Enhanced thermoelectric performance of hydrothermally synthesized polycrystalline Te-doped SnSe

2021-05-14PiLiXinAiQihaoZhangShijiaGuLianjunWangWanJianga

Pi Li,Xin Ai,Qihao Zhang*,Shijia Gu,Lianjun Wang**,Wan Jianga,

a State Key Laboratory for Modification of Chemical Fibers and Polymer Materials, College of Materials Science and Engineering, Donghua University, Shanghai 201620, China

b College of Information Science and Technology, Donghua University, Shanghai 201620, China

c State Key Laboratory of High Performance Ceramics and Superfine Microstructure, Shanghai Institute of Ceramics, Chinese Academy of Sciences, Shanghai 200050, China

d Center of Materials Science and Optoelectronics Engineering, University of Chinese Academy of Sciences, Beijing 100049, China

e Institute of Functional Materials, Donghua University, Shanghai 201620, China

f Engineering Research Center of Advanced Glasses Manufacturing Technology, Ministry of Education, Shanghai 201620, China

ABSTRACT In this study, large-scale Te-doped polycrystalline SnSe nanopowders were synthesized by a facile hydrothermal approach and the effect of Te doping on the thermoelectric properties of SnSe was fully investigated.It is found that the carrier concentration increases due to the reduction of band gap by alloying with Te, which contributes to significant enhancement of electrical conductivity especially at room temperature.Combined with the moderated Seebeck coefficient, a high power factor of 4.59is obtained at 773 K.Furthermore,the lattice thermal conductivity is greatly reduced upon Te substitution owing to the atomic point defect scattering.Benefiting from the synergistically optimized both electrical- and thermal-transport properties by Te-doping, thermoelectric performance of polycrystalline SnSe is enhanced in the whole temperature range with a maximum ZT of 0.79 at a relatively low temperature (773 K) for SnSe0.85Te0.15.This study provides a low-cost and simple lowtemperature method to mass production of SnSe with high thermoelectric performance for practical applications

Keywords:Polycrystalline SnSe Hydrothermal synthesis Thermoelectric Te doping

Thermoelectric (TE) materials which enable the direct energy conversion between electricity and heat have been the focus of attention due to their prospective applications in waste-heat recovery and portable refrigeration [1,2].The performance of a thermoelectric material is evaluated by the relation of the Seebeck coefficient(α),electrical conductivity(s),thermal conductivity(k)and absolute temperature(T),which is defined as the thermoelectric figure of merit, ZT = α2sT/k [3].Obviously, a larger ZT value requires a high power factor (α2s) together with a low thermal conductivity.During the past decades,numerous approaches have been employed to improve ZT through optimizing electrical transport properties by band engineering [4,5], resonant state doping [6,7], energy filtering effect [8], etc., and diminishing thermal conductivity by introducing point defects [9,10], secondphase nanostructures [11,12] and multiscale hierarchical architecturing [13,14].In particular, thesemiconductor PbTe exhibits excellent thermoelectric performance at the mid-temperature range (500-850 K) [15–17].However, its large-scale application is limited by the potential heavy-metal pollution of the toxic Pb.In this regard, efforts devoted to exploring TE materials with nontoxic elements are necessary.

SnSe, which is made of nontoxic and abundant elements, has drawn much attention in recent years due to its excellent thermoelectric properties [18–21].According to the report [22],SnSe single crystals exhibit a remarkable highat 923 K along the crystallographic b-axis owing to their intrinsically ultralow lattice thermal conductivity, which is derived from the strong lattice anharmonicity [23].Nevertheless, the practical application of SnSe single crystals is prevented by the poor machinability,rigid-controlled crystal growth conditions and high cost of production.Therefore, considerable efforts have been focused on exploring high performance polycrystalline SnSe with better machinability and prospect of scale-up applications [24].Disappointingly,the reported ZT values of polycrystalline SnSe are lower thanthat of single crystal due to the comparatively lower s and higher k.For pristine polycrystalline SnSe, the ZT values are generally lower than 1.0 at about 750 K [25].It is thus highly desired to develop polycrystalline bulk materials with higher ZT.

For thermoelectric materials,doping has been demonstrated as an effective route to optimize the power factor via tuning the carrier concentration [26–28].Besides, doping can also induce point defects and nanoprecipitates to reduce the lattice thermal conductivity[29].In Ag-doped p-type SnSe,Chen et al.achieved a peak ZT of 0.6 at about 750 K due to significantly increased carrier density[30].Wei et al.demonstrated that alkali dopants(Li,Na and K) can enhance the carrier concentration of polycrystalline SnSe and achieved ZT of 0.8 for 1% Na- or K-doped SnSe at 800 K [31].Chen et al.fabricated bulk SnSe0.9375Te0.0625by solid-state reaction and studied theoretically the effect of Te doping on SnSe,but the Te content was limited to 0 and 0.0625, and the low electrical conductivity resulted in a low power factor ofat 673 K [32].

Moreover, production cost is considered as another major evaluation factor of thermoelectric materials for practical application.Hydrothermal synthesis as a low-cost and simple lowtemperature method shows better control of size, structure, and morphology of the products compared with traditional synthesis methods such as melting or mechanical alloying [33].In this respect,hydrothermal method is effective to fabricate micro/nanosized products which should possess strong anisotropy.Additionally, the solution-grown products with large surface area would bring about more defects [34], which not only can enhance the phonon scattering, but can also act as electron-acceptors to raise the hole concentrations of SnSe [35].

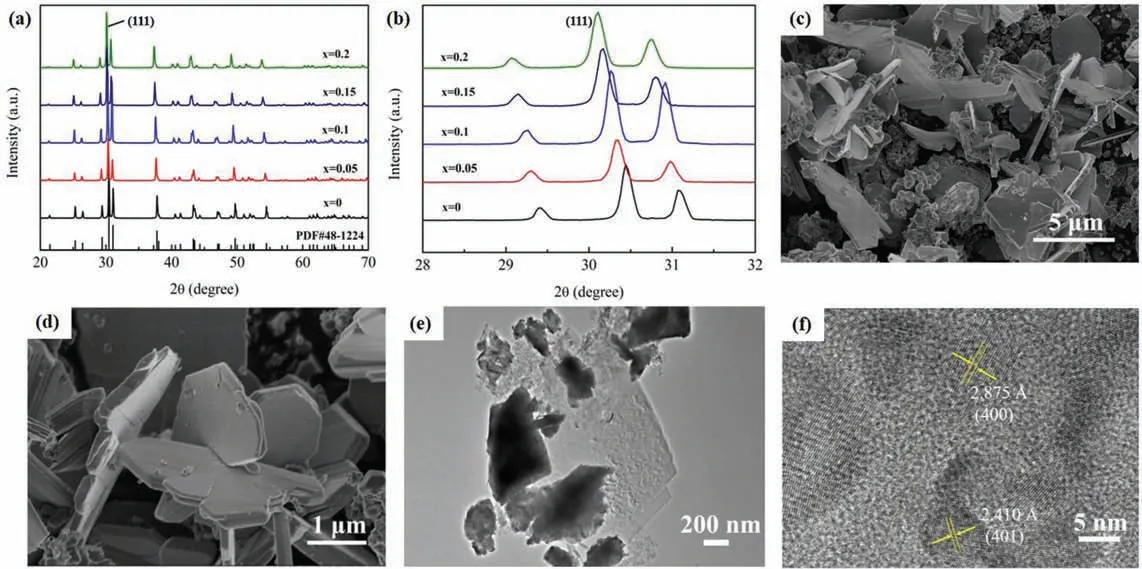

Herein, we adopt the simple and efficient hydrothermal approach for the synthesis of polycrystalline SnSe1-xTexnanopowders,which are sintered by spark plasma sintering(SPS)after annealing treatment.The details of synthesis process and characterization are described in Supporting information.Fig.1a shows the XRD patterns of as-synthesized SnSe1-xTexpowders(x=0, 0.05, 0.1, 0.15 and 0.2).All characteristic peaks are well indexed to the orthorhombic SnSe phase with Pnma space group(PDF#48-1224).No other peaks are present in the patterns,indicating the high phase purity of the crystals.Fig.1b exhibits the enlarged view of the strongest(111)diffraction peak taken from all samples.It can be seen that the(111)peak gradually shifts towards the lowerangle with the increasing Te content,which suggests the enlarged lattice parameters.This shift is attributed to the larger atomic radius of Te (1.35 Å) than that of Se (1.17 Å) [32].Based on the results, it can be concluded that Te atom successfully substitutes for Se to form the ternary SnSe1-xTexcompounds by the facile hydrothermal synthesis and annealing process.

The morphological and structural characteristics of SnSe1-xTexpowders were investigated by FE-SEM and TEM.As a typical sample, detailed SEM and TEM characterization results of SnSe0.85Te0.15powders are presented.SEM images given in Figs.1c and d clearly show the flower-like feature of as-prepared SnSe0.85Te0.15powders consisting of nanoplates with the thickness of about 200 nm and the width ranging from a few hundred nanometers to several microns, and the SnSe0.85Te0.15powders tend to stack together irregularly.Fig.1e is the low-magnification TEM micrograph of the SnSe0.85Te0.15powders, in which clear lamellar structure is observed.High-resolution TEM image(Fig.1f)of SnSe0.85Te0.15shows clear lattice fringes and the labeled lattice spacing of about 2.410 Å and 2.875 Å correspond to the (401) and(400) lattice planes of orthorhombic SnSe, respectively.All these characterizations demonstrate that SnSe0.85Te0.15nanopowders have been successfully synthesized by our facile hydrothermal method.

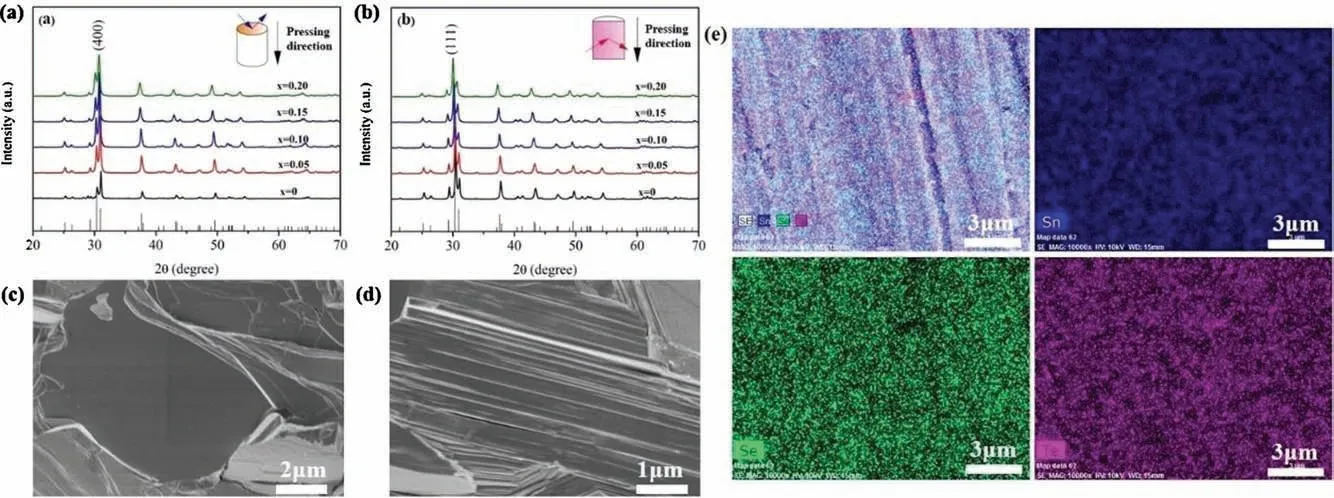

To investigate the thermoelectric performance of the hydrothermal synthesized SnSe1-xTex, the annealed powders were sintered into pellets via SPS.Figs.2a and b display the XRD profiles of SnSe1-xTexbulk samples taken in the plane perpendicular and parallel to the pressing direction.All diffraction peaks can be well matched to the crystal structure of SnSe and no impurity peaks are present in the patterns.Moreover, it can be found that the diffraction intensity shows an obviously difference in the two different direction.Typically, the strongest diffraction peak changes from (400) crystal plane in the perpendicular direction to(111)crystal planein theparallel direction,suggesting anisotropy features of the SnSe1-xTexbulk samples.Figs.2c and d are typical SEM images on the fractured surface of SnSe0.85Te0.15bulk samples,which reveals the microstructure in the planes perpendicular and parallel to the press direction.The layered morphology along the parallel direction clearly reveals the preferential orientation of the grains, indicating the strong anisotropic crystal growth.Meanwhile,no obvious micro-cracks or pores can be observed,which is consistent with the high relative density of above 98%as listed in Table 1.Furthermore, the chemical composition and elemental distribution were examined by SEM-EDS and the results of SnSe0.85Te0.15sample are presented in Fig.2e as a typical example.The results indicate that all elements(Sn,Se and Te)are uniformly distributed without enrichment,which further demonstrates that Te is successfully doped into the SnSe lattice.

Fig.1.(a)XRD patterns of SnSe1-xTex(x=0,0.05,0.1,0.15,0.2)powders and(b)enlarged view of the(111)diffraction peaks.(c,d)SEM images of SnSe0.85Te0.15powder.(e)Lowmagnification and (f) high-resolution TEM images of SnSe0.85Te0.15nanopowder.

Fig.2.XRD patterns of bulk SnSe1-xTextaken in the plane(a)perpendicular and(b)parallel to the pressing direction.SEM images of the fractured surfaces(c)perpendicular and (d) parallel to the pressing direction.(e) EDS elemental mapping results of all elements, Sn, Se and Te of bulk SnSe0.85Te0.15.

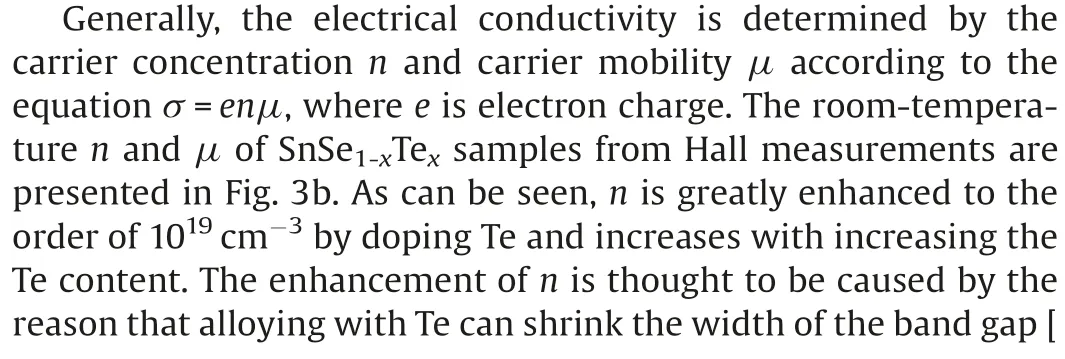

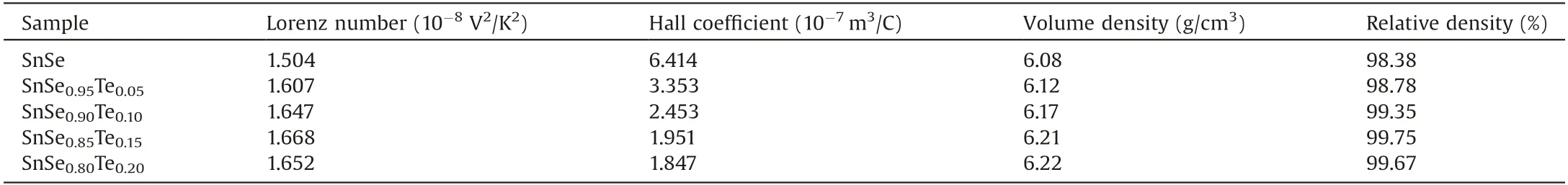

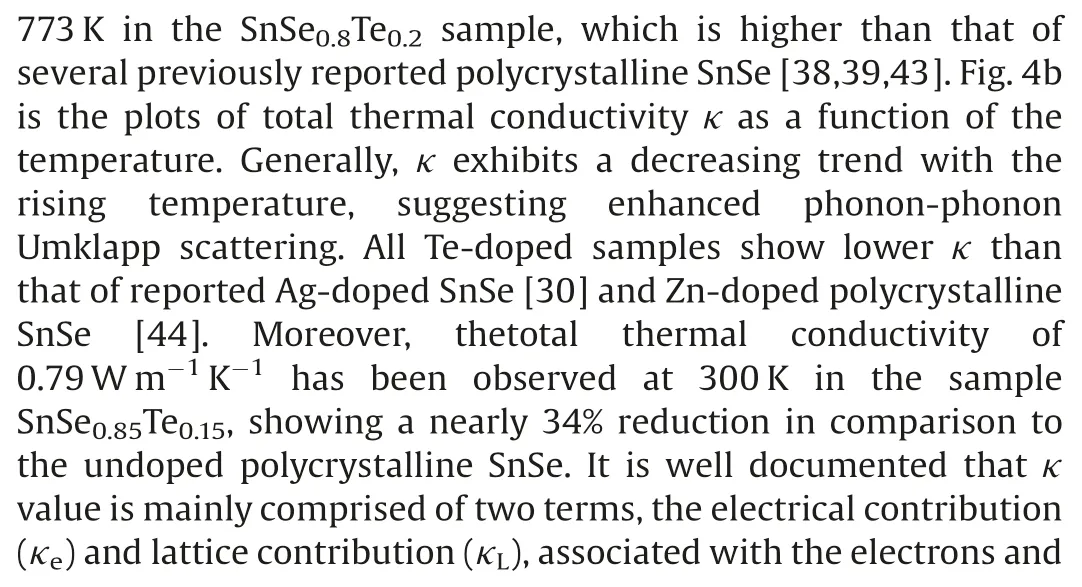

The temperature dependence of thermoelectric properties of SnSe1–xTexbulk samples were measured along the direction perpendicular to the pressure during SPS process,which present a better thermoelectric transport performance than those measured parallel to the pressure direction in our work.Fig.3a depicts electrical conductivity s as a function of temperature for different SnSe1–xTexsamples.For pristine SnSe,firstly increases with increasing temperature, then turns to decrease at450 K but finally increases above 650 K.This trend is also found in previous reports,which can be ascribed to amixed scattering mechanism of carrier transport by acoustic phonon and grain boundary potential barrier 36,37].Compared to pure SnSe, the electrical conductivities of Te-doped samples have been greatly enhanced, especially around room temperature.The maximum electrical conductivity of 98.4 S/cm for the sample SnSe0.8Te0.2is obtained at 300 K.This value is significantly higher than those reported in other polycrystalline SnSe [25, 38,39].

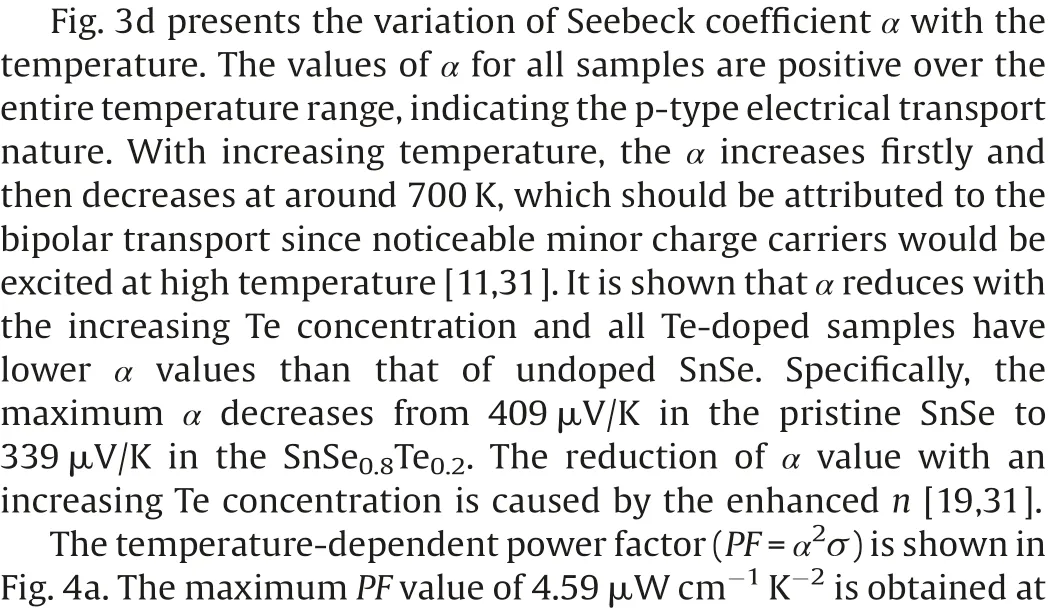

Table 1 Lorenz number, Hall coefficient, volume density and relative density of bulk SnSe1-xTexsamples at room temperature.

Fig.3.(a)Temperature-dependent electrical conductivity of bulk SnSe1-xTex.(b)Hall carrier concentration and mobility at 300 K.(c)Optical absorption spectra of SnSe1-xTex.The inset shows the calculated optical band gap.(d) Temperature-dependent Seebeck coefficient.

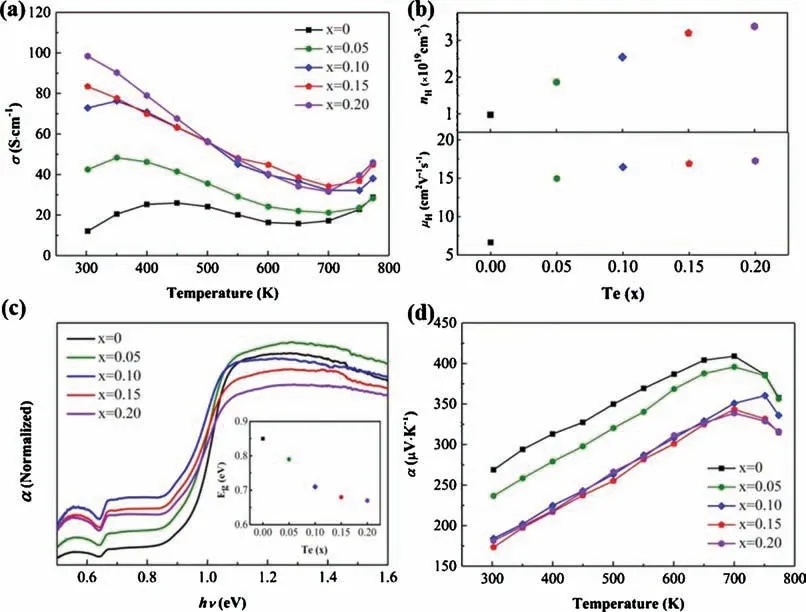

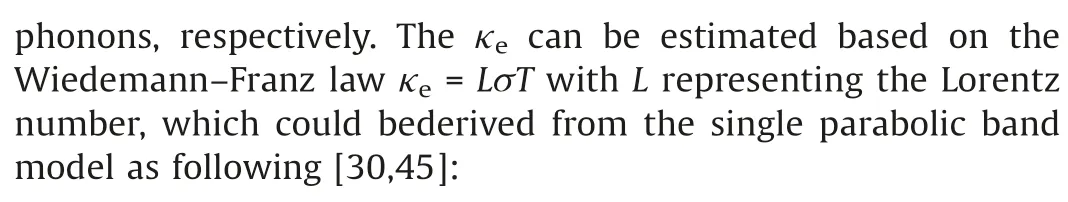

Fig.4.Temperature dependence of (a) power factor, (b) total thermal conductivity, (c) lattice thermal conductivity with the inset showing the electronic thermal conductivity, and (d) ZT for bulk SnSe1-xTexsamples together with the ZT data of some reported SnSe-based samples for comparison.

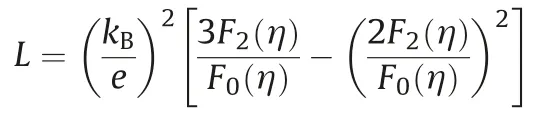

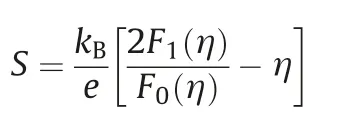

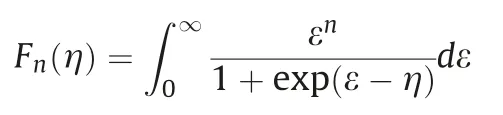

where kBandare the Boltzmann constant and reduced Fermi level, respectively.could be calculated using the measured Seebeck coefficient based on the following equation:

where e is the reduced energy.In this work,the obtained L values for different SnSe1-xTexsamples fluctuate around( Table 1),which are in accordance with the reported value for SnSe[46].Subtracting kefrom k,we calculated kLand shown the results in Fig.4c.The small difference between k and kLreveals that the heat transport of our SnSe1-xTexmaterials is mainly dominated by the phonon.It can be seen that kLreduces as Te doping content increases,which is due to the enhanced phonon scattering caused by point defect.Nevertheless, the lowest kLis obtained in the SnSe0.85Te0.15sample rather than in the SnSe0.8Te0.2sample.Owing to the similar grain size in all SnSe1- xTexsamples, the strength of grain boundary scattering can be considered relatively identical among these samples.Therefore,the difference of kLwith different Te doping content could be attributed to the synergistic effect of point defect scattering and Umklapp phonon scattering.Increasing Te doping level can not only strengthen the point defect scattering,but also affect the Umklapp scattering.According to previous study[22], the strong Umklapp scattering in SnSe is due to the strong anharmonicity of lattice dynamics resulting from the bonding instability.Such bond instability is driven by the resonantlybonding Se p-states, coupled to stereochemically active Sn lone pair.Substituting Te atoms into the Se site can change the bonding instability, giving rise to the weakened anharmonicity and thus diminishing Umklapp scattering in the SnSe1- xTexsamples.On the whole, the opposite change trend of point defect scattering and Umklapp phonon scattering with increasing Te doping level gives rise to the lowest kLin the SnSe0.85Te0.15.

The ZT values of all SnSe1-xTexsamples were calculated and presented in Fig.4d.It can be seen that ZT increases with rising temperature and is improved in the whole temperature range by doping with Te.The ZTof SnSe0.85Te0.15sample reaches a maximum value of 0.79 at a comparatively low temperature of 773 K,which is higher than that of previously reported polycrystalline SnSe materials at the same temperature [25, 40,44].This reveals that Te doping via hydrothermal approach is an effective route to enhance the thermoelectric performance of SnSe.

In summary, we have succeeded in fabricating p-type SnSe1- xTexpolycrystalline nano-powders using eco-friendly and cost-effective hydrothermal approach and densifying the nanopowders by spark plasms sintering.The electrical conductivity for Te-doped bulk SnSe samples are greatly improved in the temperature range of 300–773 K, which is ascribed to the enhanced carrier concentration and mobility due to the band gap shrinking.As a result,an enhanced power factor is achieved in spite of the decreased Seebeck coefficient.On the other hand,the thermal conductivity at room temperature is significantly reduced from 1.20 Wfor pristine SnSe to 0.79 Wfor SnSe0.85Te0.15sample, resulting from the strengthened pointdefect scattering on phonon caused by doping Te on Se site.The simultaneous optimization of both power factor andthermal conductivitycontributes to a high ZT value of 0.79 at 773 K in SnSe0.85Te0.15.This work provides a facile and low-cost method to the mass production of polycrystalline SnSe with high thermoelectric performance for practical applications.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

This work was funded by the Fundamental Research Funds for the Central Universities (No.2232020A-02), National Natural Science Foundation of China(Nos.51774096,51871053,51902333),Shanghai Committee of Science and Technology(No.18JC1411200),Program for Innovative Research Team in University of Ministry of Education of China (No.IRT_16R13).Q.Zhang acknowledges financial support sponsored by Shanghai Sailing Program (No.19YF1454000)and Key Research Program of Frontier Sciences,CAS(No.ZDBS-LY-JSC037).

Appendix A.Supplementary data

Supplementarymaterialrelatedtothisarticlecanbefound,inthe online version,at doi:https://doi.org/10.1016/j.cclet.2020.04.046.

杂志排行

Chinese Chemical Letters的其它文章

- Quantitative assessment of rhodamine spectra

- One-step straightf oward solid synthesis of high yield white fluorescent carbon dots for white light emitting diodes

- Free-standing nitrogen doped graphene/Co(OH)2composite films with superior catalytic activity for aprotic lithium-oxygen batteries

- Amorphous silicon from low-temperature reduction of silica in the molten salts and its lithium-storage performance

- Two 2D uranyl coordination complexes showing effective photocatalytic degradation of Rhodamine B and mechanism study

- Recent advances in electrochemical sensors for antibiotics and their applications