Can harvest outsourcing services reduce field harvest losses of rice in China?

2021-04-12QUXueDaizoKOJIMAYukinagaNISHIHARAWULapingMitsuyoshiANDO

QU Xue,Daizo KOJIMA,Yukinaga NISHIHARA,WU La-ping,Mitsuyoshi ANDO

1 Department of Agricultural and Resource Economics,The University of Tokyo,Tokyo 113-8657,Japan

2 Organization for Regional and Inter-regional Studies,Waseda University,Tokyo 169-8050,Japan

3 College of Economics and Management,China Agricultural University,Beijing 100083,P.R.China

Abstract The purpose of this study is to quantify the rice harvest losses in China and to evaluate the impacts of machinery and harvest outsourcing services on these losses,given the background of high-speed mechanization and outsourcing services.Data were collected from a national survey conducted in 2016 by the research team in conjunction with the Research Center for the Rural Economy of the Ministry of Agriculture and Rural Affairs of China.A non-parametric method was used to test whether combine harvesting and outsourcing services could significantly reduce harvest losses.Next,quantile regression was used to estimate the real effects of machinery and outsourcing services on harvest losses.The analysis yielded four main study outcomes.First,the harvest loss rate of rice in China was 3.65%.Second,mechanical reaping and winnowing caused greater losses than manual methods,while the opposite was true of field transportation.Third,combine harvesting increased the losses.Fourth,the effects of an outsourcing service on losses differed among the different harvesting methods.Outsourcing services increased losses in segmented harvesting but they reduced losses in combine harvesting.

Keywords:rice harvest,outsourcing service,combine harvesting,harvest loss,rice

1.Introduction

Due to the large and growing population,ensuring a sufficient food supply has always been one of China’s most important goals.There are two ways to increase the food supply.One is to increase production,which is limited by resources and environmental capacity.The other way is to reduce losses (Emiliano and Thomas 2021),especially at the post-harvest and processing stages,where developing countries lose more than 40%of all produce (FAO 2011).

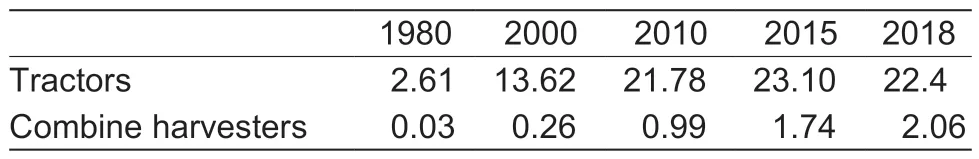

Since the reform and opening up began in 1978,mechanization has been developing gradually in rural China.Especially in the past two decades,due to increasing migration of the rural strong and young labor force to urban areas,rural mechanization has been developing more rapidly.From 1980 to 2018,the number of tractors increased from 2.61 million to 22.4 million,with annual growth rate of 5.82%.The number of combine harvesters increased by 67.7-fold,and annual growth rate reached 11.7% (Table 1).Currently in rural China,many agricultural machine owners join the Cooperatives and provide services to individual farmers (i.e.,outsource service),including tilling,sowing,harvesting,and others.

The fragmentation of farmland in China,with average field sizes of only about 0.5 ha (Zhanget al.2017),makes it difficult to operate machines.However,in 2016,80% of the rice planting area underwent mechanical harvesting,with the rate in some provinces even exceeding 90%(NBSC 2017a,b).

Mechanization can increase production efficiency,however,one unanswered question is:does machine harvesting increase or reduce field harvest losses? There are not very many published studies on rice harvesting losses.Even without considering the greater mechanical harvesting losses due to fragmented farmland,Greeley(1982) pointed out that new technology often leads to greater losses compared to traditional practices based on his study of rice losses in Bangladesh.Other studies have also shown similar results in India (Sadiya and Hassan 2018),Nigeria (Chegere 2018;Ibrahimet al.2018),and Sub-Saharan Africa (Hodgeset al.2014).

Liet al.(1991) conducted rice harvesting experiments in Zhejiang Province and found that the loss rates of rice when reaping was done manually and using combine harvesters were 0.41 and 1.84%,respectively;while threshing loss rates by pedal threshers,electric threshers,and combine harvesters were 0.82,1.52,and 1.56%,respectively.A questionnaire survey of 1 400 households,covering 574 counties in 22 provinces of China,showed that the loss rate of manual reaping was 1.7%,while those of semi-mechanical and mechanical reaping were 2.32 and 12.1%,respectively.The loss rate of manual threshing was 1.84%,while that of mechanical threshing was 1.41% (Zhan 1995).Moreover,harvest loss rates of rice varied by region.In the eastern and central regions,more than half of all farmers reported a loss rate of less than 4%.Nearly two-thirds of farmers in the western region believed that their loss rates were in the range of 3–5%,while more than two-thirds of farmers in the northeast estimated their loss rates to be around 3% (Wuet al.2017).Various scholars have estimated the harvestloss rate of rice in China to be about 3% based on a literature study (Gaoet al.2016),questionnaire survey (Hu 2017),and field experiments (Huanget al.2018).

Table 1 Mechanization in China (×106)

However,there is no consensus on whether manual or machinery-based harvesting causes higher losses.Most studies have considered the losses due to machinery usage to be greater than those due to manual harvesting(Greeley 1982;Liet al.1991;Zhan 1995;Huanget al.2018),but at least one study held the opposite view (Gaoet al.2016).However,the changes in rice harvesting practices in China are not limited to the substitution of machinery for labor,but also extend to a new division of labor,namely harvest outsourcing services.Farmers outsource harvesting to specialized mechanization service providers (hereinafter referred to as service providers).These service providers charge fees after completing the harvesting work using their own machinery.

The ageing of farm labor caused by low birth and death rates and its feminization caused by the male-dominated rural-to-urban migration driven by the wage differences between farm and non-farm employment1According to the Second National Agricultural Population Census of China,in 2006,23.1% of the agricultural workers were 41–50 years old,32.5% were over 50 years old,and 55.37% were women (Ma and Ma 2007).,coupled with the changes in the relative prices of farm labor and harvest outsourcing services have all contributed to a boom of harvest outsourcing services in China.In 2017,the farmland harvested by mechanical outsourcing service providers exceeded 280 million hectares.There are more than five million agricultural machinery specialized households and 68 000 agricultural machinery cooperatives (MARA 2018).In addition,the proportion of farmers who bought harvest outsourcing services was higher than those who bought other services (such as land preparation services).Specifically for rice,more than 70% of farmers outsourced their harvesting services(Wanget al.2011),with the proportion registering close to 85% in some areas (Cai and Cai 2014).Harvest outsourcing services create a division of labor between farmers and service providers resulting in specialization,which may reduce harvest losses.However,service providers may also speed up the machinery in order to maximize their revenue,since their income is directly proportional to the service area;and this will overload the machinery and cause greater losses (Hanet al.2007).Regardless of whether they reduce or increase losses,previous studies have ignored the impact of outsourcing services.

Therefore,considering the background of the rapid development of mechanization and harvest outsourcing services,this study assesses the influences of mechanical harvesting and harvest outsourcing services on harvest losses of rice in China.Section 2 introduces the dependent variable and core independent variables,and explains how the harvest loss rate is calculated.Next,Section 3 lists the results of the non-parametric tests and assesses the impacts of machinery as well as harvest outsourcing services on harvest losses based on recall data from the surveyed farmers.Finally,Section 4 and Section 5 present the discussion and conclusions.

2.Data and methodology

2.1.Data

Data were collected from a national survey conducted in 2016 by the research team in conjunction with the Research Center for the Rural Economy of the Ministry of Agriculture and Rural Affairs of China.The sample size of each province was allocated in proportion to the distribution of the rice planting area among the provinces in China and 1 106 sample households were surveyed in this study.

The losses discussed here refer only to physical losses due to shedding or grains which remained unthreshed,and not to other losses,such as the post-harvest loss of nutritional value due to mildew.Combine harvesters combine three separate harvesting operations -reaping,threshing,and winnowing -into a single process,making it more difficult to strictly distinguish the losses of each stage in the actual calculations.Therefore,the harvest losses analyzed in this study refer to the losses across the whole harvesting process from field to storage,and specifically include the reaping,threshing,winnowing,and field transportation stages.Field experiments are the most accurate way to obtain harvest loss,but they are time-consuming,costly and difficult to achieve,especially for the national-scale research including 1 106 sample households.

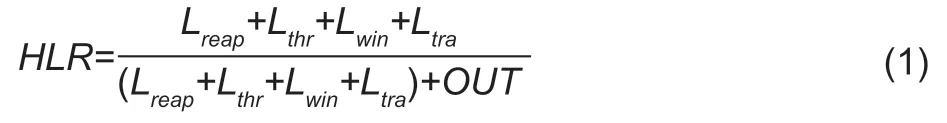

There are some published studies on the measurement of food waste (Liet al.1991;Bellemare 2017;Simone 2019),which mainly separate the life cycle of a typical food item into several stages,then measure the loss or waste in each stage and finally calculate the total loss or waste.Following this approach,the losses in this study are calculated based on farmers’ estimations of the losses at each of the four stages of harvesting:reaping,threshing,transportation and winnowing (Abasset al.2014).Although the losses here are estimated by farmers and may be biased,they can still accurately reflect the real situation in the case of large samples (Kaminski and Christaensen 2014).Moreover,in the absence of any experimental evidence to compare the loss rates based on self-reports versus direct measurements,the farmers’estimations can reasonably be considered as reliable(Sheahan and Barrett 2017).In order to compare the magnitudes of losses among different regions,harvesting methods and scales,the loss rate is used in this study instead of absolute losses.Eq.(1) shows how the harvest loss rate is calculated.

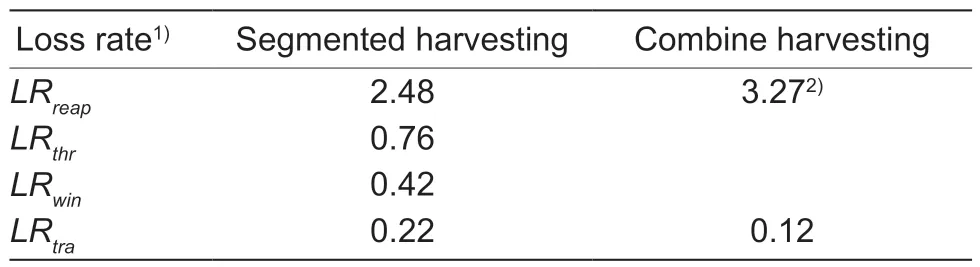

HLR(harvest loss rate) is the ratio of the total losses for these four stages to the sum of the harvested output and the total losses.Lreaprepresents reaping losses,which refers to grains that fall onto the field by contact when cutting straw.Lthris threshing loss,which refers to grains that remained on the straw or were scattered on the threshing floor when peeling the grain from the straw.Lwinrefers to winnowing loss,which means grains blown away with the chaff when separating grains from the other plant materials (Liet al.1991).Ltrarepresents field transportation loss,which refers to grains spilled on the road during transport from farmland to storage,and this loss may be caused by damaged packing.OUTis the final production quantity after harvest.Table 2 lists the loss rates at each stage.The total loss rate for reaping,threshing,and winnowing in segmented harvesting(3.66%) is higher than that in combine harvesting (3.27%).

The average harvest loss rate (HLR) of all samples in this paper is 3.65%.This value is consistent with previous research data (Hu 2017;Huanget al.2018) and the field experiments that we conducted in 2016.In 2016,China’s total rice output was 211.09 million tons with a planting area of 30.75 million hectares (NBSC 2017b).It implies that nearly eight million tons of rice was lost during the harvesting process alone,which is equivalent to more than one million hectares of farmland.

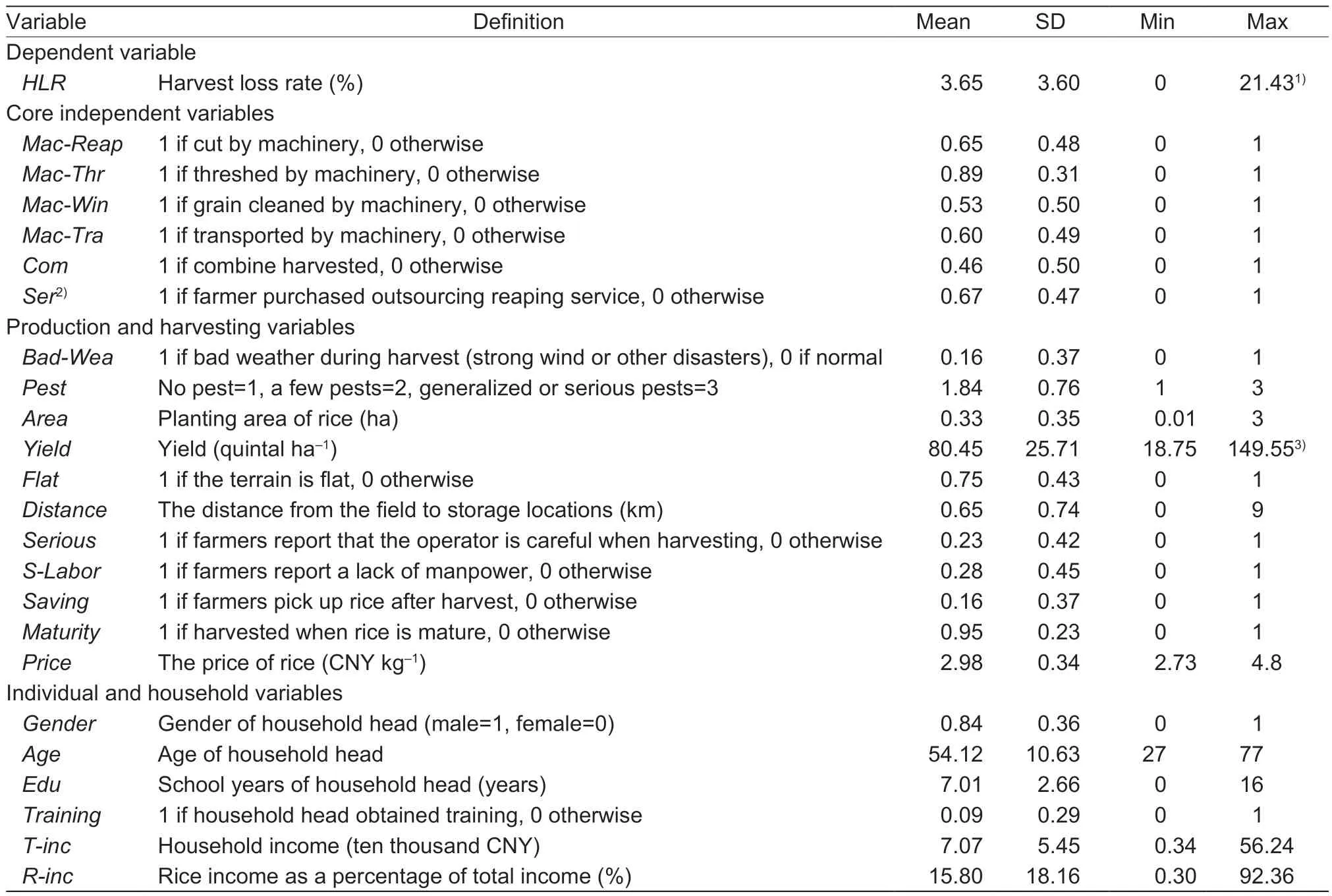

In order to analyze the effects of machinery on losses in the above four stages,Mac-Reap,Mac-Thr,Mac-Win,andMac-Travariables are introduced.If machinery was applied in the reaping stages,Mac-Reapequals 1,otherwise it is 0;and the corresponding condition is truefor the other three variables.

Table 2 Loss rates at each stage (%)

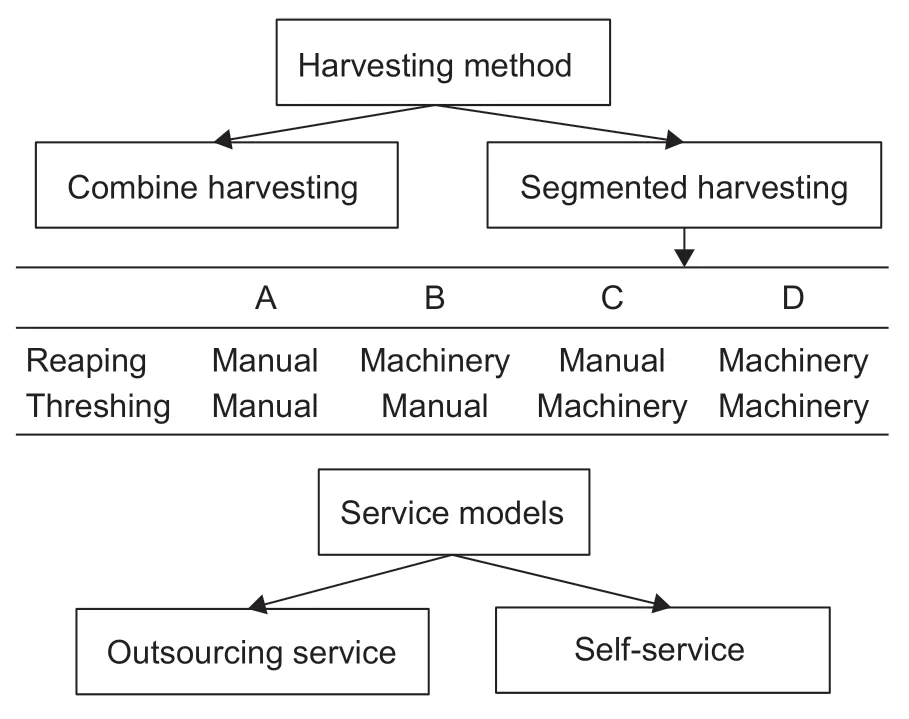

Comis a dummy variable that takes a value 1 if combine harvesting is applied,and otherwise it equals 0.Based on whether the reaping,threshing,and winnowing stages are combined into a single process,there are two harvesting methods:combine harvesting and segmented harvesting (Fig.1).Combine harvesting is completed by combine harvesters.Segmented harvesting could have four scenarios: A) both reaping and threshing are done manually;B) reaping by machinery and threshing manually;C) reaping manually and threshing by machinery;D) both reaping and threshing are done by machinery,however,there is no combine harvester so the reaping and threshing stages are finished separately.We can see that nearly half of the farmers in the survey chose combine harvesting (Table 3).

Seris a dummy variable that is introduced to capture the effect of outsourcing services on losses;it takes a value of 1 if farmers purchase outsourcing services,otherwise it equals 0.While most small farmers have no machinery for harvesting,they can still hire specialized mechanical service providers who own the necessary machinery to undertake harvesting work on their behalf.Farmers pay such service providers after the harvesting service is completed.In the combine harvesting group,if farmers purchased combine harvesting,they were deemed to have purchased the service.In the segmented harvesting group,if farmers outsourced the reaping stage,they were considered to have purchased a harvest outsourcing service and the threshing outsourcing service was not considered here.Based on Table 3,67% of all farmers engaged a harvest outsourcing service.

Fig.1 Setting of the core variables.

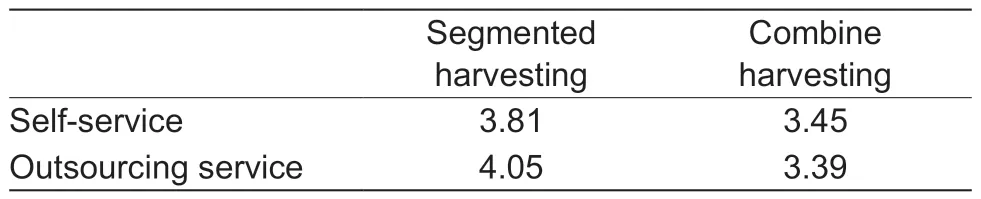

Based on the above two classifications,the harvest loss rates of each group are presented in Table 4.The combination of combine harvesting and outsourcing services has the lowest loss rate (3.39%).Combine harvesting has a lower loss rate in both the outsourcing services and self-service subsets.In segmented harvesting,the loss rate of outsourcing services is higher,but in combine harvesting,the loss rate of outsourcing services is lower.

In addition,two types of control variables are included:1) production and harvesting variables,and 2) household head and household variables.

The first type of control variables are production and harvesting variables,which includeBad-Wea(weather condition),Pest(pest disease),Area(planting area),Yield(quintal ha–1),Flat(land type),Distance(distance to storage location),Serious(attitude of operator),S-Labor(shortage of labour),Saving(whether picking up rice),Maturity(whether mature when harvesting),andPrice(CNY kg–1).Their definitions and measurements are summarized in Table 3.

Some of the key variables are explained here.The weather condition is the first factor that should be considered during the production or harvesting.Bad-Weais incorporated into the model to capture the overall weather condition.Based on the descriptive statistics in Table 3,about 16% of the sampled farmers experienced bad weather.Pest disease is another factor which is similar to weather condition.TheYieldvariable is included to capture the seed types,because different types or varieties will have different levels of tolerance to bad conditions.The methods of rice harvesting are affected mainly by the topography.In order to capture the impacts of terrain,theFlatvariable is introduced into the model.S-Laboris a dummy variable that takes a value of 1 if farmers reported a shortage of labor,which would cause more losses (Wuet al.2017),and 0 otherwise.Savingis a dummy variable that takes a value of 1 if farmers picked up fallen grains after harvesting,and 0 otherwise.Maturityis an additional dummy variable that takes a value of 1 if farmers considered the rice to be mature when it was harvested;and this is included because losses increase regardless of whether the rice is pre-or post-maturity (Wanget al.2016).Finally,Priceis used to measure the opportunity cost of farmers’ losses;and we believe that farmers will try to reduce losses when the price is high.Specifically,it refers to the sale price for the first three months after harvesting as recalled by the farmers.If no rice was sold in the first three months,the sale price for the first six months after harvest is used,and so on.Missing values are filled in using the average sale price earned by farmers in the same village for the first three months.Although the sale price is determined after harvesting,we believe that farmers are sufficientlyrational and knowledgable to predict the future price with reasonable accuracy.

Table 3 Variable summary and definitions (1 106 households)

Table 4 Harvest loss rates (%)

The second type of control variables are the household head and household characteristics,which compriseGender,Age,Edu,Training,T-inc,andR-inc(Basavarajaet al.2007;Wuet al.2017).Trainingis a dummy variable that takes a value of 1 if the household head had previously undertaken agricultural training.T-incis the total family income andR-incis the proportion of rice income to total family income.

Given that differences in planting regions may affect the results,a regional dummy variable is added in both Eqs.(2) and (3).The regions are designated by three categories,namely the Yangtze River basin,northeast plain,and southeast coast,according toRegional Layout Planning for Advantageous Agricultural Products(MARA 2008).This regional division takes into account the advantages of natural resources,planting characteristics,and geography of each province,and represents the key development areas of rice planting in the future,which is of great significance.The highest average loss rate among the three is 4.49% in the southeast coast,followed by 3.52% in the Yangtze River basin.The average loss rate of the northeast plain is the lowest,at 2.87%.

2.2.Methodology

Firstly,non-parametric tests are used to determine whether there are significant differences between combine harvesting and segmented harvesting,as well as between outsourcing service and self-service.Kruskal-Wallis and Mann-Whitney methods can be used to test for significant differences among multiple groups of variables under the condition that the normality and homogeneity of variance are not satisfied.

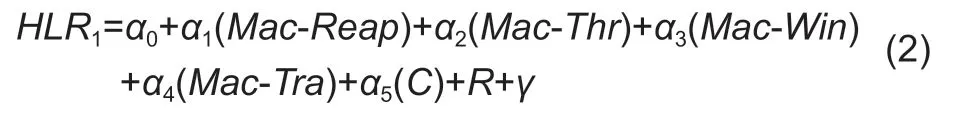

Secondly,two models are established to test the factors affecting the loss rate (Basavarajaet al.2007;Begumet al.2013;Martinset al.2014).Model 1,specified in eq.(2),is used to test the impacts of machinery on losses at each stage using the whole sample.

In addition to the variables mentioned above,CrepresentsComand control variables whileRandγare the regional dummy variable and the error term,respectively.

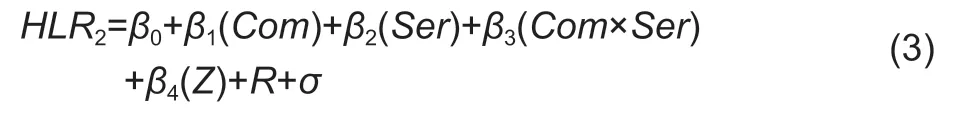

Next,model 2,specifiedpereq.(3),is used to analyze the impacts of outsourcing services on losses.Samples with manual reaping and manual threshing are dropped (group A in Fig.1),leaving a sample size of 994.In addition toComandSer,the interaction variableCom×Seris introduced to capture whether the purchase of outsourcing services has different impacts in different harvesting methods.Additionally,ZrepresentsMac-Win,Mac-Tra,and the control variables,whileRandσare the regional dummy variable and the error term,respectively.

Table 5 shows the marginal effects of the interaction variable.As we can see,β1(b–a) represents the marginal effect of combine harvesting on the loss rate for harvesting by the farmers’ own machinery;β2(c–a) represents the marginal effect of outsourcing service on the loss rate for harvesting by segmented harvesting;β1+β3(d–c) is the marginal effect of combine harvesting on the loss rate for harvesting by outsourcing service providers;andβ2+β3(d–b)is the marginal effect of outsourcing service on the loss rate of rice harvested by combine harvesting.

In crop harvesting research,harvesting conditions vary considerably,which causes considerable differences in the loss rates.For example,the loss rate will be far greater when farmers encounter disaster weather.Considering the influences of extreme values is vital.In this paper,Quantile Regression is applied because it does not require the error term to have a normal distribution,and the result is not easily affected by extreme values.Quantile Regression is more robust (Koenker and Bassett 1978),so it is applied to estimate the models.Moreover,as mentioned previously,due to the ever-changing harvesting conditions,the major factors that affect farmers with different degrees of loss rate are different.This isanother reason why Quantile Regression is adopted.Meanwhile,since some amount of loss is almost inevitable in practice,it could not be 0.In order to obtain results that are closer to reality and avoid the influences of extreme values,we chose the 0.10 quantile to capture this case of an extremely low loss rate.Stata15.0 Software is used to estimate the above models.

Table 5 Marginal effects of harvesting methods1)

3.Results

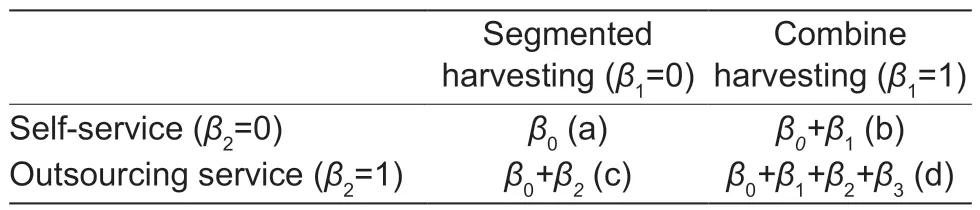

Both Kruskal-Wallis and Mann-Whitney tests show that there is a significant difference in losses between combine harvesting and segmented harvesting (Table 6).However,there is no significant difference between outsourcing service and self-service.

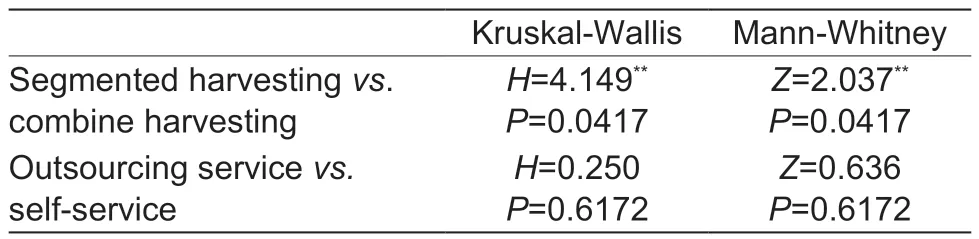

Table 7 shows the regression results ofHLR1.The use of machinery in the reaping and winnowing stages increases losses compared to manual operations.The losses when using machinery are lower than that of manual handling only in the field transportation and threshing stage.

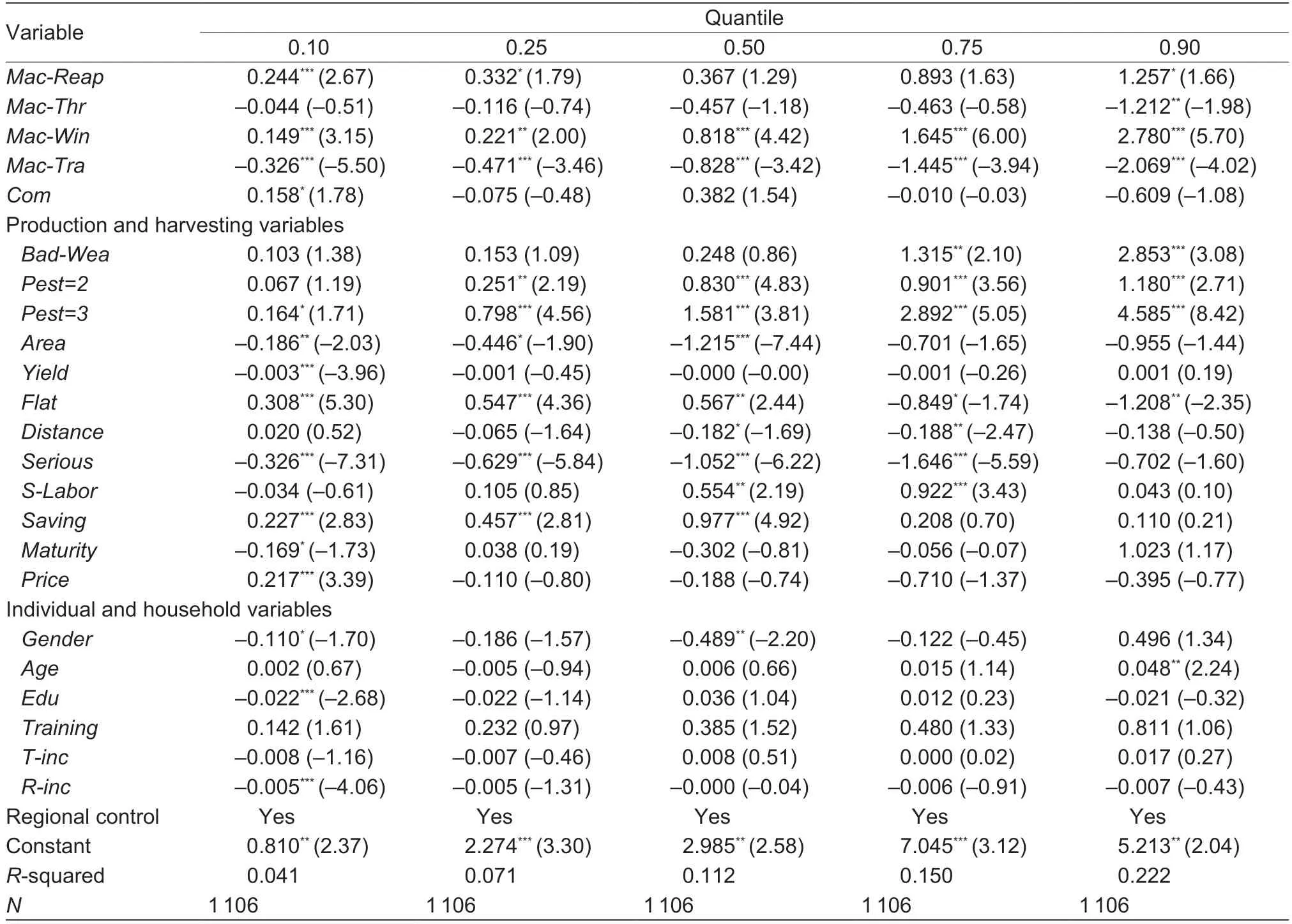

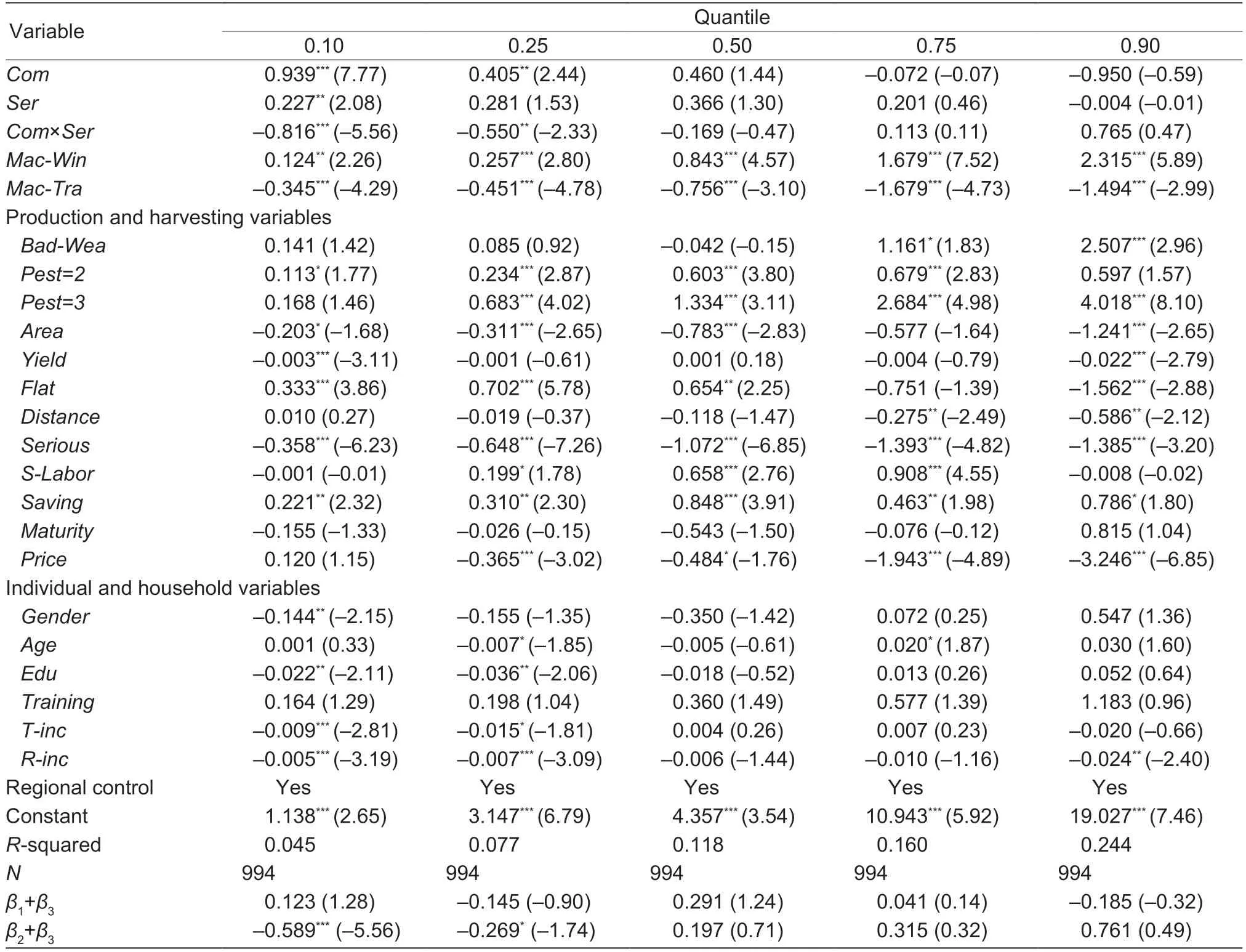

Table 8 shows the results ofHLR2.At 0.10 and 0.25 quantiles,the coefficients ofComare significantly positive.This shows that if farmers choose self-service,the loss rate of combine harvesting is higher than that of segmented harvesting,which is consistent with most previous studies(Liet al.1991;Feng and Sun 2014;Huanget al.2018).At the 0.10 quartile,the coefficient ofSeris positive and significant at the 10% statistical level,thereby implying that in the case of segmented harvesting,purchasing an outsourcing service will increase losses.In contrast,β2+β3(at the bottom of Table 8) is significantly negative at the 0.10 and 0.25 percentiles.The marginal effect of outsourcing service on the loss rate of rice harvested by combine harvesting at the 0.10 and 0.25 quantiles are,respectively,–0.589 and–0.269.Therefore,employing an outsourcing service by combine harvesting can significantly reduce harvesting loss.

In addition,it is worth noting thatCom,Ser,andβ2+β3are all significant at lower quantiles,but not significant at higher quantiles.At higher quantiles,some accidental factors,namelyBad-WeaandPest,have significantlypositive impacts on losses2We classify the bad weather into different degrees and find that the worse the weather (such as hail and frost damage),the larger the coefficient,the more the rice harvest losses..Besides,Seriousis significantly negative at all quantiles,indicating that the operator’s work attitude is also an important factor affecting losses (Hanet al.2007).

Table 6 Non-parametric analysis test1)

Table 7 Results of quantile regression (HLR1)

As a final step,the dependent variable (harvest loss rate) is replaced by the amount of losses per unit area(Basavarajaet al.2007;Begumet al.2013) to test the robustness ofHLR2.The effect of each variable on losses is consistent with the original results,indicating that the results are robust.

4.Discussion

Based on the results of model 1 (Table 7),mechanical reaping increases losses.Compared with manual reaping,additional factors can affect mechanical reaping,such as the driver’s skills,reaping speed,and crop height(Hanet al.2007).Although traditional manual reaping is time-consuming and labor-intensive,it is usually more thorough,especially for reaping rice in the corners or hilly areas and dealing with rice lodging,which helps to reduce losses.Mechanical winnowing is also affected by many factors,such as feed quantity and wind power for the machinery.If the wind power of the winnowing device is strong,grains will be blown away with straw and impurities,causing more losses (Tanget al.2013).The use of machinery causes fewer losses than manual work in the case of field transportation,as machinery can shorten the transportation time.

Next,the model 2 results (Table 8) show that combine harvesting increases losses.Combine harvesting is greatly influenced by mechanical properties and the operators’ skills (Hanet al.2007).However,segmented harvesting can extend the harvesting period and allow rice to be harvested early,which can reduce losses due to post-maturity during reaping.After rice is sun-dried in the field,the grains can be more easily threshed such that threshing losses can be reduced (Feng and Sun 2014).Moreover,in China,the average farm is too small and the cost of sole ownership of a combine harvester is too high.In order to reduce the cost,apart from their own-use,farmers who own combine harvesters also provide harvesting services to other farmers in their own or neighboring villages.The revenue from providing harvesting services to other farmers far exceeds the income from reducing the losses of their own farmlands.Therefore,the farmers who own combine harvesters may be less concerned about harvesting their own rice because they are busy providing harvesting services to other farmers,resulting in increased losses of their own farmlands,especially during the busy season when combine harvesters are in short supply.

β2+β3is significantly negative at the 0.10 and 0.25 percentiles,implying that when using combine harvesters,purchasing harvest outsourcing services reduces losses.This may be explained by the fact that service providers may have more advanced combine harvesters and more experience in using them (Qiu and Chang 2016),thereby helping to reduce losses.Conversely,in the case of segmented harvesting,service providers cause greater losses than the farmers themselves (sinceSeris significantly positive at the 0.10 percentile).The structure of segmented harvesters is simpler than that of combine harvesters (Zhanget al.2014),and the operators’technical requirements are not as high as in the case of combine harvesters.In this context,the attitude towards harvesting work becomes more important,especially in harvesting small-scale farmlands.In segmented harvesting,farmers outsource only one stage (reaping stage) to service providers,while in combine harvesting,they outsource three stages (reaping,threshing,and winnowing).Hence,service providers using combine harvesting are likely to treat the work more seriously because the service price of the combine harvesting is higher than that of segmented harvesting (Zhanget al.2014).Evidence for this scenario could be found in the available data.According to the surveyed farmers,service providers are far less conscientious in the case of segmented harvesting than in combine harvesting (since the average of the variableSeriousis 0.046 in the case of segmented harvesting and 0.209 in the case of combine harvesting).In addition,pests,topography and other factors also affect farmers with low loss rates.

Table 8 Results of quantile regression (HLR2)

Contrary to the fact that machinery has a significant impact on farmers with low loss rates,at the higher quantiles,weather and pests have the greatest impacts on loss rates,while the impact of machinery on loss rates is not obvious.High loss rates are often caused by severe weather and pests.In these cases,mechanical harvesting is not even used (for example,when there is a large area of rice lodging due to a hail storm).Therefore,farmers with low loss rates should pay more attention to the losses caused by machinery,while farmers with high loss rates should be more concerned about the losses caused by weather and pests.

5.Conclusion

This study quantified the magnitude of the harvest loss rate of rice at the national and regional levels in China,which is of great significance for future research on the reduction of losses and the study of loss reduction potential.This study focused on the impacts of machinery and harvest outsourcing services,both of which are the future trends of agricultural production.Such factors have hardly been considered in previous studies,especially the outsourcing services.This approach could also be regarded as another way to measure the efficiency of outsourcing services.

A national survey of 1 106 households in 2016 showed that the harvest loss rate of rice in China was 3.65%,which is equivalent to nearly eight million tons of rice and more than one million hectares of farmland.Compared with manual work,machinery increases losses in the reaping and winnowing stages and reduces it in the field transportation and threshing stages.For further analysis,samples of manual reaping and manual threshing were dropped,leaving 994 households for studying the impacts of harvest outsourcing services,as well as that of combine harvesting,on losses.In particular,the interaction variable between harvest outsourcing service and combine harvesting was added.Compared to segmented harvesting,combine harvesting increases losses when farmers choose self-service.Therefore,a higher degree of mechanization will increase the harvest losses of rice if there is no harvest outsourcing service.In addition,the impacts of harvest outsourcing services on losses are reversed in the two different harvesting methods,i.e.,with segmented harvesting,purchasing a harvest outsourcing service will increase losses,while in combine harvesting,such a purchase will lead to reduced losses.Hence,although combine harvesting increases harvest losses,when farmers outsource harvesting work to specialized mechanization service providers or farmers,it will reduce losses.

According to the results of this study,the government should not only focus on improving the mechanization rate,but also pay attention to reducing harvest losses due to machinery,which may be achieved by enhancing the machinery or standardizing the outsourcing service market to induce operators to adopt a more serious attitude.In addition,the government can encourage farmers to outsource combine harvesting to specialized organizations or individuals wherever conditions permit.For farmers,this outsourcing can not only reduce losses and increase production,but also free up their limited labor and capital.Moreover,it is conducive to the further development of agricultural mechanization and mechanical outsourcing services.For farmers with a high loss rate (usually those in the southeast coast),weather forecasts and pest management are the key points to reduce their losses.

Nonetheless,due to the lack of information about machinery and operators,this study is unable to control for additional characteristics related to them,which may also affect losses.Future studies can focus on the factors that cause the differences between the harvest outsourcing service and self-service,as well as the differences in influencing factors among different regions.If mechanization and outsourcing services develop to a higher level,how much can losses be reduced?Furthermore,with the emergence of more advanced machinery and a deepening of the marketization of outsourcing services,it is important to consider whether their impacts on losses will change in the future.Such issues may be the concerns of future studies.

Acknowledgements

This research is supported by the 2015 Special Scientific Research Project of Grain Public Welfare Industry,China (201513004-2),the research grant from the Murata Science Foundation,JSPS KAKENHI,Japan (JP19H03063),and the scholarship from China Scholarship Council (CSC201906350150).

Declaration of competing interest

The authors declare that they have no conflict of interest.

杂志排行

Journal of Integrative Agriculture的其它文章

- Errata regarding previously published articles

- Ultrastructural studies of seed coat and cotyledon during rapeseed maturation

- Resource utilization of agricultural solid waste

- The river chief system and agricultural non-point source water pollution control in China

- An improved scheme for infectious bursal disease virus genotype classification based on both genome-segments A and B

- Exploring the genetic features and signatures of selection in South China indigenous pigs