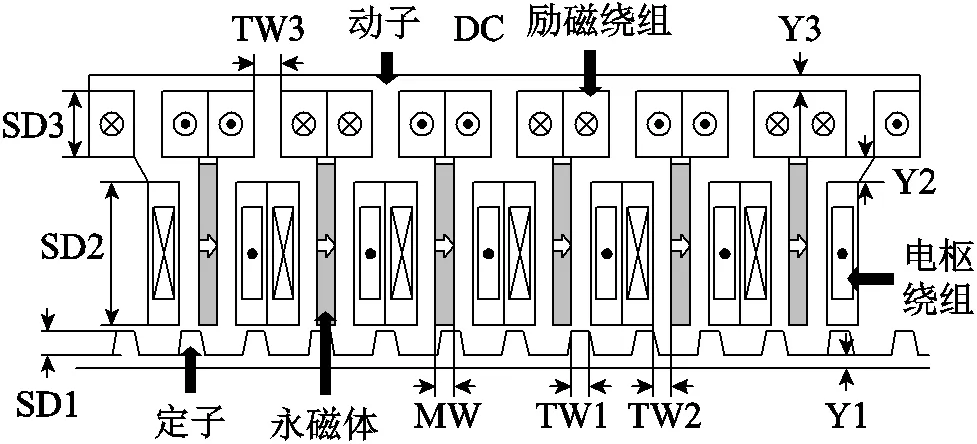

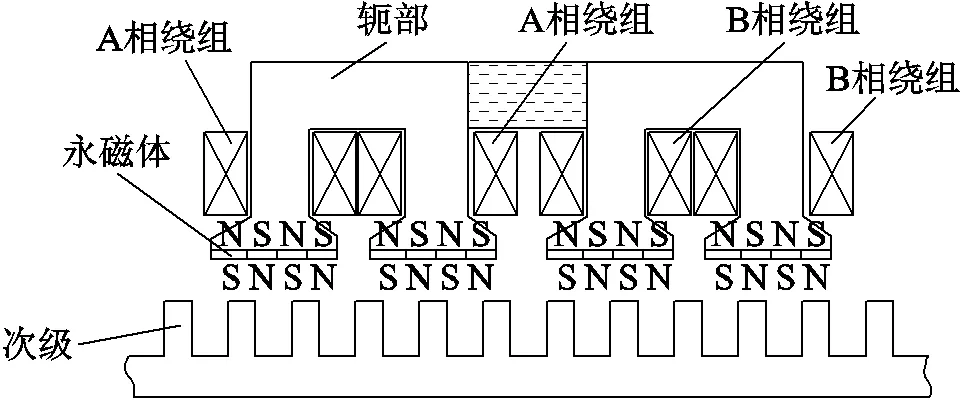

磁通切换型PMLM(Switched-Flux PMLM,SFPMLM)作为一种典型的双凸极直线电机,已成为直线电机研究领域的一大热点,其典型拓扑结构如图2所示。2008年,英国谢菲尔德大学的Z. Q. Zhu教授首次提出SFPMLM,并对不同槽极配合及绕组结构进行了对比分析[4]。同年,浙江大学的沈建新教授也对SFPMLM展开了研究,并利用次级斜极的方法减小定位力[5]。此后,越来越多的学者对SFPMLM展开深入的研究,主要集中在新型拓扑结构研究方面。

图2 磁通切换型PMLM典型拓扑结构

2.1.1 少永磁结构

文献[6]在传统U型结构的基础上,提出了C型和E型新结构以减少一半的永磁用量。研究表明,相同损耗下C型结构可比传统U型结构提高约10%~20%的推力;E型结构中的容错齿有效降低了相间互感,适合模块化容错运行。文献[7-9]进一步对初级奇数槽下的C型和E型新结构进行了深入研究,结果显示,奇数槽下可选槽极配合更多,且同样可提高电机推力密度及容错性能。

文献[10-11]提出了多齿型结构用于进一步提高电机推力密度并降低永磁用量,其结构如图3所示。研究表明,电负荷较低时多齿型结构可明显提高推力密度,但电负荷较高时,其功率因数较低且非常容易饱和,过载能力较弱。

图3 多齿型结构SFPMLM

2.1.2 圆筒型及双边型结构

圆筒型及双边型结构可以消除不平衡单边法向力的影响,且在减小定位力及推力波动、提高推力密度等方面更具优势。

文献[12]利用传统U型铁心的外电枢结构,提出了一种圆筒型SFPMLM,如图4所示。在此基础上,采用模块化E型铁心及隔磁桥结构,可以提高圆筒型SFPMLM的容错能力[13]。此外,文献[14]提出了一种采用单相圆筒型SFPMLM的直线振荡电机。总体而言,圆筒型SFPMLM结构复杂,加工及装配困难,实际应用时较少采用。

图4 圆筒型结构SFPMLM

文献[15-16]提出了一种初级无轭部双边型SFPMLM,如图5所示。研究表明,该结构可以有效减少轭部漏磁并提高永磁体利用率,同体积下推力密度可提高约50%。文献[17]进一步提出了一种双永磁结构的初级无轭部双边型SFPMLM。结果显示,该电机在同体积下推力密度可提高约80%,特别适合用作有限空间内的力电机。与此同时,文献[18]提出了一种多齿型结构的初级无轭部双边型SFPMLM,如图6所示。研究表明,去掉初级轭部并采用多齿结构后,定位力及推力波动可大幅减小,相同推力密度下永磁用量减少约30%,但是电负荷较高时非常容易饱和。此外,还有一些双边型结构以次级轭部作为对称轴,且次级通常作为短动子运动,可应用于电磁弹射等领域[19-21]。

图5 初级无轭部双边型SFPMLM

图6 多齿型结构的初级无轭部双边型SFPMLM

2.1.3 模块化容错结构

文献[22]在传统U型结构基础上,利用磁障将相邻两相磁路隔离,提出了一种模块化容错型SFPMLM,如图7所示。该电机具有相间互感小、容错能力强、永磁用量小等优点。在此基础上,文献[23-27]提出了磁路互补模块化容错型SFPMLM,如图8所示。磁路互补的目的是追求各模块合成反动势正弦度更好及合成定位力最小。此外,还有一些去掉磁障且各相独立的模块化容错型SFPMLM[28-29]。

图7 模块化容错型SFPMLM

图8 磁路互补模块化容错型SFPMLM

2.1.4 混合励磁结构

为了增强气隙磁场的调节能力,电励磁作为补充励磁源的混合励磁方式常被采用,主要有串联励磁和并联励磁两种形式。文献[30]提出了一种串联混合励磁SFPMLM,其中直流励磁绕组位于靠近气隙的电枢分裂齿内,如图9所示。结果显示,当直流励磁在±15 A/mm2范围内调节时,气隙磁场调节范围扩大至+45%~-53%。文献[31-32]提出了一种励磁绕组位于轭部的并联混合励磁SFPMLM,如图10所示。文献[33]以E型结构为基础,在E型铁心中间的容错齿上添加直流励磁绕组,构成并联混合励磁。

图9 串联混合励磁SFPMLM

图10 并联混合励磁型SFPMLM

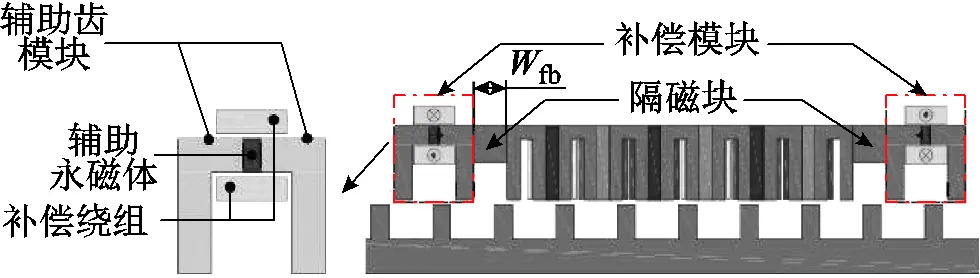

2.1.5 边端效应削弱与优化

受初级铁心开断的影响,直线电机存在边端力及三相不平衡问题。因此,在本体设计中常采用先进的优化算法对电机各尺寸进行全局优化,并利用其他辅助方法削弱边端效应。文献[34-35]提出了一种利用边端辅助齿来削弱推力波动中端部效应的方法。针对推力波动中齿槽效应成分,可以采用次级铁心斜极或分段错位、齿顶表面开槽或圆弧倒角、大小齿匹配等方式进行削弱[36]。文献[37]提出了一种带补偿绕组及永磁体的边端辅助齿新结构,如图11所示。通过分析空载定位力及负载推力波动主要谐波成分,并在补偿绕组中反向注入谐波电流,可以消除主要谐波成分的影响并提供更加平稳的推力。该方法为削弱边端效应提供了新思路。

图11 带补偿绕组及永磁体的边端辅助齿示意图

2.2 磁通反向型PMLM

磁通反向型PMLM(Flux Reversal PMLM,FRPMLM)是由Ion Boldea教授首次提出并应用于一台单相的直线振荡电机中[38],其典型拓扑结构如图12所示。提出至今,国内外众多学者对FRPMLM进行了深入地研究,取得了丰硕的研究成果。

图12 磁通反向型PMLM典型拓扑结构

2.2.1 交替极结构

在传统FRPMLM结构的基础上,文献[39-42]提出了一系列交替极少永磁结构的FRPMLM,如图13所示。交替极(Consequent-Pole,CP)指的是利用铁心取代其中一种极性的永磁体,使得永磁体只存在单极性,且永磁体的极对数与个数相同。研究表明,交替极FRPMLM在减少一半永磁用量的同时,推力密度可提高约20%。文献[43]进一步提出了一种双边型无轭部交替极FRPMLM,其永磁体嵌于电枢齿的中心而两端为铁心,在相同体积及永磁用量下,推力密度可提高约33%。

图13 交替极FRPMLM

文献[44-47]提出了多种容错型交替极FRPMLM,其典型拓扑结构如图14所示。该结构将三相绕组彼此隔离并形成独立模块,永磁体嵌于电枢齿的中心位置,相邻两个电枢齿中间留有容错齿。图15所示为混合励磁容错型交替极FRPMLM,其中直流励磁绕组绕制在容错齿上,与电枢齿上的永磁体形成并联磁路,可以同时获得永磁励磁带来的高推力密度及电励磁带来的宽调磁范围。

图14 容错型交替极FRPMLM

图15 混合励磁容错型交替极FRPMLM

2.2.2 横向磁通结构

FRPMLM的一大特点是励磁结构的多样性,其永磁阵列可以是多对NS极、单对NS极和永磁-铁心单极性阵列。当永磁阵列的极性在横、纵两个方向上同时变化时,可以实现横向磁通结构。哈尔滨工业大学的寇宝泉教授对横向磁通FRPMLM展开了深入研究,提出了多种新型拓扑结构。文献[48]提出了一种扩展U型横向磁通FRPMLM,其整体结构如图16a所示,电枢齿在横、纵两个方向上均贴有极性交变的永磁体。从图16b所示的横向磁路看,同一时刻相邻电枢齿上的磁通方向相反;从图16c所示的纵向磁路看,三相初级模块沿着运动方向依次错开120°电角度排列。在此基础上,文献[49-50]用铁心替代其中一种极性的永磁体,提出了交替极横向磁通FRPMLM。文献[51]提出了一种E型横向磁通FRPMLM,用于减少绕组端部数量从而降低铜耗。研究表明,E型横向磁通FRPMLM的推力密度高达183kN/m3。

图16 扩展U型横向磁通FRPMLM

上述平面型横向磁通FRPMLM虽然具有较高的推力密度,但存在不平衡单边法向力的问题。因此,一些研究团队提出了圆筒型横向磁通FRPMLM以消除不平衡单边法向力[52-53],如图17所示。在此基础上,文献[54-55]充分利用交替极结构的特点,提出了一种旋转-直线二自由度圆筒型横向磁通FRPMLM,可同时实现旋转和直线运动。

图17 圆筒型横向磁通FRPMLM

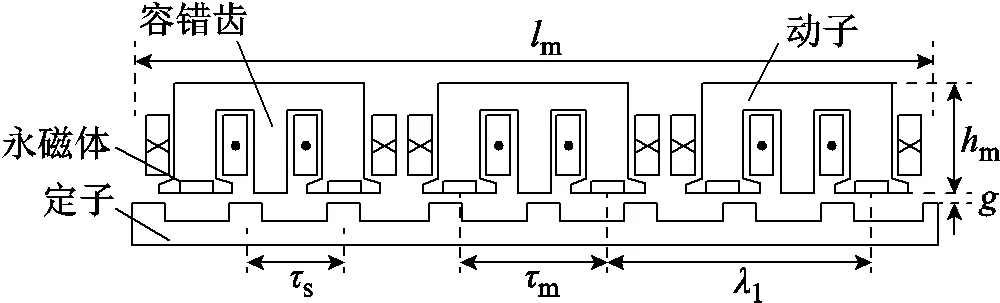

2.3 游标型PMLM

根据磁阻最小原理,游标型PMLM(Vernier PMLM,VPMLM)次级移动较小的位置即可使气隙磁导产生较大的变化。利用其“磁齿轮效应”,可以实现低速大推力,其典型拓扑结构如图18所示。游标型与磁通反向型PMLM结构非常相似,两者的差异在于游标型的永磁体极对数较高而磁通反向型极对数较低。按照永磁体的极性,游标型PMLM同样可分为双极性结构和交替极结构。

图18 游标型PMLM典型拓扑结构

2.3.1 双极性结构

日本安川电机公司的Nagahiko Nagasaka等于1994年提出了图19所示的双极性VPMLM[56]。其中,初级电枢齿上表贴有两对永磁体,而次级仅由凸极铁心构成。文献[57-60]进一步提出了类似结构的双边型双极性VPMLM,其中初级铁心包括C型和E型结构,每个电枢齿上表贴有三对永磁体,如图20所示。在此基础上,文献[61-69]将电枢齿上的永磁体极数从偶数扩展到奇数,其拓扑结构如图21所示。研究表明,采用奇数极结构时永磁体漏磁与齿槽力可明显降低,且“磁齿轮效应”仍明显存在。

图19 双极性游标型PMLM

图20 双边型双极性游标型PMLM

图21 奇数极双极性游标型PMLM

2.3.2 交替极结构

为了进一步降低永磁用量并减少漏磁,部分研究人员开始对交替极结构的VPMLM展开研究。文献[70]在双极性奇数极结构的基础上,用铁心替代其中两块相同极性的永磁体,得到了一种交替极VPMLM。结果显示,该电机永磁用量为原来的75%,但主要次谐波及推力却分别提高了43%和34%。

针对交替极结构存在的漏磁问题,江苏大学的赵文祥教授对永磁体进行了改进,并提出了一类Halbach聚磁式交替极VPMLM,如图22所示。围绕解析建模[71-72]、槽极配合[73-77]、新型拓扑结构[78-79]和模块化设计[80-81]等方面,该类电机得到了深入研究。研究表明,Halbach永磁阵列可以有效减少漏磁并提高气隙磁通密度,并且当永磁体极对数为3时推力密度最高。

图22 Halbach聚磁式交替极游标型PMLM

与此同时,文献[82-88]提出了两种不同结构的V型和Halbach型聚磁式交替极VPMLM,如图23所示。与图22相比,图23b所示的Halbach型永磁阵列与分裂齿的相对位置不同。研究表明,V型和Halbach型聚磁式交替极结构可比原交替极结构进一步提高约10%的推力。

图23 聚磁式交替极游标型PMLM

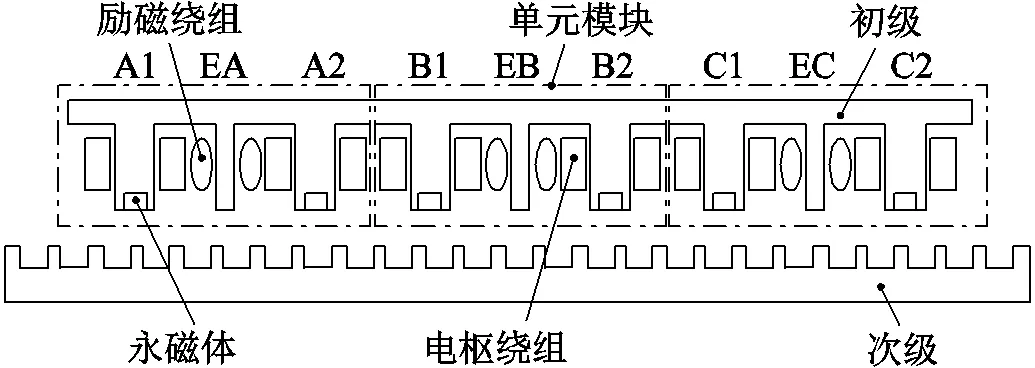

2.4 磁通偏置型PMLM

与双凸极旋转电机类似,初级励磁型PMLM也可以将永磁体嵌于轭部。文献[89]提出了一种模块化E型双凸极PMLM,并分析了其在无刷直流和无刷交流两种驱动模式下的推力性能。磁通偏置型PMLM在双凸极PMLM的基础上增加了永磁体的数量,使得相邻两电枢齿之间的轭部均嵌有永磁体,且每个线圈所匝链的磁链根据永磁体的极性存在一个偏置量。

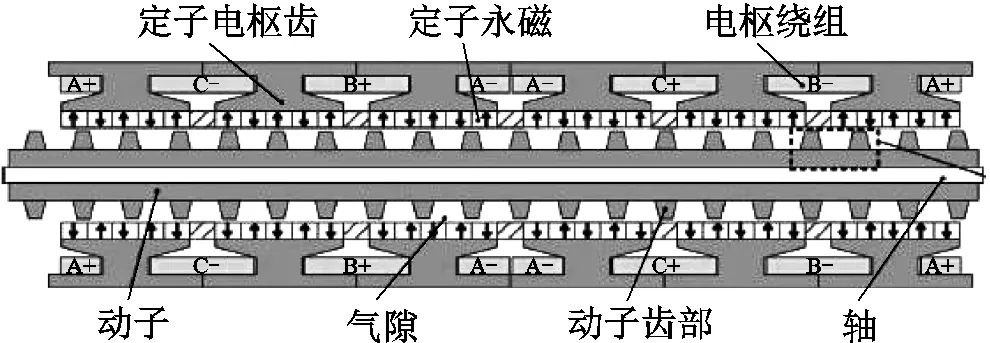

文献[90-91]提出了一种36槽20极的双边磁通偏置型PMLM,如图24所示。该槽极配合下永磁体极对数与次级极数相近,因而电机具有明显的磁齿轮效应。在此基础上,文献[92]在初级铁心槽口处加入永磁体作为并联励磁源,得到了一种双永磁结构的磁通偏置型PMLM,如图25所示。结果显示,槽口加入永磁体后,电机推力密度可以提升约36%。

图24 双边磁通偏置型PMLM

图25 双永磁磁通偏置型PMLM

2.5 槽口永磁型PMLM

传统电机设计中,槽开口空间常采用槽楔进行填充,而不会用来放置永磁体进行励磁。日本芝浦工业大学的Shoji Shimomura教授在游标型PMLM的基础上,充分利用槽开口空间,提出了一种槽口永磁型PMLM[93-96],如图26所示。该电机永磁体的充磁方向垂直于运动方向且只有单极性,其本质上是一种交替极结构的游标型PMLM。

图26 单极性槽口永磁型PMLM

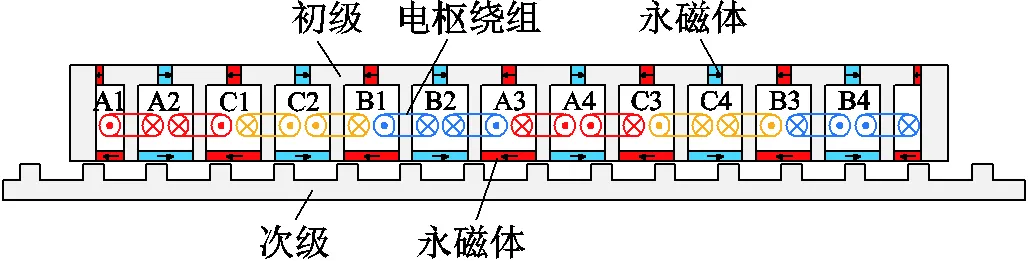

浙江大学的卢琴芬教授提出了一类槽口永磁型PMLM,并对其槽极配合与绕组结构[97-98],混合励磁结构[99-100]展开了深入研究,如图27所示。研究表明,该类电机在空载条件下具有非常小的定位力及反电动势;在负载条件下,永磁体具有缓解初级铁心饱和的作用,因而其过载能力较强,适合用于短时工作制的力电机。

图27 双极性槽口永磁型PMLM

2.6 初级分裂型PMLM

初级励磁型PMLM中永磁体与电枢绕组位于同一侧,当电负荷较高时,初级铁心很容易饱和。为了降低饱和,可以将初级分离成两部分,构成初级分裂型PMLM。其中,分离后的两个初级子模块分别放置电枢绕组与永磁体,而次级仍然仅由铁心构成。由于额外增加了一部分初级,初级分裂型PMLM具有更多自由度,可以实现包括磁通切换型和磁通反向型在内的多种拓扑结构。

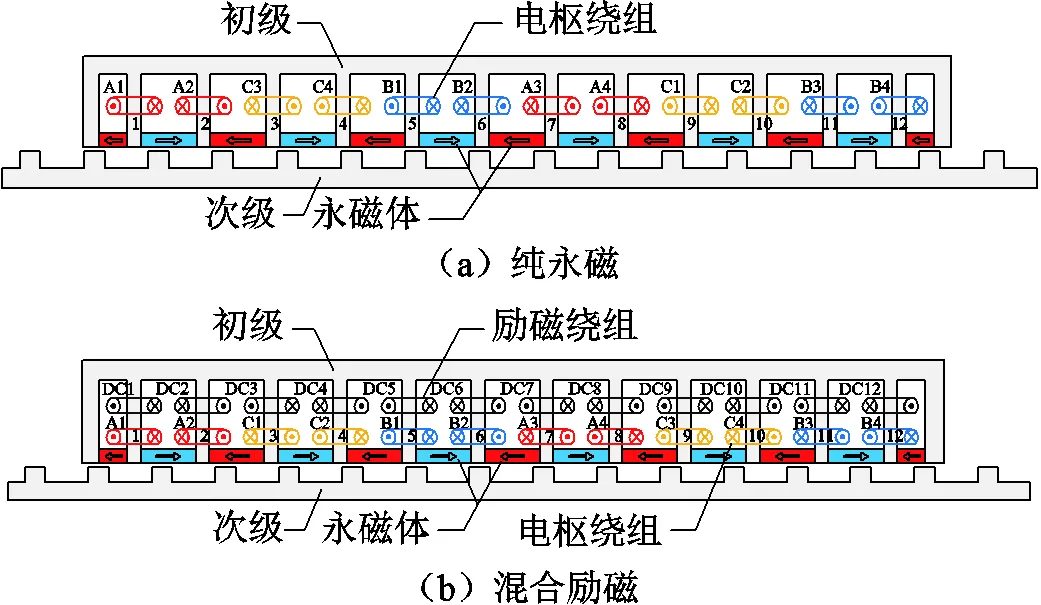

浙江大学的卢琴芬教授对初级分裂型PMLM展开了深入研究,提出了多种拓扑结构,其中包括磁通切换型结构[101]、磁通反向型结构[102]和混合励磁结构[103-105]。图28所示为其中一种磁通切换型结构的初级分裂型PMLM。结果显示,该初级分裂型结构在同体积下可比传统结构提高约30%的推力,并且随着电负荷的增加,提升的效果更为明显。图29所示为混合励磁式初级分裂型PMLM,其中直流励磁绕组位于短初级的一侧,电枢绕组和永磁体位于短初级的另一侧。结果显示,增加直流励磁后电机的调磁能力大幅增强。

图28 磁通切换式初级分裂型PMLM

图29 混合励磁式初级分裂型PMLM

与此同时,初级分裂型PMLM存在一个共性问题:双气隙的存在使得机械结构变得更为复杂,初级装配困难且可靠性较低。

3 驱动控制技术

初级励磁型PMLM的驱动方式与传统PMLM一致,采用正弦波驱动,因而针对传统PMLM的控制策略也适用于初级励磁型PMLM,如空间矢量脉宽调制[106-107]、速度闭环控制[108-109]、位置闭环控制[110]与直接推力控制[111-112]等。另外,也有一些高性能控制策略用于改善初级励磁型PMLM的性能,主要包括定位力与推力波动抑制、无位置传感器控制及容错控制等。

3.1 定位力与推力波动抑制

初级励磁型PMLM双凸极的结构本质使其具有定位力与推力波动较大的缺点。因此,除了在电机结构设计上需要利用斜极、边端辅助齿等方式对定位力进行削弱外,还需要在控制策略上进一步采取补偿措施。根据推力波动产生的机制,主要可以从以下两个方面对其进行抑制[113]:

(1)研究具有高动态响应、高稳态精度且强鲁棒性的电流控制策略,从提高电流品质的角度出发直接提高输出推力的响应速度和稳态精度。

(2)研究高性能的推力波动估计或观测方法,从推力波动抑制的角度出发直接提高输出推力的平稳性。

针对传统PMLM推力波动抑制问题,不少学者展开了深入的研究。传统PMLM一般采用电流和位置双闭环控制结构以保证系统的高动态响应,电流环作为最内环,其性能直接决定了系统的品质。文献[114-117]采用预测电流控制以提高电流响应速度,并保证暂态时间内的高精度控制。相比于滞环电流控制和PI控制,该方法可以实现较高的稳态电流精度和较低的电流谐波,但其本质上是一种基于模型的控制方法,其控制性能非常依赖电机参数的准确度。文献[118-120]对推力波动的特征进行了分析,并利用离线或在线辨识结果对其进行前馈补偿。该方法对推力波动抑制具有一定的作用,但其本质上也是一种基于模型的控制方法,辨识或补偿效果依赖推力波动模型的准确度。

在实际系统中,推力波动建模不准确、模型参数时变等因素会导致前馈补偿效果受限。因此,很多学者从改进控制方法的角度来间接抑制推力波动。文献[121]将PID反馈控制、自适应前馈控制和滑模控制相结合,提出一种摩擦力和推力波动自适应补偿方法。美国普渡大学的Yao Bin教授将自适应鲁棒控制用于直线电机运动控制中,在提高跟踪精度的同时又可以保证系统镇定[122-125]。

区别于改进反馈控制策略,不少学者从改进观测方法的角度来改善推力波动抑制性能并提高位置控制精度,如基于自适应控制的扰动观测器[115, 126]、滑模扰动观测器[114, 127]、扩张状态观测器、通用比例积分观测器[117]、扩展卡尔曼滤波器等[116, 128]。

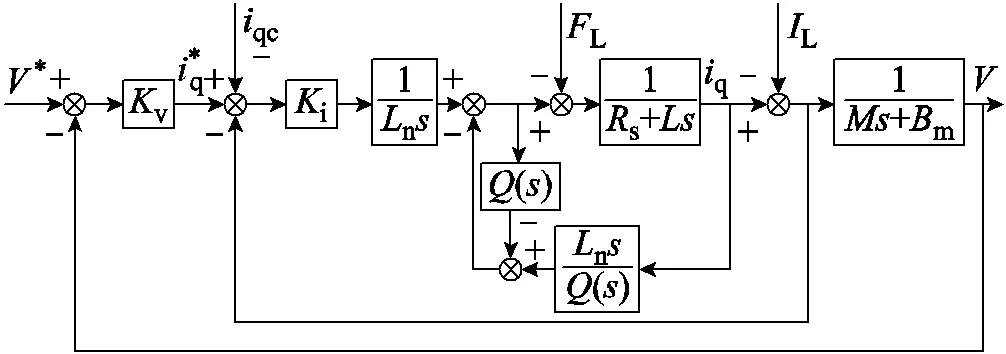

借鉴传统PMLM推力波动抑制的方法,初级励磁型PMLM也可以采用。文献[129]提出了一种将谐波抑制算法和扰动观测器相结合的联合控制策略,用于抑制磁通切换型PMLM的推力波动,其控制框图如图30所示。该文献通过q轴电流谐波注入的方式补偿定位力,并设计扰动观测器对电机模型误差和外部干扰所带来的系统扰动进行在线估计和补偿。该控制策略具有一定的扩展性,可为相似结构的初级励磁型PMLM控制研究提供参考。文献[130]将时变的域信号,变换为具有固定周期的域信号,再对其进行重复控制器的设计,从而达到抑制定位力和速度脉动的目的。

图30 扰动观测器及定位力补偿联合控制框图

文献[131]提出了一种模型预测推力控制策略用于降低模块化磁通切换型PMLM运行时的推力波动,其控制策略如图31所示。利用有效电压矢量选择(Active Voltage Vector Selection,AVVS)可以降低控制计算量,最优双电压矢量合成(Two-Voltage Vector Synthesis,TVVS)可以提高电机的稳态性能。研究结果表明,该控制策略与传统滞环电流控制和模型预测控制相比,可以有效降低谐波电流与推力波动。

图31 磁通切换型PMLM模型预测推力控制框图

3.2 无位置传感器控制

初级励磁型PMLM在长行程直驱式直线运动领域具有较大优势。在一些对位置精度要求不高的场合,可以利用无位置传感器控制策略对动子位置进行估计,从而省去在长行程范围内铺设的位置传感器,如光栅、磁栅等,进一步降低成本。

文献[132]提出了一种基于模型参考自适应系统的无位置传感器控制策略,其控制框图如图32所示。结果显示,该控制策略在速度突变、低速运行、负载突变及带载工况下速度波动小且估算准确,系统鲁棒性好,具有良好的动静态特性。此外,也有文献利用滑模观测器[133]、扩展卡尔曼滤波[134]、改进的扰动观测器[135]及磁链观测器[136-137]等方式,对磁通切换型和游标型PMLM进行无位置传感器控制,均具有不错的控制精度与动态性能。

图32 磁通切换型PMLM模型参考自适应控制系统

3.3 容错控制

在可靠性非常重要的应用场合,电机系统需要在故障条件下继续运行一段时间。因此,针对高可靠性应用场合,除了采用常规的控制方式外,还需要额外增加容错控制功能。

江苏大学的赵文祥教授对游标型PMLM的容错控制展开了系统研究,针对开绕组结构下逆变器开关管故障提出了一系列新的容错控制策略。文献[138]通过驱动电路容错重构、电压矢量重新合成,可以将容错后的电压利用率提高到正常状况下的 75%,为开绕组结构下初级励磁型PMLM的容错控制策略研究提供了新思路,其控制框图如图33所示。文献[139]提出了一种单位功率因数容错控制策略,连接到直流电源的主逆变器,负责提供有功功率,连接到浮式电容器的电容逆变器用于补偿无功功率,该控制策略可以有效改善故障状态下的功率因数。文献[140]提出了一种采用混合调制方法的容错控制策略,通过在主逆变器侧采用六拍调制方法,在保证容错运行的同时可以有效降低开关频率与损耗。

图33 开绕组游标型PMLM故障容错重构图

4 技术发展与展望

初级励磁型PMLM相比于传统PMLM具有更加丰富的拓扑结构,各拓扑结构各有优缺点,下面将从推力密度、铁心饱和度、结构简易度与可靠性、退磁风险等几个方面对各类初级励磁型PMLM的综合性能进行比较:

(1)推力密度。推力密度的定义有多种,常用的主要有单位体积下的推力和单位永磁下的推力。按照单位体积下的推力进行比较,初级励磁型PMLM的推力密度仍不如传统PMLM,其约为后者的60%~80%;而按照单位永磁下的推力进行比较,则初级励磁型PMLM远高于传统PMLM,并且随着行程的增加优势更加明显。在各类初级励磁型PMLM中,磁通切换型、磁通反向型和游标型PMLM具有较高的推力密度。

(2)铁心饱和度。由于永磁体与电枢绕组同时位于初级侧,初级励磁型PMLM相比于传统PMLM更容易饱和,因而在设计时需要综合考虑推力密度与过载能力,以便选取合适的永磁体尺寸。

(3)结构简易度与可靠性。对于磁通反向型、游标型和槽口永磁型PMLM,其初级铁心为整体结构,永磁体以表贴的形式固定在铁心上,结构简单且容易装配,可靠性较高;而对于磁通切换型、磁通偏置型和初级分裂型PMLM,初级铁心模块化分立,结构较为复杂且装配困难,可靠性较低。

(4)退磁风险。磁通切换型和槽口永磁型PMLM以并联励磁形式存在,电枢磁场不经过永磁体,因而退磁风险较低;磁通反向型、游标型和磁通偏置型PMLM以串联励磁形式存在,电枢磁场需要经过永磁体,因而存在大规模退磁的风险,需要采用较高工作温度的永磁体牌号如SH、UH等。

综合而言,磁通反向型、游标型PMLM及其交替极结构更具有综合性能优势,值得关注并进一步深入研究,以下将给出几个潜在的研究方向供探讨:

(1)拓扑结构优化。对于磁通反向型和游标型PMLM,各永磁体间漏磁较多,交替极结构虽可以减小部分漏磁,但漏磁问题仍较为突出,需要在拓扑结构上进一步优化以减小漏磁并提高推力密度。

(2)多物理场作用下电机系统电磁参数时变规律。初级励磁型PMLM气隙磁场相比传统PMLM具有更多的谐波,在非理想激励及多物理场耦合工况下电磁参数的变化规律更为复杂。为了提高控制精度,需要探明多物理场耦合作用下电机系统关键电磁参数时变特征,进一步还原电磁参数与电机运行状态间的映射关系。

(3)高性能控制策略。初级励磁型PMLM本质上是一类谐波电机,相比于传统PMLM这类基波电机,其气隙磁场谐波丰富,但定位力及推力波动较大,在伺服领域应用时,需要采取额外的控制策略补偿定位力及推力波动。因此,初级励磁型PMLM高性能控制需要从谐波电机的电磁参数出发,建立电机系统电磁、变流、控制及负载参数间的动态耦合模型,提高电机系统整体性能。

5 结论

初级励磁型PMLM是从传统PMLM衍生而来的一类新型特种电机,具有高推力密度、高效率、高精度和高可靠性等优点,在长行程直驱式直线运动领域有其独特的性能与成本优势,具有很高的研究价值和广阔的应用前景。

本文主要针对初级励磁型PMLM,回顾并总结了国内外相关研究的技术现状和发展趋势。从磁场调制理论出发,揭示了初级励磁型PMLM气隙磁场谐波分布与推力产生的原理。从拓扑结构的角度梳理了各类电机的技术要点及研究进展,介绍了针对初级励磁型PMLM的高性能控制策略。最后对比分析了各类初级励磁型PMLM的综合性能,探讨了未来的发展方向。

初级励磁型PMLM研究尚有诸多关键技术需要突破,主要有以下几个方面:

1)新型高推力密度拓扑结构及优化设计是初级励磁型PMLM研究和进一步发展的重要基础。初级励磁型PMLM拓扑结构虽然丰富,但其核心的单位体积推力密度指标与传统PMLM相比仍有一定距离。因此,需要深刻理解并充分利用初级励磁型PMLM气隙磁场多谐波的特点,构造具有更高推力密度的拓扑结构。

2)宽禁带电力电子器件及其功率变换技术的发展为初级励磁型PMLM的高性能控制带来新的手段。初级励磁型PMLM本质上是一类双凸极结构的谐波电机,相比于传统PMLM这类基波电机,其气隙磁场谐波丰富,但定位力及推力波动较大,在应用于高精度伺服领域时,需要采取额外的高性能控制策略用于补偿定位力及推力波动。

3)实际工业应用背景下的系统综合问题。初级励磁型PMLM最有潜力应用于长行程直线运动领域,如长行程直线伺服系统、高速物流系统和高速无绳电梯等。因此,长行程下电机系统的初级无线缆供电、无位置传感器控制、多电机协同控制运行等系统综合问题需要重点突破。

[1]马伟明, 王东, 程思为, 等. 高性能电机系统的共性基础科学问题与技术发展前沿[J]. 中国电机工程学报, 2016, 36(8): 2025-2035. Ma Weiming, Wang Dong, Cheng Siwei, et al. Common basic scientific problems and development of leading-edge technology of high performance motor system[J]. Proceedings of the CSEE, 2016, 36(8): 2025-2035.

[2]卢琴芬, 沈燚明, 叶云岳. 永磁直线电动机结构及研究发展综述[J]. 中国电机工程学报, 2019, 39(9): 2575-2588. Lu Qinfen, Shen Yiming, Ye Yunyue. Development of permanent magnet linear synchronous motors structure and research[J]. Proceedings of the CSEE, 2019, 39(9): 2575-2588.

[3]沈燚明. 新型初级并联式混合励磁变磁阻直线电机研究[D]. 杭州: 浙江大学, 2020.

[4]Zhu Z Q, Chen X, Chen J T, et al. Novel linear flux-switching permanent magnet machines[C]//2008 International Conference on Electrical Machines and Systems, Wuhan, China, 2008: 2948-2953.

[5]Wang C F, Shen J X, Wang L L, et al. A novel permanent magnet flux-switching linear motor[C]// 2008 4th IET Conference on Power Electronics, Machines and Drives, York, UK, 2008: 116-119.

[6]Min W, Chen J T, Zhu Z Q, et al. Optimization and comparison of novel E-core and C-core linear switched flux PM machines[J]. IEEE Transactions on Magnetics, 2011, 47(8): 2134-2141.

[7]Lu Qinfen, Li Yanxin. Novel linear switched-flux PM machine with 9/10 primary/secondary pole number combination[J]. COMPEL: The International Journal for Computation and Mathematics in Electrical and Electronic Engineering, 2015, 34(6): 1656-1672.

[8]Liu Jiabao, Chen Yi, Lu Qinfen, et al. Optimization and comparison of C-core and E-core linear switched-flux PM machines with odd primary poles[C]//2015 18th International Conference on Electrical Machines and Systems, Pattaya, Thailand, 2015: 254-259.

[9]刘嘉宝. 奇数极直线开关磁链永磁电机少永磁结构的分析与优化[D]. 杭州: 浙江大学, 2016.

[10]蔡炯炯, 卢琴芬, 叶云岳. 一种新型多齿开关磁链直线电机的关键问题[J]. 电机与控制学报, 2012, 16(3): 8-14. Cai Jiongjiong, Lu Qinfen, Ye Yunyue. Key problems for a novel multi-tooth flux-switching linear motor[J]. Electric Machine and Control, 2012, 16(3): 8-14.

[11]蔡炯炯. 新型开关磁链永磁直线电机研究[D]. 杭州: 浙江大学, 2014.

[12]Wang Jiabin, Wang Weiya, Atallah K, et al. Design considerations for tubular flux-switching permanent magnet machines[J]. IEEE Transactions on Magnetics, 2008, 44(11): 4026-4032.

[13]Yan Liang, Li Wei, Jiao Zongxia, et al. Design and modeling of three-phase tubular linear flux-switching permanent magnet motor[C]//Proceedings of 2014 IEEE Chinese Guidance, Navigation and Control Conference, Yantai, China, 2014: 2675-2680.

[14]Yin Zuosheng, Sui Yi, Han Liang, et al. Research on a tubular flux-switching permanent-magnet linear machine[C]//2017 20th International Conference on Electrical Machines and Systems, Sydney, NSW, Australia, 2017: 1-5.

[15]Gandhi A, Parsa L. Thrust optimization of a flux-switching linear synchronous machine with yokeless translator[J]. IEEE Transactions on Magnetics, 2013, 49(4): 1436-1443.

[16]Gandhi A, Parsa L. Thrust optimization of a five-phase fault-tolerant flux-switching linear synchronous motor[C]//IECON 2012 38th Annual Conference on IEEE Industrial Electronics Society, Montreal, QC, Canada, 2012: 2067-2073.

[17]Zhang Bangfu, Cheng Ming, Wang Jiabin, et al. Optimization and analysis of a yokeless linear flux-switching permanent magnet machine with high thrust density[J]. IEEE Transactions on Magnetics, 2015, 51(11): 1-4.

[18]Shen Yiming, Lu Qinfen, Li Huanwen, et al. Analysis of a novel double-sided yokeless multitooth linear switched-flux PM motor[J]. IEEE Transactions on Industrial Electronics, 2018, 65(2): 1837-1845.

[19]Huang Lei, Yu Haitao, Hu Minqiang, et al. Study on a long primary flux-switching permanent magnet linear motor for electromagnetic launch systems[J]. IEEE Transactions on Plasma Science, 2013, 41(5): 1138-1144.

[20]曹瑞武, 张铮, 金毅, 等. 次级无轭部双边磁通切换永磁直线电机及其控制[J]. 中国电机工程学报, 2017, 37(22): 6585-6593. Cao Ruiwu, Zhang Zheng, Jin Yi, et al. Double-sided linear flux-switching permanent magnet motor with yokeless secondary and control System[J]. Proceedings of the CSEE, 2017, 37(22): 6585-6593.

[21]Cao Rui, Jin Yi, Zhang Zheng, et al. A new double-sided linear flux-switching permanent magnet motor with yokeless mover for electromagnetic launch system[J]. IEEE Transactions on Energy Conversion, 2019, 34(2): 680-690.

[22]Jin Menjia, Wang Canfei, Shen Jianxin, et al. A modular permanent-magnet flux-switching linear machine with fault-tolerant capability[J]. IEEE Transactions on Magnetics, 2009, 45(8): 3179-3186.

[23]Cao Ruiwu, Cheng Ming, Mi C C, et al. Influence of leading design parameters on the force performance of a complementary and modular linear flux-switching permanent-magnet motor[J]. IEEE Transactions on Industrial Electronics, 2014, 61(5): 2165-2175.

[24]曹瑞武, 程明, 花为, 等. 磁路互补型模块化磁通切换永磁直线电机[J]. 中国电机工程学报, 2011, 31(6): 58-65.

Cao Ruiwu, Cheng Ming, Hua Wei, et al. Novel modularized flux-switching permanent magnet linear machine with complementary magnetic circuits[J]. Proceedings of the CSEE, 2011, 31(6): 58-65.

[25]Cao Ruiwu, Cheng Ming, Mi C C, et al. Modeling of a complementary and modular linear flux-switching permanent magnet motor for urban rail transit applications[J]. IEEE Transactions on Energy Conversion, 2012, 27(2): 489-497.

[26]Cao Ruiwu, Cheng Ming, Hua Wei. Investigation and general design principle of a new series of complementary and modular linear FSPM motors[J]. IEEE Transactions on Industrial Electronics, 2013, 60(12): 5436-5446.

[27]Cao Ruiwu, Cheng Ming, Mi C C, et al. Comparison of complementary and modular linear flux-switching motors with different mover and stator pole pitch[J]. IEEE Transactions on Magnetics, 2013, 49(4): 1493-1504.

[28]Farrok O, Islam M R, Sheikh M R I, et al. A split translator secondary stator permanent magnet linear generator for oceanic wave energy conversion[J]. IEEE Transactions on Industrial Electronics, 2018, 65(9): 7600-7608.

[29]Zhang Zongsheng, Tang Xu, Zhang Chao, et al. Novel decoupling modular permanent magnet flux-switching linear motor[J]. IEEE Transactions on Industrial Electronics, 2019, 66(10): 7603-7612.

[30]Cao Ruiwu, Cheng Ming, Mi C C, et al. A hybrid excitation flux-switching permanent magnet linear motor for urban rail transit[C]//2011 IEEE Vehicle Power and Propulsion Conference,Chicago, IL, USA, 2011: 1-5.

[31]Hwang Chang-Chou, Li Ping-Lun, Liu Cheng-Tsung. Design and analysis of a novel hybrid excited linear flux switching permanent magnet motor[J]. IEEE Transactions on Magnetics, 2012, 48(11): 2969-2972.

[32]Liu Cheng-Tsung, Hwang Chang-Chou, Li Ping-Lun, et al. Design optimization of a double-sided hybrid excited linear flux switching PM motor with low force ripple[J]. IEEE Transactions on Magnetics, 2014, 50(11): 1-4.

[33]曾志强, 卢琴芬, 叶云岳. 一种新型九相模块化混合励磁开关磁链直线电机[J]. 中国电机工程学报, 2017, 37(21): 6158-6167. Zeng Zhiqiang, Lu Qinfen, Ye Yunyue. A novel nine-phase modular hybrid-excited flux-switching linear machine[J]. Proceedings of the CSEE, 2017, 37(21): 6158-6167.

[34]Wang Canfei, Shen Jianxin, Wang Yu, et al. A new method for reduction of detent force in permanent magnet flux-switching linear motors[J]. IEEE Transactions on Magnetics, 2009, 45(6): 2843-2846.

[35]Wang Canfei, Shen Jianxin. A method to segregate detent force components in permanent-magnet flux-switching linear machines[J]. IEEE Transactions on Magnetics, 2012, 48(5): 1948-1955.

[36]沈建新, 王灿飞, 费伟中, 等. 永磁开关磁链直线电机若干优化设计方法[J]. 电工技术学报, 2013, 28(11): 1-8. Shen Jianxin, Wang Canfei, Fei Weizhong, et al. Some optimal design methods for permanent magnet flux switching linear machines[J]. Transactions of China Electrotechnical Society, 2013, 28(11): 1-8.

[37]Zhao Jing, Mou Qunasong, Guo Keyu, et al. Reduction of the detent force in a flux-switching permanent magnet linear motor[J]. IEEE Transactions on Energy Conversion, 2019, 34(3): 1695-1705.

[38]Boldea I, Wang Congxiao, Yang Bin, et al. Analysis and design of flux-reversal linear permanent magnet oscillating machine[C]//Conference Record of 1998 IEEE Industry Applications Conference. Thirty-Third IAS Annual Meeting (Cat. No.98CH36242), St. Louis, MO, USA, 1998: 136-143.

[39]Chung S, Lee H, Hwang S. A novel design of linear synchronous motor using FRM topology[J]. IEEE Transactions on Magnetics, 2008, 44(6): 1514-1517.

[40]Chung S, Kang D, Chang J, et al. New configuration of flux reversal linear synchronous motor[C]//2007 International Conference on Electrical Machines and Systems, Seoul, South Korea, 2007: 864-867.

[41]Chung S, Lee H, Hong D, et al. Development of flux reversal linear synchronous motor for precision position control[J]. International Journal of Precision Engineering and Manufacturing, 2011, 12(3): 443-450.

[42]Chung S, Kim J, Woo B, et al. Dynamic simulation and experimental verification of flux reversal linear synchronous motor[J]. International Journal of Precision Engineering and Manufacturing, 2012, 13(2): 175-181.

[43]Gandhi A, Mohammadpour A, Sadeghi S, et al. Doubled-sided FRLSM for long-stroke safety-critical applications[C]//IECON 2011 37th Annual Conference of the IEEE Industrial Electronics Society, Melbourne, VIC, Australia, 2011: 4186-4191.

[44]Zhao Wenxiang, Ji Jinghua, Liu Guohai, et al. Design and analysis of a new modular linear flux-reversal permanent-magnet motor[J]. IEEE Transactions on Applied Superconductivity, 2014, 24(3): 1-5.

[45]Xu Liang, Liu Guohai, Zhao Wexiang, et al. Analysis of new modular linear flux reversal permanent magnet motors[J]. IEEE Transactions on Magnetics, 2015, 51(11): 1-4.

[46]Xu Liang, Zhao Wenxiang, Ji Jinghua, et al. Design and analysis of a new linear hybrid excited flux reversal motor with inset permanent magnets[J]. IEEE Transactions on Magnetics, 2014, 50(11): 1-4.

[47]Xu Liang, Liu Guohai, Zhao Wenxiang, et al. Comparison of two linear hybrid excitation flux reversal machines with different permanent-magnet arrays[C]//2017 IEEE 26th International Symposium on Industrial Electronics (ISIE), Edinburgh, UK, 2017: 252-256.

[48]Kou Baoquan, Luo Jun, Yang Xiaobao, et al. Modeling and analysis of a novel transverse-flux flux-reversal linear motor for long-stroke application[J]. IEEE Transactions on Industrial Electronics, 2016, 63(10): 6238-6248.

[49]Luo Jun, Kou Baoquan, Zhang He, et al. Development of a consequent pole transverse flux permanent magnet linear machine with passive secondary structure[J]. CES Transactions on Electrical Machines and Systems, 2019, 3(1): 39-44.

[50]Luo Jun, Kou Baoquan, Yang Xiaobao, et al. Modelling of a dual-side excited transverse flux permanent magnet linear motor[C]//2019 22nd International Conference on Electrical Machines and Systems, Harbin, China, 2019: 1-5.

[51]Luo Jun, Kou Baoquan, Zhou Yiheng, et al. Analysis and design of an E-core transverse-flux flux-reversal linear motor[C]//2016 19th International Conference on Electrical Machines and Systems,Chiba, Japan, 2016: 1-5.

[52]Dong Dingfeng, Huang Wenxin, Bu Feifei, et al. Modeling and optimization of a tubular permanent magnet linear motor using transverse-flux flux-reversal topology[J]. IEEE Transactions on Industry Applications, 2019, 55(2): 1382-1391.

[53]Zhao Xing, Niu Shuangxia. Development of a novel transverse flux tubular linear machine with parallel and complementary pm magnetic circuit for precision industrial processing[J]. IEEE Transactions on Industrial Electronics, 2019, 66(6): 4945-4955.

[54]Guo Kaikai, Fang Shuhua, Lin Heyun, et al. 3-D analytical analysis of magnetic field of flux reversal linear-rotary permanent-magnet actuator[J]. IEEE Transactions on Magnetics, 2017, 53(6): 1-5.

[55]Guo Kaikai, Guo Youguang. Key parameter design and analysis of flux reversal linear rotary permanent magnet actuator[J]. IEEE Transactions on Applied Superconductivity, 2019, 29(2): 1-5.

[56]Iwabuchi N, Kawahara A, Kume T, et al. A novel high-torque reluctance motor with rare-earth magnet[J]. IEEE Transactions on Industry Applications, 1994, 30(3): 609-614.

[57]Mueller M A, Baker N J. Modelling the performance of the vernier hybrid machine[J]. IEE Proceedings - Electric Power Applications, 2003, 150(6): 647-654.

[58]Raihan M A H, Baker N J, Smith K J, et al. An E-core linear veriner hybrid permanent magnet machine with segmented translator for direct drive wave energy converter[C]//2017 IEEE International Electric Machines and Drives Conference, Miami, FL, USA, 2017: 1-6.

[59]Baker N J, Raihan M A H, Almoraya A A. A cylindrical linear permanent magnet vernier hybrid machine for wave energy[J]. IEEE Transactions on Energy Conversion, 2019, 34(2): 691-700.

[60]Raihan M A H, Baker N J, Smith K J, et al. Development and testing of a novel cylindrical permanent magnet linear generator[J]. IEEE Transactions on Industry Applications, 2020, 56(4): 3668-3678.

[61]Du Yi, Chau K T, Cheng Ming, et al. Theory and comparison of the linear stator permanent magnet vernier machine[C]//2011 International Conference on Electrical Machines and Systems, Beijing, China, 2011: 1-4.

[62]Du Yi, Chau K T, Cheng Ming, et al. Design and analysis of linear stator permanent magnet vernier machines[J]. IEEE Transactions on Magnetics, 2011, 47(10): 4219-4222.

[63]杜怿, 程明, 邹国棠. 初级永磁型游标直线电机设计与静态特性分析[J]. 电工技术学报, 2012, 27(11): 22-30. Du Yi, Cheng Ming, Chau K T. Design and analysis of a new linear primary permanent magnet vernier machine[J]. Transactions of China Electrotechnical Society, 2012, 27(11): 22-30.

[64]Du Yi, Cheng Ming, Chau K T. Simulation of the linear primary permanent magnet vernier machine system for wave energy conversion[C]//2013 International Conference on Electrical Machines and Systems, Busan, South Korea, 2013: 262-266.

[65]Du Yi, Cheng Ming, Chau K T, et al. Comparison of linear primary permanent magnet vernier machine and linear vernier hybrid machine[J]. IEEE Transactions on Magnetics, 2014, 50(11): 1-4.

[66]Du Yi, Cheng Ming, Chau K T, et al. Linear primary permanent magnet vernier machine for wave energy conversion[J]. IET Electric Power Applications, 2015, 9(3): 203-212.

[67]杜怿, 邹春花, 朱孝勇, 等. 初级永磁型游标直线电机绕组连接及其电磁特性比较[J]. 电工技术学报, 2017, 32(3): 130-138. Du Yi, Zou Chunhua, Zhu Xiaoyong, et al. Comparison of winding arrangements and electromagnetic characteristics of a linear primary permanent magnet vernier machine[J]. Transactions of China Electrotechnical Society, 2017, 32(3): 130-138.

[68]Du Yi, Chau K T, Cheng Ming, et al. A linear stator permanent magnet vernier HTS machine for wave energy conversion[J]. IEEE Transactions on Applied Superconductivity, 2012, 22(3): 5202505.

[69]Xiao Feng, Du Yi, Wang Yubin, et al. Modeling and analysis of a linear stator permanent-magnet vernier HTS machine[J]. IEEE Transactions on Applied Superconductivity, 2015, 25(3): 1-4.

[70]Liu Xianxing, Zou Chunhua, Du Yi, et al. A linear consequent pole stator permanent magnet vernier machine[C]//2014 17th International Conference on Electrical Machines and Systems, Hangzhou, China, 2014: 1753-1756.

[71]Liu Guohai, Jiang Shan, Zhao Wenxiang, et al. Modular reluctance network simulation of a linear permanent-magnet vernier machine using new mesh generation methods[J]. IEEE Transactions on Industrial Electronics, 2017, 64(7): 5323-5332.

[72]Liu Guohai, Ding Ling, Zhao Wenxiang, et al. Nonlinear equivalent magnetic network of a linear permanent magnet vernier machine with end effect consideration[J]. IEEE Transactions on Magnetics, 2018, 54(1): 1-9.

[73]Ji Jinghua, Zhao Wenxiang, Fang Zhuoya, et al. A novel linear permanent-magnet vernier machine with improved force performance[J]. IEEE Transactions on Magnetics, 2015, 51(8): 1-10.

[74]Zhao Wenxiang, Zheng Junqiang, Wang Jiabin, et al. Design and analysis of a linear permanent-magnet vernier machine with improved force density[J]. IEEE Transactions on Industrial Electronics, 2016, 63(4): 2072-2082.

[75]Wang Shiyuan, Zhao Wenxiang, Ji Jinghua, et al. Magnetic gear ratio effects on performances of linear primary permanent magnet vernier motor[J]. IEEE Transactions on Applied Superconductivity, 2016, 26(7): 1-5.

[76]Zhong Huan, Liu Guohai, Xu Liang. Comparative study of linear primary permanent-magnet vernier machine and conventional linear permanent-magnet machine[C]// 2019 22nd International Conference on Electrical Machines and Systems,Harbin, China, 2019: 1-5.

[77]Ma Anqi, Zhao Wenxiang, Xu Liang, et al. Influence of armature windings pole numbers on performances of linear permanent-magnet vernier machines[J]. IEEE Transactions on Transportation Electrification, 2019, 5(2): 385-394.

[78]Wang Shiyuan, Zhao Wenxiang, Kang Mei. Design and analysis of double-sided linear primary permanent magnet vernier motor[C]//2016 19th International Conference on Electrical Machines and Systems, Chiba, Japan, 2016: 1-5.

[79]Zhao Wenxiang, Wang Shiyuan, Ji Jinghua, et al. A new mover separated linear magnetic-field modulated motor for long stroke applications[J]. IEEE Transactions on Magnetics, 2017, 53(11): 1-5.

[80]Shen Yang, Kang Mei, Ji Jinghua, et al. Design and analysis of a novel modular six-phase linear permanent-magnet vernier machine[C]//2017 20th International Conference on Electrical Machines and Systems,Sydney, NSW, Australia, 2017: 1-5.

[81]Yao Tian, Zhao Wenxiang, Bian Fangfang, et al. Design and analysis of a novel modular-stator tubular permanent-magnet vernier motor[J]. IEEE Transactions on Applied Superconductivity, 2018, 28(3): 1-5.

[82]Almoraya A A, Baker N J, Smith K J, et al. Development of a double-sided consequent pole linear vernier hybrid permanent-magnet machine for wave energy converters[C]//2017 IEEE International Electric Machines and Drives Conference, Miami, FL, USA, 2017: 1-7.

[83]Raihan M A H, Baker N J, Smith K J, et al. Investigation of a doubly salient halbach array linear permanent magnet machine for wave energy converters[C]//2017 20th International Conference on Electrical Machines and Systems, Sydney, NSW, Australia, 2017: 1-5.

[84]Almoraya A A, Baker N J, Smith K J, et al. A new configuration of a consequent pole linear vernier hybrid machine with V-shape magnets[C]//2018 XIII International Conference on Electrical Machines, Alexandroupoli, Greece, 2018: 2002-2008.

[85]Baker N J, Raihan M A H, Almoraya A A, et al. Evaluating alternative linear vernier hybrid machine topologies for integration into wave energy converters[J]. IEEE Transactions on Energy Conversion, 2018, 33(4): 2007-2017.

[86]Raihan M A H, Baker N J, Smith K J, et al. Development of low translator mass linear Vernier machine for wave energy power take off[J]. The Journal of Engineering, 2019, 2019(18): 5224-5228.

[87]Almoraya A A, Baker N J, Smith K J, et al. Design and analysis of a flux-concentrated linear vernier hybrid machine with consequent poles[J]. IEEE Transactions on Industry Applications, 2019, 55(5): 4595-4604.

[88]Raihan M A H, Baker N, Smith K, et al. Linear consequent pole halbach array flux reversal machine[J]. The Journal of Engineering, 2019, 2019(17): 4560-4565.

[89]Cao Ruiwu, Cheng Ming, Mi Chris, et al. A linear doubly salient permanent-magnet motor with modular and complementary structure[J]. IEEE Transactions on Magnetics, 2011, 47(12): 4809-4821.

[90]Zhao Wenxiang, Zhu Jian, Ji Jinghua, et al. Improvement of power factor in a double-side linear flux-modulation permanent-magnet motor for long stroke applications[J]. IEEE Transactions on Industrial Electronics, 2019, 66(5): 3391-3400.

[91]Zhao Wenxiang, Ma Anqi, Ji Jinghua, et al. Multiobjective optimization of a double-side linear vernier pm motor using response surface method and differential evolution[J]. IEEE Transactions on Industrial Electronics, 2020, 67(1): 80-90.

[92]Shen Yiming, Zeng Zhiqiang, Lu Qinfen, et al. Investigation of a modular linear doubly salient machine with dual-PM in primary yoke and slot openings[J]. IEEE Transactions on Magnetics, 2019, 55(6): 1-6.

[93]Shoji S, Masayasu F, Katsuhiro H. Studies to decrease cogging force and pulsating thrust in the prototype linear permanent magnet vernier motor[C]//2008 International Conference on Electrical Machines and Systems, Wuhan, China, 2008: 3417-3422.

[94]Shimomura S, Takano M. Linear vernier machine with permanent magnets only on armature side[J]. Applied Mechanics and Materials, 2013, 416-417: 233-240.

[95]Imada T, Shimomura S. Magnet arrangement of linear PM vernier machine[C]//2014 17th International Conference on Electrical Machines and Systems, Hangzhou, China, 2014: 3642-3647.

[96]Ninomiya T, Gasim A, Shimomura S. Magnet arrangement suitable for large air gap length in linear PM vernier motor[C]//2018 International Power Electronics Conference, Niigata, Japan, 2018: 2836-2841.

[97]Shen Yiming, Zeng Zhiqiang, Lu Qinfen, et al. Design optimization and performance investigation of linear doubly salient slot permanent magnet machines[J]. IEEE Transactions on Industry Applications, 2019, 55(2): 1524-1535.

[98]Shen Yiming, Lu Qinfen, Huang Xiaoyan. Analysis of a novel linear doubly salient slot permanent magnet motor[J]. IEEE Transactions on Magnetics, 2017, 53(11): 1-4.

[99]Shen Yiming, Lu Qinfen. Design and analysis of linear hybrid-excited slot permanent magnet machines[J]. IEEE Transactions on Magnetics, 2018, 54(11): 1-6.

[100]Shen Yiming, Lu Qinfen. A novel linear hybrid-excited slot permanent magnet machine with dc-biased sinusoidal current[C]//2019 22nd International Conference on Electrical Machines and Systems, Harbin, China, 2019: 1-5.

[101]Lu Qinfen, Yao Yihua, Shi Jiameng, et al. Design and performance investigation of novel linear switched flux PM machines[J]. IEEE Transactions on Industry Applications, 2017, 53(5): 4590-4602.

[102]Shuraiji A L, Zhu Z Q, Lu Qinfen. A novel partitioned stator flux reversal permanent magnet linear machine[J]. IEEE Transactions on Magnetics, 2016, 52(1): 1-6.

[103]Zeng Zhiqiang, Lu Qinfen. Investigation of novel partitioned-primary hybrid-excited flux-switching linear machines[J]. IEEE Transactions on Industrial Electronics, 2018, 65(12): 9804-9813.

[104]Zeng Zhiqiang, Shen Yiming, Lu Qinfen, et al. Comparative study of two novel double-sided hybrid-excitation flux-reversal linear motors with surface and interior PM arrangements[J]. IEEE Transactions on Magnetics, 2019, 55(6): 1-7.

[105]Zeng Zhiqiang, Shen Yiming, Lu Qinfen, et al. Investigation of a partitioned-primary hybrid-excited flux-switching linear machine with dual-PM[J]. IEEE Transactions on Industry Applications, 2019, 55(4): 3649-3659.

[106]王欣, 程明, 花为, 等. 轨道交通用磁通切换永磁直线电机空间矢量脉宽控制[J]. 微电机, 2013, 46(4): 35-39. Wang Xin, Cheng Ming, Hua Wei, et al. Space-vector PWM control of linear flux-switching permanent magnet motor on rail transportation[J]. Micromotors, 2013, 46(4): 35-39.

[107]陈仲华, 赵文祥, 张建, 等. 高推力永磁游标直线电机的开放式绕组SVPWM控制[J]. 电工技术学报, 2016, 31(增刊2): 210-218. Chen Zhonghua, Zhao Wenxiang, Zhang Jian, et al. SVPWM control for dual two-level inverter fed open-end winding high thrust permanent magnet vernier linear motor[J]. Transactions of China Electrotechnical Society, 2016, 31(S2): 210-218.

[108]Cao Ruiwu, Cheng Ming, Zhang Bangfu. Speed control of complementary and modular linear flux-switching permanent-magnet motor[J]. IEEE Transactions on Industrial Electronics, 2015, 62(7): 4056-4064.

[109]Zhang Zheng, Cao Ruiwu, Lu Minghang, et al. Speed control of double-sided linear flux-switching permanent magnet motor system for electromagnetic launch system[C]//2017 20th International Conference on Electrical Machines and Systems, Sydney, NSW, Australia, 2017: 1-4.

[110]Zhang Yanze, Cao Ruiwu, Jin Yi, et al. Closed-loop position control of complementary and modular linear flux-switching permanent magnet motor[C]//2016 IEEE International Conference on Aircraft Utility Systems, Beijing, China, 2016: 923-926.

[111]Zhang Liqi, Cao Ruiwu, Jiang Ning. Direct thrust control of complementary and modular linear flux-switching permanent magnet motor[C]//2017 20th International Conference on Electrical Machines and Systems, Sydney, NSW, Australia, 2017: 1-4.

[112]Wu Binyu, Kang Mei, Ji Jinghua, et al. Direct thrust force control of open-end winding linear vernier permanent-magnet motor with reduced force ripple[C]//IECON 2017 43rd Annual Conference of the IEEE Industrial Electronics Society,Beijing, China, 2017: 3659-3663.

[113]杨瑞. 精密永磁直线同步电机系统扰动抑制方法研究[D]. 哈尔滨: 哈尔滨工业大学, 2020.

[114]Wang Mingyi, Yang Rui, Tan Qiang, et al. A high-bandwidth and strong robust current control strategy for PMLSM drives[J]. IEEE Access, 2018, 6: 40929-40939.

[115]Yang Rui, Wang Mingyi, Li Liyi, et al. Robust predictive current control with variable-gain adaptive disturbance observer for PMLSM[J]. IEEE Access, 2018, 6: 13158-13169.

[116]Yang Rui, Wang Mingyi, Li Liyi, et al. Robust predictive current control of PMLSM with extended state modeling based Kalman filter: for time-varying disturbance rejection[J]. IEEE Transactions on Power Electronics, 2020, 35(2): 2208-2221.

[117]Yang Rui, Li Liyi, Wang Mingyi, et al. Force ripple compensation and robust predictive current control of PMLSM using augmented generalized proportional integral observer[J]. IEEE Journal of Emerging and Selected Topics in Power Electronics, 2021, 9(1): 302-315.

[118]Bascetta L, Rocco P, Magnani G. Force ripple compensation in linear motors based on closed-loop position-dependent identification[J]. IEEE/ASME Transactions on Mechatronics, 2010, 15(3): 349-359.

[119]Chen Silu, Tan K K, Huang Sunan, et al. Modeling and compensation of ripples and friction in permanent-magnet linear motor using a hysteretic relay[J]. IEEE/ASME Transactions on Mechatronics, 2010, 15(4): 586-594.

[120]Zhu Yuwu, Jin Sangmin, Chung K, et al. Control-based reduction of detent force for permanent magnet linear synchronous motor[J]. IEEE Transactions on Magnetics, 2009, 45(6): 2827-2830.

[121]Tan K K, Huang S N, Lee T H. Robust adaptive numerical compensation for friction and force ripple in permanent-magnet linear motors[J]. IEEE Transactions on Magnetics, 2002, 38(1): 221-228.

[122]Xu Li, Yao Bin. Adaptive robust precision motion control of linear motors with negligible electrical dynamics: theory and experiments[J]. IEEE/ASME Transactions on Mechatronics, 2001, 6(4): 444-452.

[123]Yao Bin, Hu Chuxiong, Lu Lu, et al. Adaptive robust precision motion control of a high-speed industrial gantry with cogging force compensations[J]. IEEE Transactions on Control Systems Technology, 2011, 19(5): 1149-1159.

[124]Lu Lu, Chen Zheng, Yao Bin, et al. Desired compensation adaptive robust control of a linear-motor-driven precision industrial gantry with improved cogging force compensation[J]. IEEE/ASME Transactions on Mechatronics, 2008, 13(6): 617-624.

[125]Chen Zheng, Yao Bin, Wang Qingfeng. Accurate motion control of linear motors with adaptive robust compensation of nonlinear electromagnetic field effect[J]. IEEE/ASME Transactions on Mechatronics, 2013, 18(3): 1122-1129.

[126]王立俊, 赵吉文, 董菲, 等. 基于自适应内模观测器的永磁同步直线电机高带宽强鲁棒预测电流控制策略研究[J]. 中国电机工程学报, 2019, 39(10): 3098-3107.

Wang Lijun, Zhao Jiwen, Dong Fei, et al. High-bandwidth and strong robust predictive current control strategy research for permanent-magnet synchronous linear motor based on adaptive internal model observer[J]. Proceedings of the CSEE, 2019, 39(10): 3098-3107.

[127]Yang Rui, Wang Mingyi, Li Liyi, et al. Integrated uncertainty/disturbance compensation with second-order sliding-mode observer for PMLSM-driven motion stage[J]. IEEE Transactions on Power Electronics, 2019, 34(3): 2597-2607.

[128]Yang Rui, Li Liyi, Wang Mingyi, et al. Force ripple estimation and compensation of PMLSM with incremental extended state modeling-based Kalman filter: a practical tuning method[J]. IEEE Access, 2019, 7: 108331-108342.

[129]孟高军, 袁野, 张亮, 等. 基于谐波抑制和扰动观测器的磁通切换永磁直线电机联合控制方法[J]. 电工技术学报, 2018, 33(9): 1957-1966. Meng Gaojun, Yuan Ye, Zhang Liang, et al. A joint control method for linear flux-switching permanent magnet machine based on harmonic suppression and disturbance observer[J]. Transactions of China Electrotechnical Society, 2018, 33(9): 1957-1966.

[130]孟高军, 余海涛, 黄磊, 等. 基于x域重复控制的磁通切换永磁直线电机定位力抑制方法[J]. 中国电机工程学报, 2015, 35(16): 4224-4231. Meng Gaojun, Yu Haitao, Huang Lei, et al. A cogging force reduction method for linear flux-switching permanent magnet machines based on the x-domain repetitive controller[J]. Transactions of China Electrotechnical Society, 2015, 35(16): 4224-4231.

[131]Huang Wentao, Hua Wei, Yin Fangbo, et al. Model predictive thrust force control of a linear flux-switching permanent magnet machine with voltage vectors selection and synthesis[J]. IEEE Transactions on Industrial Electronics, 2019, 66(6): 4956-4967.

[132]孔龙涛, 程明, 张邦富. 基于模型参考自适应系统的模块化磁通切换永磁直线电机无位置传感器控制[J]. 电工技术学报, 2016, 31(17): 132-139. Kong Longtao, Cheng Ming, Zhang Bangfu. Position sensorless control of modular linear flux-switching permanent magnet machine based on model reference adaptive system[J]. Transactions of China Electrote-chnical Society, 2016, 31(17): 132-139.

[133]Cao Ruiwu, Jiang Ning, Lu Minghang, et al. Sliding-mode observer based sensorless vector control of LFSPM motor for long-distance drive system[J]. IET Electric Power Applications, 2019, 13(5): 643-651.

[134]Cao Ruiwu, Jiang Ning, Lu Minghang. Sensorless control of linear flux-switching permanent magnet motor based on extended Kalman filter[J]. IEEE Transactions on Industrial Electronics, 2020, 67(7): 5971-5979.

[135]Zhao Wenxiang, Jiao Shuai, Chen Qian, et al. Sensorless control of a linear permanent-magnet motor based on an improved disturbance observer[J]. IEEE Transactions on Industrial Electronics, 2018, 65(12): 9291-9300.

[136]Zhao Wenxiang, Yang Anchen, Ji Jinghua, et al. Modified flux linkage observer for sensorless direct thrust force control of linear vernier permanent magnet motor[J]. IEEE Transactions on Power Electronics, 2019, 34(8): 7800-7811.

[137]Ji Jinghua, Jiang Yang, Zhao Wenxiang, et al. Sensorless control of linear vernier permanent-magnet motor based on improved mover flux observer[J]. IEEE Transactions on Power Electronics, 2020, 35(4): 3869-3877.

[138]Zhao Wenxiang, Wu Binyu, Chen Qian, et al. Fault-tolerant direct thrust force control for a dual inverter fed open-end winding linear vernier permanent-magnet motor using improved SVPWM[J]. IEEE Transactions on Industrial Electronics, 2018, 65(9): 7458-7467.

[139]Zhao Wenxiang, Chen Zhonghua, Xu Dezhi, et al. Unity power factor fault-tolerant control of linear permanent-magnet vernier motor fed by a floating bridge multilevel inverter with switch fault[J]. IEEE Transactions on Industrial Electronics, 2018, 65(11): 9113-9123.

[140]Zhao Wenxiang, Zhao Peng, Xu Dezhi, et al. Hybrid modulation fault-tolerant control of open-end windings linear vernier permanent-magnet motor with floating capacitor inverter[J]. IEEE Transactions on Power Electronics, 2019, 34(3): 2563-2572.

Overview of Permanent Magnet Linear Machines with Primary Excitation

Shen Yiming Lu Qinfen

(College of Electrical Engineering Zhejiang University Hangzhou 310027 China)

The permanent magnet linear machine with primary excitation (PE-PMLM) is a new type of special machine derived from the traditional permanent magnet linear machine, which has the advantages of high thrust force density, high efficiency, high precision and high reliability. In the field of long stroke direct drive linear motion, it exhibits unique performance and cost advantages, and has high research value as well as broad application prospect. This paper reviews and summarizes the current status and development trend of the PE-PMLM technology. Based on the flux modulation theory, the harmonic distribution and thrust generation principle of the PE-PMLM are revealed. From the perspective of topology, the technical points and research progress of various kinds of PE-PMLM are reviewed. Based on the characteristics of PE-PMLM, high performance control strategies are introduced. Finally, comprehensive performances of all kinds of PE-PMLM are compared and analyzed, and the future development direction is discussed.

Permanent magnet linear machine, primary excitation, doubly salient, flux modulation theory, high thrust force density, long stroke

TM351

10.19595/j.cnki.1000-6753.tces.201125

国家自然科学基金(51777190)和中国博士后科学基金(2020M681856)资助项目。

2020-08-21

2020-11-02

沈燚明 男,1993年生,博士,研究方向为新型永磁电机及其控制技术等。E-mail:ym_shen@zju.edu.cn

卢琴芬 女,1972年生,教授,博士生导师,研究方向为直线电机优化设计、驱动控制及应用技术等。E-mail:luqinfen@zju.edu.cn(通信作者)

(编辑 郭丽军)