TC4合金表面熔覆石墨烯增强钛基复合涂层的组织及性能

2021-05-08孟君晟李成硕弭德振王铀

孟君晟,李成硕,弭德振,王铀,2

TC4合金表面熔覆石墨烯增强钛基复合涂层的组织及性能

孟君晟1,李成硕1,弭德振1,王铀1,2

(1.山东交通学院 船舶与港口工程学院,山东 威海 264200;2.哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001)

通过氩弧熔覆技术在TC4合金表面制备石墨烯增强钛基复合涂层,以改善其耐磨性能。将钛粉和石墨烯在球磨机中充分混合。将混合后的粉末涂覆于TC4合金表面,采用氩弧熔覆技术将预涂覆粉末熔化,制备出陶瓷颗粒增强钛基熔覆层。采用X射线衍射分析仪分析涂层的物相,利用光学显微镜、扫描电子显微镜分析熔覆层中颗粒相的组成及分布。采用显微维氏硬度仪和摩擦磨损试验机,测试熔覆层的显微硬度和磨损性能。熔覆层厚度可达1 mm,且表面及横截面没有气孔、裂纹等缺陷产生,物相主要包括TiC和α-Ti。熔覆层中不同区域的组织存在差别,涂层的中上部组织主要为树枝晶,底部组织中树枝晶逐渐减少。熔覆层与基体呈冶金结合,组织致密。增强相TiC以颗粒状和花瓣状形式存在。石墨烯增强钛基复合涂层的显微硬度高达845.4HV。在相同磨损条件下,TC4合金基体与熔覆层的磨损量分别是0.153 g和0.0123 g,熔覆层的磨损量明显降低。涂层的磨损机制主要是磨粒磨损。与TC4合金基体对比,熔覆层的显微硬度提高约2.5倍,耐磨性提高12倍。氩弧熔覆原位自生TiC陶瓷颗粒增强钛基熔覆层可显著提高TC4合金表面的耐磨性。

TC4合金;氩弧熔覆;石墨烯;显微硬度;耐磨性

TC4合金材料由于具有优良的机械性能而广泛应用于航空航天、医疗和军事工业等关键零部件,如采用钛合金构件代替传统的钢构件,可以极大地降低飞机的质量,从而提升飞机的性能。然而,TC4合金的应用和发展因其显微硬度低和耐磨性差而受到限制[1-4]。近几十年来,表面改性技术成为解决这一问题的有效方式,在TC4合金表面添加或原位反应生成陶瓷颗粒可以极大地提高耐磨性能,如气相沉积[5-6]、等离子熔覆[7]、微弧氧化[8]、激光熔覆[9]和氩弧熔覆[10-12]等。目前已经利用熔覆技术修复燃气涡轮发动机零件等,并获得了性能优异的涂层,提高了零件抗微动磨损的能力。在这些钛合金表面改性技术中,氩弧熔覆技术由于具有操作简单、能量稳定、绿色安全、无氧化等优点[13-14],已成为钛合金表面高质量熔覆层制备的重要方式之一。

石墨烯(Graphene,Gr)具有优异的性能(如导电性、力学性能等),在材料科学、机械、能源和生物医学等领域有着广泛的应用[15-16]。石墨烯由于其独特的二维层状结构,比石墨、碳纳米管等传统材料具有更大的比表面积,与基体材料具有更高的接触面积,从而提高结合强度。近年来,石墨烯已应用在金属基复合材料涂层中,使涂层具有优良的导电性和导热性、高强度和韧性、较好的耐磨性和耐腐蚀性等,石墨烯已被认为是金属基复合材料涂层最有前途的增强体[17-18]。研究表明,石墨烯可以显著改善纯钛复合材料的强度和耐磨性[19],如Zhang等人[20]利用激光熔覆技术制备了石墨烯增强Ti6Al4V复合涂层,石墨烯与钛原位合成羽毛状的TiC。通过上述分析可知,石墨烯作为一种新的复合材料,与熔覆技术结合起来制备涂层,具有广阔的应用前景,但目前仅限于激光熔覆技术,使得制备成本提高。为了进一步降低涂层制备的成本及拓宽石墨烯在熔覆技术中的应用,文中采用氩弧熔覆技术制备出石墨烯增强钛基复合涂层,探讨了石墨烯的加入对涂层的组织及力学性能的影响,本研究对石墨烯在工程领域的应用具有一定的指导意义。

1 试验

1.1 混合粉末及涂层制备

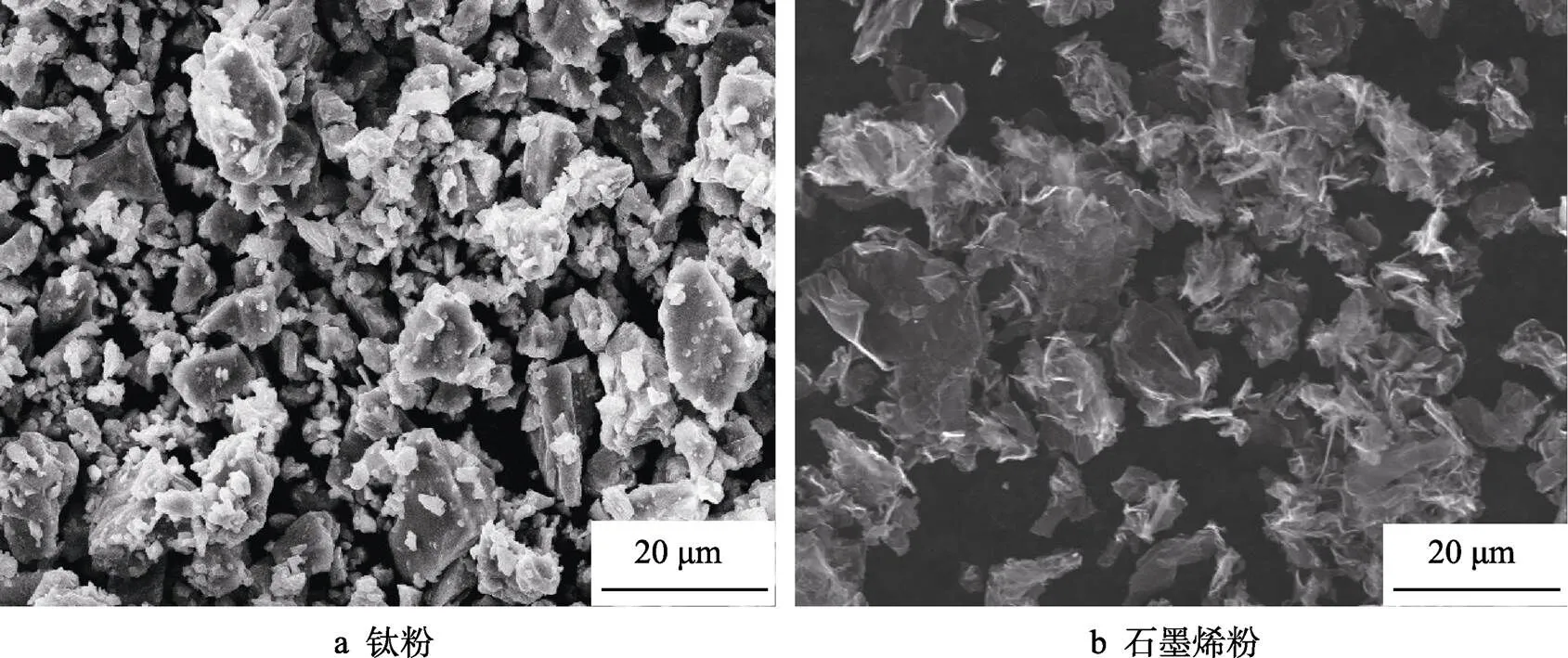

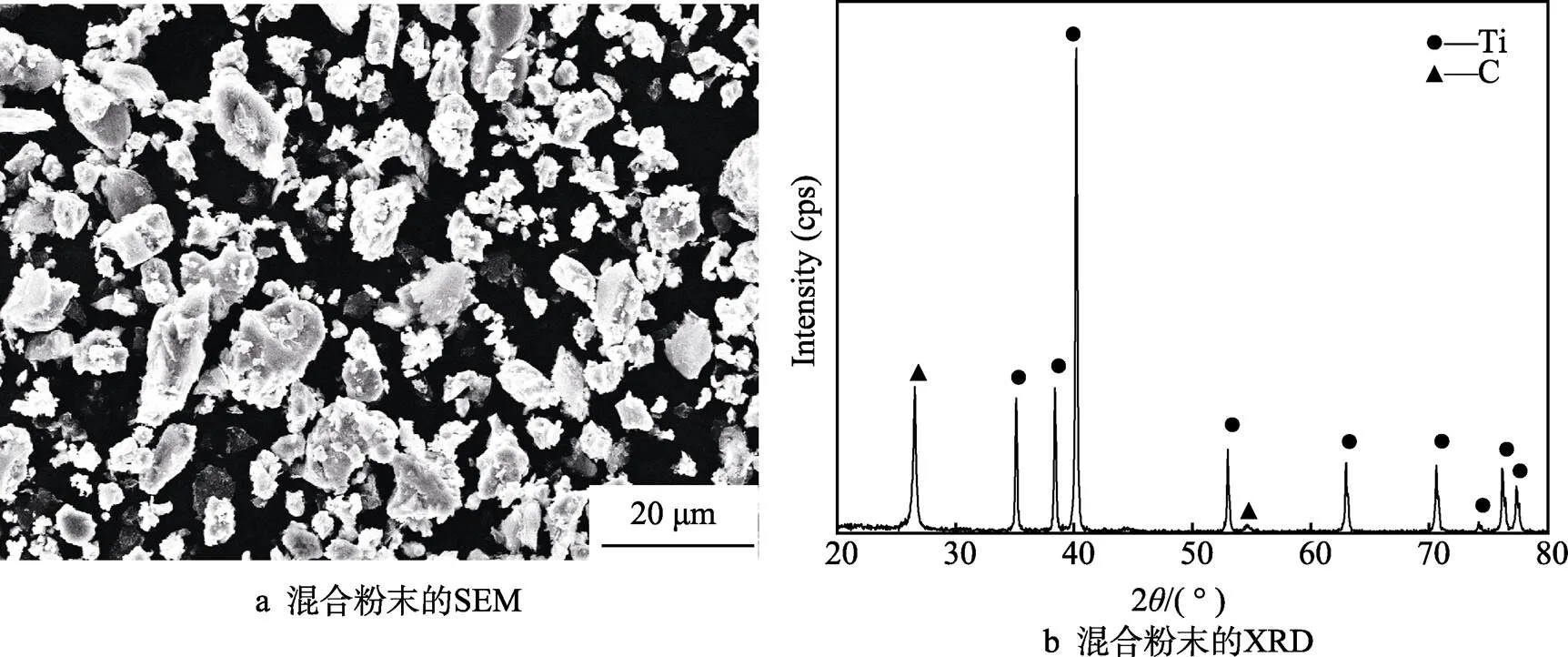

选用TC4合金为基体材料,其化学成分(以质量分数计)为:6.05%Al,3.72%V,0.10%C,0.30%Fe,Ti余量。将其加工成尺寸为800 mm×20 mm×10 mm的长方体,采用水磨砂纸打磨表面,利用无水乙醇进行超声波清洗。选用钛粉和石墨烯粉作为熔覆材料,其中钛粉纯度为99.5%,粒径为10~20 μm;石墨烯粉纯度为99.5%,如图1所示。钛粉和石墨烯粉的总质量为20 g,石墨烯粉的质量占总质量的0.5%。采用BS-224S分析天平称量粉体,在氩气(99.99%Ar)气氛保护作用下,在行星式球磨机中混合240 min,球磨后的粉体SEM照片及XRD图谱如图2所示。利用胶水作为黏结剂将混合后的粉末调匀,涂覆于经处理后的TC4合金表面,厚度控制在1.0 mm。利用RX841Y型电热鼓风干燥箱,将涂覆后的试样在120 ℃下烘烤120 min。熔覆设备选用国产DXT-400型逆变直流氩弧焊机,具体熔覆工艺参数如表1所示。

图1 钛粉和石墨烯粉的SEM照片

图2 混合粉末的SEM照片及XRD谱图

表1 氩弧熔覆工艺参数

Tab.1 Process parameters of argon arc cladding

1.2 显微组织观察及性能测试

采用型号为Bruker D8 Advance的X射线衍射仪对打磨后的涂层表面进行微观组织结构表征。采用400#—1200#水砂纸对复合涂层的横截面进行金相试样的制备,之后采用Cr2O3的悬浮液进行抛光处理,使用硝酸、氢氟酸和水的混合液(HCl∶HF∶H2O=3∶5∶10)对抛光后的熔覆层横截面进行腐蚀,时间为8~10 s,之后采用FEI SIRION型扫描电子显微镜分析显微组织。利用MHV2000型显微维氏硬度计对熔覆试样进行显微硬度测试,施加载荷为1.92 N,加载时间为10 s,从复合涂层表面进行测试,之后沿复合涂层的横截面每隔0.2 mm测试1点,直至基体。采用国产MVF-2A型多功能摩擦磨损试验机测试TC4合金基体和熔覆层室温下的耐磨性能,转速为200 r/min,施加载荷为200 N,时间为60 min,摩擦副采用平均硬度为59HRC的GCr15钢。使用分析天平称量基体及涂层磨损前后的质量,计算得出磨损量,并观察磨损形貌。

2 结果及分析

2.1 涂层物相组成

图3为熔覆涂层的X射线衍射图谱。分析表明,熔覆涂层中主要由TiC和α-Ti组成,说明石墨烯与钛发生了原位反应。氩弧熔覆涂层的横截面形貌OM图像如图4所示。熔覆层由表面至界面的深度约为1 mm,截面较平滑,由于具有较好的保护,使得涂层中未见气孔缺陷。熔覆层的形状取决于涂层对基体的润湿性,较好的润湿性使表面呈凹陷状[21]。基体与涂层之间存在明显的白亮带,说明熔覆涂层和基体形成良好的冶金结合[11]。同时,在熔覆层中形成了非常细小的枝晶结构。

图3 熔覆涂层X射线衍射图谱

图4 氩弧熔覆涂层横截面的OM图像

2.2 涂层显微组织

图5为熔覆层横截面不同区域的SEM图像,区域分别为熔覆层的表面、中部(深度400 μm)和底部(深度900 μm)。通过对比发现,熔覆层不同部位的微观结构存在差别。从图5a可以看出,细小的颗粒相组成了枝晶组织,也有一些颗粒分布在枝晶周围,原位形成的颗粒尺寸比较小。对于深度为400 μm的涂层(图5b),熔覆层的显微组织主要以细枝晶、颗粒状等形式存在,且直径减小。从图5c可以看出,在接近基体界面时,树枝晶逐渐减少,主要以颗粒状分布在黑色的基体中,且形成的颗粒相比顶部和中部区域小得多,分布比较均匀,在界面处形成了良好的冶金结合。很明显,熔覆层中枝晶的大小随深度的增加而减小。

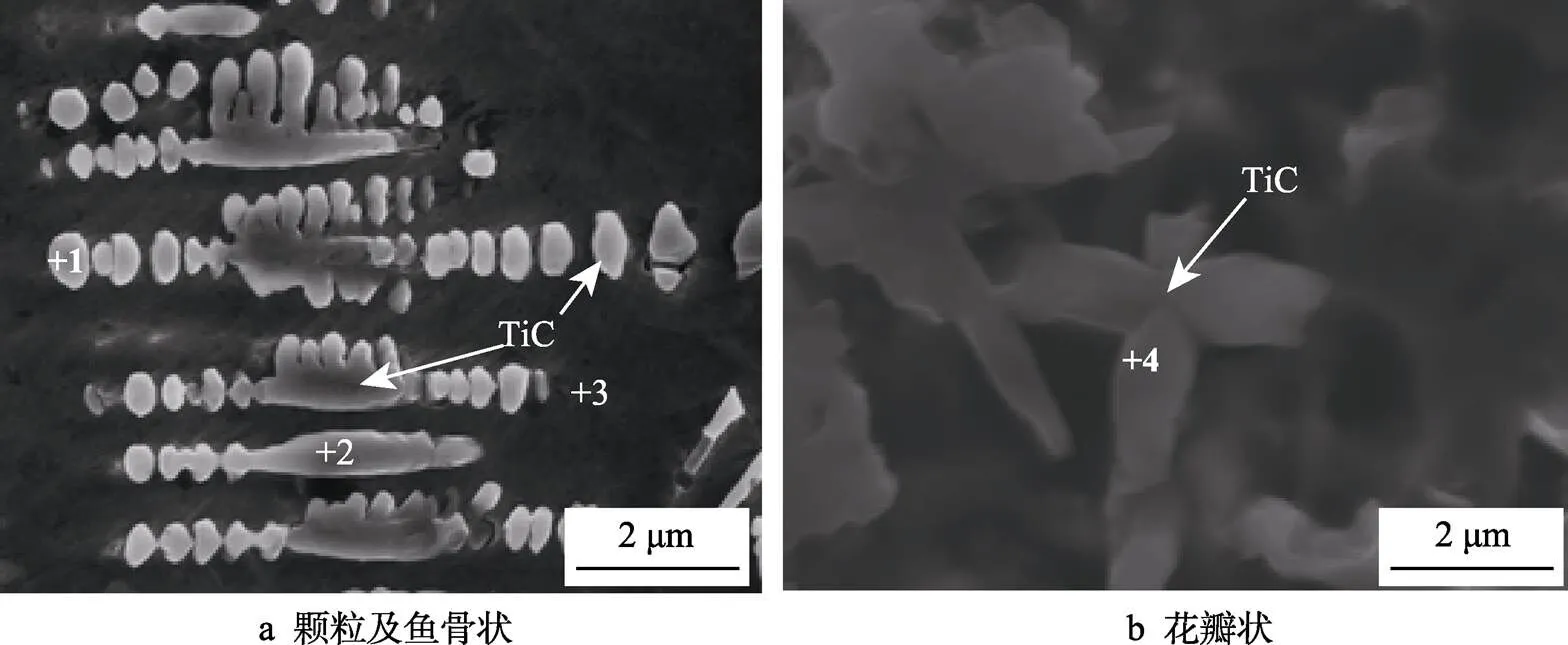

图6为熔覆层典型的组织形貌。可以发现,熔覆层中树枝晶主要由棒状结构及周围的细小颗粒状相构成(图6a)。如图6b所示,显微组织主要由花瓣状结构构成。对不同部位进行EDS分析,结果见表2。从表2中的元素及其含量,可以分析出颗粒状相、鱼骨状组织和花瓣状组织的元素主要是Ti和C,结合XRD分析可以确定是TiC相。位置2主要含有Ti、Al和V,因此可以推断是基体α-Ti相。熔覆层中TiC以颗粒相结构为主,且颗粒相尺寸十分细小,为0.3~1.0 μm,枝晶中的鱼骨状组织尺寸约为4 μm×0.5 μm。石墨烯粉和钛粉在氩弧热作用下,原位反应生成了大量均匀分布且细小的TiC颗粒,这些尺寸细小的TiC颗粒将有助于提高TC4合金的力学性能。

图5 氩弧熔覆涂层横截面不同区域SEM形貌

图6 熔覆涂层SEM高倍形貌及能谱分析

表2 图6不同位置的能谱分析

Tab.2 Energy dispersive spectrometer of different regions in Fig.6

2.3 熔覆层显微硬度及耐磨性

图7显示了熔覆层的显微硬度。从图7中可以看出,熔覆层具有较高的显微硬度。从显微硬度曲线的分布来看,存在3个区域:熔覆层区域、热影响区和基体。熔覆层的显微硬度由表面到基体逐渐减少,熔覆层的平均显微硬度可达845.4HV,且硬度分布比较均匀,曲线波动较小,熔覆层的硬度约为基体硬度的2.5倍。这主要是由于在熔覆层中,石墨烯与钛原位反应生成了细小的第二相(TiC),且生成的第二相分布均匀,具有较高的硬度(TiC硬度可达3400HV);根据第二相强化理论,这些细小且在涂层中均匀分布的第二相会阻碍位错的运动,从而显著增强位错的稳定性,提高涂层的强度和硬度。

图7 熔覆涂层截面的硬度分布

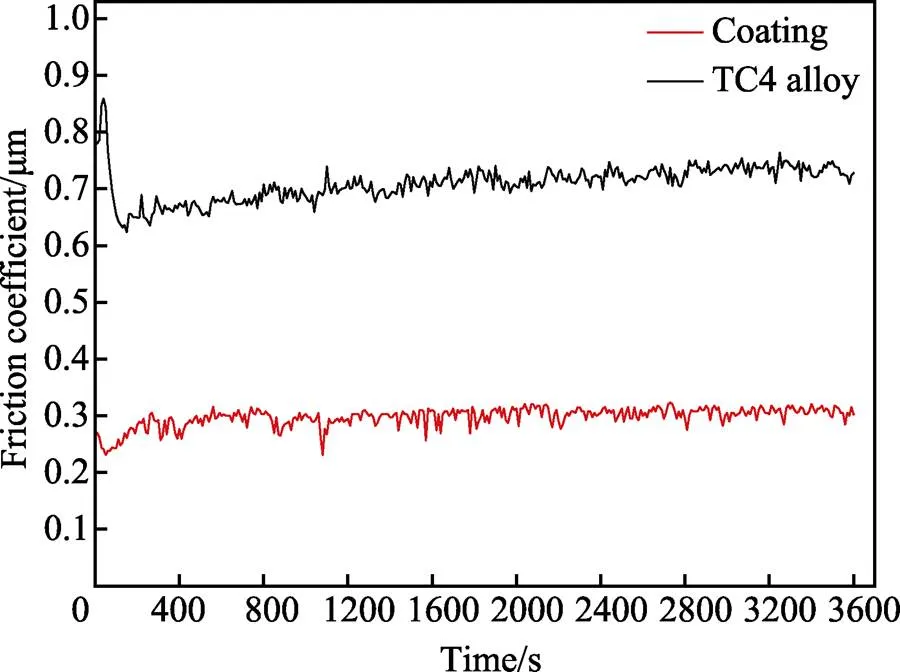

图8为熔覆层与TC4合金基体摩擦因数随时间的变化曲线。从图8中可以看出,在稳定阶段,TC4合金基体表面的平均摩擦因数达到0.69,而石墨烯增强钛基涂层的摩擦因数较基体合金要小得多,平均摩擦因数仅为0.28,说明熔覆层的抗磨性能优于TC4合金。在复合材料/涂层中若生成的增强颗粒分布均匀且与基体有良好的结合时,可有效地降低复合材料/涂层的摩擦因数[22]。通过氩弧熔覆制备的石墨烯增强钛基熔覆层,原位生成的第二相颗粒与基体具有良好的结合,且弥散分布,因此熔覆层的摩擦因数大幅度降低。

图8 TC4合金表面与熔覆层摩擦系数曲线

图9为熔覆层与TC4合金基体的磨损量及其耐磨性示意图。在相同磨损条件下,TC4合金基体的磨损量为0.153 g,熔覆层的磨损量仅为0.0123 g,相对耐磨性表明熔覆层的耐磨性较基体提高了12倍,熔覆层的耐磨性得到了极大的提高,这与氩弧熔覆条件下形成的组织有关。由于石墨烯的加入,熔覆层组织中获得了大量的第二相,使得涂层具有较高的硬度,在磨损过程中,硬质颗粒相与α-Ti基体达到一种强韧性配合,进一步提高涂层的耐磨性。

TC4合金基体和熔覆层的磨损形貌如图10所示。图10a所示的TC4合金基体表面有相当多的磨屑堆积,在磨损表面同时存在犁槽,通过对区域A进行放大(图10b所示),发现在表面发生了撕脱现象,表明TC4合金基体受到严重的粘着磨损和磨粒磨损。熔覆层磨损表面比较光滑,通过对区域B进行放大(图10d所示),发现熔覆层磨损表面的犁沟深度较浅,只是轻微划伤,没有发现严重的粘着痕迹,说明熔覆层的磨损程度要低于TC4合金基体,熔覆层的磨损机理仅是磨粒磨损。这是由于在熔覆层内均匀分布的第二相可以分担载荷,使得摩擦副表面微凸体难以压入表面,减少粘着现象的发生,提高涂层的耐磨性。此外,尚未发现由石墨烯在摩擦过程中产生的润滑膜,这说明石墨烯在涂层中的添加量较低,无法形成大面积的润滑膜。

3 结论

1)采用氩弧熔覆技术,以石墨烯粉和Ti粉为原料,在氩气气氛下制备了石墨烯增强钛基熔覆层,熔覆层与基体呈现冶金结合,表面无飞溅,内部无缺陷。

2)熔覆层的物相主要由TiC和α-Ti组成。熔覆层中的组织主要以颗粒状和棒状构成的树枝晶以及花瓣状组成,石墨烯的加入使得生成的第二相颗粒尺寸更为细小,且弥散分布于熔覆层中。熔覆层不同区域的组织存在差别,沿表面至涂层界面树枝晶逐渐减少,颗粒相增多。

3)石墨烯增强钛基熔覆层具有优异的摩擦磨损性能,熔覆层的平均显微硬度可达854.4HV,摩擦因数(~0.28)低且波动小,在高载荷长时间摩擦磨损作用下仍可以表现出较好的耐磨性能。

[1] LU Xiao-long, LIU Xu-bo, YU Peng-cheng, et al. Synthesis and characterization of Ni60-hBN high temperature self- lubricating anti-wear composite coatings on Ti6Al4V alloyby laser cladding[J]. Optics & laser technology, 2016, 78(5): 87-94.

[2] LYU Y H, LI J, TAO Y F, et al. Oxidation behaviors of the TiNi/Ti2Ni matrix composite coatings with different contents of TaC addition fabricated on Ti6Al4V by laser cladding[J]. Applied surface science, 2016, 679: 202-212.

[3] WENG Fei, YU Hui-jun, LIU Jian-li, et al. Microstructure and wear property of the Ti5Si3/TiC reinforced Co-based coatings fabricated by laser cladding on Ti-6Al-4V[J]. Optics & laser technology, 2017, 92: 156-162.

[4] WANG Han, YAO Zheng-jun, TAO Xue-wei, et al. Role of trace boron in the microstructure modification and the anisotropy of mechanical and wear properties of the Ti6Al4V alloy produced by electron beam freeform fabrication[J]. Vacuum, 2020, 172: 109053.

[5] BAI Yan-yun, XI Ye-ting, GAO Ke-wei, et al. Brittle coating effects on fatigue cracks behavior in Ti alloys[J]. International journal of fatigue, 2019, 125: 432-439.

[6] CSARNOVICS I, HAJDU P, BIRI S, et al. Preliminary studies of creation of gold nanoparticles on titanium surface towards biomedical applications[J]. Vacuum, 2016, 126: 55-58.

[7] VLCAK P. Evidence of a defect structure in high fluence nitrogen ion implanted titanium and its effect on corrosion[J]. Results in physics, 2018, 11: 274-277.

[8] XIE Riu-zhen, LIN Nai-ming, ZHOU Peng, et al. Surface damage mitigation of TC4 alloy via micro arc oxidation for oil and gas exploitation application: characterizations of microstructure and evaluations on surface performance[J]. Applied surface science, 2017, 436: 467-476.

[9] OBADELE B A, ANDREWS A, MATHEW M T, et al. Improving the tribocorrosion resistance of Ti6Al4V surface by laser surface cladding with TiNiZrO2composite coating[J]. Applied surface science, 2015, 345: 99-108.

[10] AN Qi, HUANG Lu-jun, JIANG Shan, et al. Microstructure evolution and mechanical properties of TIG cladded TiB reinforced composite coating on Ti-6Al-4V alloy[J]. Vacuum, 2017, 145: 312-319.

[11] 孟君晟, 金国, 史晓萍, 等. Ti6Al4V表面氩弧熔覆Ti+BN复合涂层组织及耐磨性[J]. 表面技术, 2020, 49(12): 184-190. MENG Jun-sheng, JIN Guo, SHI Xiao-ping, et al. Microstructure and wear resistance of Ti+BN composite coating on Ti6Al4V alloy by argon arc cladding[J]. Surface technology, 2020, 49(12): 184-190.

[12] 孟君晟, 史晓萍, 王振廷, 等. TC4合金表面氩弧熔覆TiCp/Ti基复合涂层组织及耐磨性[J]. 稀有金属材料与工程, 2012, 41(7): 1259-1262.MENG Jun-sheng, SHI Xiao-ping, WANG Zhen-ting, et al. Microstructure and wear resistance of TiCp/Ti composite coating on TC4 alloy by argon arc cladding[J]. Rare metal materials and engineering, 2012, 41(7): 1259-1262.

[13] OLIVEIRA V M C A, SILVA M C L, PINTO C G, et al. Short-term creep properties of Ti-6Al-4V alloy subjected to surface plasma carburizing process[J]. Journal of materials research and technology, 2015, 4(4): 359-366.

[14] NOURI S, SAHMANI S, ASAYESH M, et al. Study on the oxidation resistance of γ-TiAl intermetallic alloy coatedvia different diffusion coating processes[J]. Materials researcher express, 2019, 6(10): 1-20.

[15] WANG Pei, ZHANG Bai-cheng, TAN Cheng-cheh, et al. Microstructural characteristics and mechanical properties of carbon nanotube reinforced Inconel 625 parts fabricated by selective laser melting[J]. Materials & design, 2016, 112: 290-299.

[16] LIN Dong, LIU C R, CHENG G J. Single-layer graphene oxide reinforced metal matrix composites by laser sintering: Microstructure and mechanical property enhancement[J]. Acta materialia, 2014, 80: 183-193.

[17] SALUR E, ASLAN A, KUNTOGLU M, et al. Experimentalstudy and analysis of machinability characteristics of metal matrix composites during drilling[J]. Composites part B: Engineering, 2019, 166: 401-413.

[18] ZHANG Dan, CUI Xiu-fang, JIN Guo, et al. Effect of in-situ synthesis of multilayer graphene on the microstructure and tribological performance of laser cladded Ni-based coatings[J]. Applied surface science, 2019, 495: 143581.

[19] MU X N, CAI H N, ZHANG H M, et al. Interface evolution and superior tensile properties of multi-layer graphene reinforced pure Ti matrix composite[J]. Materials & design, 2018, 140: 431-441.

[20] ZHANG Li-zheng, ZHAO Zhan-yong, BAI Pei-kang, et al. In-situ synthesis of TiC/graphene/Ti6Al4V composite coating by laser cladding[J]. Materials letters, 2020, 270: 127711.

[21] ZHANG Ke-min, ZOU Jian-xin, LI Jun, et al. Synthesis of Y2O3particle enhanced Ni/TiC composite on TC4 Ti alloy by laser cladding[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(8): 1817-1823.

[22] HORLOCK A J, MCCARTNEY D G, SHIPWAY P H, et al. Thermally sprayed Ni(Cr)-TiB2coatings using powder produced by self-propagating high temperature synthesis: Microstructure and abrasive wear behaviour[J]. Materials science and engineering, 2002, 336(1): 88-98.

Structure and Properties of Graphene Reinforced Ti-based Composite Coatings on TC4 Alloy

1,1,1,1,2

(1.Naval Architecture and Port Engineering Colloge, Shandong Jiaotong University, Weihai 264200, China; 2.School of Materials Science and Engineering, Harbin Insitute of Technology, Harbin 150001, China)

The work aims to study the graphene reinforced titanium-based composite coating is prepared on the surface of TC4 alloy by argon arc cladding technology to improve its wear resistance. In this work, the Graphene power and Ti powder are ball-milled and mixed. The mixed powder was coated on the surface of TC4 alloy, and the ceramic particle-reinforced titanium-based cladding coating is prepared by alloy melting the precoated powder by argon arc cladding technology. The phase of the cladding coating was analyzed by X-ray diffraction analyzer. The composition and distribution of ceramic particles in cladding coating was analyzed by optical microscope and scanning electron microscope and optical microscope. Microhardness and wear properties of the cladding coating was measured by vickers hardness tester and universal friction and wear tester. The thickness of cladding coating of this paper is 1.0 mm, without obvious defects like pores, cracks on the surface and cross section.The phases of the cladding coating mainly include α-Ti and TiC. However,the results show that the microstructure of different areas in the coating is different. The dendrite structure is mainly distributed in the middle and upper part of the coating, while the dendrites in the bottom part decrease gradually. The cladding coating and the substrate are metallurgically bonded, and the structure is dense. The enhanced phase is granular and petal. The microhardness of the coating is as high as 845.4HV, the wear loss of, the pure copper matrix and the cladding layer is 0.153 g and 0.0123 g under the same wear conditions, respectively. and the wear amount of the cladding layer is significantly reduced; there is no adhesion mark on the wear of the cladding coating, and the wear mechanism is abrasive wear. Compared with the pure copper matrix, the microhardness of the cladding layer is increased by about 2.5 times, and the wear resistance increased by 12 times. The TiC ceramic particle cladding coating can significantly improve the wear resistance of theTC4 alloy surface.

TC4 alloy; argon arc cladding; graphene; microhardness; wear resistance

2021-01-25;

2021-04-07

MENG Jun-sheng (1982—), Male, Doctor, Associate professor, Research focus: toughening of metallic materials and its surface modification.

王铀(1954—),男,博士,教授,主要研究方向为纳米表面工程及纳米材料改性。邮箱: wangyou@hit.edu.cn

Corresponding author:WANG You (1954—), Male, Doctor, Professer, Research focus: nano surface engineering and nano modified materials. E-mail: wangyou@hit.edu.cn

孟君晟, 李成硕, 弭德振, 等. TC4合金表面熔覆石墨烯增强钛基复合涂层的组织及性能[J]. 表面技术, 2021, 50(4): 79-85.

TG174.44;TH117

A

1001-3660(2021)04-0079-07

10.16490/j.cnki.issn.1001-3660.2021.04.007

2021-01-25;

2021-04-07

山东省自然科学基金项目(ZR2019MEE107);大学生创新创业训练计划项目(S202011510012);山东交通学院博士基金项目(BS2018005)

Fund:Supported by the Natural Science Foundation of Shandong Province (ZR2019MEE107), the Innovation and Entrepreneurship Training Program for College Students (S202011510012), Ph. D. Scientific Research Foundation of Shandong Jiaotong University (BS2018005)

孟君晟(1982—),男,博士,副教授,主要研究方向为金属材料强化及表面改性。

MENG Jun-sheng, LI Cheng-shuo, MI De-zhen, et al. Structure and properties of graphene reinforced Ti-based composite coatings on TC4 alloy[J]. Surface technology, 2021, 50(4): 79-85.