柴油机瞬态VNT开度优化研究

2021-06-01杨仕臣万明定申立中王正江黄粉莲

杨仕臣,万明定,申立中,王正江,黄粉莲

柴油机瞬态VNT开度优化研究

杨仕臣,万明定,申立中※,王正江,黄粉莲

(昆明理工大学云南省内燃机重点实验室,昆明 650500)

瞬态工况下,可变喷嘴涡轮增压器(Variable Nozzle Turbocharger,VNT)开度的调节对柴油机增压压力、扭矩响应及污染物排放具有较大影响。为优化瞬态工况下VNT开度,实现瞬态工况下柴油机与VNT的协调控制,该研究以配备VNT的高压共轨柴油机为对象,通过台架试验研究了不同转速下负荷1、3和5 s从0瞬变至50%、75%和100%时,不同VNT开度对柴油机瞬态性能及排放的影响。结果表明:2 000 r/min下,负荷1、3和5 s从0瞬变至50%、75%、100%的过程中,VNT开度对负荷1 s瞬变工况的影响比3和5 s明显;随着VNT开度减小,增压压力响应时间逐渐缩短,扭矩响应时间先减小后增大。1 600、2 000和2 600 r/min下,负荷1 s从0瞬变至75%的过程中,NOx体积分数先增大后减小,然后再逐渐增大趋于稳定;颗粒物数量(PN)峰值随VNT开度的减小而增大。综合考虑柴油机瞬态响应和排放,对全工况范围下柴油机的VNT开度控制进行优化,获得了柴油机瞬态工况下的优化VNT开度协调控制方案,并进行WHTC循环试验,结果表明:与原机相比,冷、热态下WHTC循环扭矩回归线的截距分别下降0.03和0.37,标准偏差分别下降0.11和1.07;WHTC冷、热态循环NOx比排放与原机相比分别下降7.59%和2.21%;颗粒物排放量(PM)下降8.64%和25.28%;PN下降6.74%和12.4%。研究结果可为柴油机瞬态工况下VNT的协调控制提供参考。

柴油机;排放;瞬态工况;VNT开度;WHTC循环

0 引 言

车用柴油机在实际运行中频繁处于加减速和负荷变化等瞬态工况,瞬态工况占66%~80%[1]。由于增压器迟滞[2-4]等原因,增压压力及进气量的变化速率滞后于喷油量的变化速率[5-6]造成瞬态工况下柴油机性能和排放恶化[7-11]。研究表明[12-14],采用可变喷嘴涡轮增压器(Variable Nozzle Turbocharger,VNT)是改善柴油机瞬态性能的有效措施之一。周鹏程等[15]建立GT-Power和MATLB/Simulink联合仿真模型,研究了可变截面涡轮增压器(Variable Geometry Turbocharger,VGT)对发动机性能的影响,结果表明:VGT明显改善瞬态工况下柴油机的动力性、经济性和动态响应特性,有效降低涡轮迟滞时间约为30%。张众杰等[16]建立高海拔VGT与固定截面涡轮增压器串联的二级可调增压柴油机仿真模型,研究了不同海拔瞬态工况下VGT叶片的调节特性,结果表明:等速加载工况下,VGT最优控制策略为加载初期保持VGT叶片开度不变至加载中段,之后开度线性增加至加载后稳态工况对应开度;恒载加速工况下,加速初期开始增大VGT叶片开度,至加载中段开度增加至最大转速对应开度,之后VGT开度保持不变持续至加速结束的调节策略加速性能最好。Wijetugne等[17]建立以排气压力作为反馈变量的VNT瞬态控制策略,采用PID(Proportion Integration Differentiation,PID)控制器调节喷嘴环开度,通过控制EGR开度调节进气流量,结果表明:该方法降低了反馈延迟,提高了瞬态响应,减少了泵气损失,降低了瞬态烟度。Black等[18]研究了不同VGT开度对柴油机增转速下瞬态性能的影响,结果表明:合理的VGT开度可以降低压比和排气背压,从而减小泵气损失,改善了瞬态性能。孙万臣等[19]试验研究了VNT对车用柴油机瞬态性能与排放的影响,结果表明:合理调节VNT喷嘴环开度,可减小高瞬变率工况下柴油机性能恶化的程度,有效改善加速工况和增负荷工况下的排气烟度。

综上所述,合理控制VNT开度是改善柴油机瞬态性能和排放的关键[20]。VNT开度过小,虽然提高了增压压力瞬态响应,但是较小的VNT开度会造成泵气损失增大,从而导致扭矩响应差,经济性恶化,极端情况下还会造成油耗上升、增压器喘振和超速等问题[21-22]。VNT开度过大,增压压力响应慢,发动机进气量滞后,造成发动机瞬态工况下燃烧、性能和排放等出现不同程度的恶化[18]。因此,需要根据发动机瞬态工况的变化合理协调控制瞬态VNT开度,以保证增压压力、扭矩等快速响应的同时有效降低NOx和PM等排放。

为优化柴油机瞬态工况下VNT开度,改善柴油机瞬态性能和排放,本文以配备VNT的柴油机为研究对象,利用大气压力模拟系统,试验研究了标准大气压力下不同VNT开度对柴油机恒转速增转矩瞬态模式下增压压力及扭矩响应和排放的影响及变化规律,然后对柴油机全工况范围内的瞬态VNT开度进行了优化,以期为柴油机瞬态工况下VNT的控制提供参考。

1 试验设备及试验方案

1.1 试验设备

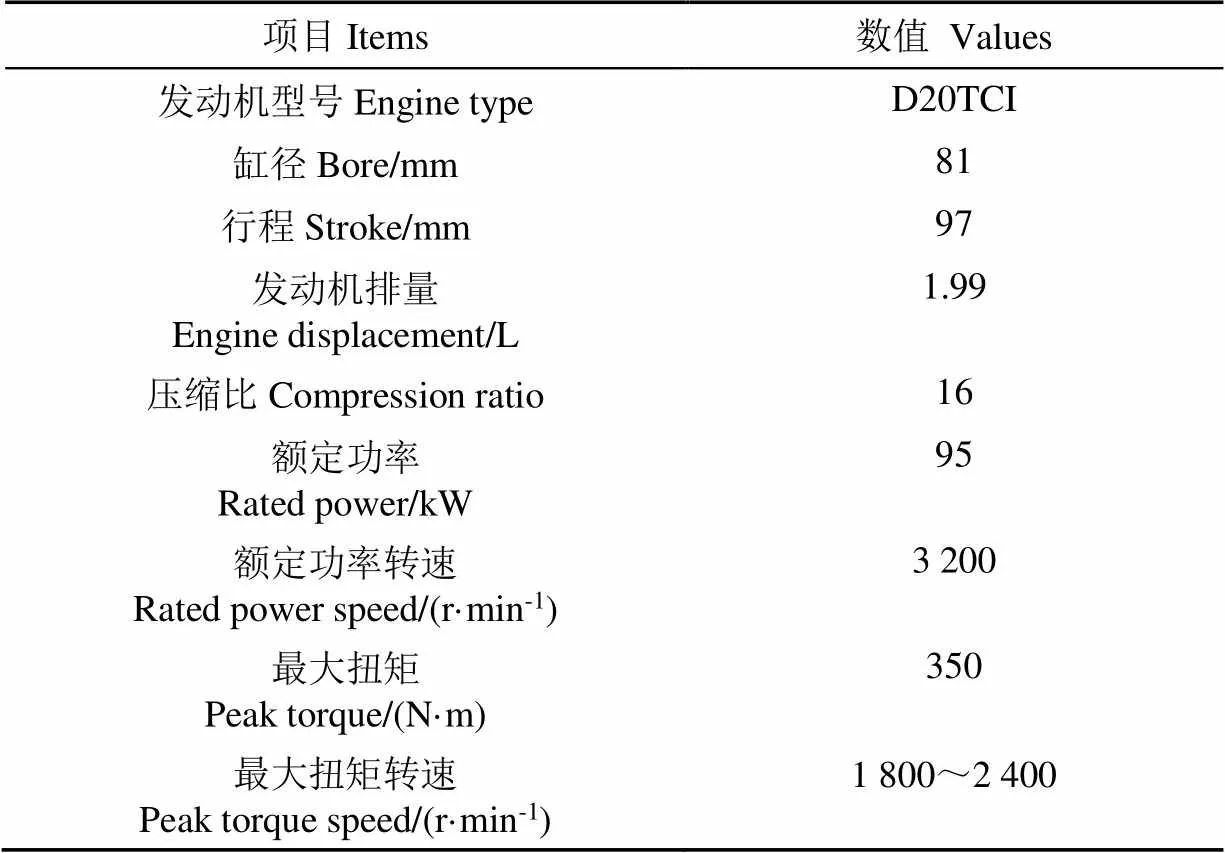

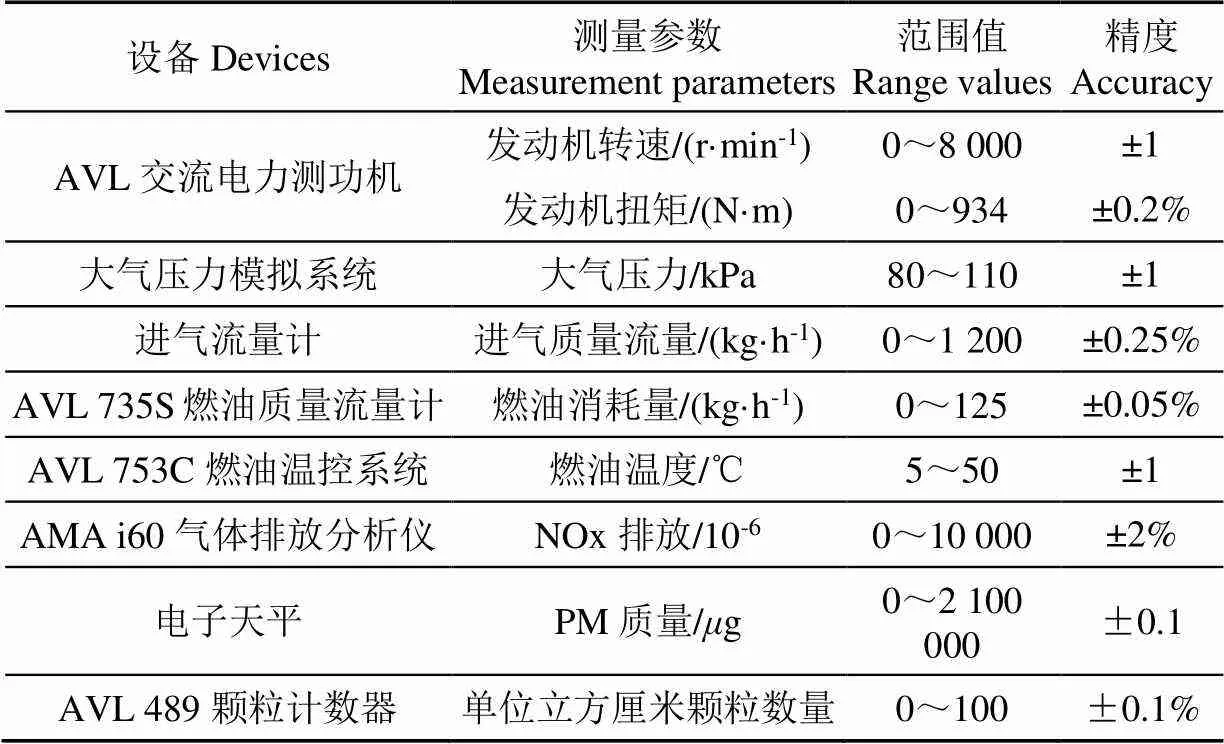

试验用发动机为一台配备VNT和EGR的直列四缸高压共轨柴油机,基本参数如表1所示。其中涡轮增压器为Honeywell GTC 1446VZ,压气机A/R(R为涡轮轴承中心到压气机出口横截面中心点的距离,A为压气机壳体的出口对应以上中心点所在的横截面积)值为0.39,涡轮A/R值为0.27,最高转速为220 000 r/min。设备仪器包括AVL Dynoroad 202/12 交流电力测功机、AVL PUMA OPEN 测控系统、AVL 735S 燃油质量流量计、AVL 753C燃油温控系统、AVL AMA i60部分流排放分析仪、AVL 489颗粒计数器、AVL SPC 478颗粒采集器、电子天平、大气压力模拟系统、BOSCH可标定发动机控制单元、ES590、INCA 标定软件等,主要设备参数如表 2所示。试验台架布置如图1所示。

表1 发动机基本参数

1.2 试验方案

1)试验工况选择:由于车用柴油机在实际运行中,转速和负荷频繁变化。为保证研究结果尽可能接近实际情况,选择1 600、2 000和2 600 r/min作为试验转速。在3个转速下,分别以对应的0负荷作为起始负荷,50%、75%和100%负荷为终止负荷进行恒转速增转矩瞬态试验,负荷响应时间分别设置为1、3和5 s。

2)VNT协调控制方案:在瞬态工况下,VNT开度是影响柴油机瞬态性能的重要因素之一[23]。瞬态工况下,减小VNT开度能提高增压压力和进气量响应速度。恒转速增转矩瞬态模式下,瞬态初期保持VNT开度不变,中后期逐渐增大的瞬态VNT开度控制方式能够保证最佳的柴油机瞬态性能[16]。因此,提出随循环喷油量(负荷)增大逐渐增大VNT开度的瞬态VNT开度控制策略。为优化瞬态VNT开度控制,以稳态工况VNT开度减小5%作为对应转速下初始瞬态VNT开度(VNT1),以步长5%逐渐减小VNT开度直至喷油量为0时VNT开度全关。每一转速下分别组成如图2所示的4组瞬态VNT开度,VNT1~VNT4表示VNT开度逐渐减小(95%代表全关,0代表全开)。试验过程中,喷油正时和喷油压力不受VNT开度变化的影响,仅随喷油量的变化而变化,如图 3所示。为保证试验数据的准确性,每组试验重复做3次,结果取平均值。

表2 主要设备参数

2 试验结果与分析

2.1 不同VNT开度对瞬态响应的影响

瞬态工况下,不同的VNT开度会导致柴油机的增压压力和进气量响应不同,进而导致柴油机瞬态性能和排放的差异[24]。

图4所示为2 000 r/min下不同VNT开度、不同负荷响应时增压压力的响应时间,其中增压压力响应时间定义为负荷变化开始至增压压力达到目标值的95%所用时间。由图4可看出,0~50%负荷的瞬变过程中,VNT2~4增压压力响应时间与VNT1相比,1 s负荷响应时间下减小0.2、0.3和0.4 s,3 s负荷响应时间下减小0.8、0.9和1.3 s,5 s负荷响应时间下减小0.6、0.7和0.8 s,如图 4a。0~75%负荷的瞬变过程中,VNT2~4增压压力响应时间与VNT1相比,1 s负荷响应时间下减小1、1.3和1.4 s,3 s负荷响应时间下减小0.8、0.9和1.3 s,5 s负荷响应时间下减小0.6、0.7和0.8 s,如图4b。0~100%负荷的瞬变过程中,VNT2~4增压压力响应时间与VNT1相比,1 s负荷响应时间下减小0.9、1.4和1.7 s,3 s负荷响应时间下为1.1、1.5和1.6 s,5 s负荷响应时间下为0.5、0.6和0.7 s,如图4c。造成这种现象的主要原因是:瞬态工况下,VNT开度越小,增压压力响应时间越快[18]。

图5所示为2 000 r/min下不同VNT开度、不同负荷响应时扭矩的响应时间,其中扭矩响应时间定义为负荷变化开始至扭矩达到目标值的95%所用时间。由图5可看出,扭矩响应时间随VNT开度减小先减小后增大。这是因为:VNT开度减小后,增压压力响应至目标值的时间缩短,而在VNT开度过小后,虽然增压压力迅速上升,但是压差的增大造成背压和泵气损失增大,导致扭矩响应变慢。因此需要选择最佳的VNT协调控制开度匹配不同的瞬态工况,以保证增压压力和扭矩的快速响应。

2.2 不同转速下VNT开度对瞬态性能和排放的影响

图6所示为不同转速下不同VNT开度、负荷响应1 s时增压压力和扭矩的响应时间。由图6可看出:1 600 r/min下的增压压力响应时间为3.5、2.62、2.58和2.7 s,扭矩响应时间为3.75、3.7、3.5和3.8 s,如图6a。2 000 r/min 下的增压压力响应时间为4.2、3.2、2.9和2.8 s,扭矩响应时间为4.4、2.4、2.7和4.2 s,如图6b。2 600 r/min下的增压压力响应时间为3.5、3.3、2.8和2.3 s,扭矩响应时间为3.9、3.6、3.1和3.7 s,如图6c。

图7所示为瞬变过程中不同转速下NOx体积分数和颗粒数量PN的变化。不同转速下NOx体积分数先增大后减小,产生一个峰值和一个谷值,然后又增大趋于稳定,随着VNT开度的减小,峰值和谷值逐渐减小。由图 7a可看出:1 600 r/min下VNT1~4对应的NOx体积分数向上的峰值各为510、489、466和447 mL/L,VNT2~4与VNT1相比下降4.12%、8.63%和12.3%;谷值各为391、355、340和330 mL/L,VNT2~4较VNT1下降9.21%、13.04%和15.6%。2 000 r/min下不同VNT开度对应NOx体积分数向上的峰值分别为580、560、502和478 mL/L,VNT2~4与VNT1相比减小3.45%、13.45%和17.59%;谷值各为546、513、424和337 mL/L,VNT2~4与VNT1相比减小了6.04%、22.34%和38.28%。2 600 r/min下不同VNT开度对应NOx体积分数向上的峰值分别为437,397、382和351 mL/L,VNT 2~4与VNT1相比下降了9.15%、12.59%和19.68%;谷值分别为416、343、261和216 mL/L,VNT2~4与VNT1相比下降了17.55%、37.26%和48.08%。造成不同转速下NOx体积分数先增大再减小然后增大趋于稳定的主要原因是:负荷1 s响应至目标值,由于进气歧管及EGR管路的填充排空效应,空气具有可压缩性[25],导致增压压力和进气量滞后于喷油速率,VNT在瞬变过程开始后开度关小,EGR率也较小,较小的VNT开度使增压压力快速升高,NOx产生了尖峰;而当增压压力接近或大于目标压力时,进气量已可以匹配喷油量,VNT逐渐增大开度,同时通过协调控制增大了EGR阀,NOx排放降低产生向下的峰值,此时的VNT开度越小,EGR阀的开度就越大,所以NOx下降越多。

由图7b可看出,瞬变过程中,粒子数量PN产生向上的峰值。其中1 600 r/min下粒子数量PN峰值在瞬变过程中随VNT开度的减小尖峰值逐渐增大,分别为2.49×108、2.54×108、2.58×108和2.61×108#/cm3,VNT2~4与VNT1相比增大2.01%、3.21%和4.82%。2 000 r/min下VNT1~4对应PN峰值为7.75×107、1.17×108、1.33×108和1.37×108#/cm3,VNT2~4与VNT1相比增大51.06%、71.85%和77.29%。2 600 r/min下VNT1~4对应的PN峰值为1.66×108、1.78×108、1.98×108和2.36×108#/cm3,VNT2~4与VNT相比增大7.23%、19.28%和42.17%。造成瞬变过程中PN产生这种现象的主要原因是:在负荷1 s响应的瞬变过程中,油量响应比增压压力响应快,另外,可从图6看出,不同的VNT开度下增压压力在1 600、2 000和2 600 r/min下平均响应时间分别为2.85、2.95和2.98 s,进气量的滞后使燃油燃烧不充分,从而使粒子数量骤增,产生尖峰[26],且峰值随VNT开度的减小而增大。

通过以上分析及对比,综合考虑瞬态响应和排放,得到1 600、2 000和2 600 r/min下负荷从0瞬变至75%的恒转速增转矩工况的最佳VNT开度分别为对应转速下的VNT2、VNT2和VNT2。

3 瞬态VNT开度优化

基于前面的分析结果,在综合柴油机瞬态响应和排放的基础上,对全工况范围柴油机VNT开度控制进行优化,获得了柴油机瞬态工况下的优化VNT开度协调控制方案。然后进行WHTC循环试验,对优化前后柴油机扭矩允差和污染物排放进行对比分析。

3.1 原机与优化后扭矩响应对比分析

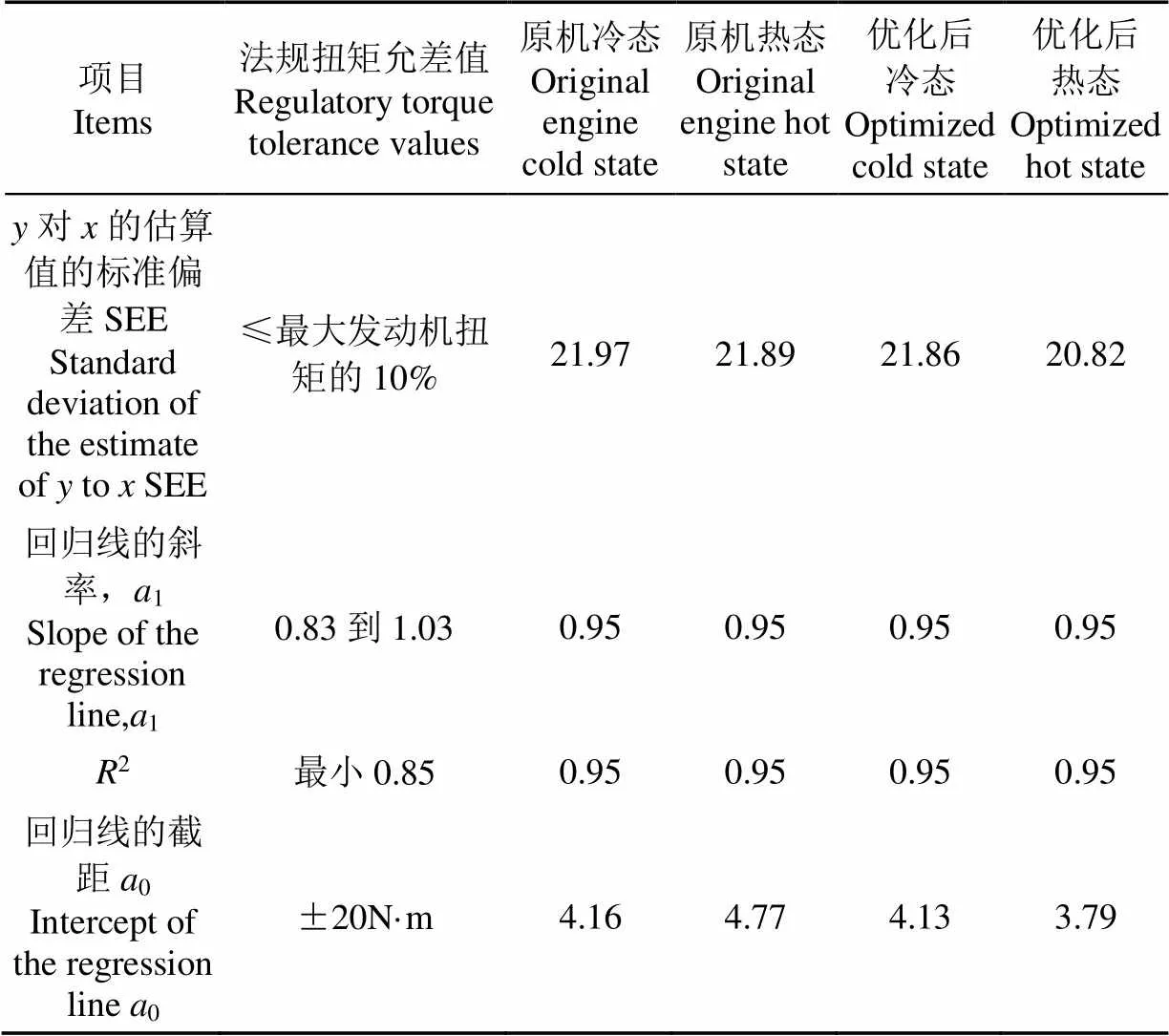

根据国六法规要求,采用最小二乘法对WHTC循环下扭矩响应进行基于基准值和实际值的线性回归分析[27]。公式为

=1+0,

式中为循环中扭矩的实际值,为基准值,1为回归线的斜率,0为回归线的截距。

表3所示为原机与优化后WHTC循环回归线扭矩的允差。从表中可以看出,原机与优化后扭矩的回归线斜率1和决定系数2值均为0.95;优化后冷、热态回归线的截距分别下降了0.03和0.37,热态扭矩回归线截距下降明显;优化后冷态扭矩基准值与对于实际值的标准偏差减小0.11,热态减小1.07,标准偏差分别下降了0.72%和4.89%。标准偏差越小,偏离平均值就越小。协调控制后的VNT开度降低了循环中转矩的标准偏差,提升了瞬态响应。

3.2 原机与优化后排放对比

WHTC循环试验可得出冷、热态循环的1 800个工况点的累计排放量,然后计算获得WHTC循环比排放[28]。

表3 WHTC回归线扭矩的允差

图8所示为原机与不同VNT开度协调控制后WHTC冷、热态循环下不同排放污染物的比排放。由图8a可看出,原机WHTC循环冷、热态NOx比排放分别为3.69和3.93 g/kW·h,优化后降至3.41和3.84 g/kW·h,与原机相比下降了7.59%和2.21%;由图8b可看出,PM原机冷、热态循环比排放分别为0.220和0.265 g/kW·h,优化后下降至0.201和0.198 g/kW·h,优化后与原机相比下降了8.64%和25.28%;由图8c可看出,粒子数量PN原机冷、热态循环比排放分别为2.97×1014和2.91×1014#/kW·h,优化后下降至2.77×1014和2.55×1014#/kW·h,与原机相比下降了6.74%和12.4%。

VNT控制开度协调优化后WHTC循环冷态NOx比排放、热态PM和PN比排放显著下降,存在trade-off关系的NOx和PM排放物[29-30]在WHTC循环中都有不同比例的下降,说明了协调控制的VNT开度对瞬态工况排放物优化的可行性。

4 结 论

1)2 000 r/min下不同VNT开度、不同负荷响应时,对负荷1 s的响应影响最大。增压压力响应时间随VNT开度减小而缩短,VNT开度越小,增压压力响应越快,扭矩响应时间随VNT开度的减小先减小后增大。

2)VNT开度对1 600、2 000和2 600 r/min下负荷1 s从0瞬变至75%的排放影响明显,瞬变过程中随VNT开度的减小,NOx体积分数先增大后减小然后增大并趋于稳定;PN峰值随VNT开度减小而增大。

3)优化瞬态VNT开度后进行WHTC循环试验,结果优于原机。扭矩冷、热态回归线的截距与原机相比分别下降了0.03和0.37;冷、热态标准偏差下降0.72%和4.89%。WHTC循环比排放与原机相比,冷、热态NOx比排放分别下降7.59%和2.21%;颗粒物排放量下降8.64%和25.28%;颗粒物数量下降6.74%和12.4%。

[1] 黄粉莲,纪威,周炜,等. 车用涡轮增压柴油机加速工况瞬态特性仿真[J]. 农业工程学报,2014,30(3):63-69. Huang Fenlian, Ji Wei, Zhou Wei, et al. Simulation of transient performance of vehicle turbocharged diesel engine during acceleration process[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(3): 63-69. (in Chinese with English abstract)

[2] Yum K K, Lefebvre N, Pedersen E. An experimental investigation of the effects of cyclic transient loads on a turbocharged diesel engine[J]. Applied Energy, 2017, 185: 472-481.

[3] Vafaie M H, Dehkordi B M, Moallem P, et al. A new predictive direct torque control method for improving both steady-state and transient-state operations of the PMSM. IEEE Transactions on power electron, 2015, 31(5), 3738–3753.

[4] 张众杰,刘瑞林,夏南龙,等. 车用柴油机瞬态特性劣变机理及优化策略[J]. 军事交通学院学报,2018,20(8):34-39. Zhang Zhongjie, Liu Ruilin, Xia Nanglong, et al. Transient performance deterioration mechanism and optimization strategy for vehicle diesel engine[J]. Journal of Military Transportation University, 2018, 20(8): 34-39. (in Chinese with English abstract)

[5] 董天普,张付军,刘波澜,等. EGR对涡轮增压柴油机瞬态特性的影响[J]. 内燃机学报,2017,35(2):118-124. Dong Tianpu, Zhang Fujun, Liu Bolan, et al. Effect of EGR on transient characteristics of turbocharged diesel engine[J]. Transactions of CSICE, 2017, 35(2): 118-124. (in Chinese with English abstract)

[6] 田径,刘忠长,许允,等. 柴油机瞬变过程烟度排放的劣变分析[J]. 内燃机学报,2016,34(2):125-134. Tian Jing, Liu Zhongchang, Xu Yun, et al. Analysis of soot deterioration in diesel transient process[J]. Transactions of CSICE. 2016, 34(2):125-134. (in Chinese with English abstract)

[7] Kang H, Farrell P. Experimental investigation of transient emissions (HC and NOx) in a high speed direct injection (HSDI) diesel engine[C]//SAE 2005 Powertrain & Fluid Systems Conference & Exhibition, 2005.

[8] 王敏,杨蓉,叶洲,等. 商用车用电控柴油机增转矩工况的燃烧特性分析[J]. 内燃机工程,2020,41(5):23-31. Wang Min, Yang Rong, Ye Zhou, et al. Research on combustion characteristics of electronically controlled diesel engine for commercial vehicles at torque-increasing condition[J]. Chinese Internal Combustion Engine Engineering, 2020, 41(5): 23-31. (in Chinese with English abstract)

[9] 田荐伊,陆国祥,徐宏明. 可变增量的EGR控制策略对柴油机瞬态排放的影响[J]. 内燃机学报,2016,34(5):394-400. Tian Jianyi, Lu Guoxiang, Xu Hongming. Incremental variable EGR strategy for optimizing transient emissions of turbo-charged diesel engines[J]. Transactions of CSICE. 2016, 34(5): 394-400. (in Chinese with English abstract)

[10] Saad S M, Mishra R. Performance of a heavy-duty turbocharged diesel engine under the effect of air injection at intake manifold during transient operations[J]. Arabian Journal for Science and Engineering, 2019, 44(6): 5863-5875.

[11] Rakopoulos C D, Dimaratos A M, Giakoumis E G, et al. Exhaust emissions estimation during transient turbocharged diesel engine operation using a two-zone combustion model[J]. International Journal of Vehicle Design, 2009, 49(1-3): 125-149.

[12] Filipi Z, Wang Y, Assanis D. Variable geometry turbine (VGT) strategies for improving diesel engine in-vehicle response: A simulation study[J]. International Journal of Heavy Vehicle Systems, 2004, 11(3): 303-326.

[13] Gurel Cetin, Ozmen Elif, Yilmaz Metin, et al. Multi-objective optimization of transient air-fuel ratio limitation of a diesel engine using DoE based pareto-optimal approach[C]//SAE 2017 World Congress Experience, 2017.

[14] Filipi Z, Wang Y, Assanis D N. Effect of variable geometry turbine (VGT) on diesel engine and vehicle system transient response[C]//SAE 2001 World Congress, 2001.

[15] 周鹏程,王银燕,王贺春,等. 可变截面涡轮增压瞬态性能仿真研究[J]. 船舶工程,2018,40(1):76-80. Zhou Pengcheng, Wang Yinyan, Wang Hechun, et al. Simulation study of transient characteristics of variable geometry turbocharging[J]. Ship Engineering, 2018, 40(1): 76-80. (in Chinese with English abstract)

[16] 张众杰,刘瑞林,林春城,等. 二级可调增压柴油机高海拔瞬态特性仿真[J]. 内燃机学报,2019,37(5):393-400. Zhang Zhongjie, Liu Ruilin, Lin Chuncheng, et al. Simulation on transient characteristics of regulated two-stage-turbocharged diesel engine at high altitudes[J]. Transactions of CSICE, 2019, 37(5): 393-400. (in Chinese with English abstract)

[17] Wijetunge R S, Hawley J G, Vaughan N D. An exhaust pressure control strategy for a diesel engine[J]. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, 2004, 218(4): 449-464.

[18] Black J, Eastwood P G, Tufail K, et al. The effect of VGT vane control on pumping losses during full-load transient operation of a common-rail diesel engine[C]//SAE 2007 8th International Conference on Engines for Automobiles, 2007.

[19] 孙万臣,韩永强,刘忠长,等. 可变喷嘴涡轮增压器对车用柴油机瞬态性能的影响[J]. 汽车工程,2006,28(2):122-124. Sun Wanchen, Han Yongqiang, Liu Zhongchang, et al. Effect of variable nozzle turbocharger on transient performance of automotive diesel engine[J]. Automotive Engineering, 2006, 28(2): 122-124. (in Chinese with English abstract)

[20] 杨殿勇,王忠,历宝录,等. VNT增压柴油机与整车速度瞬态响应的试验分析[J]. 车用发动机,2005(5):44-47. Yang Dianyong, Wang Zhong, Li Baolu, et al. Analysis of the velocity transient response of VNT in turbocharged diesel &vehicle[J]. VEHICLE ENGINE, 2005(5): 44-47. (in Chinese with English abstract)

[21] 施新,张双双,李斌. 可变几何涡轮与压气机协同调节对柴油机瞬态性能影响的仿真研究[J]. 汽车工程,2014,36(9):1046-1050. Shi Xin, Zhang Shuangshuang, Li Bin. A simulation study on the effect of coordinated regulation between VGT and VGC on the transient performance of diesel engine[J]. Automotive Engineering, 2014, 36(9): 1046-1050. (in Chinese with English abstract)

[22] TufailK, Winstanley T, Karagiorgis S, et al. Characterisation of diesel engine transient pumping-loss and control methodology for transient specific fuel consumption (SFC)[C]//SAE 2009 Powertrains Fuels and Lubricants Meeting, 2009

[23] Llamas X, Eriksson L. Optimal transient control of a heavy duty diesel engine with EGR and VGT[J]. IFAC Proceedings Volumes, 2014, 47(3): 11854-11859.

[24] Han Y, Zhang L, Liu Z, et al. Investigation of transient deterioration mechanism and improved method for turbocharged diesel engine[J]. Energy, 2016, 116: 250-264.

[25] 郑广勇,于秀敏,侯福建,等. 通过增压器匹配提高发动机瞬态性能[J]. 吉林大学学报:工学版,2013,43(1):45-50. Zheng Guangyong, Yu Xiumin, Hou Fujian, et al. Turbocharger matching to improve engine transient performance[J]. Journal of Jilin University: Engineering and Technology Edition, 2013, 43(1): 45-50. (in Chinese with English abstract)

[26] 熊兴旺,高俊华,周涛,等. 基于WHTC循环的柴油机颗粒物数量峰值的研究[J]. 汽车工程,2017,39(4):381-385. Xiong Xingwang, Gao Junhua, Zhou Tao, et al. A study on particulate number peaks in a diesel engine based on WHTC cycle[J]. Automotive Engineering, 2017, 39(4): 381-385. (in Chinese with English abstract)

[27] 国家市场监督管理总局. 重型柴油车污染物排放限值及测量方法(中国第六阶段):GB17691—2018[S]. 北京:中国环境科学出版社,2018.

[28] Bai S Z, Han J L, Liu M, et al. Experimental investigation of exhaust thermal management on NOx emissions of heavy-duty diesel engine under the world Harmonized transient cycle (WHTC)[J]. Applied Thermal Engineering, 2018, 142: 421-432.

[29] Zamboni G, Moggia S, Capobianco M. Effects of a dual-loop exhaust gas recirculation system and variable nozzle turbine control on the operating parameters of an automotive diesel engine[J]. Energies, 2017, 10(1): 47.

[30] Wu B Y, Zhan Q, Yu X Y, et al. Effects of miller cycle and variable geometry turbocharger on combustion and emissions in steady and transient cold process[J]. Applied Thermal Engineering, 2017, 118: 621-629.

Optimization of transient VNT opening of diesel engines

Yang Shichen, Wan Mingding, Shen Lizhong※, Wang Zhengjiang, Huang Fenlian

(,,650500,)

The opening of a variable nozzle turbocharger (VNT) has a significant impact on the boost pressure, torque response, and emissions of a diesel engine under transient conditions. In order to achieve better diesel engine transient performance, realize the coordinate control of the diesel engine and the VNT nozzle opening and to improve the transient response of the diesel engine while reducing the emissions. In this study, the VNT opening was calibrated on the bench of a high-pressure common-rail diesel engine for better performance. A bench test was conducted to investigate the effect of VNT openings on the transient performance and emissions of diesel engine at the rotation rate of 1 600, 2 000, and 2 600 r/min, when the response load was transient from 0 to 50%, 75%, and 100% at 1, 3, and 5 s of an accelerator pedal. The results show that there was a much more obvious effect of VNT opening on the transient condition of load response time 1, 3, and 5 s from 0 to 50%, 75%, and 100% of the load at 2 000 r/min than that of 3 and 5 s. The response time of boost pressure gradually decreased, while the response time of torque decreased and then increased, as the VNT opening decreased. The NOx volume fraction first increased, then decreased, and finally increased to a stable value, when the response time of accelerator pedal at 1s from 0% to 50%, 75% and 100% at 1 600, 2 000 and 2 600 r/min. The particle number (PN) emission increased gradually with the decrease of VNT opening. A World Harmonized Transient Cycle (WHTC) test was carried out after the optimum VNT opening was obtained at different speeds. The simulation data showed that the VNT opening reduced the intercept and standard deviation for the WHTC cycle torque regression line. The intercept decreased by 0.03 and 0.37 in cold and hot states, while the standard deviation decreased by 0.11 and 1.07, respectively. The NOx brake specific emissions decreased by 7.59% and 2.21% under the WHTC cold and hot cycles, while the particulate matter (PM) brake specific emissions reduced by 8.64% and 25.28%, and the PN brake specific emissions dropped by 6.74% and 12.4%, compared with the original engine. After optimizing the VNT opening, the standard deviation of the actual torque value from the reference value is reduced, and the main pollutants are reduced in different proportions, which shows the feasibility of the coordinated control of the VNT opening to optimize the transient performance and emissions of the diesel engine. The finding can provide a sound reference for the coordinated control of VNT opening under transient operating conditions in a diesel engine.

diesel engine; emissions; transient conditions; VNT openings; WHTC cycle

杨仕臣,万明定,申立中,等.柴油机瞬态VNT开度优化研究[J]. 农业工程学报,2021,37(6):35-41.doi:10.11975/j.issn.1002-6819.2021.06.005 http://www.tcsae.org

Yang Shichen, Wan Mingding, Shen Lizhong, et al. Optimization of transient VNT opening of diesel engines[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(6): 35-41. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2021.06.005 http://www.tcsae.org

2021-01-15

2021-03-05

国家自然科学基金项目(52066008,51666005);云南省科技计划项目(2019FB073);云南省科技计划项目(2018FA030)

杨仕臣,研究方向为柴油机燃烧及污染物排放控制。Email:1051550445@qq.com

申立中,教授,博士生导师,主要研究方向为内燃机电控技术、不同海拔下内燃机工作过程。Email:lzshen@foxmail.com

10.11975/j.issn.1002-6819.2021.06.005

TK427

A

1002-6819(2021)-06-0035-07